- Offer Profile

- VELTRU provides components and logistics software for pick-and-place applications to machine manufacturers and system integrators. We can support you "hands on" with training, engineering and project assistance as required. Our Application Template allows to configure standard applications and to program additional functionality for special project demands.

Components and logistics software for pick-and-place applications

- VELTRU provides components and logistics software for pick-and-place applications to machine manufacturers and system integrators. We can support you "hands on" with training, engineering and project assistance as required. Our Application Template allows to configure standard applications and to program additional functionality for special project demands.

Robots

-

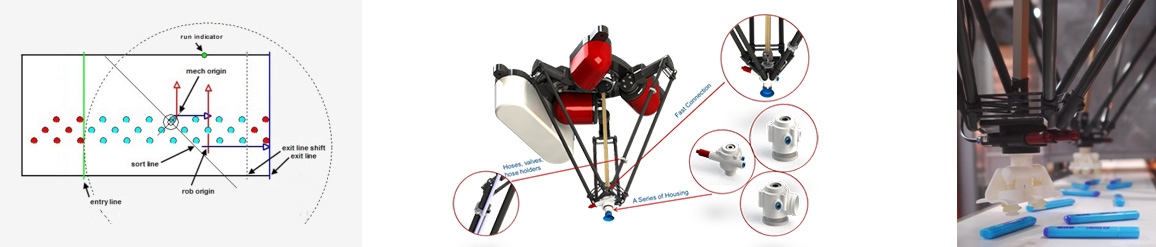

VELTRU offers an up-to-date and unrivaled range of parallel kinematic robots. Their maximum payload and work range suits the most typical applications in the packaging and assembly automation industry.

Key areas of application for our robots are the production, handling and packing of food, medical devices, cosmetic and products for personal care, as well as technical items. The modular structure of every VELTRU robots enables a quick and simple adaptation of each robot for specific applications and environments.

Therefore, VELTRU provides robot base designs in 2-, 3- and 4-axis construction, which can be applied for handling individual parts with payloads between 10 g and 3 kg and which can be applied for manipulating grouped sets of objects with payloads between 3 kg and 6 kg.

D8 Delta Robot

-

- Speedy Pick-and-Place robot

- 3- or 4-axis execution

- Top mounting

- Work range: 800 mm

- Payload: up to 1 kg

D12H Delta Robot

-

- Flexible Pick-and-Place robot

- 3- or 4-axis execution

- Top mounting

- Work range: 1200 mm

- Payload: up to 3 kg

U10H Unloader

-

- Loading robot for medium payloads

- 2-axis execution

- Top mounting

- Work range: y = 1000 mm, z = 300 mm

- Payload: to 6 kg

D12W Delta Robot

-

- Hygienic version, wash down

- 3- or 4-axis execution

- Top mounting

- Work range: 1200 mm

- Payload: up to 3 kg

Motion Control

-

PLC programming technologies are widely used for development of control circuits in the packaging and assembly machinery industry. VELTRU therefore focuses their development on current PLC technology. Time critical and motion related functionalities, such as path planning, motion interpolation, and robot coordinate transformations for all VELTRU and custom robot kinematics are realized strictly in IEC 61131-3. This widely applied and used programming standard provides several benefits:

- One single programming tool for all automation issues including robotics

- Powerful and well-known tools for the application development

- Integrated visualization modules for the developer and for the end user

C10 Motion Controller

-

Machine builder and plant manufacturer can focus on the application – VELTRU offers the robots and additional technology required for system integration in Pick-and-Place.

- Soft PLC based Motion Control

- Visualization

- Remote Accessibility

- Pick-and-Place functionality

Options:- Vision Connector

- Language Handler for Visualization

- Engineering and Support

- Training Application

Machine Vision

-

Product handling for randomly fed parts requires a recognition of the position and orientation of each single part. Depending on the application, vision sensors with integrated processor or networked cameras with centralized processor can be used.

Demanding algorithms for inspection, sorting and grading require the recognition of additional product characteristics for each single part. Critical and validated applications in the medical, pharmaceutical or semiconductor industry may even require multiple inspections or advanced data matching with an external data base.

VELTRU specifies a simple minimal standard interface for machine vision to allow integrating any vision system. This interface makes use of the existing calibration routines to determine the sensor location relative to the robot and to communicate product location and orientation on a conveyor belt. V10 Vision

-

The VELTRU V10 Vision Connection is a tight integration for the Matrox Design Assistant, a flow chart based configuration tool for Matrox Machine Vision products. The V10 Vision Connection has been designed for integrating machine vision into VELTRU's robotics applications, but may as well be used as a stand-alone feature to integrate Matrox Machine Vision into the CODESYS PLC environment.

The V10 Vision Connection allows the communication of any parameter between the robot controllers and the machine vision system. For example the robot controller may trigger a capture on the camera. The results of the vision algorithm as position, orientation and quality features of products are sent back to the robot controller. It is also possible to communicate configuration parameters of the vision system. This allows to centralize the format parameters (recipe). The visualization of the robot application allows to incorporate live pictures of the vision system. The V10 Vision Connection allows controlling several cameras with one robot controller. It is also possible to connect several robot controller to one and the same vision system. The Ethernet communication is monitored and automatically reestablished, if needed.

For the calibration of the system the V10 Vision Connection and the C10 Application Templates offer all necessary functionalities and visualizations. The default parameters match the VELTRU Calibration Toolkit.

VELTRU V10 Vision includes a Matrox Iris GT* camera, the V10 Vision Connection and a Connection Box. The Matrox Iris GT* camera is available in various resolutions and with several sensors. The Connection Box considerably simplifies the wiring and optionally is available with integrated 12W LED strips, resulting in a very compact solution for standard applications. The PWM output of the Connection Box allows dimming additional VELTRU VL LED products.

Line Control & Simulation

Line Control & Simulation

-

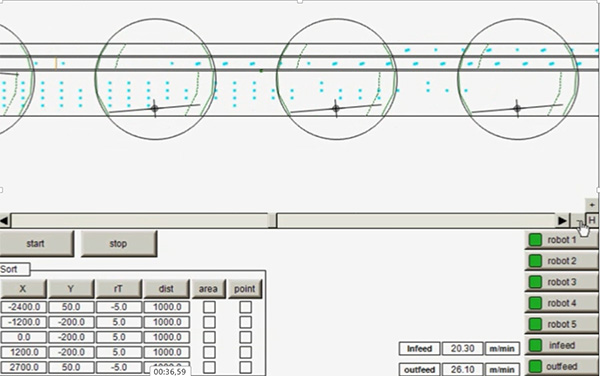

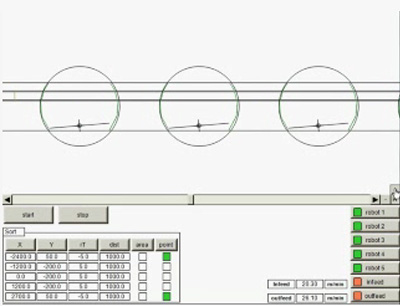

Simulation

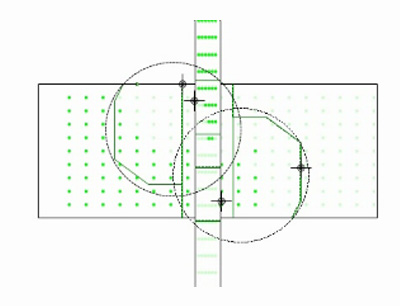

For a single cell application, the main focus is typically on handling issues and robot motion; however, more complex, for example multi-robot, integration tend to have logistics as the key feature. VELTRU offers the possibility to simulate the flow of products in multi-robot systems using real control code and making use of the on-board visualization elements. This approach allows to transfer any algorithms and functionality used for simulation into the project.Multi-Robot System Concepts

Fast handling equipment is often used in processes where volumes cannot be handled by one robot only. The product architecture of VELTRU has multi-robot systems in mind. Our customers may download the corresponding Application Notes describing further technical details from our FTP. VELTRU is able to offer its customer access to all three major concepts for multi-robot lines:Assortment configuration

The assortment is where several different products are combined into one packaging, common for chocolate and confectionery applications. Each product is fed on an individual conveyor, perpendicular to the conveyor for the packaging.Parallel flow configuration

In systems with one product type only, the products and the packaging are transported in parallel direction. If moving into the same direction, the last robot will have few products to fit into few cavities of the packaging. This typically leads to errors such as products not being packaged and packaging not getting completely filled. VELTRU is offering a concept allowing to disconnect the speed of the respective conveyors and thus to overcome the mentioned problems.Counterflow configuration

An alternative method is using the counterflow principle, running the products and packaging in opposite direction. VELTRU is able to support this proven and robust concept.

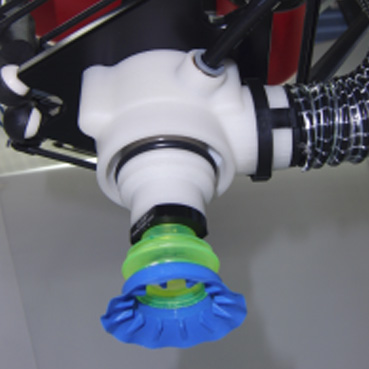

Robot Peripherals

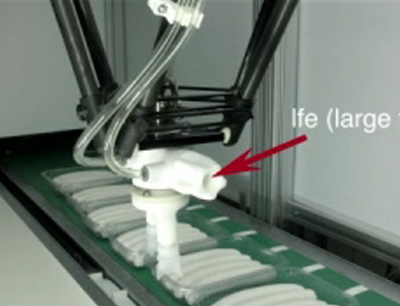

Rotary Feed Throughs

- The performance of most Delta robot applications is limited by the handling of

the product. An optimized pneumatic system is key for allowing maximizing the

system performance. VELTRU is offering a range of rotary feed throughs and is

happy to adapt to project specific needs, if necessary. The range covers systems

with external vacuum generation from low volume and high vacuum level to systems

with high air flow. It also includes a range of ejector based system allowing to

generate the vacuum within the rotary feed through. Special options are

available for hygienic applications, like handling perishable food.

VELTRU is also offering ultra-flexible, lightweight vacuum tubings with large cross-section for high volume flow applications. Pneumatic quick connectors and brackets standardize the mounting on the robotic arm.

LED lights for machine vision

- 24VDC – integrated current controller

- WashDown execution

- 7 standard sizes

- Thin design, 20mm height

- Standard 4-pol M8 connector

- Dimmable 0-10V or 4…20mA, can be used as low current switch

Options:- 300 x 185 to 1130mm, in increments of 35mm

- Contact VELTRU for other requests

Calibration Toolkit

-

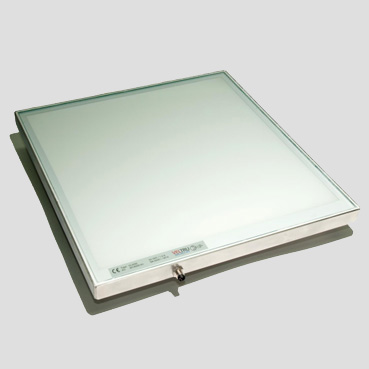

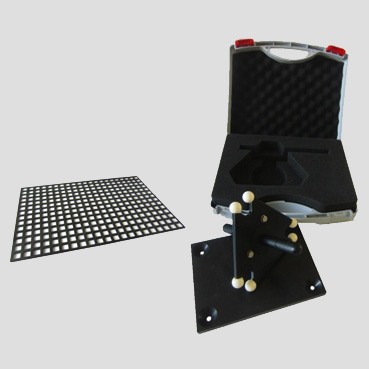

Sometimes, small details are making the difference. The Calibration Kit is compatible with all offered Delta Robot tool carrier base plates. The calibration needle can be reverted to fit into the calibration plate with its rounded end or to point on a target with its sharp end to precisely verify the calibration results.

The entire kit is offered with a handy case. For vision distortion calibration, the vision calibration grid is available in various standard sizes or can be ordered with project specific size. The coating minimizes reflections.- Calibration Set with gripper and reference plate

- Case for transport and storage

- Calibration Grid for Machine Vision

- Fully integrated in Calibration Wizards

- Help videos and documentation available

The VELTRU Calibration Toolkit allows using the C10 Application Templates to perform all necessary calibration steps of Pick-and-Place applications. It covers machine vision distortion, encoder resolution and sensor to conveyor to robot calibrations. Multi robot system support robot to robot calibration as well. The compact case allows safe transport and convenient storage of the equipment.

Applications

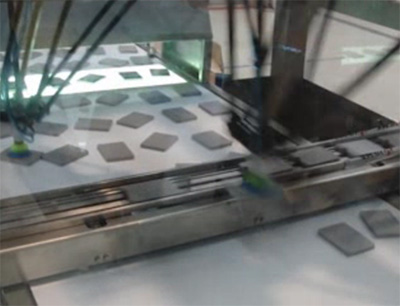

Twin Cell loading flowpack

- Twin Cell distribution system feeding products to a flowpack. The robots make use of a shared workrange, which is dynamically allocated to avoid mechanical collisions. The 'cell overview' HMI page in the middle of the Video shows the reserved areas in red.

Twin Robot Cell with Double Pick

- Twin robot cell loading a flowpack machine. Both VELTRU D12H robots are using double pick gripper, allowing to pick two individual products per cycle. The robot software ensures the second pick with one product already on the gripper does not lead to collisions with products still on the conveyor.

Hygienic Ejectors

- The hygienic ejectors allow creating vacuum with pressurized air. Any contamination with the product will remain locally, at the gripper head. The large crosssections help avoiding clogging.

Stacking Products

- Handling application examples stacking products directly on the gripper.

Distribution System Simulation

- Two robot distribution system. The system uses overlapping workranges of the robots on the outfeed chain.

Flow Wrapper Loading

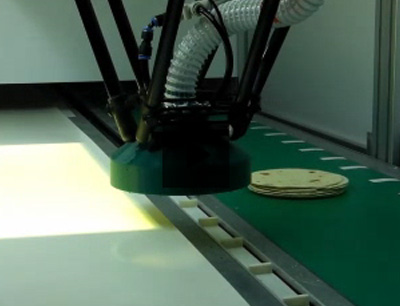

- A D8 Delta Robot is loading Oreo biscuits into a flow wrapper infeed chain. The products are located using machine vision and handled pneumatically with a suction cup.

Pepper Loading

- Calibrated peppers are located using vision system and loaded into boxes and totes using suction cups.

Random Sample Quality Inspection

- Random samples of medical devices are located by a vision system and fed to a turntable using a VELTRU D8 Delta Robot. Multiple sensors inspect the devices for quality defects. A two axis mechanism retrieves the tested parts and deposits them according to the quality information gathered. The entire logistics of the application is handled by VELTRU and demonstrates the possibilities of the Queue Module.

5 Robot Counterflow System

- A production process is feeding 1160 products per minutes

on carriers. 5 VELTRU D8 Delta robots share the load to place the products

for carton sleeving, picking the products with a double head with pneumatic

suction cups. The robot line allows to change over to different packaging

styles without any hardware change.

The VELTRU L10 Line Control allows to balance the workload of the robots and to operate the system from a central control panel.