- Offer Profile

- We are specialized in almost

everything regarding industrial cleaining systems and technology for the

industry, and has a wide range of standard solutions, but works to a great

extent with customized solutions for the industry, like cleaning system with

robots.

Our knowledge is specialized in the fields of: ultrasonic cleaning, spraywashing, cleaning chemicals and solvents.

ULTRASONIC CLEANERS

-

YOUR EXPERT IN ULTRASONIC CLEANING

Ultrasonic cleaning effectively and carefully removes both organic and inorganic soils from parts, using high frequency soundwaves. Ultrasonic cleaning is also friendly to the environment and cost-saving plus its cleaning the parts effectively on the inside.

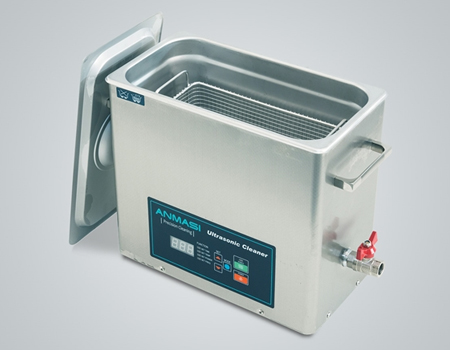

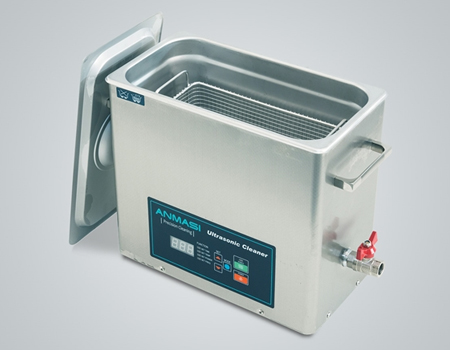

CL-series

-

High quality ultrasonic cleaner with a high ultrasonic effect for reliable parts cleaning every day. Suitable for many tasks.

Analogue display

- Setting of time 0-60 min

- Setting of temperature 0-80°C

- Standard frequency 40 khz.

Digital multifunction display

- Setting of time and temperature

- Powerfunction – setting of frequency and watt-usage

- Multifrequency, Choose between 21,5 or 40 khz

Technical data Model CL100 - CL600

- Volume 4,0 L - 25 L

- Tanksize (LxWxH) 245x135x140 mm - 500x300x190 mm

- Basketsize 190x100x120 mm - 450x250x150 mm

- Outside dimensions 300x170x300 mm - 600x330x420 mm

- Ultrasonic effect 160W - 640W

- Frequency 21,5 / 40 Khz - 21,5 / 40 Khz

- Temperature 0-80°C - 0-80°C

Combi-series

-

This is our most popular ultrasonic cleaning system which is manufactured as a single and multistage machine depending on the cleaning application.

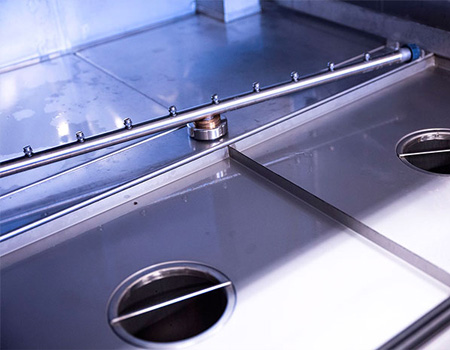

We produce the ultrasonic cleaning system in stainless steel for automotive, aerospace, pharmaceutical and a wide-range of other manufacturing industries. A solid frame construction and welded tanks, its completely insulated on both tank and cabinet to reduce heat loss and noise-pollution.

Available standard modules:- Ultrasonic cleaning

- Venturi jet-nozzle turbulence

- Spray washing chamber

- Rinsing with air-bubble turbulence

- Hot air drying

- Vacuum drying

Technical data Model COMBI 28 -COMBI 150

- Volume 28 L - 150 L

- Tanksize 260x400x270 mm - 520x700x400 mm

- Basketsize 240x380x250 mm - 500x680x380 mm

- Outside dimensions 480x500x500 mm - 680x800x900 mm

- Ultrasonic effect 360W - 2000W

- Frequency 25 or 40 Khz - 25 or 40 Khz

- Temperature 0 - 85°C

- Heating effect 1,6 kW - 2,5 kW

- Power supply AC 230V - 230/400V - 16 amp.

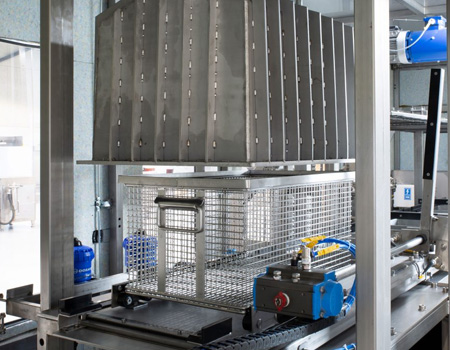

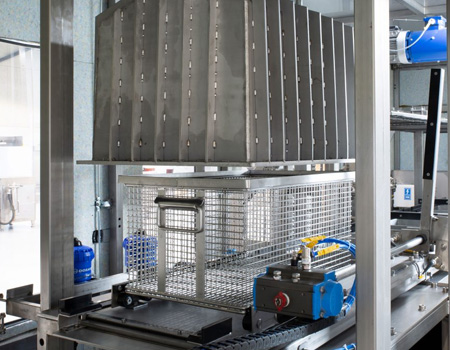

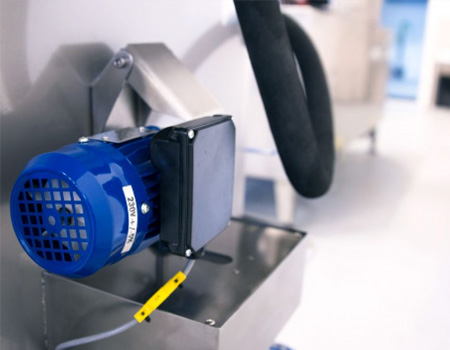

Maxiline

-

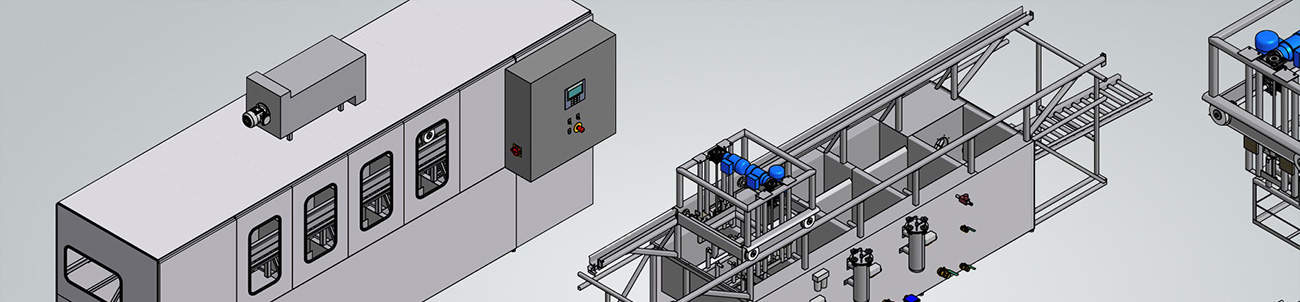

This is our fully automatic in-line ultrasonic cleaning system tailored for customer needs. It is a multistage heavy-duty cleaning system designed for around-the-clock operation.

Available standard modules:

- Ultrasonic cleaning

- Venturi jet-nozzle turbulence

- Spray washing chamber

- Rinsing with air-bubble turbulence

- Hot air drying tank

- Vacuum drying.

Technical data Model MAXILINE 530 - 670

- Tank volume (pr. zone) 150 L - 300L

- Ultrasonic effect (pr. zone) 2000 W - 4000W

- Ultrasonic frequency 25 or 40 Khz

- Basket loading max. 50 kg - 100kg

- Basket size (external) 521x321x200 mm - 651x469x300 mm

- Cleaning height max. 200mm - 300mm

- Temperature 30 85 °C

- Heating effect (pr. zone) 4000 W - 8000 W

- Drying power 2200 W

- Temperature drying °C 40 110 °C

Maxi-series

-

This is our heavy-duty industrial ultrasonic cleaning system that includes several standard options. It is ideal for workshops, tools cleaning and the metal industry.

Available standard modules:- Ultrasonic cleaning

- Venturi jet-nozzle turbulence

- Spray washing chamber

- Rinsing with air-bubble turbulence

- Hot air drying tank

- Vacuum drying.

Technical data Model Maxi A - Maxi E

- Volume 144 L - 508 L

- Tanksize 500x640x450 mm - 560x1800x500 mm

- Basketsize 480x620x450 mm - 520x1750x500 mm

- Ultrasonic effect 1,5 kW - 5,0 kW

- Frequency 25 or 40 Khz

- Temperature 0 - 85°C

- Heating effect 2,3 kW - 8,0 kW

- Power supply 230/400V - 16 amp. - 230/400V - 25 amp.

Maximatic

-

This ultrasonic cleaning solution is very similar to the Maxi-series, but includes the pneumatic agitation system and a stainless steel housing.

The ultrasonic cleaning system is produced for heavy-duty parts, and offers a two-step cleaning process combining ultrasonic cleaning and pneumatic agitation of the parts. It is equipped with a stainless steel housing including front cover with gas springs for reducing noise.

Available standard modules:- Ultrasonic cleaning

- Venturi jet-nozzle turbulence

- Rinsing with air-bubble turbulence

- Hot air drying tank

- Vacuum drying.

Technical data Model Maximatic A - Maximatic E

- Volume 216 L - 717 L

- Tanksize 620x660x530 mm - 680x1820x580 mm

- Basketsize 480x620x450 mm - 520x1760x500 mm

- Ultrasonic effect 2,0 kW - 7,0 kW

- Frequency 25 or 40 Khz

- Temperature 0 - 85°C

- Heating effect 2,9 kW - 12,5 kW

- Power supply 230/400V - 16 amp. - 230/400V - 25 amp. 230/400V - 25 amp.

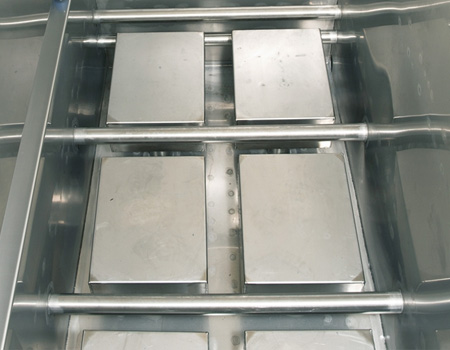

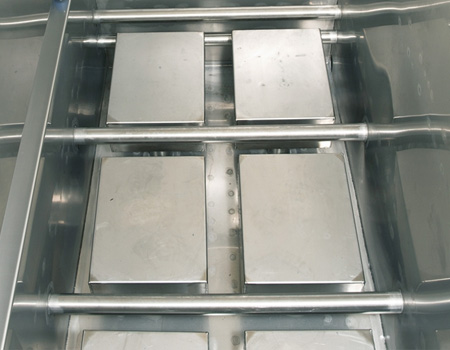

Pharmaline

-

This ultrasonic cleaning system is designed for the pharmaceutical- and electronics industry. Therefor its designed to meet the strict industry standards within these segments which means its including a complete documentation package, traceability on all washed parts with data tracking, communication module and process monitoring for internal systems.

This washing system is made in complete stainless steel of the highest quality which meets all the requirements for the welds, joints and surfaces of the equipment, for which all welding and materials are fully documented as required in the pharmaceutical industry.

The equipment comes with fully calibrated components with associated certificate, as well as with an advanced control panel where the customer has the possibility to have “calibration assistance” in connection with service, data tracking, reporting and communication with external production system. So that the customer can verify and document which process each cleaned part has been through.

The equipment is offered with a wide range of options depending on the customer’s needs and is produced both as a manual and automatic solution depending on the customer’s needs. Note that all Pharmaline ultrasonic cleaning systems are tailored to the customer’s needs.

Technical data Model Pharmaline 80 - 150

- Volume 80 l -150 l

- Tanksize 480x320x200 mm - 600x400x300 mm

- Max. weight 50kg

- Ultrasonic effect 1000W -2000W

- Frequency 40 eller 132 kHz

- Temperature 0 - 85°C

- Heating effect 2000W - 4000W

- Power connection 3×230/400V, 50 hz.

SPRAYWASHERS

- We have more then 25 years of experience with spraywashing

Toploader ECO

-

This is our spray washing system which is highly efficient and economic and includes a lot of standard equipment which makes it very attractive.

The ECO model of our standard spray washing system is produced in the same high quality as all of our spray washers.

It has a more simple construction and includes several options to ensure the same cleaning results as our PRO models.

The spraywasher is only available in one size, and it is aimed at low cost operations, mainly related to maintenance and service

operations.Available options

- Filtration system

- Automatic water filling

- Automatic chemical dosing

- Extraction fan

- Integrated stainless steel coarse filter

- Stainless steel baskets and fixtures

- Digital control panel.

Toploader PRO

-

This is our spray washing system which is highly efficient and includes a lot of standard options. Its very user-friendly and can be operated by crane.

The PRO model is our highly efficient spray washing system with toploading. It is manufactured of high quality materials and is popular for many applications such as: Parts after machining, workshops, tools cleaning, maintenance, robot cells etc.

Available modules

- Spray washing

- Spray rinsing

- Hot air drying.

Available options

- Filtration system

- Automatic water filling

- Automatic chemical dosing

- Extraction fan

- Stainless steel baskets and fixtures

- Digital control panel.

Frontloader AFL

-

This is our spray washer for heavy-duty parts with a manual frontloading system which also works as a loading and an unloading table.

The spraywasher AFL-type is the ideal solution for repair workshops, tools cleaning and large parts after CNC machining.

It is very easy to operate, and is available in four different sizes. The compact design makes it a good choice for smaller workshops and for production facilities with a low ceiling.

Available modules:

- Spray washing

- Spray rinsing

- Hot air drying.

Extra options:

- Filtration system

- Automatic chemical dosing

- Extraction fan

- Automatic water filling

- Oil separator

- Siemens touchscreen

- Motordriven basket.

Frontloader AFP

-

This is our spray washer for heavy-duty parts with a pneumatic front cover. It is a very compact and reliable cleaning system for a wide range of applications.

Besides from the pneumatic front cover the spraywasher AFP-type is very similar to the AFL-type. It is very easy to operate and is available in five different sizes.

The smart and compact design makes it a good choice for workshops, tools cleaning and after machining of large parts.

Available modules:

- Spray washing

- Spray rinsing

- Hot air drying.

CONVEYOR WASHERS

- Your partner for highly automated tailored in-line Precision Cleaning systems.

Beltline

-

This is our high quality in-line cleaning system with conveyor. It is designed in modules and customized to meet customer requirements.

The Beltline cleaning system is designed for manufacturing around-the-clock. It is the ideal solution for implementation directly into the production line.

Available modules

- Spray washing

- Spray rinsing

- Hot air drying.

: Extra options:

- Ultrasonic cleaning

- Vacuum drying

- Filtration system

- Oil separator

- Extraction fan

- Customized belts

- Pure-water final rinsing

- Conveyors, pick-and.place systems etc.

ATB

-

This is our simple and low-cost washing module with conveyor. It is a very compact and flexible solution, which is easy to implement.

The spraywashing system is designed for simple applications where only a washing module is necessary. It is used mostly for washing parts

between steps in the manufacturing process.This is an ideal solution for washing before welding of steel parts, or before assembly depending on the cleanliness requirements.

Available modules:

- Spray washing.

Extra options:

- Filtration system

- Automatic chemical dosing

- Extraction fan

- Automatic water filling

- Oil separator.

Drumline

-

The Drumline spray washing system is designed for cleaning of high quantities and is very efficient due to the rotation of the parts inside the machine.

The Drumline cleaning system is very similar to the Beltline series in terms of process. It is designed for manufacturing around-the-clock and is normally implemented directly into the production line. The rotating drum transports the parts instead of a conveyor belt through each module.

This is an ideal solution for smaller parts in high quantities for example after stamping.

Available modules

- Spray washing

- Spray rinsing

- Hot air drying.

Extra options:

- Filtration system

- Oil separator

- Extraction fan

- Automatic chemical dosing.

FILTRATION

-

PROLONG FLUID LIFECYCLE

Filtration systems are often considered a nice-to-have investment. And if you consider lower operation costs, improved working environment and better CSR nice-to-have this might be true. But if, like most, you consider them need-to-have, then you need to consider installing a filtration system to complement your existing cleaning equipment.

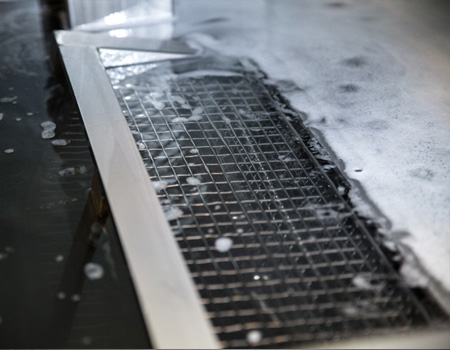

Bandfilter UF

-

Anmasis high quality bandfilters are produced in stainless steel. They are mainly being used for filtration of non-explosive fluids for filtering of lubricants, oils and process fluids from cleaning systems and CNC-machines. The bandfilters are produced in different sizes depending on customer needs and can filtrate up to 800 liters pr. minute. The bandfilters are using filtration paper which can be aquired in different types depending on the application. The bandfilters can be used separately as stand-alone-units or a build-in unit for larger filtration systems.

Applications:

- Refrigerants and lubricants

- Process fluid

- Oil

- Water Treatment

- Sewage

Bandfilter TM

-

High quality band filter designed for large volumes and heavy-duty contamination. Its with a belt-conveyor which is transporting the filter cake and is available for volumes up to 3.000 l/min.

Available options:

- Filter paper

- Stainless steel support frame

- Polypropylene- or stainless-steel containers

- Tank units

- Available in AISI 316 L

Bandfilter TMP

-

Its developed for application with highly corrosive fluids like salt water and acids and is based on the TM design used for the stainless-steel filters. The bandfilter is made in polypropylene on all surfaces in contact with the fluid and is using filter paper for efficient filtration.

Available options:

- Filter paper

- Stainless steel support frame

- Polypropylene containers

- Tank units

Applications:

- Salt water

- Highly corrosive substances

- Acids

Bandfilter Endless TME

-

High quality band filter designed for large volumes and heavy-duty contamination, it made for coarse filtration and is with a endless-band system. This means the bandfilter is not using filter paper for the filtration process, but instead a conveyor which is self-cleaning by either using a brush or high-pressure air.

Available options:

- Stainless steel support frame

- Tank units

- Available in AISI 316 L

Filter housings

-

We offer a wide-range of filter housings in stanless steel for both filterbags- and cartridges.

The filter housings are constructed following general industrial standards, and can be offered including filtration pumps. The main part of our filter housings are used in cleaning- and filtration systems for treating process fluids.

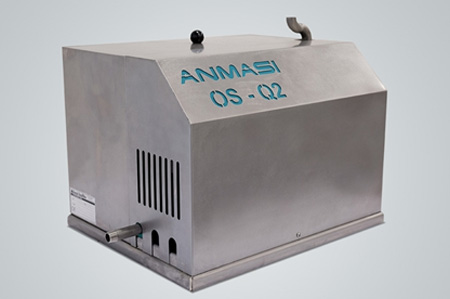

Oilseparator

-

Innovative high-quality oilseparator constructed in stainless steel. The oilseparator is designe with a four-chamber labyrint system which ensures efficient separation of the oils.

This gives the process fluid optimal conditions for separation the oils which are removed from the tank units using a highly-efficient suction head. This ensures that the process fluids are always free of unwanted oils which can affect operation and process fluid life-cycle.

Applications- Tank units from washing systems

- Machining centers

- Process fluid tanks

- Waste water treatment

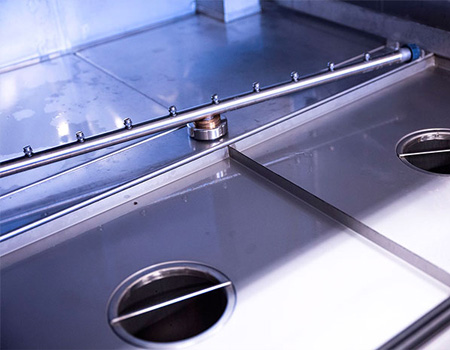

Masterclean systems

-

Reduce your operating costs significantly, extend the life of your tools and protect the environment with a central filtration system from us.

Our tailor-made central filtration systems for efficient filtration of lubricants and process fluids made at our factory in Denmark.

Its available either as a part- or full flow system constructed in powerful stainless steel with bandfilter, oil separator, pumps, level control, automatic dosing and touchscreen.

This is a complete solution with user-friendly control including monitoring and alarms as well as the possibility of SMS warning and a wide range of extra options.

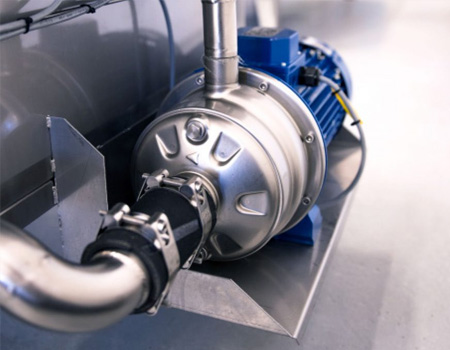

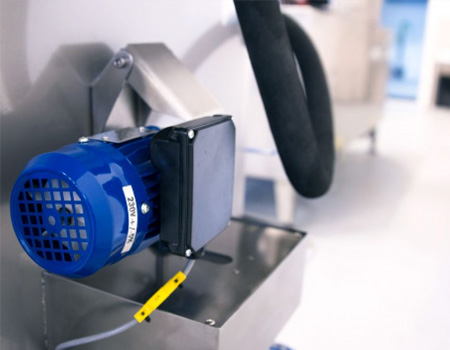

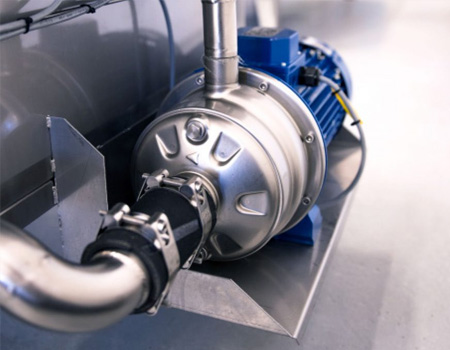

Machine connections

-

That’s why its very important to consider the type of machine connection when installing a filtration system, because this part is just as important as the filtration system itself, and the installation must be carried out by trained professionals to avoid issues with the efficiency.

Anmasi manufacture and install two types of machine connections, which is used depending on customer application and economy. The first type is our high-end external connection with frequency-regulated pump, stainless steel self-cleaning suction tank and level sensor. The second type is our economic integrated connection, which is placed in a small container directly inside the process fluids.

It’s our technical specialists who in dialog with the customer determines which solution is most suitable depending on several factors such as contamination level, pump pressure, volume and space.

VITO Compact Filter

-

Experience the economical and innovative VITO compact filter developed in Germany to efficiently filter process fluids and lubricants.

The filter system is constructed of stainless steel and comes with a handle and a tray so that it can be transported easily. Therefore, it can be used both as a stationary and movable solution for machining centers, process plants and cleaning systems.

It excels by removing particles down to 5 microns while venting the fluid during filtration, thereby counteracting bacterial growth and bad odors.

VITO comes with a smart programmable control where you can set the process time and process intervals via an app.

Magnetic separator

-

Compact magnetic separator that is easy to integrate into existing equipment and is mainly used for mounting on a bandfilter. This magnetic separator comes with a very powerful magnet and a large surface area which makes it extremely effective in removing the magnetic particles. The magnet separator can be offered on request in a special edition that can be used for acid and corrosive liquids.

It comes standard in stainless steel including manifold for distribution of liquid and dirt tray ready for installation.

Applications- Lubricants

- Process fluids

- Oil

- Waste water treatment

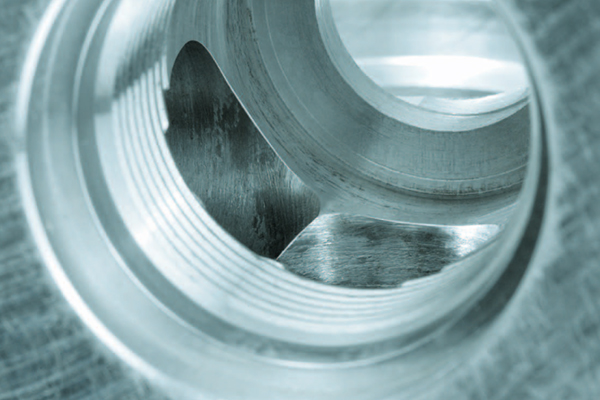

ROTATING BASKET WASHER

Rotoline ST

SINGLE CHAMBER ROTATING BASKET WASHER

Precision cleaning for complex parts in a single chamber

This is our rotating basket system designed for high precision cleaning of complex parts. It is designed in modules and customized to meet customer requirements.

The Rotoline cleaning system is a powerful and robust solution for complex parts such as hydraulic blocks, moulding tools etc.

The Rotoline can be delivered as a single-chamber solution or in separated modules.

It is available as a manual or fully automated solution with conveyor system according to customer requirements.

Available modules:

- Spray washing

- Ultrasonic cleaning

- High-flow turbulence

- Hot air drying

- Vacuum drying.

Rotoline MT

MULTI STAGE ROTATING BASKET WASHER

Precision cleaning for high volumes of complex parts in several stages

This is our rotating basket system designed for high precision cleaning of complex parts. It is designed in modules and customized to meet customer requirements.

The Rotoline MT cleaning system is a powerful and robust solution for complex parts such as hydraulic blocks, moulding tools etc.

Its a multi-stage system designed in modules build together based on customer demands and is always tailored to the customer application.

It is available as a manual or fully automated solution with conveyor system, transport trolleys, filtration systems and oil separators.

Available modules:

- Spray washing

- Ultrasonic cleaning

- High-flow turbulence

- Hot air drying

- Vacuum drying.

Applications

Oils and lubricants

-

We have delivered a wide range of different industrial cleaning systems to remove oils and lubricants from machined parts and maintenance components. We can clean almost any surface made of metal, plastic, glass etc.

The process time varies depending on the cleaning chemical and equipment. It also depends on which types of oil and lubricants we are working with, but common for all our solutions is they are waterbased and based on either a neutral, alkaline or acid solution.

Which type of industrial cleaning equipment such as ultrasonic cleaning or spraywash depends on the specific needs of the customer.

Rust and corrosion

-

We effectively remove corrosion using our neutral waterbased cleaning chemical combined with ultrasonic cleaning equipment. This solution removes both old and new rust from maintenance parts etc.. The solution is very environmental friendly and effective.

The product is most effecitve combined with a ultrasonic cleaning solution and demiralized water at a temperature of 55°C. The cleaning chemical can also be used pure for manual cleaning. At the same time the cleaning chemical also removes small apperances of oil and grease.

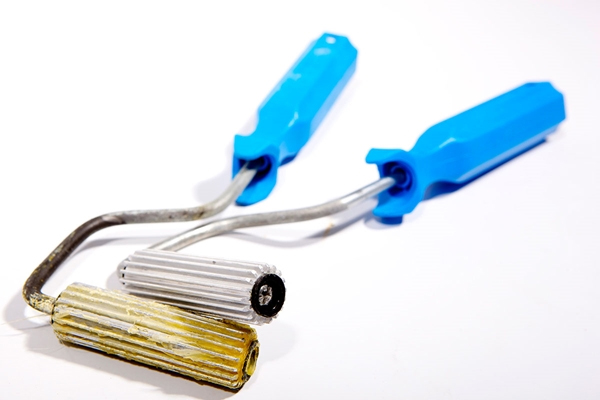

Paint

-

We have great expertise in removing paint from a large variation of parts. Typically we are removing paint from hooks, fixtures, pumps, painting pistols and nozzles.

The benefit with having an industrial cleaning solution for the job, is your removing the paint in a closed proces, and avoid manual cleaning with strong chemicals like a thinner. Instead you get a automatic and waterbased cleaning process which effectively removes the paint without compromising worker safety.

Our solutions can remove both liquid and hardened paint which is mainly done with ultrasonic cleaning.

Epoxy

-

We have a expertise in removing both hardenen and liquid epoxy from parts. Which in some cases can be a hard job depending on the type of epoxy.The key to removing epoxy effectively is having the right cleaning chemical and machine for the type of parts and form of epoxy that is being removed.

Through the last couple of years we have developed alot of customized solutions for removing this especially for major players in the windpower industry.

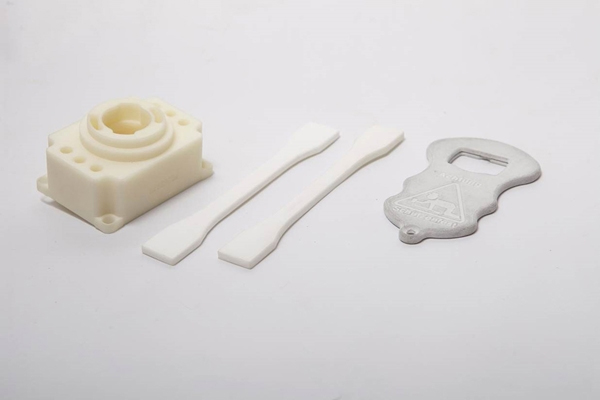

3D PRINT: SLA, FDM, Polyjet

- We have an extensive knowledge in ultrasonic cleaning of components after 3D-printing, and offer both standard- and customized solutions for the application. We have a complete range of both cleaning machines and water-based cleaning chemicals for removing epoxy and support materials.

Rubber parts

- We manufacture cleaning machines for rubber-parts in both the medical- food- and metalindustry. Every machine is customized for the user to meet the specific requirements of the application.

Thermal deburring

-

We have a wide expertise in cleaning both large- and small components after thermal deburring. During the deburring process a oxide-layer is created on the parts which has to be removed in the production process.

This layer is most efficiently removed using an ultrasonic cleaning system, and specialized chemicals optimized for the application. We supply the complete solution offering both the cleaning systems and chemicals for the application which guarantees the best results.

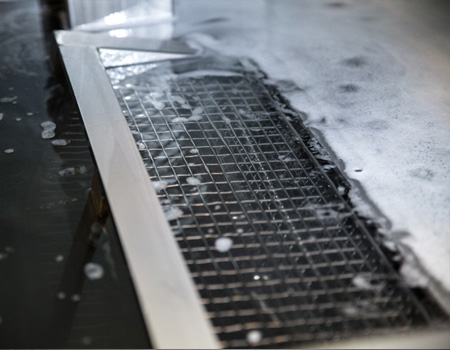

Wire-spark cutting

-

Efficiently clean the parts after wire-spark cutting, removing the surface layer after the process and achieving the original metal-surface from before the process. The cleaning process is efficiently carried out using ultrasonic cleaning and a special developed cleaning chemical for this purpose.

This method can replace other equipment as sandblasting equipment and automate the process completely, and make the process more easy and less costly.