- Offer Profile

- For 25 years, we have been proving ourselves in environmental technology as a flexible, innovative idea provider, developer and problem solver. We specialise in conveying, dosing, sorting, pressing and binding a wide variety of materials such as paper, plastic, straw and cardboard. Our high-quality range of products, which we tailor to the individual needs of our customers, includes stationary and mobile channel baling presses as well as bulkhead presses, conveyor belts, dosing bunkers and sorting systems. We are a medium-sized company with an experienced, high-performance and motivated team that maintains a good rapport with our customers.

EUROPRESS Channel Balers

Efficient and safe compression

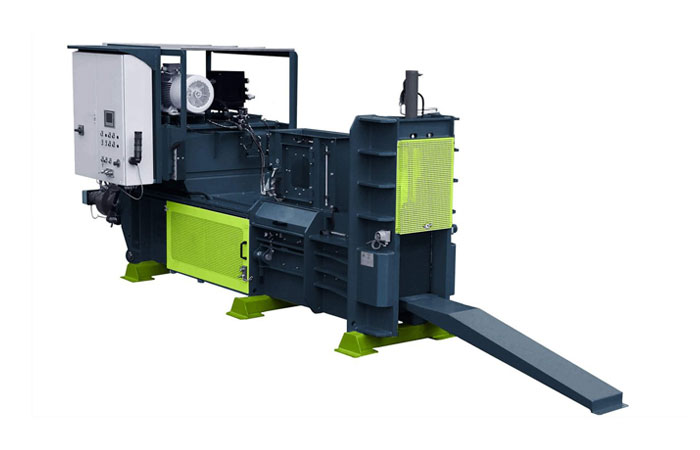

The compact channel balers compact and bind paper, cardboard, plastics, films, PET bottles, wood wool and many other waste products to greatly facilitate storage, handling, transportation and possible further processing.Stationary channel-ballers - Channel-Balers with wire-tying - EP SERIES

Reliability in a slim design

Basic format - 1100 x 750 Bale-Size

Channel Balers with Wire - BINDING EP 60

- Tying

4-Fold Horizontal

5-Fold Horizontal high-rise format

5-Fold Vertikal - Press force: 60 tons

- Filling opening: 1.000 x 1.600 mm

- Channel cross-section: 750 x 1.100 mm

- Drive power: 22 - 2 x 45 kW

- Bale weight: 400 - 500 kg

- Bale length: up to 1,8 m

- Length: 9.800 mm

- Width: 2.580 mm

- Height: 3.900 mm

- Machine weight: 18,5 Tons

The optimal equipment

With various additional features that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and versatile in use. As required, each baler can be equipped with, among other things, a fast-lift cylinder for energy savings or protected against wear and tear by full Hardox equipment. Remote control operation also facilitates work, with maximum security provided by the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in line with customer requirements.

Compact power density

The optimized design of our wire-bound channel balers enables easy maintenance, saving both time and money. Perfectly matched cutting edges ensure an energy-efficient, millimeter-accurate cut with little wear. The straight-line compactness of the EP series stands for effectiveness, proven over a long period of time in the compaction of waste products. A wide variety of materials such as paper, cardboard, and plastics are compressed into firm, space-saving bales that significantly reduce storage and transport requirements.- Suitable for industrial applications or low to medium material volumes

- Edged press body

- Pressing force of 60 or 80 tons Low space requirement

- Height adjustability of the pressing shield

- Stable construction of the base frame

- Easy handling High performance

- Reliable

- Tying

Channel Balers with Wire - TYING EP 80

- Tying

4-Fold Horizontal

5-Fold Horizontal High-rise format

5-Fold Vertical

5-Fold Vertical + 3-Fold Horizontal - Press force: 80 Tons

- Filling opening: 1.000 x 1.600 mm

- Channel cross-section: 750 x 1.100 mm

- Drive power: 22 - 2x45 kW

- Bale weight: 500 - 700 kg

- Bale length: up to 2,0 m

- Length: 10.000 mm

- Width: 2.580 mm

- Height: 4.980 mm

- Total weight: approx. 19,5 Tons

The high standard

In the EP series, our channel balers with wire tying present themselves as slim systems of high stability and reliability. Waste such as paper, cardboard, and PET bottles is compacted fully automatically and securely tied with strong wire. Only the amount of wire actually required for an effective result is used. The waste products can then be transported or stored as compact bales to save costs and space.

Compact power density

The optimized design of our wire-bound channel balers enables easy maintenance, saving both time and money. Perfectly matched cutting edges ensure an energy-efficient, millimeter-accurate cut with little wear. The straight-line compactness of the EP series stands for effectiveness, proven over a long period of time in the compaction of waste products. A wide variety of materials such as paper, cardboard, and plastics are compressed into firm, space-saving bales that significantly reduce storage and transport requirements.- Suitable for industrial applications or low to medium material volumes

- Edged press body

- Pressing force of 60 or 80 tons

- Low space requirement

- Height adjustability of the press ram

- Stable construction of the base frame

- Easy handling

- High performance

- Reliable

- Tying

Channel Balers with Wire - TYING EP 100

- Tying

4-Fold Horizontal

5-Fold Horizontal high-rise format

5-Fold Vertical

5-Fold Vertical + 3-Fold Horizontal - Press force: 80 Tons

- Filling opening: 1.000 x 1.800 mm

- Channel cross-section: 750 x 1.100 mm

- Drive power: 22 - 2x45 kW

- Bale weight: 500 - 700

- Bale length: up to 2,0 m

- Length: 10.000 mm

- Width: 2.580 mm

- Height: 4.980 mm

- Total weight: approx. 20 Tons

The optimal equipment

With various additional features that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and versatile in use. As required, each baler can be equipped with, among other things, a fast-lift cylinder for energy savings or protected against wear and tear by full Hardox equipment. Remote control operation also facilitates work, with maximum security provided by the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in line with customer requirements.

Everything and more

With its technically advanced but easy-to-use additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear, or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.- Pressing force between 100 and 180 tons

- Stable construction of the base frame

- Height adjustability of the pressing shield

- Piston bottom closing plates

- Cardanic suspension of the main cylinder

- Tying

Channel Balers with Wire - TYING EP 120

- Tying

4-Fold Horizontal

5-Fold Horizontal high-rise format 5-Fold Vertical

5-Fold Vertical + 3-Fold Horizontal - Press force: 120 Tons

- Filling opening: 1.000 x 2.000 mm

- Channel cross-section: 750 x 1.100 mm

- Drive power: 45 - 2 x 75 KW

- Bale weight: 500 - 700 KG

- Bale length: up to 2.000 mm

- Machine length: 12.800 mm

- Machine width: 2.400 mm

- Machine height: 4.250 mm

- Machine weight : 32 Tons

The high Standard

In the EP series, our channel balers with wire tying present themselves as slim systems of high stability and reliability. Waste such as paper, cardboard and PET bottles are compacted fully automatically and securely tied with strong wire. Only the amount of wire that is actually necessary for an effective result is used. The waste products can then be transported or stored as compact bales to save costs and space.

Compact power density

EP series - reliability without embellishment

The optimised design of our wire-tied channel balers allows for easy maintenance, which saves both time and money. Perfectly matched cutting edges ensure an energy-efficient, millimetre-accurate cut with little wear. The straight-line compactness of the EP series stands for effectiveness that has proven itself over a long period of time in the compaction of waste products. A wide variety of materials such as paper, cardboard and plastics are compressed into firm, space-saving bales that significantly reduce the effort required for storage and transport.- Suitable for industrial applications or low to medium material volume

- Edged press body

- Pressing force of 60 up to 120 tons

- Height adjustability of the press plate

- Stable construction of the base frame

- Easy handling

- Powerful

- Reliable

- Tying

Channel Balers with Wire - TYING HP 100

- Tying

4-Fold Horizontal

5-Fold Horizontal high-rise format

5-Fold Vertical

5-Fold Vertical + 3-Fold Horizontal - Press force: 100 Tons

- Filling opening: 1.000 x 2.000 mm

- Channel cross-sections: 750 x 1.100 mm

- Drive power: 45 - 2 x 75 KW

- Bale weight: 500 - 800 KG

- Bale length: up to 2.000 mm

- Machine length: 12.800 mm

- Machine height: 4.250 mm

- Machine weight: ca. 30 Tons

The perfect equipment

Thanks to various additional functions that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and powerful in use. If required, each baler can be equipped with, among other things, a high-speed main cylinder for energy saving or be protected against wear and tear by a Hardox full equipment. Operation by remote control also makes work easier, with the highest possible level of security thanks to the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in a customer-oriented manner.

Everything and more

With its technically sophisticated but easy-to-use additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.- Pressing force between 100 and 180 tons

- Stable construction of the base frame

- Height adjustability of the press shield

- Piston- and bottom sliders

- Cardanic suspension of the main cylinder

- Tying

Channel Balers with Wire - TYING HP 120

- Tying

4-Fold Horizontal 5-Fold Horizontal high-rise format

5-Fold Vertical

5-Fold Vertical + 3-Fold Horizontal - Press force: 120 Tons

- Filling opening: 1.000 x 2.000 mm

- Channel cross-section: 750 x 1.100 mm

- Drive power: 45 - 2 x 75 KW

- Bale weight: 500 - 700 KG

- Bale length: up to 2.000 mm

- Machine length: 12.800 mm

- Machine width: 2.400 mm

- Machine height: 4.250 mm

- Machine weight: 32 Tons

Thanks to various additional functions that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and powerful in use. If required, each baler can be equipped with, among other things, a high-speed main cylinder for energy saving or be protected against wear and tear by a Hardox full equipment. Operation by remote control also makes work easier, with the highest possible level of security thanks to the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in a customer-oriented manner.

Everything and more

With its technically sophisticated but easy-to-use additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.- Pressing force between 100 and 180 tons

- Stable construction of the base frame

- Height adjustability of the press shield

- Piston- and bottom sliders

- Cardanic suspension of the main cylinder

- Tying

Channel Balers with Wire - TYING HP 150

- Tying

4-Fold Horizontal 5-Fold Horizontal high-rise format

5-Fold Vertical

5-Fold Vertical + 3-Fold Horizontal - Press force: 150 tons

- Filling opening: 1000 x 2000 mm

- Channel cross-section: 750 x 1100 mm

- Drive power: 45 - 3 x 75 KW

- Bale weight: 500 - 800 KG

- Bale length: up to 2.000 mm

- Machine length: 13.900 mm

- Machine width: 2.450 mm

- Machine height: 4.250 mm

- Machine weight: ca. 35 Tons

The perfect equipment

Thanks to various additional functions that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and powerful in use. If required, each baler can be equipped with, among other things, a high-speed main cylinder for energy saving or be protected against wear and tear by a Hardox full equipment. Operation by remote control also makes work easier, with the highest possible level of security thanks to the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in a customer-oriented manner.

Everything and more

With its technically sophisticated but easy-to-use additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.- Pressing force between 100 and 180 tons

- Stable construction of the base frame

- Height adjustability of the press shield

- Piston- and bottom sliders

- Cardanic suspension of the main cylinder

- Tying

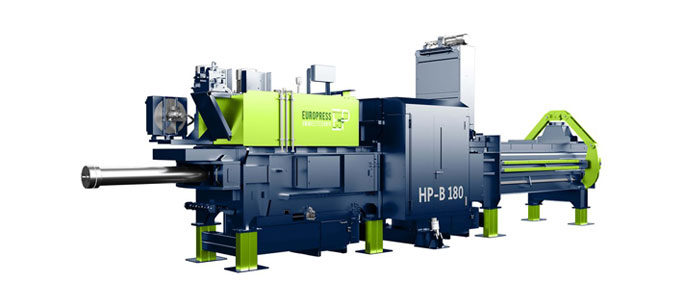

Channel Balers with Wire - TYING HP 180

- Tying

4-Fold Horizontal

5-Fold Horizontal high-rise format

5-Fold Vertical

5-Fold Vertical + 3-Fold Horizontal - Press force: 180 Tons

- Filling opening: 1.000 x 2.000 mm

- Channel cross-section: 750 x 1.100 mm

- Drive power: 45 - 3 x 75 kW

- Bale weight: 600 - 900 KG

- Bale length: up to 2.000 mm

- Machine length: 13.900 mm

- Machine width: 2.450 mm

- Machine heigth: 4.250 mm

- Machine weight: ca. 36 Tons

The perfect equipment

Thanks to various additional functions that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and powerful in use. If required, each baler can be equipped with, among other things, a high-speed main cylinder for energy saving or be protected against wear and tear by a Hardox full equipment. Operation by remote control also makes work easier, with the highest possible level of security thanks to the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in a customer-oriented manner.

Everything and more

With its technically sophisticated but easy-to-use additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.- Pressing force between 100 and 180 tons

- Stable construction of the base frame

- Height adjustability of the press shield

- Piston- and bottom sliders

- Cardanic suspension of the main cylinder

- Tying

Large format

1100 x 1100 Bale-Size

Channel Balers with Wire - TYING EP-B 120

- Tying

4-Fold horizontal

5-Fold vertical

5-Fold vertical + 4-Fold horizontal - Press force: 120 Tons

- Filling opening: 1.000 x 2.000 mm

- Channel cross-section: 1.100 x 1.100 mm

- Drive power: 45 - 2 x 75 kW

- Bale weight: 750 - 1.200 kg

- Bale length: up to 2,0 m

- Length: 14.380 mm

- Width: 2.580 mm

- Height: 5.100 mm

- Total weight: approx. 47 Tons

The optimal equipment

With various additional features that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and versatile in use. As required, each baler can be equipped with, among other things, a fast-lift cylinder for energy savings or protected against wear and tear by full Hardox equipment. Remote control operation also facilitates work, with maximum security provided by the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in line with customer requirements.

Everything and more

With its technically advanced but easy-to-use additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear, or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.- Pressing force between 150 and 210 tons

- Stable construction of the base frame

- Height adjustability of the press ram

- Piston bottom sliders

- Cardanic suspension of the main cylinder

- Tying

Channel Balers with Wire - TYING HP-B 150

- Tying

4-Fold horizontal

5-Fold Vertical

5-Fold Vertical + 4-Fold Horizontal - Press force: 150 Tons

- Filling opening: 1000 x 2000 mm

- Channel cross-section: 750 x 1100 mm

- Drive power: 45 - 3 x 75 kW

- Bale weight: 650 - 1.400 kg

- Bale length: up to 2,0 m

- Length: 13.900

- Width: 2.550 mm

- Height: 4.250 mm

- Total Weight: approx. 35 To.

The optimal equipment

With various additional features that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and versatile in use. As required, each baler can be equipped with, among other things, a fast-lift cylinder for energy savings or protected against wear and tear by full Hardox equipment. Remote control operation also facilitates work, with maximum security provided by the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in line with customer requirements.

Everything and more

With its technically advanced but easy-to-use additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear, or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.- Pressing force between 150 and 210 tons

- Stable construction of the base frame

- Height adjustability of the press ram

- Piston bottom sliders

- Cardanic suspension of the main cylinder

- Tying

Channel Balers with Wire - TYING HP-B 180

- Tying

5-Fold horizontal

5-Fold vertical

5-Fold vertical + 4-Fold horizontal - Press force: 180 Tons

- Filling opening: 1.000 x 2.000 mm

- Channel cross-section: 750 x 1.100 mm

- Drive power: 45 - 3 x 75 kW

- Bale weight: 600 - 900 KG

- Bale length: up to 2,0 m

- Length: 13.900 mm

- Width: 2.550 mm

- Height: 4.250 mm

- Total Weight: approx. 36 Tons

The optimal equipment

With various additional features that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and versatile in use. As required, each baler can be equipped with, among other things, a fast-lift cylinder for energy savings or protected against wear and tear by full Hardox equipment. Remote control operation also facilitates work, with maximum security provided by the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in line with customer requirements.

Everything and more

With its technically advanced but easy-to-use additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear, or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.- Pressing force between 150 and 210 tons

- Stable construction of the base frame

- Height adjustability of the press ram

- Piston-Bottom-Slider

- Cardanic suspension of the main cylinder

- Tying

Channel Balers with Wire - HP-B 210

- Tying

5-Fold horizontal

5-Fold vertical

5-Fold vertical + 4-fold horizontal - Press force: 210 Tons

- Filling opening: 1.000 x 2.000

- Channel Cross-Section: 1.100 x 1.100

- Drive power: 45 - 3 x 75 kW

- Bale weight: 1.100 - 1.900

- Bale length: up to 2,0 m

- Length: 15.500 mm

- Width: 2.580 mm

- Height: 3.900 mm

- Total Weight: 61 Tons

The optimal equipment

With various additional features that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and versatile in use. As required, each baler can be equipped with, among other things, a fast-lift cylinder for energy savings or protected against wear and tear by full Hardox equipment. Remote control operation also facilitates work, with maximum security provided by the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in line with customer requirements.

Everything and more

With its technically advanced but easy-to-operate additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear, or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.- Pressing force between 150 and 210 tons

- Stable construction of the base frame

- Height adjustability of the press ram

- Piston bottom Slider

- Cardanic suspension of the main cylinder

- Tying

Hooklift-mobile solutions

Chanlle Balers with Hooklift - EP Mobil 60 V

- Tying: 5-Fold verical

- Press force: 60 Tons

- Filling opening: 1000 x 1450 mm

- Channel cross-section: 750 x 1100 mm

- Drive power: 2 x 22 kW

- Bale weight: 400 - 550 KG

- Bale length: up to 1,8 m

- Length: 6645 mm

- Width: 2580 mm

- Height: 3350 mm

- Total weight: 12 Tons

Efficiency on the hook

As a hook lift mobile solution, the mobile channel baler has a hook lift mount and can be lifted onto suitable vehicles with appropriate systems. The local independence enables safe and reliable operation in the field, e.g. on landfills. Both wire and twine binding are possible to tie the compressed material tightly.

Use on site

From paper to cans, our mobile channel balers compress many different waste products directly on site. The machines' easy handling, low energy consumption and high maintainability ensure the safe and efficient compression of large quantities of waste. The bales created by this process require significantly less space than uncompressed materials and significantly reduce storage and transport costs. The alternative to the hook-lift-mobile solution is the vehicle-mobile variant.- Pressing force 60 tons

- Stable construction of the base frame

- Height adjustability of the press shield

- Highest flexibility

- Equipped with piston bottom slide

Mobile-trailer solutions - Mobile Channel Balers

EP 80 VG 6 mobile

- Tying: 6-Fold Vertical

- Press force: 80

- Filling opening: 1000 x 1450

- Channel cross-section: 750 x 1100

- Drive power: 2 x 22

- Bale weights: 400 - 550

- Bale length: up to 1,8

- Length: 8300

- Width: 1620

- Height: 2250

- Total weight: 40

Straight to the destination

In the vehicle-mobile variant, our location-independent channel balers are mounted on a trailer and can thus be brought to their place of use. Like the hook-lift mobile solution, which is available as an alternative, the vehicle-mounted channel baler is an energy-efficient and safe machine for pressing directly on site. It can be requested with wire or twine binding.

Independent at full power

The mobile channel balers can be used in a wide range of applications. The flexible machines can be used at changing locations to compress waste materials. Materials such as paper, cardboard and plastics, but also natural waste of various kinds, are compressed into solid bales that require significantly less storage and transport and are suitable for reuse. Both the vehicle-mobile and the hook-lift-mobile solutions are easy to handle, powerful and reliable all round.- Press force of 80 Tons

- Stable construction of the base frame

- Height adjustability of the press shield

- Highest flexibility

- Optionally with piston bottom valve

EP 120 VG7 mobile

- Tying: 6-Fold vertical

- Press force: 120 Tons

- Filling opening: 1.000 x 2.000 mm

- Channel cross-section: 620 x 1.100 mm

- Drive power: 75 kW - 2 x 55 kW

- Bale weight: 500 - 700 KG

- Bale length: up to 1.800 mm

- Length: 13.500 mm

- Width: 2.500 mm

- Height: 2.900 mm

- Total Weight: 45 Tons

Benefits EP 120 VG7 mobil

Product details

The mobile channel balers can be used almost anywhere. Whether in the field, at the landfill or at various disposal sites. An optional diesel unit offers smooth self-sufficient operation compared to the electric drive. As the permissible transport weight is limited, twine binding on this machine is particularly attractive. This makes it possible to carry a large amount of twine without wasting large capacities of the transport weight. The optional bale wrapping unit, which can also be installed on the trailer, ensures sealed bales, which is particularly interesting for small grain sizes or hazardous material such as artificial mineral fibres.

Bulkhead Balers

Efficient and safe compression

With a pressing force of 80 to 150 tons, our bulkhead presses reduce the volume of aluminum beverage cans, sheet metal, and punching waste many times over.Small format

PEP 150

- Press force: 150 Tons

- Filling opening: 850 x 540 mm

- Channel cross-section: 600 x 600 mm

- Drive power: 22 - 30 kW

- Bale weight: 140 - 160 kg

- Bale length: up to 600

- Length: 8100 mm

- Width: 1680 mm

- Height: 2580 mm

- Total Weight: 12 Tons

Small bales, big advantages

In the small-format version, our bulkhead presses produce solid bales measuring 600 x 600 mm with a maximum length of 600 mm. This compression significantly reduces the storage and transport volume of sheet materials and optimally prepares further processing measures, such as melting in blast furnaces. In addition to saving time and space, the use of bulkhead presses also saves costs.

More space through less sheet metal

The bulkhead presses, which are also often referred to as closed-end baler in German-speaking countries, can be optionally expanded with accessories and adapted to individual requirements. They are successfully used in the metal and aluminum processing industry as well as in waste disposal companies, in companies specializing in plastics recycling, and in large-scale industry. The small-format or large-format solution can be selected according to the requirements.- Height adjustment of the pressing plate

- Energy saving due to axial piston pump

- Control: ET 200 5 (Siemens)

- Optional with remote control

Standard format

SPAL 180

- Press force: 180 Tons

- Filling opening: 1250 x 1100 mm

- Channel cross-section: 700 x 1100 mm

- Drive power: 45 kW

- Bale weight: 400 - 500

- Bale length: up to 700

- Length: 7100 mm

- Width: 1800 mm

- Height: 3345 mm

- Total Weight: 25 Tons

Sheet metal becomes tight

As the bigger brother of the small-format bulkhead presses, our large-format bulkhead presses produce a bale size of 700 x 1000 mm and have a more extended material feed chute. In terms of power, reliability and ease of maintenance, the small and large formats are extremely similar. Both designs compact sheet metal waste efficiently and result in a reduction in storage and transport requirements.

Power with impressive endurance

Optional accessories allow our bulkhead presses to be adapted to individual requirements. In the metal and aluminum processing industry as well as in waste disposal companies and large-scale industry, our large-format bulkhead presses prove to be efficient powerhouses that are reliable in use over a long period of time. The high ease of maintenance simplifies handling and reduces downtime. The low energy consumption proves to be another major advantage from which our customers benefit.- Height adjustment of the press ram

- Energy saving due to axial piston pump

- Control: ET 200 5 (Siemens)

- Optional with remote control

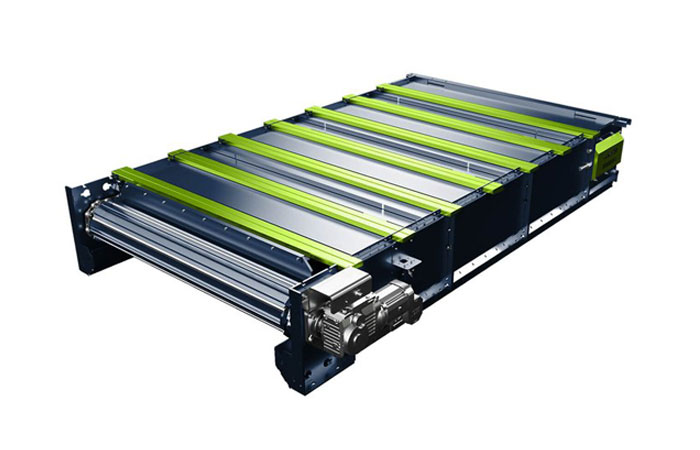

Conveyor technology

Chain Belt Conveyor

- Effective width [mm]: 600 - 2000

- Chain: M112

- Feeding section: Infloor / Overfloor

- Belt quality: EP400/3 4:2

- Conveying speed [m/s]: 0,3 - 0,7

- Material carriers: Size and distance as required

Growing with the challenges

Due to their stable and durable design, the chain conveyors are preferably used in the recycling industry. The high stability goes hand in hand with remarkable flexibility due to subsequent extension or conversion options according to the respective requirements. Carriers specially adapted to the material to be conveyed and different equipment variants ensure optimum conditions for every project.

A strong construction

Our chain conveyors are excellently suited for the transport of loose and already baled bulk material in different, also large dimensions. The easy maintenance due to very good accessibility saves time and costs. Both the underfloor variant for operation without a lifting bucket and the overfloor variant with additional elevation of the side walls as material storage are possible. For filling the belt, this variant requires a lifting bucket or similar lifting device.- For feeding balers, sorting plants and pre-shredders

- Usable widths from 600 to 2800 mm

- Standard with M112 chain

- Bolted wear rails on solid crossbars

- Assembly even under spatially difficult conditions

Sliding belt conveyors

- Effective width [mm]: 600 - 2000

- Material carriers: Size and distance variable

- Feeding section: Infloor / Overfloor

- Belt quality: EP400/3 2,5:0

- Conveying speed [m/s]: 0,3 - 0,7

Good design

For the optimal implementation of customer-specific requirements, the sliding belt conveyors from EUROPRESS have a stable frame design with C-profile in the substructure. Project-related extensions can be realized quickly and cost-effectively. The belt is completely gliding. The sliding plate is made of wear-resistant steel and can also be equipped with fan rollers on request. The secure lateral sealing in bolted design prevents material loss during conveying. The entire belt frame is characterized by high safety standards combined with practical flexibility.

Stability with flexibility

Our sliding belt conveyors are suitable for a wide range of uses in the paper industry and recycling. The drive drum is selected on a customer-specific basis and is basically protected against slippage in the event of moisture. When a slip-on gear design is selected, pedestal bearings with adapter sleeves are used. This means that both the drum and the shaft can be replaced easily and separately if necessary. The low maintenance and long service life of the sliding belt conveyors guarantee high economic efficiency.- Usable widths from 300 to 2800 mm

- Bearing supported via housing flange bearing

- Accelerating belts for automatic sorting systems

- Sorting belts, reversing and traversing belts possible

- RAL painting according to customer requirements

Steel Plate Conveyors

- Material carriers: GröÃe und Abstand variabel

- Effective width [mm]: 600 - 2000

- Chain: M112

- Feeding area: Unter- / Oberflur

- Plate material: Steel, Plastic or Aluminium

- Drive power [kW]: as required

- Conveying speed [m/s]: 0,3 - 0,7

Simply good under difficult conditions

For particularly heavy, hot or sharp-edged materials, we implement extremely robust apron conveyors based on our chain belt conveyor technology. The plate material can be precisely adapted to the respective requirements. Possible materials include steel, plastic or aluminium. The focus is always on safe, smooth operation. At the same time, we create the conditions for easy maintenance in order to offer an economically optimal solution.

As band and bunker

An M112 chain, which is characterised by high durability, and welded-on plates are included as standard. With appropriate side panels, the system can also be used as a material storage or metering unit. Optionally, the apron conveyors can be equipped with a sensor-controlled overload cut-off to prevent damage and ensure even greater safety.- Effective widths from 300 to 2800 mm

- Optional central lubrication units

- Lower and upper belt covers on customer request

Mobile Conveyors

- Material Carriers: Size and distance variable

- Effective width [mm]: 1400

- Chain: M80

- Feeding area: Overfloor

- Belt quality: EP400/3 4:2

- Drive power [kW]: 4 kW

- Conveying speed [m/s]: 0,3

Stay flexible

With our hook-lift mobile chain belt conveyor you can fill your plants anytime and anywhere. This conveyor can be ideally combined with our hook lift mobile channel baler.

Highest flexibility

An M80 chain, which is characterised by its high durability, and welded lugs are included as standard. With the pick-up hook, this conveyor can also be used flexibly at different locations, and the set-up time is less than 30 minutes.- Usable width of 1400 mm

- Optional central lubrication units

- Bottom and top belt covers on customer request

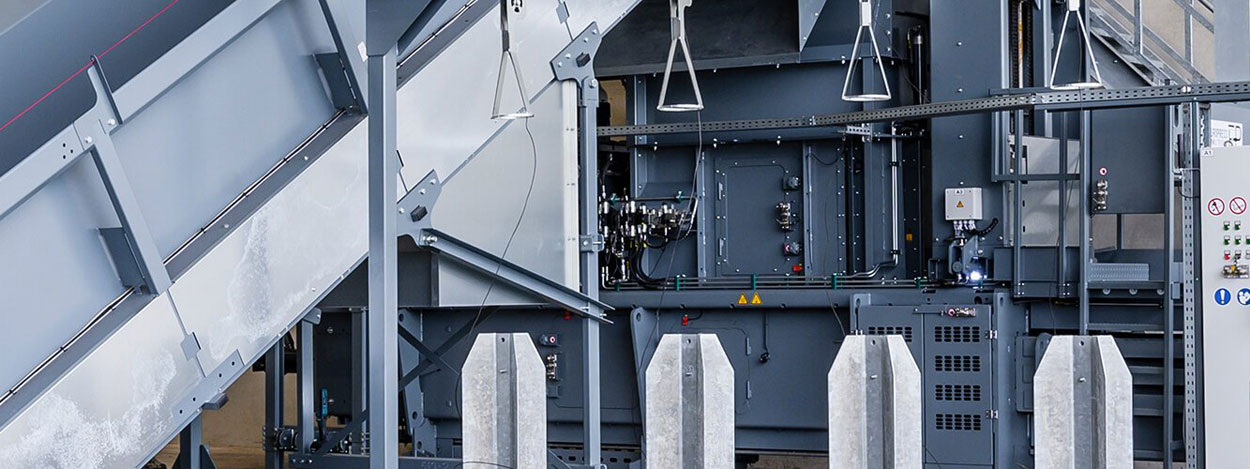

Sorting Systems

-

The task of EUROPRESS sorting systems is to facilitate waste separation, separating mixed material flows quickly, safely, and correctly. The usually time-consuming and inaccurate manual sorting on the conveyor belt is no longer necessary and is replaced by an automated process of high efficiency. Our state-of-the-art sorting systems separate paper, lightweight packaging, plastics, mixed construction waste, wood residues, and metals, among other things.

The sorters are used particularly frequently for unfiltered household waste, which is made up of many different waste products. A throughput of up to 100,000 tonnes of household waste per year characterizes our plants as particularly powerful and productive.

The throughput is implemented according to the customer's requirements. Europress also acts as a general contractor for the customer and coordinates interfaces between the individual sorting units.

Better separated

- The task of EUROPRESS sorting systems is to separate mixed material flows quickly, safely and correctly. The usually time-consuming and inaccurate manual sorting on the conveyor belt is no longer necessary and is replaced by an automated process of high efficiency. Our state-of-the-art sorting systems separate paper, lightweight packaging, plastics, mixed construction waste, wood residues and metals, among other things.

The sorters are used particularly frequently for unfiltered household waste, which is made up of many different waste products. A throughput of up to 100,000 tonnes of household waste per year characterises our plants as particularly powerful and productive.

The throughput is implemented according to the customer's requirements. Europress also acts as general contractor for the customer and coordinates interfaces between the individual sorting units.

Two Ram Baler

Automated process of high efficiency

Two Ram Baler - This is the name of a completely newly developed innovation from Europress.

A mobile two-way press was constructed here that is mounted on a crawler chassis. No time-consuming conversion is necessary before driving to the site of operation. The Two Ram Baler is driven to its place of operation by means of a remote control.

The material is pre-compressed with the two pre-compression flaps and then fed into the main compression chamber. The material is compressed with a pressure of 350 bar. Then the material is pressed into the wrapping chamber with the secondary press blade. With a direct film wrapper, the compacted material is packed and wrapped with stretch film without tying during the pressing out process.

The Two Ram Baler is equipped with a highly efficient extraction system that extracts a volume flow of 7000 cubic metres. For the separated material from the filter pre-separator and bag filter, a waste screw conveyor with BigBag pick-up is mounted. Thus, no released dust penetrates to the outside.Mobile baler for artificial mineral fibres

- Until now, the packed waste containing KMF (artificial mineral fibres) was dumped in the designated area, covered with suitable material and only compacted by loading and later driving over it. With the help of the new two-way press, this waste is compacted about four times more.

The special feature of the press is that it is the only one of its kind in the world with negative pressure maintenance or active extraction of the entire processing process, so that no fibres are emitted. The exhaust air is cleaned by a multi-stage filter system (H14, separation efficiency > 99.995%).

The procedure:

The delivered KMF bags are taken out of the container individually with a special loading excavator with sorting grab and placed in the feed hopper without being destroyed. They then pass through a system of sluices into the press chamber. A main press compresses the waste in this chamber into a cuboid bale. This is pressed out of the pressing chamber by a secondary press and immediately wrapped in film.

The finished bale leaves the machine via another airlock on a conveyor belt. The result resembles a foiled straw bale as known from agriculture. The bales are then taken by a wheel loader with bale tongs to the nearby installation site and installed with little void space.

Industry

Solutions for a better world

For customers in more than 40 countries, we thus make an important contribution to protecting the environment and conserving resources.

Waste management

- In top form: environmental technology for waste disposal

EUROPRESS Umwelttechnik develops and manufactures high-quality channel baling presses and sorting systems for the waste disposal industry. With our high-performance and individually adapted solutions, waste disposal specialists are well equipped for their particular challenges now and in the future.

Channel baling presses and sorting systems: industry-specific solutions for the waste disposal industry

For the optimal compaction of mixed materials, waste disposal companies need user-friendly and economically convincing machines. Stationary or mobile channel baling presses from EUROPRESS reliably bring paper, cardboard, film, household and commercial waste, PET or even plastics into the right shape with a pressing force of 60 to 210 tonnes. The compact channel baling presses, stable conveyor belts in various designs as well as the automated and highly efficient sorting systems from EUROPRESS can be excellently integrated into existing production processes.

Smaller companies to large enterprises in the waste management industry benefit from our holistic solution expertise and have done so for more than 25 years. Ask about our reference projects, which we have developed and already successfully implemented for renowned customers in more than 40 countries.

Plastic recycling

- Optimally compacted: Environmental technology for plastics

EUROPRESS Umwelttechnik manufactures highly efficient channel baling presses and sorting systems for plastics recycling. Our stable and individually configurable machines support recycling companies with their special requirements for effective sorting and the best possible pressing result.

Channel baling presses and sorting systems: powerful machines for plastics recycling

Plastics can only be compacted to a high degree with enormously powerful technology. The channel balers from EUROPRESS are specially equipped for this: with pre-press flaps, piston slide and bottom slide. The piston and bottom slides ensure a consistent and smooth working performance, especially with splintery or particularly small-particle materials. The pre-compression flaps not only pre-compress plastics, they also decisively simplify the feed to the compression channel. Our modern sorting systems have a throughput capacity of high efficiency. They automatically separate colourfully mixed material streams, safely and sorted by type. Sorting systems, robust conveyor belts and baling presses from EUROPRESS are used successfully throughout Europe. We advise small companies through to large enterprises on which solution can be optimally integrated into your existing production processes.

Paper and Packaging

- In shape everywhere: Environmental technology for paper and packaging

EUROPRESS Umwelttechnik is a specialist in mechanical engineering for channel baling presses and sorting systems. We offer custom-fit solutions to specialist companies for recycling paper and packaging. Our technology is also successfully used in the pressing of production and punching residues.

Channel baling presses and sorting systems: reliable technology for recycling paper and packaging

By compacting paper and packaging into material bales, you reduce storage and transport costs. A channel baler from EUROPRESS can compress an original volume of 50 kg/m³ to 550 kg/m³ with the pressing force of 120 tonnes. The compact solutions from EUROPRESS are also convincing in tight spaces. The mobile and stationary channel balers can be seamlessly integrated into existing processes. If waste is collected in roll containers, these can be hooked into a lift-and-tilt device and the baler can be filled directly. Automated sorting systems from EUROPRESS also replace time-consuming, inaccurate sorting by hand. With over 25 years of experience, we will also find an all-round convincing recycling concept for your requirements.

Shipping and Logistics

- Simply profitable: environmental technology for shipping and logistics

EUROPRESS Umwelttechnik designs and produces user-friendly channel balers for the shipping and logistics sectors. EUROPRESS machines support companies in the economic use of their storage areas and also reduce transport costs.

Mobile and stationary channel balers: smooth technology for shipping and logistics

Modern waste logistics save valuable space and money directly on site. By efficiently compacting paper, cardboard or film, you cleverly conserve limited storage capacity. EUROPRESS channel balers are suitable for mobile and stationary use. Whether low material volume or high throughput: Our machines are individually adapted to your performance requirements and fit into your already proven processes. This means that even bulky cartons can be processed without any problems, if required, thanks to large feed openings. Already pre-pressed material, for example from supermarket branches, can be further compressed in the central warehouse with channel balers to save space for storage or transport. Contact the experts at EUROPRESS for your personal offer.

Agriculture

- Naturally good: environmental technology for agriculture

EUROPRESS Umwelttechnik is a manufacturer of mobile and stationary channel balers. Our machines are excellently suited for use in the agricultural industry. We manufacture solutions with individual special dimensions, which allow you an economic utilisation during transport.

Mobile and stationary channel balers: flexible solutions for agriculture

Locally independent and manoeuvrable machines are crucial for many areas of application in agriculture. That is why EUROPRESS develops stationary and mobile channel balers. Use our technology exactly where and how it best suits your work processes. EUROPRESS solutions are suitable for wire tying, but also tying with PP twine. If feed is compressed, tying with yarn is indispensable. This way, no wire residues remain in the highly compressed bales. Twine tying also reduces your operating costs. Because the procurement of twine is significantly cheaper than wire. EUROPRESS supports companies throughout Europe with comprehensive solution expertise and 24-hour service. Convince yourself of our range of services, we will advise you in partnership and without obligation.

Data shredding

- Information density: environmental technology for document destruction

EUROPRESS Umwelttechnik supplies individually adapted channel baling presses and conveyor systems for document destruction. Together with our partner Neuenhauser Umwelttechnik, we develop turnkey systems including high-quality shredding technology for the demanding process of document destruction.

Channel balers, conveyors & more: turnkey technology for document destruction

Machines used in document destruction must ensure the special requirements for high-performance and stable compression of the material. EUROPRESS channel balers reliably compress small to large volumes of material and produce a consistently high bale density. Adapted to your specific conditions, we integrate additional moistening systems or an FE separation for the magnetic removal of metal-containing impurities. We manufacture the conveyor technology exactly according to your wishes and ideally matched to the respective output of the baler. In this way, we ensure that you can continuously use the full throughput capacity of the machines and that unplanned machine downtimes are effectively prevented. Benefit from an innovative overall solution: Together with the Neuenhauser group of companies, EUROPRESS also offers you complete systems with shredding technology, screening technology and dosing technology.

Dispose of artificial mineral fibres

- Intensive work: Environmental technology for disposal of artificial mineral fibres

EUROPRESS Umwelttechnik is an experienced designer of mobile and stationary channel baling presses that can also be used to efficiently compact hazardous materials such as artificial mineral fibres. The machine solutions from EUROPRESS are equipped with special protective measures and safety devices for this purpose.

Mobile and stationary duct baling presses: sophisticated machine solutions for artificial mineral fibre disposal

In the disposal of KMF materials, highly compressed bales save resources in landfills. To ensure that no hazardous substances are released during compression and endanger health, the baling press must also be comprehensively modified for this sensitive area of application. In the mobile and stationary channel baling presses from EUROPRESS, among other things, a fogging system binds dust particles that can be released during the transfer from the conveyor belt to the press hopper. Vacuum extraction, flexible seals, additional roller drawers, etc.: The comprehensive KMF equipment package for safe plant operation has already been successfully approved by the first authorities. You can combine the balers for disposal of artificial mineral fibres with fully or semi-automatic bale wrappers. Ask us: EUROPRESS implements special designs for processing artificial mineral fibres according to your wishes.