- Offer Profile

- We, STRÖDTER GmbH with headquarters in Hamm Westphalia, have been developing and supplying handling technology for all branches of industry for over 40 years. Wherever production or storage parts have to be lifted and moved, our STRÖDTER industrial manipulators and light crane systems can be used.

We have a very wide range of manipulators for the weight range of manual handling up to 500 kg and beyond for load transport up to 3 tons. Our strength is that we can always offer the appropriate technology for the most diverse tasks required by the market.

Industrial manipulators

-

Handling equipment - Our manipulators

In principle, the manually guided industrial manipulator is the part that one usually mentally associates with an industrial robot, e.g. in TV documentaries from automobile factories, where these devices work together on the assembly line and form the basis of handling technology.

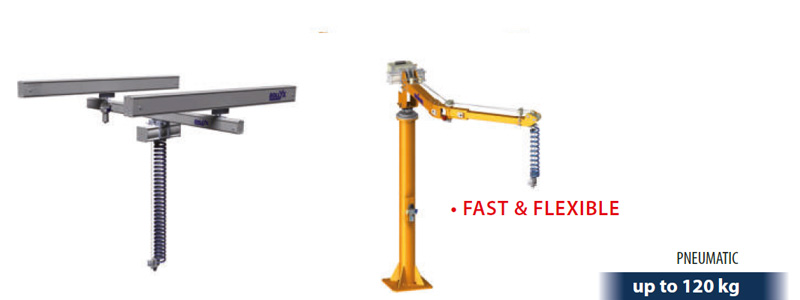

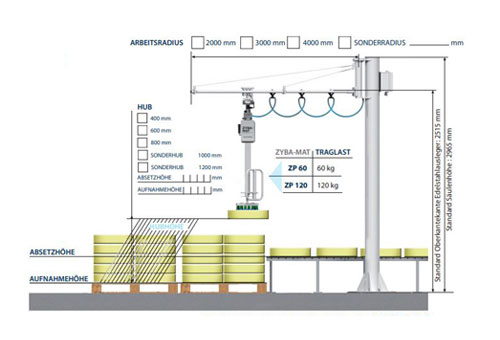

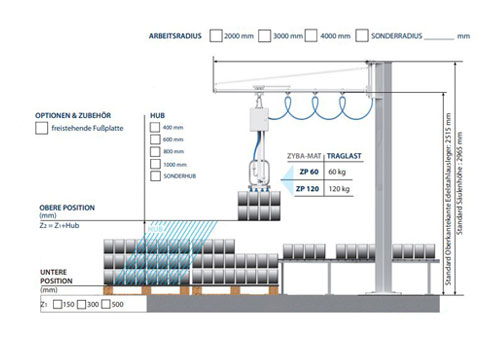

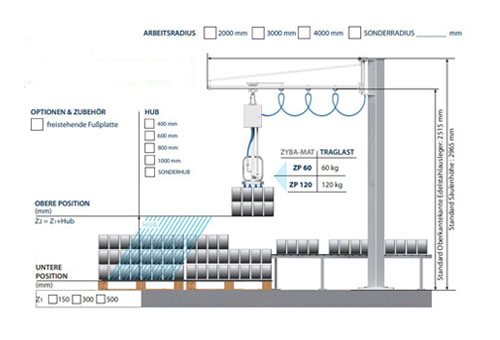

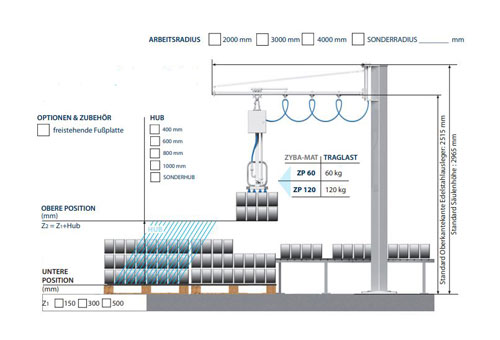

ZYBA-MAT Pneumatic balancer

- The ZYBA-MAT is a new type of pneumatic balancer. Due to its deliberately low-cost design, the ZYBA-MAT pneumatic balancer manages to offer an alternative to conventional chain hoists, rope balancers and vacuum tube lifters.

The ZYBA-MAT pneumatic balancer offers up to 350 kg payload, depending on the type of device (it is available in 5 gradations). The technology of the industrial manipulator allows the user to work quickly and ergonomically.

VIGO-MAT Articulated arm manipulator

- VIGO-MAT VH 500 - Handling of machine parts

The manipulator VIGO-MAT VP is a hand-guided articulated arm manipulator with pneumatic weight compensation. Loads up to 300 kg are suspended by the articulated arm device for easy stepless handling.

The manipulator VIGO-MAT is optionally designed as a standing or suspended device. In combination with the ROLLYX easy-running rail system from the aluminum crane construction kit, the VIGO-MAT is used for large-scale work areas.

The industrial manipulator VIGO-MAT lifts, rotates, swivels or transports loads without swinging in connection with mechanical or powered load handling devices.

For special requirements, the manipulator VIGO-MAT can also be equipped with a hydraulic drive > VIGO-MAT VH

The most common grippers for this purpose are vacuum traverses, magnetic traverses, pneumatic clamps and mandrel clamps.

The system perfects material handling at the workplace.

TELO-MAT Pneumatic Lifting Axis

- The TELO-MAT type FP pneumatic lifting axis is a hand-guided telescopic manipulator with a pneumatic lifting column drive. Loads up to 500 kg are lifted steplessly by the lifting column device for flexible and sensitive handling and moved on the smooth-running rail system with the lifting axis.

Depending on the application, the TELO-MAT lifting axis is also equipped with a hydraulic or electric drive. We then speak of a pneumatic lifting axis or hydraulic lifting axis.

In combination with the ROLLYX easy-running rail system from the aluminum crane construction kit, the TELO-MAT is used for large-scale working areas.

The TELO-MAT industrial manipulator lifts, rotates, swivels or transports loads without oscillation in connection with mechanical or powered load handling attachments.

The most common load handling devices for this are vacuum traverses, magnetic traverses, pneumatic clamps and mandrel clamps.

The system perfects material handling at the workplace.

PICO-MAT Double Rope Balancer

- The PICO-MAT TWIN rope balancer is a hand-operated double rope manipulator with pneumatic balancing control. Loads of up to 100 kg are pneumatically suspended (balanced) by the double rope device for easy and stepless handling.

The rope balancer PICO-MAT TWIN is used manually movable, depending on the required working range, either with the ROLLYX aluminum light rail system or a slewing crane.

The PICO-MAT TWIN rope balancer lifts, rotates, swivels or transports loads in conjunction with mechanical or pneumatically driven load handling devices.

The most common grippers for this are vacuum traverses, magnetic traverses, pneumatic clamps and mandrel clamps.

With its lifting technology, the industrial manipulator perfects material handling as a load balancer at workstations.

GANTRY SYSTEMS - Light Crane Systems

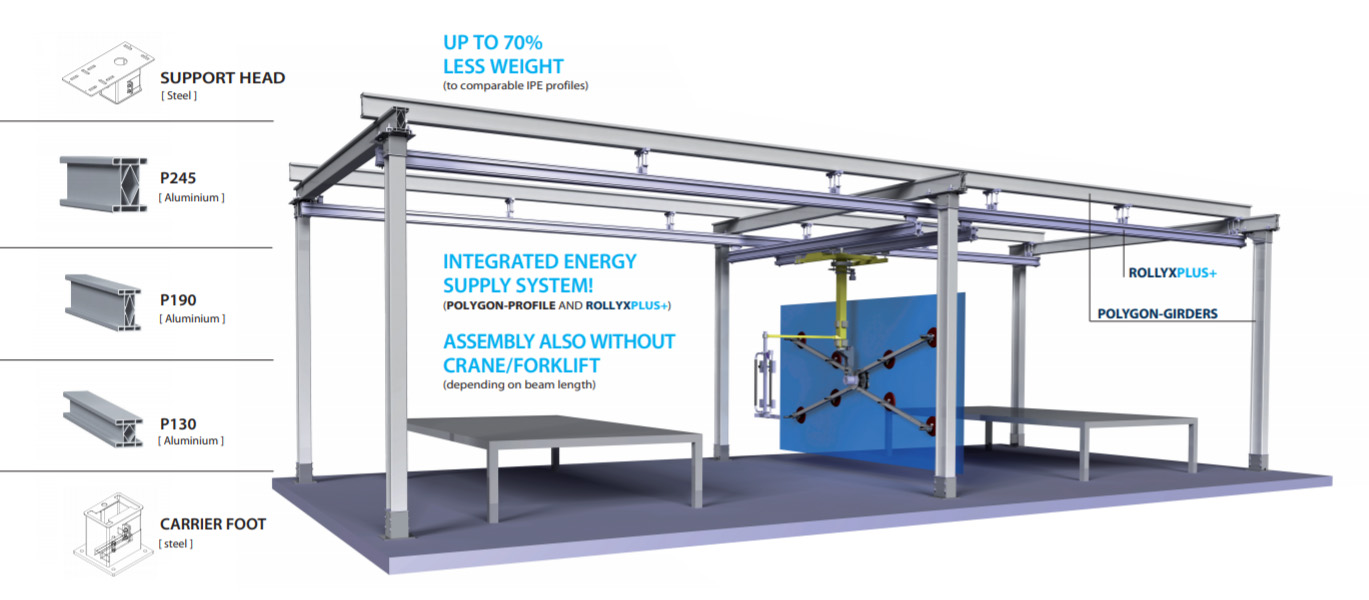

Aluminum girder portal polygon system

-

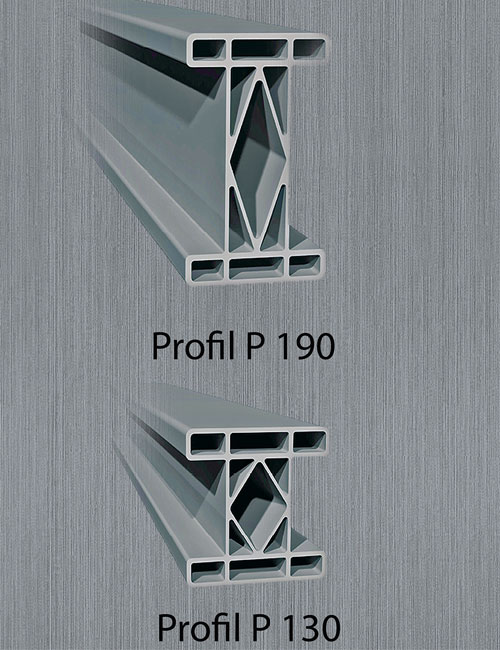

Profiled girders in lightweight construction with which conventional steel girders, e.g. IPE and HEA profiles, can be replaced.

The future realization of gantries becomes considerably easier.These profiles are also available from STRÖDTER as semi-finished products or as a modular system with connectors and suspensions.

The POLYGON BEAMS are available in lengths of 4 m, 5 m, 6 m, 7 m and 8 m or as fixed lengths and also in a finished version.Heavy-duty profiles

Lightweight aluminum beams instead of heavy steel beams- Modern mechanical and plant engineering requires more and more lightweight constructions.

- With the polygonal aluminum beam modular system designed by Strödter, steel structures can be replaced in many AREAS.

- The aluminum system offers high torsional stiffness: aluminum beams in 3 profile sizes and a wide range of fasteners and stand shoes.

- This makes it possible to quickly create lightweight load-bearing structures.

- The advantages over steel girder constructions are obvious. The aluminum profiles with anodized, clean, smooth surface only need to be sawn to design length or can be purchased with exact length dimensions and are thus ready for installation.

- Steel girder profiles, which are three times heavier than aluminum profiles, can only be manufactured at much greater expense, requiring multiple surface treatments (blasting, painting or galvanizing).

Polygon aluminum beams with their lightweight are easier to transport. This saves further costs in truck transport, simplifies in-house transport to the assembly site, and even assembly can be carried out more cost-effectively. Depending on the length of the polygonal beams, they can be installed manually by the fitters. Optically, of course, everything is flawless, special color requests are no problem. The polygon beams and beam elements are available in powder-coated finishes in all colors.

Beam Gantries (steel)

2-portal steel structure

-

ROLLYXPLUS+ rail system with ZYBA-MAT and KLT gripper on 2-portal steel structure. Load capacity up to 3000 kg

An easy-to-operate light crane system is part of the sensible equipment of workplaces. Start with our basic system (steel construction gantry with ROLLYX or ROLLYXPLUS+ light-duty rails). The unit consists of a 2-portal steel structure, an X/Y rail system and an industrial-grade chain hoist. For practical use, the rail system made of extruded and hard-anodized multi-chamber precision aluminum profiles means smooth movement of the load in all planes. Alternatively, the steel gantry structure can also be replaced by the polygonal girder system in its entirety (made of aluminum).

3-portal Steel Construction

-

ROLLYXPLUS+ rail system with with electric chain hoist on 3-portal steel structure. Load capacity up to 3000 kg

The 3-portal steel structure as a light crane system is suitable for the realization of large working areas and, as a modular system, offers the rapid design of customized workstations. The ROLLYX (or ROLLYXPLUS+) rail system consists of extruded and hard anodized multi-chamber precision aluminum profiles. In conjunction with the industrial-grade chain hoist, this allows loads to be easily moved at all levels. Alternatively, the steel gantry structure can also be replaced by the polygonal girder system in its entirety (made of aluminum).

3-portal Steel Construction

-

ROLLYXPLUS+ rail system with with electric chain hoist for roof suspension. Load capacity up to 3000 kg

Simply use your existing hall steel structure for the installation of an X/Y rail system. The rail system from the aluminum crane construction kit consists of extruded and hard-anodized multi-chamber precision aluminum profiles. For practical use, this means a low dead weight with maximum bending and torsional rigidity. Equipped with an industrial-quality electric chain hoist, you get an ergonomically operable workstation.

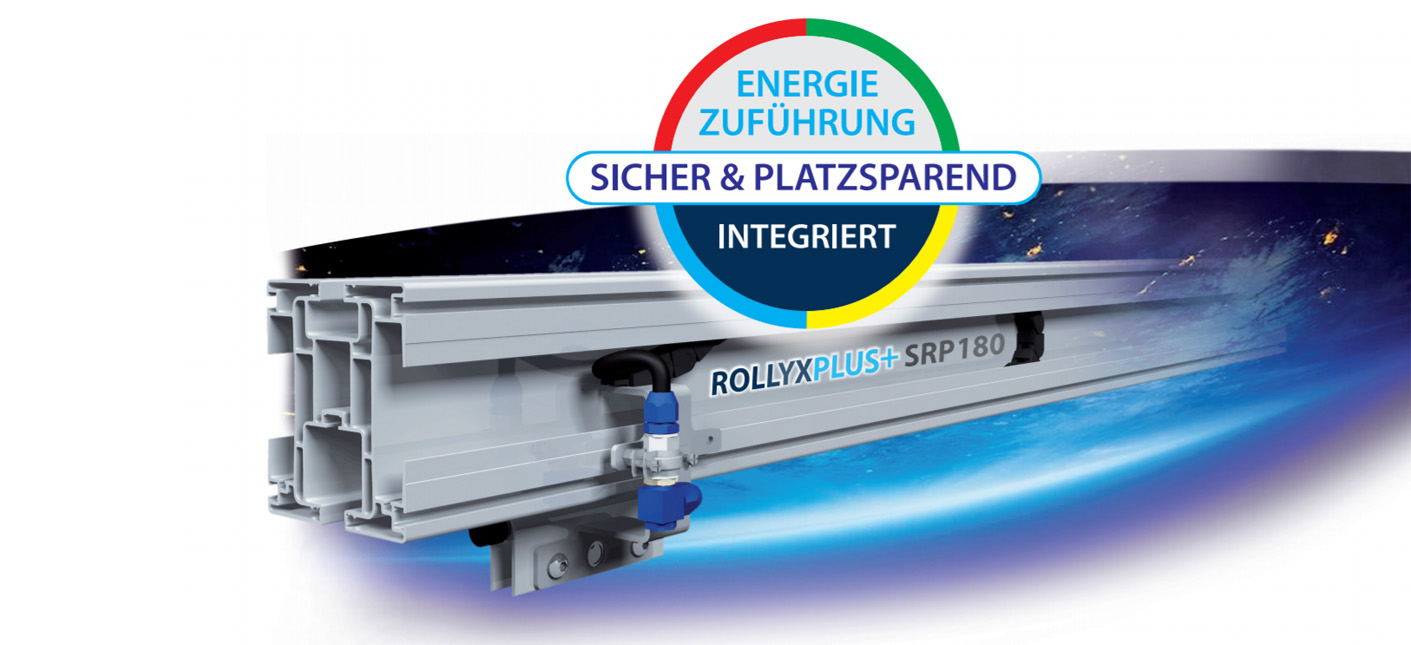

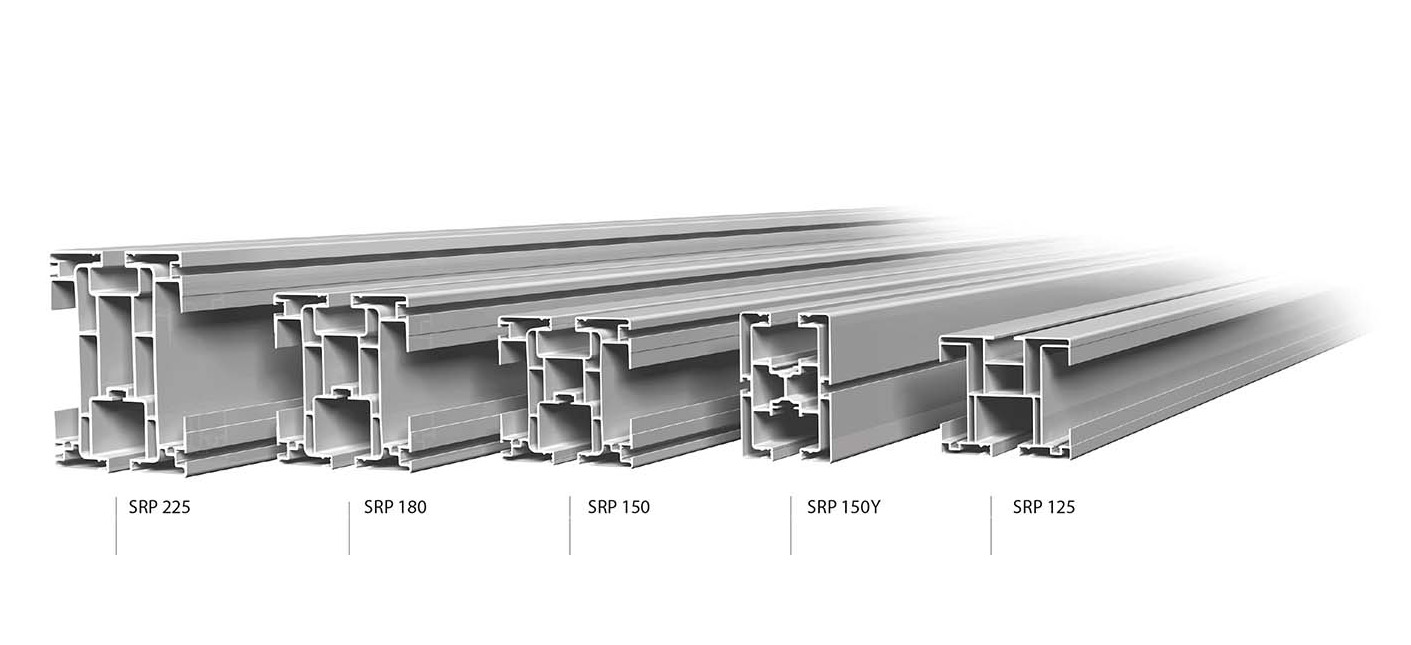

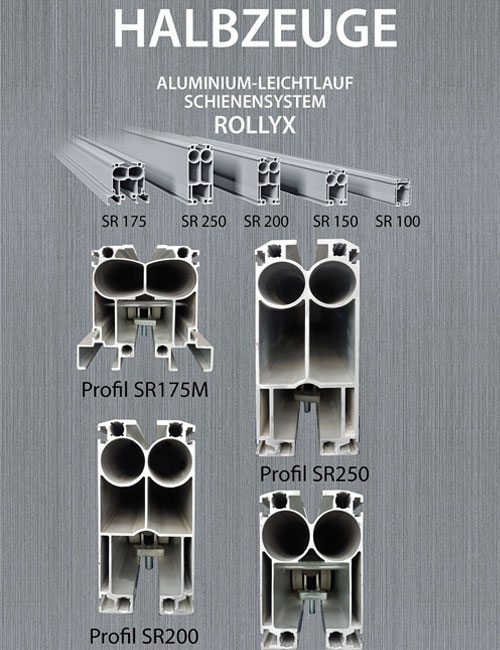

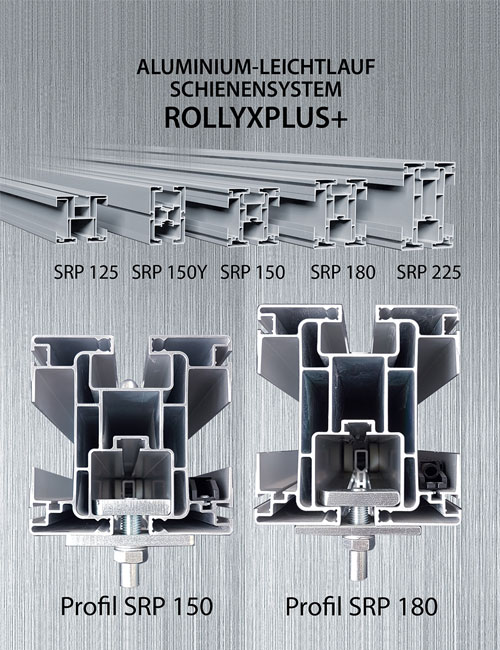

Aluminium smooth-running railsystems ROLLYX and ROLLYXPLUS+

ROLLYX Aluminum Easy-Running Track System

- ROLLYX & ROLLYXPLUS+

Aluminum - light run - rail systems

The aluminum easy-running rail systems have been developed as construction systems with aluminum crane rails for the creation of rail tracks and X/Y easy-running crane systems, for the load range up to 3000 kg for production lines.

With these two aluminum crane construction kits, crane systems can be created easily and quickly. Thus, the spectrum ranges from straight-line connection of two workplaces with only a few meters of conveying distance, to area-wide transport with simple, light manual guidance, to systems for automatic operation.

We have further developed the proven ROLLYX rail system by adding decisive functions.

Clean Room Technology

- Food sector

- Semiconductor sector

- Pharmaceutical sector

- Chemistry sector

Lifting technology for clean rooms and clean areas

- For the food industry

- For the semiconductor industry

Clean room facilities place the highest demands on hygiene, freedom from particles and process reliability.

We supply and develop with you the appropriate lifting techniques, manipulators, grippers and crane rails.

We manufacture these techniques with care, assemble the equipment and put it into operation.- Lifting equipment Grippers - 1 vacuum suction cup & 2 bar grippers

- Manipulators

- Rail systems

Food Sector

- Lifting technology for cleanrooms and clean areas

Clean room facilities and clean room facilities place the highest demands on hygiene, freedom from particles and process reliability.

We supply and develop with you the appropriate lifting techniques, manipulators, grippers and crane rails.

We manufacture these techniques with care, assemble the equipment and put it into operation.- Devices

- Grippers = 1 vacuum suction cup & 2 bar grippers

- Manipulators

- Rail systems

Semiconductor Industry

- Lifting technology for clean rooms and clean areas

Clean room facilities and clean room systems place the highest demands on hygiene, freedom from particles and process reliability. We supply and develop with you the appropriate lifting techniques, manipulators, grippers and crane rails. We manufacture these techniques with care, assemble the equipment and put it into operation.- Devices

- Grippers = 1 vacuum suction cup & 2 bar grippers

- Manipulators

- Rail systems

Pharmaceutical Sector

- Lifting technology for cleanrooms and clean areas

Clean room facilities and clean room systems place the highest demands on hygiene, freedom from particles and process reliability. We supply and develop with you the appropriate lifting techniques, manipulators, grippers and crane rails. We manufacture these techniques with care, assemble the equipment and put it into operation.- Devices

- Grippers = 1 vacuum suction cup & 2 bar grippers

- Manipulators

- Rail systems

Chemical Sector

- Lifting technology for clean rooms and clean areas

Clean room plants and clean room facilities place the highest demands on hygiene, freedom from particles and process reliability. We supply and develop with you the appropriate lifting techniques, manipulators, grippers and crane rails. We manufacture these techniques with care, assemble the equipment and put it into operation.- Devices

- Grippers = 1 vacuum suction cup & 2 bar grippers

- Manipulators

- Rail systems

Handling Technology

Gripper Technology (Industry Solutions)

- For load-free movement of containers, sheet material, packaging, rolls and many other products, STRÖDTER offers the market special, standardized industrial grab systems.

The industrial grab systems complete the STRÖDTER light crane and manipulator program.

As pedestal units for individual workstations or for large-scale work areas on the STRÖDTER light rail system and STRÖDTER gantries, complete workstation systems for lifting, transporting and moving are thus available to the market.

The ergonomic workstations consist of handling hoists or column-mounted slewing cranes with product grippers.

For fast lifting and moving of production parts at production workstations or in the storage area STRÖDTER offers a comprehensive industrial manipulator program.

Preferably, the manipulators are equipped with balance control. This allows the production parts to be moved in a floating, fast and gentle manner.

For simple lifting and occasional transfer of loads, optional variants with chain hoist are also available.

The technology, which is perfectly adapted to your product, leads to an increase in productivity in the production and logistics area and at the same time to a physical relief of the employees.

We deliver our handling technology in sophisticated function and quality.

Gripper Technology (General)

- Here we present some load handling equipment examples (industrial grabs) also from the non-automotive sector.

Vacuum technology- Bath tub handling

- Pressure vessel handling

- Carton handling

- Bag handling

- Solar panel handling

Clamping technology- Drum handling (200 ltr.)

- Carton handling

- Hybrid engine handling

- Suspension strut handling

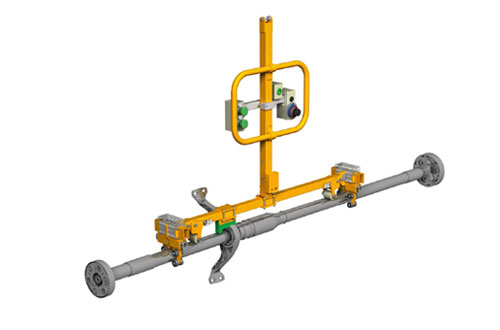

- Cardan shaft handling

Hook technique- Generator handling

- KLT box handling

- Compressor handling

- Front axle half handling

- Small load carrier handling

Standard Complete Systems

- At Strödter, an industrial manipulator or light crane does not stop at the hook.

Strödter offers the market complete systems for all tasks, where everything fits.

Standard complete systems

VIGO-MAT (pneumatic)

For handling production and storage parts with industrial manipulators in the weight range:- pneumatic from 2 to 150 kg piece weight, special up to 250 kg

- hydraulic 100 to 600 kg, special up to 1000 kg

- electric 80 to 1000 kg, special up to 2000 kg STRÖDTER Handhabungstechnik GmbH offers manipulators for many industrial fields.

The manipulators are specially and functionally designed for the parts to be handled.

Manipulators are used in production, warehouse and logistics areas where parts are still lifted and moved manually by employees on a daily basis.

Especially in the production of mass-produced parts and in their packaging, manipulators offer the company a high economic benefit.

Manipulators take over the physical strain of the employee.

The ergonomic position of the employee in front of the device protects his health, because the manipulator protects him from unhealthy movements.

STRÖDTER ensures that the lifting and moving activities of the human are taken over by the manipulators quickly, gently, sensitively and with positional accuracy.

Slewing Cranes

Slewing Crane ROLLYX Jib Boom

Slewing Crane Universal Program

Slewing Crane with ZYBA-MAT

Articulated Slewing Crane MANO-MAT

Articulated Slewing Crane Manipulator

Automotive Industry

Car Production

In this chapter we present gripper solutions (LAM) and complete systems for the automotive industry. Select your area and we will give you an overview of the solutions we have implemented. Use also the contact form for first questions about the inquiry of lifting technology for the automotive industry.

Gripper

Manipulators

- In principle, the manually guided industrial manipulator is the part that one usually mentally associates with an industrial robot, e.g. in TV documentaries from automobile factories, where these devices work together on the assembly line and form the basis of handling technology.

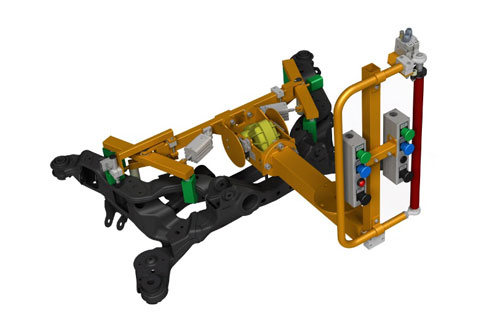

Body-in-white Gripper

- Sheet handling with a ZYBA-Mat ZP120

Body-in-white

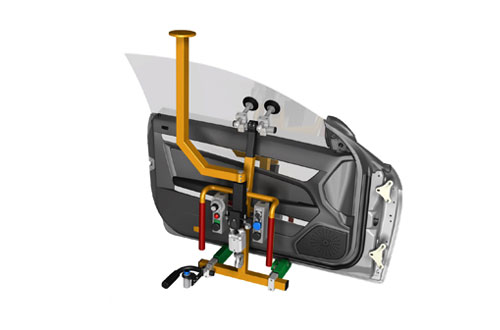

In the body shop, the sheet metal parts are moved from the press shop to their intended installation locations. The variety of shapes of the parts requires special gripper solutions and suitable handling equipment.

Aggregate Construction/Pre-assembly

- In the pre-assembly stage, elements are assembled into subassemblies that are later fed into the final assembly stage in the further course of production.

Vehicle Assembly/Final Assembly

- In final assembly, finished assemblies are mounted on the assembly line. The equipment travels with the vehicles on the belt until the assembly is fastened securely and undamaged.

Supplier

E-Mobility

- STANDARD EQUIPMENT FOR E-MOBILITY ASSEMBLY LINE - COMPLETE SYSTEM!

This equipment series for suspended load handling is particularly suitable for the use on the ROLLYXPLUS+ rail system. Great snapshots characterize this manipulator. The ideal combination for the mass production of e-vehicles for electric mobility.

INSTALLATION IN STANDARDIZED SYSTEM ENVIRONMENT

ADVANTAGE OF THE STANDARDIZED COMPLETE SOLUTION.

Minimizes planning effort and enables identical, clean production processes at different production sites in Europe and worldwide.

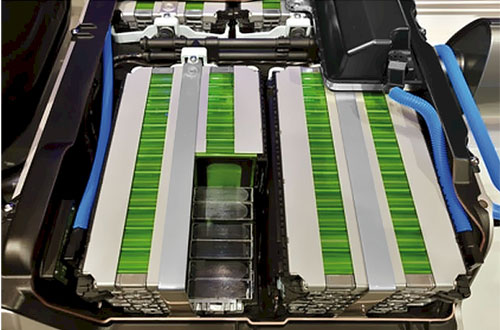

Battery Module Handling

High Voltage Battery Assembly

- Production acceleration in high-voltage battery manufacturing

High-voltage battery assembly - High-voltage battery installation

Due to the enormous demand for high-voltage batteries in connection with e-mobility, our company can draw on a wide range of handling solutions already designed. The various weights and formats are directly adapted by design, thus reducing the planning phase to a minimum.

For sub-processes of battery production, e.g. merging of modules, stacking of modules, handling of housing parts or lifting of battery packs up to a weight of 800 kg, we already have the solution ready. Tried and tested equipment variants are available for the installation of high-voltage batteries in the automotive industry. All components such as a rail system can also be found in our program.

High Voltage Battery Manufacturing

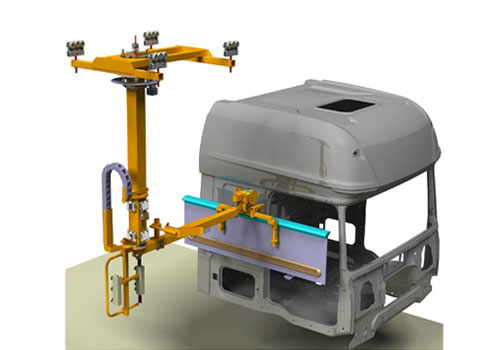

Commercial Vehicle Industry

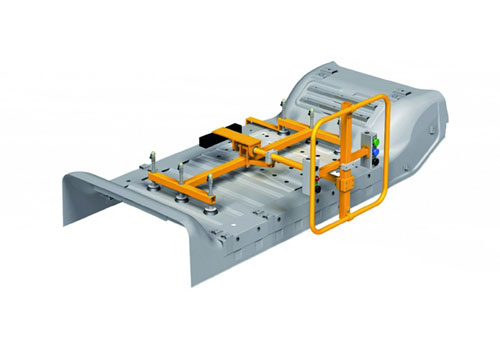

Bed Handling Driver's Cab

- We offer a wide range of solutions for the commercial vehicle sector. Our handling technology is extremely flexible and offers both turnkey and customized equipment and systems for production.

Cab Floor Handling

- We offer a wide range of solutions for the commercial vehicle sector. Our handling technology is extremely flexible and offers both turnkey and customized equipment and systems for production.

Entry-level Sheet Handling

- We offer a wide range of solutions for the commercial vehicle sector. Our handling technology is extremely flexible and offers both turnkey and customized equipment and systems for production.

Body Sheet Handling

- We offer a wide range of solutions for the commercial vehicle sector. Our handling technology is extremely flexible and offers both turnkey and customized equipment and systems for production.

Engine cover handling

- We offer a wide range of solutions for the commercial vehicle sector. Our handling technology is extremely flexible and offers both turnkey and customized equipment and systems for production.

Engine cover handling

- We offer a wide range of solutions for the commercial vehicle sector. Our handling technology is extremely flexible and offers both turnkey and customized equipment and systems for production.

Aggregate handling

- We offer a wide range of solutions for the commercial vehicle sector. Our handling technology is extremely flexible and offers both turnkey and customized equipment and systems for production.

Body sheet handling

- We offer a wide range of solutions for the commercial vehicle sector. Our handling technology is extremely flexible and offers both turnkey and customized equipment and systems for production.

Engine tunnel handling

- We offer a wide range of solutions for the commercial vehicle sector. Our handling technology is extremely flexible and offers both turnkey and customized equipment and systems for production.

Semi-finished Products