Hydrosila

Videos

Loading the player ...

- Offer Profile

- Nowadays Hydrosila Group is the leading manufacturer of fluid power machines and hydraulic system components for agricultural, construction and road-building equipment in Eastern Europe.

Product Portfolio

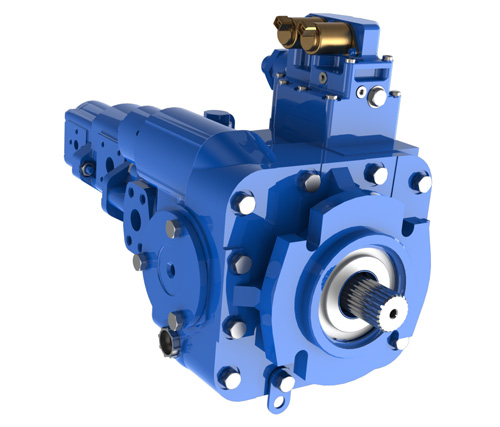

Axial-piston units

Variable displacement axial piston pumps (Series S & H)- Variable displacement axial-piston pumps in swashplate design are intended for hydraulic actuators combined of pump and motor, operating in closed circuit systems. Operate in stroke of mobile machines – harvesters, concrete mixers, paving compactors and other.

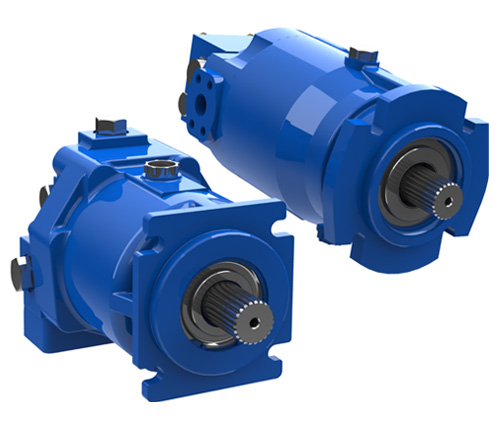

Fixed displacement axial piston motors (Series S & H)

- Fixed displacement axial-piston motors in swashplate

design are used both in closed and open circuits.

Motor rotating speed is proportional to the flow which is supplied to it. Torque produced is proportional to the hydraulic pressure the motor receives.

Fixed displacement bent axis axial-piston pumps (Series BF10)

- Fixed displacement bent axis piston pumps are implied in hydraulic systems to transform the mechanical power of the the drive shaft into the hydraulic power.

Fixed displacement bent axis axial-piston motors (Series BF10)

- Fixed displacement bent axis piston motors are implied in hydraulic systems to transform the hydraulic power into the mechanical power of the drive shaft.

Variable displacement axial-piston motors (Series BV10)

- Variable displacement axial-piston motors in swashplate design are used to operate in closed circuit systems, where it is essential to widen the range of regulation of actuator rotation speed.

Fixed displacement bent axis axial-piston pumps (Series BF20)

- Fixed displacement bent axis piston pumps are implied in hydraulic systems to transform the mechanical power of the the drive shaft into the hydraulic power.

Fixed displacement bent axis axial-piston motors (Series BF20)

- Fixed displacement bent axis piston motors are implied in hydraulic systems to transform the hydraulic power into the mechanical power of the drive shaft.

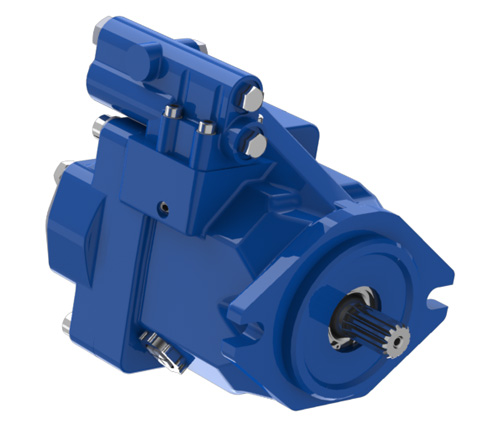

VARIABLE AXIAL-PISTON PUMPS FOR OPEN CIRCUITS WITH LS CONTROL (Series C)

- Variable displacement axial-piston pump is used in open circuits. Pump is applied at tractors, agricultural, mobile machines and other equipment in temperate and tropical climate.Pump control is realized by supply and pressure adjuster, which limits maximum pressure level in pressure line and keeps pump supply at preset level regardless of load and speed. Axial-piston pump is easily controlled and relatively compact.

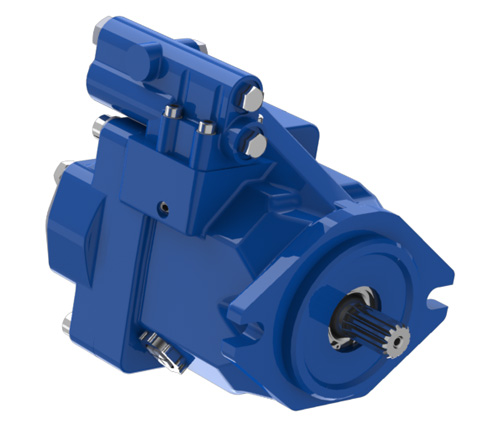

Variable axial-piston pumps for open circuits with LS control (Series C1)

- Variable displacement axial-piston pumps Series C1 are

used in open circuits. Pumps are applied at tractors, agricultural and

mobile machines and other equipment.

Features of Variable displacement axial-piston pumps Series C1

Pump control is realized by supply and pressure adjuster, which limits maximum pressure level in pressure line and keeps pump supply at preset level regardless of load and speed.

Gear pumps

Gear pumps Series «K»

- The pump housing is made of extruded aluminum with the

usage of PTFE bearings. The pumps are intended for hydraulic system with

nominal pressure 250 bar.

Gear pumps series ‘К’ are manufactured under the standard DIN, SAE and ISO.

Gear motors series «К»

- The gear motor housing is made of extruded aluminum with the usage of PTFE bearings. The gear pumps are intended for hydraulic system with nominal pressure 250 bar.

Gear pumps Series K Profit

- Gear pumps Series K Profit - The best solution for

hydraulic power packs at a price of $ 15

Gear pumps series ‘К’ are manufactured under the standard DIN, SAE.

Displacement 1,2-6,2cm3/rev

Maximum pressure 220 bar

Maximum speed 3000 min-1

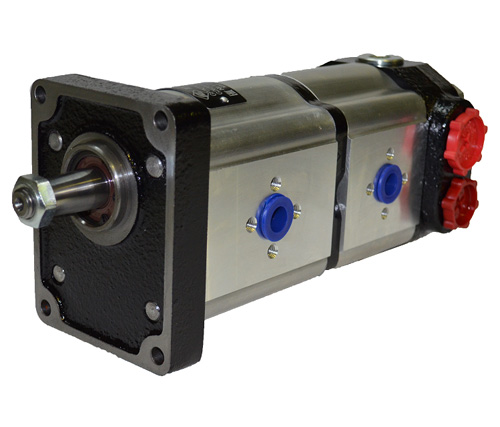

Multiple pumps series «K»

- Multiple pumps series K are presented in 1, 2, 2.5, 3 and

4 groups. They are manufactured with thru-bolt body of rolled aluminium,

usage of solid sleeves of high-strength aluminium alloy and PTFE bearings

Multiple gear pumps series K are manufactured uner the standart DIN, SAE and ISO

Gear pumps Series «T»

- Gear pumps series "T" are manufactured with left, right

and reversible rotation of drive shaft hydraulic systems of various mobile

machines: trucks, truck mounted cranes, aerial work platform, municipal

vehicles and other types of machines.

Displacements

16-150 cm3/rev

Pressure

Max. continuous pressure - 290 bar

Max. intermittent pressure - 315 bar

Max. peak pressure - 325 bar

Rotational speed

Max. speed - 3000 min-1

Min. speed - 300 min-1

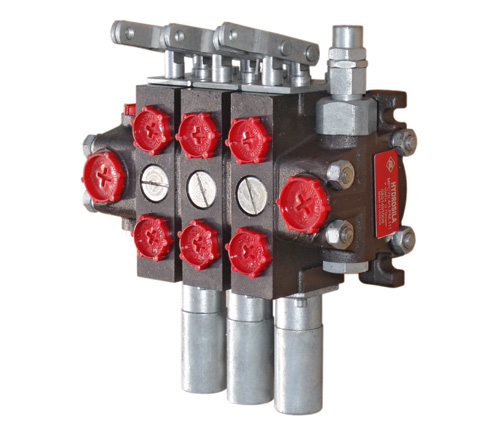

Control valves

- Control valves are the components of hydraulic system,

the main assignment of which is to control the flow in the hydraulic lines.

Spool valves. In the spool type valves the flow direction is fulfilled by means of axial shift of spool control element. Hydrosila manufactures two types of control valves: monoblock and modular control valves.

Monoblock control valves have classic effective design. All the spools are installed in one body and it gives the opportunity to refine the size and the weight of the control valve for the separate kind of machine.

Modular control valves have several cells, what gives the opportunity to use the valve for control of hydraulic system with different actuators. The main advantage of the modular control valve – when using the valve only the separate section may be changed if it’s out of order. Monoblock control valves

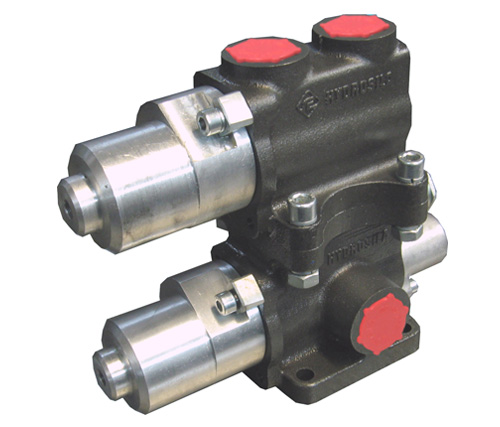

Tipping valve MR100.T1

- Proportional pneumatic tipping valve with open center MR100.T1 suitable for medium- and heavy-duty trucks.

Tipping valve MR100.T2

- Proportional pneumatic tipping valve with open center MR100.T2 suitable for medium- and heavy-duty trucks.

Tipping valve MR100.T4

- Proportional pneumatic tipping valve with open center MR100.T4 is intended for use on dump trucks with multiloop hydraulic systems that allows to operate trucks with a dump trailer.

Sectional control valves

MPC70.4

- The valves are used to change the fluid flow and protect hydraulic systems of tractors, agricultural, construction and other mobile machines against overloads.

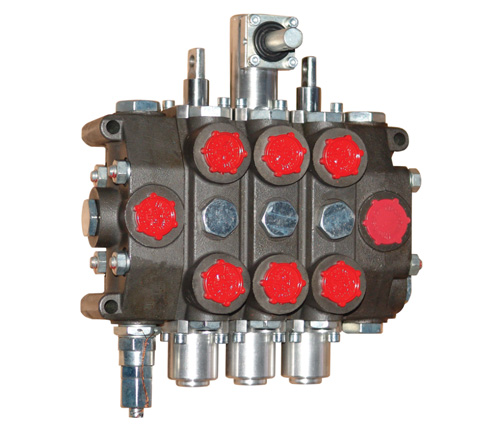

MRS120.B1

- Directional control valves MRS120 series are universal control valves of a wide application. MRS120 series control valves are intended for use on excavators, cranes, loaders, trucks, drilling machines and other equipment.

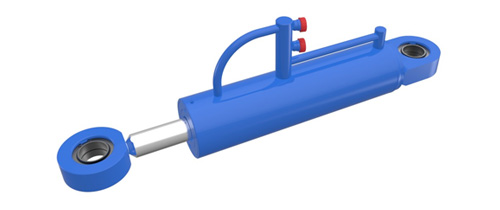

Hydraulic cylinders

Piston-type / Plunger-type

Piston-type - MC-series hydraulic cilinders

- Piston double-acting hydraulic cylinders. Used in agricultural, road construction, utility machines and other equipment.

Plunger-type - MCP-series hydraulic cilinders

- Plunger single-action hydraulic cilinders. Used in agricultural, road construction, utility machines and equipment.

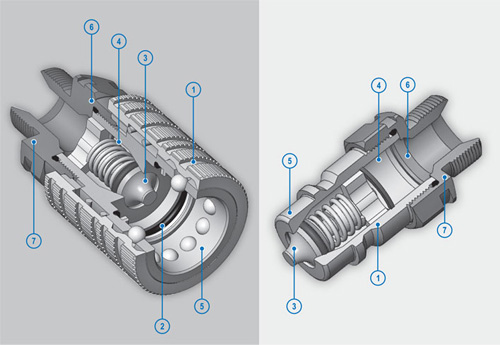

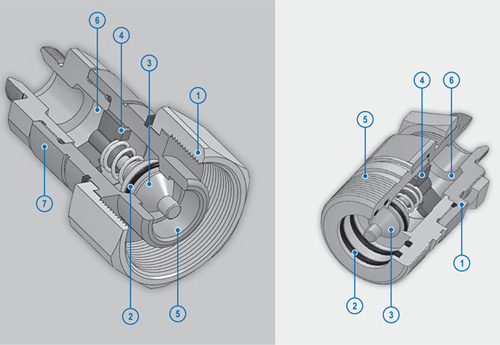

Quick release couplings

- Quick-release couplings are available in various sizes

(from 1/4 "to 1") with interchangeability of the contact part of the socket

and nipple according to ISO 7241-A, ISO 14541, ISO 16028 ("Flat Face").

Quick-release couplings can be manufactured with various types of fittings with metric and inch threads.

1. The couplings are made on high-precision equipment made of carbon steel with high-quality external and internal galvanic zinc coating, which ensures their hermetic connection and long service life with repeated connection-disconnection, as well as the necessary corrosion resistance.

2. The O-ring is made of high-strength rubber based on oil-and-petrol resistant rubber, which ensures optimum tightness of the coupling coupling and long service life of the quick-release coupling.

3. The shut-off valve in both coupling halves automatically shut off the flow of working fluid during disconnection and is made in a conical shape, which ensures full opening and closing of these valves.

4. The diameter of the inner working chamber allows the working fluid to work in the optimal temperature regime without overheating, without hindering the operation of the hydraulic connections.

5. The connecting dimensions of both coupling halves correspond to the ISO 7241-A standard, which makes it possible to use the "HYROSILA" coupling half-couplings with the coupling halves of the world manufacturers of the same size.

6. The valve base in both coupling halves is made of a high-strength alloy, which increases the life of the quick-release coupling.

7. Fittings are connected to the main part of the coupling half by threaded connection through a sealing rubber ring, which ensures tightness and a long service life.

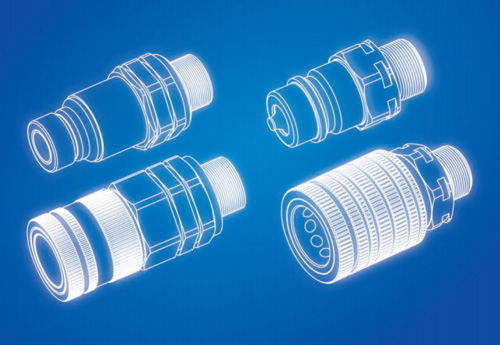

Quick release couplings "QR"

- Interchangeability according to ISO 7241-series A. Ball clamping of half couplings. Poppet valve. Two-way "connection-disconnection" (the so-called "breakaway function" or "Push-pull" connection). Connection by pushing the male coupling. Disconnection by pulling the male part. Connectable with male part (ISO A) under pressure. Most often found on agricultural and communal machinery. Designed for light operating conditions, as well as where there are no ultra-high pressures.

Quick release couplings "QS"

- Interchangeability according to ISO 7241-series A. Ball clamping of half couplings. Poppet valve. One-way "connection-disconnection". Most often found on agricultural and communal machinery. Designed for light operating conditions, as well as where there are no ultra-high pressures.

Quick release coupling "QT"

- Interchangeability according to ISO 14541. Threaded locking half couplings. Poppet valve. They are used for high, as well as pulse pressure. It is most often used on agricultural, construction and road machinery, and machinery working in quarries.

Quick release coupling "QF"

- Interchangeability according to ISO 16028. Ball clamping of half couplings. The valve is a flat face ("flat face"). The presence of a lock to prevent spontaneous detachment. Used in hydraulic systems, where it is necessary to eliminate the possibility of external oil leaks and there is a risk of contamination of the liquid. This type of connection allows you to successfully work with impulse loads such as a hammer.

High pressure hoses

High pressure hoses

- Under the TM Hydrosila there are manufactured several

kinds of pressure hoses of different series:

Series "STANDART".

For manufacturing of these series is used the high-quality 1-braided rubber and operation life - at least 250,000 cycles and 2-braided rubber and operation life - at least 350,000 cycles.

And high quality 4-winder rubber. Operation life - not less than 600,000 cycles.

The hoses are manufactured:- according to standards DIN, SAE;

- or hydraulic systems with rated pressure 105 bar to 420 bar;

- with nominal bore 6 to 32 mm;

- with straight and corner fitting (angles 0 to 900), standards DKM type (with spherical nipple) and DKO type (cone nipple and sealing), may be of light and hard series and other standards;

- with thread (metric and inch) and flange mounting;

- of length variety according to customers request.

Spare parts for axial-piston pumps and motors

- Under the trademark “Hydrosila” are produced spare

parts for axial-piston pumps and motors of next Series:

Series S – axial-piston units pumps and motors are produced since 1980 under the license of German company Sauer-Sundstrand.

Variable Displacement Axial-piston pump Series PVS

- Rated pressure, bar: 22,5

Maximum pressure, bar: 35,77

Rated flow, lpm: 47,4 - 126,8

Rated speed, c-1: 25±0,83

Fixed Displacement Axial-piston motor Series MFS

- Displacement ccm: 33,3 - 89

Rated pressure, bar: 22,5

Maximum pressure, bar: 35,77

Rated torque, N m : 92,6 - 311,8

Rated speed, c-1: 25±0,83

Fan Drive

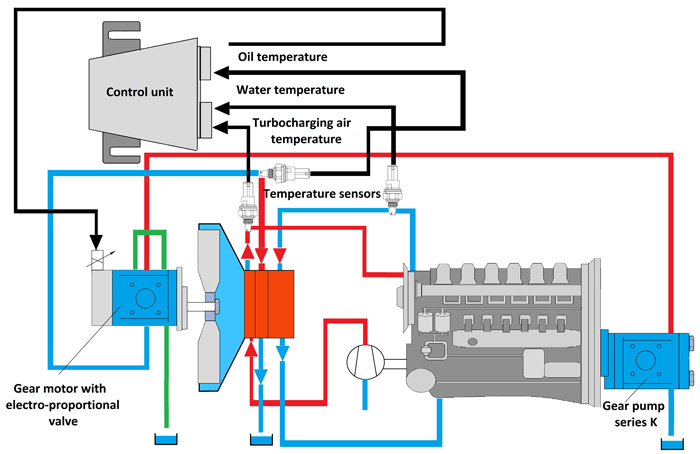

Scheme with gear pump

- Hydraulic drive systems for engine cooling fans.

Scheme with gear pump and motor and electro-proportional relief valve.

Advantages:

Free choice of location on the vehicle;

Smooth fan speed control;

Automatically increase fan speed by engine temperature rises;

Reducing fuel consumption.

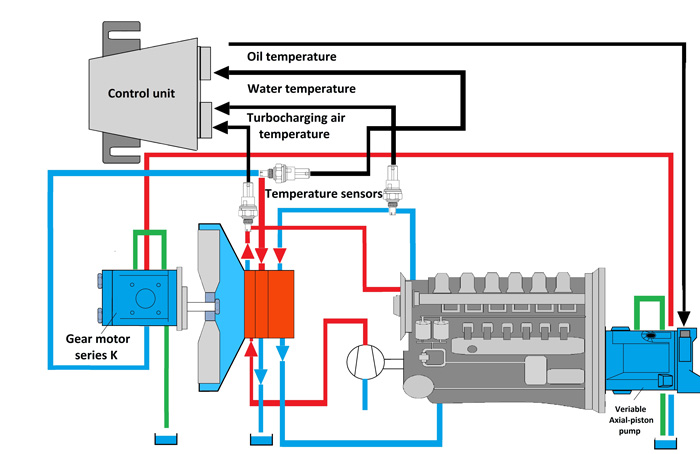

Scheme with variable axial-piston pump

- Hydraulic drive systems for engine cooling fans.

Scheme with variable axial-piston pump and gear motor.

Advantages:

Free choice of location on the vehicle;

Smooth fan speed control;

Automatically increase fan speed by engine temperature rises;

Reducing fuel consumption.