JESSBERGER

- Offer Profile

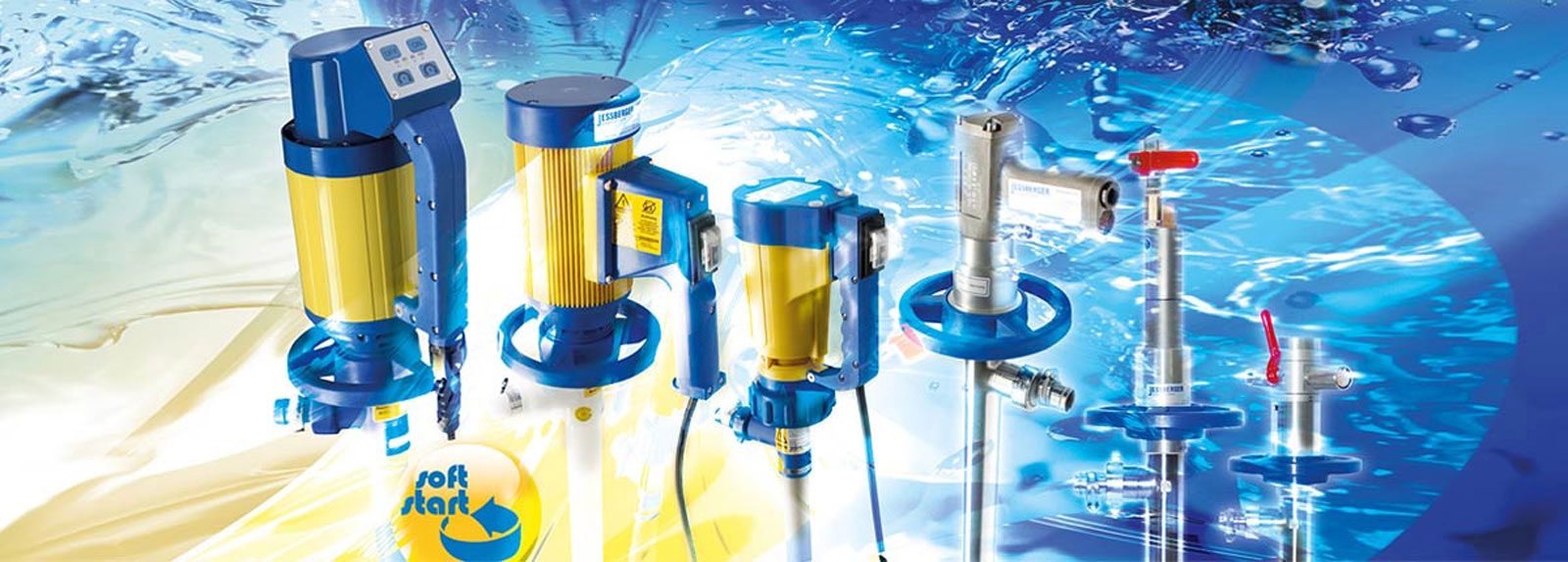

- Your reliable manufacturer of

drum pumps, container pumps, vertical and horizontal eccentric screw pumps

and hand pumps with an optimal price / performance ratio.

Air operated diaphragm pumps, vertical centrifugal pumps, horizontal centrifugal pumps as well as a wide range of accessories complete our product range.

For the production of drum pumps, hand pumps our company is based in Ottobrunn near Munich since March 2008. We deliver in more than 70 countries worldwide.

The highest quality components and decades of experience in drum pumps guarantee a high quality of our pumps at an attractive price. Convince yourself of the benefits of the family business company JESSBERGERER.

Product Portfolio

Manual hand pumps

-

FOR A SAFE AND CONVENIENT EMPTYING OF DRUMS AND CONTAINERS WE ALSO OFFER A COMPLETE SERIES OF MANUAL HAND PUMPS

Hand pumps are pumps that are manually operated by hand. Depending on the medium different materials of the pump and of the seals are available. In principle the hand pumps by JESSBERGER can be divided into three groups: for mineral oil products, for chemicals / cleaning solutions and flammable media like gasoline or solvents.

JP-02

-

For acids, alkalies and water-based chemicals.

Pump material: Polypropylene

Shaft: Stainless steel 304

Seals: FKM

Flow rate: 0,3, 0,37 or 0,45 l/stroke* depending on lever position

Pump tube length: 340–900 mm

Pump tube diameter: max. 40 mm

Thread adapter: G 2″ and G 1½”

JP-03

-

For oils, diesel, alcohol up to max. 50%, antifreeze liquid, water, etc.

Pump material: Polypropylene

Shaft: Tool steel

Seals: NBR

Flow rate: 0,3, 0,37 or 0,45 l/stroke* depending on lever position

Pump tube length: 340–900 mm

Pump tube diameter: max. 40 mm

Thread adapter: G 2″ and G 1½” mm

JP-04

-

For different media.

Pump material: Polypropylene

Shaft: Polypropylene

Seals: depending on the media

Flow rate: ca. 0,3 l/stroke*

Hose connection: ¾”

Pump tube length: 500–900 mm

Pump tube diameter: max. 34 mm

Thread adapter: G 2″

JP-04 YELLOW with FKM seals for aggressive media such as acids and alkalis

JP-04 BLUE with NBR seals for mineral oil products

JP-04 RED with EPDM seals for alkaline media

JP-04 BLUE/ WHITE with fluoropolymer seals for liquid foods

JP-05

-

Suitable for flammable liquids.

Pump material: Stainless steel 316Ti

Seal: PTFE

Flow rate: 0,3–0,6 l/stroke*

Pump tube length: 700 and 1000 mm

Pump tube diameter: 32 mm

Suitable for flammable liquids such as solvents (including acetone)

Certified: risk analysis made by TUEV Munich

Necessary accessories:- Discharge arc with PTFE seal and wing nut

- Hose connection made of stainless steel ¾ or 1″, with PTFE seal and wing nut made of brass, nickel plated

- Drum adapter made of brass nickel plated R2″ with fixing device

- Anti-static set consisting of 4 copper cables (absolutely

- necessary when pumping flammable liquids)

JP-06

-

Suitable for water, slightly aggressive acids and alkalies.

Pump material: Polyethylene and PVC

Flow rate: 0,08 l/pumping process and 20 l/min at an independent transferring*

Pump tube length: 850 mm

Pump tube diameter: 25 mm

Thread adapter: G 2″

Hand pump complete with 130 cm long discharge hose and drum adapter G 2″.

This hand pump is designed as a siphon pump. After the suction pipe and discharge hose arc had been filled manually the pump works independently.

JP-07

-

Available with different seals, pump body made of polypropylene, inner parts but also made of stainless steel.

Pump body: made of polypropylene, internal parts also made of stainless steel

Seal: acc. media

Flow rate: Water: 20 l/min*, Oil SAE 30: 9 l/min. at 20°C*

Pump tube length: Suction pump consisting of four parts, each 250

mm

Pump tube diameter: max. 31 mm

Rubber adapter: for bung hole diameters from 46,5 to 60 mm

Temperature: 40°C*

Viscosity: 400 mPas*

By pumping movement pressure can be generated in a barrel or canister. After this pressure has been build, the medium flows out independently after opening the filling tap, so that a certain quantity can be filled by the tap.

Three adapters for bunghole diameters of 46.5 to 60 mm are included.

JP-07 BLUE with NBR seals for the transfer of oily substances and petroleum-based products.

JP-07 RED with EPDM seals for the transfer of basic media. Attention: the internal parts of the hand pump are also made of stainless steel.

JP-07 GREEN with FKM seals for light acids and chemicals. Attention: the internal parts of the hand pump are also made of stainless steel.

JP-08

-

The pump is suitable for thin fluid, highly aggressive media such as acids and alkalies.

Pump material: PVDF

Seals: PTFE

Flow rate: 0,3 l/rotation*

Pump tube length: 3 x 35 cm

Pump complete with discharge arc and drum adapter G 2″.

Regular lubrication required.

JP-09

-

Suitable for almost all highly liquid and slightly aggressive media such as acids, alkalis and chemicals. Better resistance as JP-02 due PP-sheathed shaft.

Pump material: Polypropylene

Seals: FKM

Flow rate: 0,5 l/stroke*

Telescopic suction tube: 3 parts, polyethylene

Suction depth: for containers to 960 mm

PE hose: 2 m

Weight: 1.2 kg

Thread G 2″ for screwing in standard barrels.

Adapters available for plastics drums and cans of 60-220 l.

Outlet piece DN 19, 3/4″.

The pump is not to be used for pumping media of hazard classes AI / AII, other flammable media or in an explosive environment.

JP-11

-

The pump is suitable for thin fluid, non-flammable liquids such as diesel, gear oil, heating oil, hydraulic oil, machine oil, mineral oil, motor oil, etc. up to 1000 mPas.

The pump is not suitable for water.

Pump material: Aluminium and zinc plated steel

Seals: NBR

Flow rate: 1 l/rotation* Changing from forward to reverse transferring possible. Thus results an optimal dosing.

Pump tube length: 1,080 mm

Pump tube diameter: 53 mm (sieve)

Head: 15 m*

Horizontal distance: 50 m*

Pump complete with discharge hose and drum adapter G 2″.

JP-12

-

The pump is suitable for thin fluid, non-flammable liquids such as diesel, gear oil, heating oil, hydraulic oil, machine oil, mineral oil, motor oil, etc. up to 1000 mPas.

The pump is not suitable for water.

Pump material: Aluminium and zinc plated steel

Seals: NBR

Flow rate: 1 l/rotation*, changing from forward to reverse transferring possible. Thus results an optimal dosing.

Pump tube length: 1,080 mm

Pump tube diameter: 53 mm (sieve)

Head: 15 m*

Horizontal distance: 50 m*

Pump complete with special mineral oil hose 2000 mm, discharge arc and drum adapter G 2″.

JP-13

-

The pump is suitable for diesel, heating oil, oils (up to SAE 90) and all other self-lubricating, non-aggressive and non-flammable media.

Pump material: pump housing made of cast iron

Seals: NBR

Flow rate: 0,25 l/rotation*

Pump tube length: 1000 mm, three parts therefore suitable for smaller containers and 200 liter drums.

Pump tube diameter: max. 40 mm

Pump complete with discharge arc and drum adapter G 2″.

JP-15

-

For transferring many thin fluid, non-flammable media such as diesel, oils, anti freezing liquid, etc.

Material: Steel zinc plated

Seals: NBR

Flow rate: 0,35 l/stroke*

Pump tube length: 450–865 mm

Pump tube diameter: 40 mm

The telescopic suction tube enables an universal use for all barrel sizes.

G 1½” and G 2″ drum adapter pump with discharge arc. The outlet has a ¾” – thread. Therefore other connection options exist.

JP-15

-

For transferring many thin fluid, non-flammable media such as diesel, oils, anti freezing liquid, etc.

Material: Steel zinc plated

Seals: NBR

Flow rate: 0,35 l/stroke*

Pump tube length: 450–865 mm

Pump tube diameter: 40 mm

The telescopic suction tube enables an universal use for all barrel sizes.

G 1½” and G 2″ drum adapter pump with discharge arc. The outlet has a ¾” – thread. Therefore other connection options exist.

JP-16

-

ATEX compliant, single-acting hand pump that can be used for following media of hazard classes A I-III:

Diesel, heating oil, fuel, petroleum, anti freezing liquid for cooler (undilated), thin fluid mineral oils and rapeseed methyl ester.

Execution for fire brigade with flexible suction hose instead of a rigid tube.

Suction hose DN 19 x 4; 1,5 m

Discharge hose DN 19 x 4; 1,5 m

Flow rate: app. 0,25 l/stroke*

In pump housing integrated drum adapters with M 64×4 and G 2″ enable an easy fixing in drums.

JP-111

-

Suitable for water, diesel, lightly oils, neutral, lightly aggressive and non flammable media.

Only suitable for short-term operation.

Pump material: PP, PE and ABS

Flow rate: 8 l/min*

Pump tube length: 460 mm

Largest suction tube diameter: 33 mm

Discharge hose: 600 mm

Driven by batteries, size D, 1,5 V (not included in price)

Laboratory Pumps

-

ELECTRIC OR AIR OPERATED LABORATORY PUMPS WITH PUMP TUBES MADE OF POLYPROPYLENE (Ø 25, 28 OR 32 MM) OR STAINLESS STEEL 1.4571 (Ø 28 OR 32 MM).

Laboratory pumps are the economical and safe solution for filling and transferring small quantities of acids and alkalis.

With a weight of just 3 to 4 kg and easy use, the laboratory pumps can be applied to transfer smaller quantities of liquids.

ELECTRIC UNIVERSAL MOTOR JP-120 / JP-140

-

230 VOLT, 50 HZ, 250 WATT OR 450 WATT, IP 24,

ALTERNATIVELY 115 VOLT, 60 HZ

The drive is a compactly built, not explosion-proof, internally ventilated universal motor.

The lightweight, handy and powerful device can be used as drive for the pump tubes of the laboratory and drum pumps and is useful in this combination for many thin fluid, neutral, aggressive and non-flammable media. Its sophisticated, technically clear structure ensures an efficient and safe use when transferring a variety of water-like liquids.

The drum pump motor is characterized not only by its light weight (2 and 2,3 kg) but also by its elegant design and ease of use. The non-stationary and stationary usable drive is particularly suitable for intermittent operation. As internally ventilated motor it has an optimal air cooling, low noise level and ensures high operational safety and long time life.

The motor housing made of polypropylene ensures high chemical resistance when aggressive vapours of acids and alkalies are present.

The standard in the on/off switch integrated low voltage release is intended to prevent an uncontrolled start of the drum pump motor after a power failure or voltage drop and thus guarantees maximum safety. By the presence of a thermal protection the life of the engine is significantly increased.

The flow rate of the media that will be pumped can be adjusted by the optionally available speed control that is mounted laterally in the motor housing and therefore adapted to the needs of the user.

The maximum density of the media is for the JP-120 universal motor 1.2, the maximum viscosity 200 mPas.

The maximum density of the media is for the JP-140 universal motor 1.4, the maximum viscosity 400 mPas.

AIR OPERATED MOTOR JP-AIR 1

-

300 WATT AT MAX. 6 BAR OPERATING PRESSURE

The drive JP-AIR 1 is a compactly built, elegant designed air operated motor with an aluminium housing.

The lightweight, handy and powerful device can be used as drive for the laboratory and drum pump tubes and is suitable in this combination for many thin liquid, neutral and aggressive media. Flammable media are not allowed to be transferred with the laboratory pump tubes made of stainless steel cause of missing ATEX certification. The sophisticated, technically clear structure ensures an efficient and safe use when transferring various media.

The air operated drum pump motor is characterized beside its light weight (2 kg) by its ease of use. The non-stationary and stationary usable drive is particularly suitable for intermittent operation.

Via the included ball valve the compressed air can be dosed at the air inlet, and thereby the rotational speed of the motor. Therefore the flow rate of the pumped media can be adjusted to the users requirements.

The maximum operating pressure is 6 bar. The included silencer ensures a low noise level. The air consumption of the engine is under load 13 l/sec.

The maximum density of the media is for the air operated motor JP-AIR 1 1.3, the maximum viscosity 400 mPas.

PUMP TUBES FOR LABORATORY PUMPS

-

FOR CONVEYING SMALL QUANTITIES MADE OF POLYPROPYLENE AND STAINLESS STEEL

Suction tubes for conveying neutral and slightly aggressive (with stainless steel or polypropylene suction tubes and stainless steel drive shaft) or aggressive (polypropylene suction tubes and Hastelloy drive shaft) media from containers and cans with narrow opening.

Suction tubes made of polypropylene (PP) or stainless steel, with various pump tube diameters and lengths, complete with 1/2″ hose connection (in PP Ø 25 mm) or 3/4″ (in PP Ø 28 and 32 mm), 3/4″ or 1” for stainless steel. The suction tubes can be combined with electric and air operated motors outside the hazardous area.

PVDF PUMP TUBES FOR LABORATORY PUMPS

-

For conveying aggressive media such as highly concentrated acids and alkalies, Ø 32 mm

Polyvinylidene fluoride = PVDF pump tubes up to 90 °C

The laboratory pump is made of highly resistant fluoroplastic PVDF (polyvinylidene fluoride) and a drive shaft made of Hastelloy C-2.4610. The materials have excellent chemical and thermal resistance.

It was chosen a suction tube diameter of 32 mm, so that the emptying of all common small containers is possible and a good stability of the dip tube is given. Immersion depths of 500 and 700 mm (for canisters), 1000 mm (200 liters) and 1200 mm (IBC with 1000 liters) are available. Special lengths can be made within 1-3 days.

In particular, highly aggressive media such as sodium hypochlorite, chromic acid, hydrofluoric acid, sodium hypochlorite, nitric acid and other chemicals can be safely transferred with this pump.

Hose connection ¾” included.

LABORATORY PUMPS WITH ELECTRIC MOTOR JP-120

-

LABORATORY PUMP TUBE MADE OF STAINLESS STEEL OR POLYPROPYLENE WITH A STAINLESS STEEL DRIVE SHAFT AND A SUCTION TUBE DIAMETER OF Ø 25 OR 28 MM

- For transferring and pumping small quantities of neutral or slightly aggressive media out of containers with narrow necks.

- Universal motor JP-120, 230 V, 50 Hz, 250 W, IP 24, alternatively 115 V, 60 Hz, double insulated protection class II, on/off switch, thermal protection, 5 m cable with plug.

LABORATORY PUMPS WITH ELECTRIC MOTOR JP-140

-

Laboratory pump made of PVDF with Hastelloy drive shaft and suction tube diameter of Ø 32 mm

- The laboratory pump is made of highly resistant fluoroplastic PVDF (polyvinylidene fluoride) and a drive shaft made of Hastelloy C-2.4610. The materials have excellent chemical and thermal resistance.

- In contrast to many other models available on the market, the motor with low voltage release has an output of 450 watts and is therefore suitable for densities up to 1.3 and viscosities up to 400 mPas.

LABORATORY PUMPS WITH AIR OPERATED MOTOR JP-AIR 1

-

LABORATORY PUMP MADE OF POLYPROPYLENE OR STAINLESS STEEL WITH A PUMP TUBE DIAMETER OF Ø 25, 28 AND 32 MM

- For transferring and pumping small quantities of neutral and slightly aggressive (with stainless steel pump tube or polypropylene pump tube with stainless steel shaft) or aggressive (with polypropylene pump tube and hastelloy drive shaft) media out of containers with narrow necks.

- Air operated motor JP-AIR 1, 300 W at max. 6 bar, with ball valve and silencer, air consumption under load 13 l/sec.

LABORATORY PUMP SETS

-

From JESSBERGER are the perfect assistents for fast and safe filling and transferring or emptying of drums and containers

Laboratory pump, hose and pump nozzle were perfectly matched based on our decades of experience and guarantee therefore an immediate usability and durability of our laboratory pumps.

Each of our laboratory pump sets consists of an electric or air operated laboratory pump motor, a pump tube suitable for the application, two meter media-proof dispensing hose and a nozzle, which facilitates filling and transferring.

ACCESSORIES FOR LABORATORY PUMPS

-

Universal motor JP-120 230 V, 50 Hz, 250 W, protection class IP 24, double insulated category II, over load protection switch with low voltage release, thermo protection, 5 m cable and plug.

Pump tube:

Polypropylene, outer-Ø 28 mm, Hastelloy-shaft

Connection thread G 1″

Hose connection ¾” (DN 19)

2 m PVC-Hose ¾” (DN 19)

2 Hose clamps Stainless steel

1 Nozzle Polypropylene ¾”

ELECTRONIC FLOWMETER

-

ACCORDING TO THE MEASURING PRINCIPLE OF THE TURBINE WHEEL AND OVAL WHEEL COUNTER

PULSE OUTPUT OR QUANTITY PRESET FOR CONTROLLING A PUMP, A MAGNETIC VALVE OR A BALL VALVE AS AN OPTION

TURBINE WHEEL COUNTER

The recording of the measured values for these devices from flow technical point of view takes place on the principle of the turbine wheel meter:

The turbine wheel counter is a volume counter. The meter consists of the axial turbine wheel, the measuring electronics and the display with keyboard. The axial turbine wheel, which moves freely according to the flowing medium, indicates the average speed of the flow velocity. The speed is proportional to the flowing volume. The resulting measured values are passed on without contact.

Any medium reflows are reseted directly.

OVAL WHEEL COUNTER

At this device, the recording of the measured values, as seen in flow technology, based on the principle of the oval gear meter:

Oval wheel counters belong to the group of direct volume meters for liquids with movable partitions (displacement meters). An oval wheel counter consists of a measuring chamber casing with two rotatably mounted oval wheels, which interlock on toothing and rolling on one another in a counter-rotating movement.

The oval wheels transfer four partial volumes (separated between the oval wheel and the measuring chamber) for each revolution through the counter. For measurement, the rotary motion of the oval wheels will be forwarded to the pulse generator by magnets.

The counters are absolutely insensitive to vibration, pressure changes, pulsations and viscosity changes.

Drum pumps

-

THE PRINCIPLE OF THE DRUM PUMP HAS PROVEN ITS WORTH IN THE FIELD OF PUMPS FOR DECADES AND IS SUITABLE FOR MOST APPLICATIONS AS WELL AS INDUSTRIAL BRANCHES.

For transferring low-viscous media such as acids, alkalis and cleaning agents (with pump tube made of polypropylene), highly aggressive chemicals (with PVDF pump tubes).

Mineral oil products up to 1,000 mPas (with pumping tube made of aluminum) or flammable media as well as food (with pump tube made of stainless steel 1.4571).

ELECTRIC UNIVERSAL MOTORS JP-120 | JP-140

-

230 V, 50 Hz, 250 W or 450 W, IP 24, alternatively 115 V, 60 Hz

The drive is a compactly built, not explosion-proof, internally ventilated universal motor.

The lightweight, handy and powerful device can be used as drive for the pump tubes of the laboratory and drum pumps and is useful in this combination for many thin fluid, neutral, aggressive and non-flammable media. Its sophisticated, technically clear structure ensures an efficient and safe use when transferring a variety of water-like liquids.

The drum pump motor is characterized not only by its light weight (2 and 2,3 kg) but also by its elegant design and ease of use. The non-stationary and stationary usable drive is particularly suitable for intermittent operation. As internally ventilated motor it has an optimal air cooling, low noise level and ensures high operational safety and long time life.

The motor housing made of polypropylene ensures high chemical resistance when aggressive vapours of acids and alkalies are present.

The standard in the on/off switch integrated low voltage release is intended to prevent an uncontrolled start of the drum pump motor after a power failure or voltage drop and thus guarantees maximum safety. By the presence of a thermal protection the life of the engine is significantly increased.

The flow rate of the media that will be pumped can be adjusted by the optionally available speed control that is mounted laterally in the motor housing and therefore adapted to the needs of the user.

The maximum density of the media is for the JP-120 universal motor 1.2, the maximum viscosity 200 mPas.

The maximum density of the media is for the JP-140 universal motor 1.4, the maximum viscosity 400 mPas

ELECTRIC UNIVERSAL MOTORS JP-400

-

230 Volt, 50 Hz, 550 Watt, IP 54, alternatively 115 Volt, 60 Hz

The drive JP-400 is a compactly built, robust explosion-proof universal motor that is built and approved in accordance with the latest explosion protection guidelines ATEX 2014/34/EC. The collector motor is explosion-proof according to II 2G Ex de IIA T6 and has an EC-type examination certificate ZELM 09 ATEX 0425 X. The electric motor Ex-JP-400 offers in addition to the air operated motors maximum protection when pumping flammable media or for use in hazardous environments. At such applications separate authorizations for the drive motor and the pump tube acc. directives ATEX 2014/34/EU are required.

The handy and powerful device can be used as a drive for the ATEX certified sealless pump tubes made of stainless steel (Ø 41 mm), the mixing pump tubes in stainless steel, the pump tubes in stainless steel with mechanical seal or complete drum emptying function and the eccentric screw pump tubes series JP-700 SR PTFE ATEX. In this combination the drive is suitable for many thin liquid to viscous, neutral, slightly aggressive and easily flammable media with a flash point below 55°C. Its sophisticated, technically clear structure ensures an efficient and safe use when transferring a wide range of media.

The drum pump motor is characterized in addition to its robustness by its elegant design and ease of use. The non-stationary and stationary usable drive is particularly suitable for intermittent operation. As externally ventilated motor it has an optimal air cooling, low noise and ensures high operational safety and long lifetime.

The standard in the on/off switch integrated low voltage release is intended to prevent an uncontrolled start of the drum pump motor after a power failure or voltage drop. Thus guarantees maximum safety.

The maximum density of the media is for the JP-400 universal motor 1,5, the maximum viscosity 600 mPas.

EX-PROOF AIR OPERATED MOTORS JP-AIR1

-

300 Watt at max. 6 bar operating pressure

The air operated motor JP-AIR 1 made of aluminium is a compactly built, robust explosion-proof air operated motor in accordance with the latest explosion protection guidelines ATEX 2014/34/EC, category 2. The pneumatic motor is explosion-protected according to Ex 2 GD c IIC T6 (80°C) X and has a type-certificate IBEX U05 ATEX B007 X. The motor JP-AIR 1 provides beside other air operated motors and the electric motor JP-400 maximum safety when pumping flammable media or for use in hazardous environments. At such applications for the drive motor and the pump tube separate approvals acc. to directive ATEX 2014/34/EU are required and a potential equalization has to be installed.

The handy and powerful device (2.1 kg) can be used as a drive for the laboratory pump tubes (not Ex-certified) or in hazardous areas for the ATEX certified sealless pump tubes made of stainless steel (Ø 41 mm), the mixing pump tubes in stainless steel, the stainless steel pump tubes with mechanical seal or complete drum emptying function. In combination with ATEX certified pump tubes, the drive is suitable for many low-viscous, neutral, slightly aggressive media and especially for highly flammable media with a flash point below 55°C. Its sophisticated, technically clear structure ensures an efficient and safe use when transferring the wide range of media.

The drum pump motor is characterized in addition to its robustness by its elegant design and ease of use. The non-stationary and stationary usable drive is particularly suitable for intermittent operation. The construction of the motor guarantees an high operational safety and a long lifetime.

The very robust aluminium motor housing ensures a good chemical resistance when aggressive solvent vapours are present.

The speed of the motor can be controlled by means of a ball valve, which regulates the air supply and thus adjusts the flow rate according to the requirements of the user.

The air operated motor is supplied with a silencer and a ball valve at the air inlet for controlling the compressed air and thereby the motor speed.

The maximum density of the media is for the explosion-proof air operated motor JP-AIR 1 1.3, the maximum viscosity 400 mPas.

PUMP TUBES FOR ELECTRIC AND AIR OPERATED MOTORS

-

Pump tubes made of polypropylene (PP)

are suitable for neutral, aggressive and hardly combustible liquids. They are used specifically for pumping aggressive chemicals such as acids, alkalies or detergents.

Drive shaft: Stainless steel 316Ti or hastelloy 2,4610

Media temperature: max. 50°C

Media: Formic acid (50%), ammonia, boric acid, distilled water, liquid fertilizers, iron-II and III-chloride, acetic acid (80%), photo developers, fruit acids, potassium hydroxide, copper chloride, lactic acid, sodium hydroxide, phosphoric acid, hydrochloric acid, sulfuric acid (up to 90%), hydrogen peroxide, citric acid and many other me.

DRUM PUMP SETS FOR CHEMICALS

-

From JESSBERGER are the perfect assistents for fast and safe filling and transferring or emptying of drums and containers.

Drum pump-Sets PP are suitable for neutral, aggressive and hardly combustible liquids. They are used specifically for pumping aggressive chemicals such as acids, alkalies or detergents

Drum pump, hose and pump nozzle were perfectly matched based on our decades of experience and guarantee therefore an immediate usability and durability of our drum pumps.

Each of our drum pump sets consists of an electric or air operated drum pump motor, a pump tube suitable for the application, two meter media-proof dispensing hose and a nozzle, which facilitates filling and transferring.

Outside of hazardous areas you can combine each pump tube with each drum pump motor and corresponding accessories and therefore select the a individual drum pump set from JESSBERGER.

DRUM PUMP SETS FOR MINERAL OIL PRODUCTS

-

From JESSBERGER are the perfect assistents for fast and safe filling and transferring or emptying of drums and containers.

Drum pump sets ALU are suitable for neutral and hardly combustible liquids. With these pump tubes particularly mineral oil products up to a maximum viscosity of 1.000 mPas will be transferred.

Drum pump, hose and pump nozzle were perfectly matched based on our decades of experience and guarantee therefore an immediate usability and durability of our drum pumps.

Each of our drum pump sets consists of an electric or air operated drum pump motor, a pump tube suitable for the application, two meter media-proof dispensing hose and a nozzle, which facilitates filling and transferring.

Outside of hazardous areas you can combine each pump tube with each drum pump motor and corresponding accessories and therefore select the a individual drum pump set from JESSBERGER.

DRUM PUMP SETS FOR PVDF

-

From JESSBERGER are the perfect assistents for fast and safe filling and transferring or emptying of drums and containers

Drum pump set PVDF are especially suitable for highly aggressive liquids such as concentrated acids and bases.

Drum pump, hose and pump nozzle were perfectly matched based on our decades of experience and guarantee therefore an immediate usability and durability of our drum pumps.

Each of our drum pump sets consists of an electric or air operated drum pump motor, a pump tube suitable for the application, two meter media-proof dispensing hose and a nozzle, which facilitates filling and transferring.

Outside of hazardous areas you can combine each pump tube with each drum pump motor and corresponding accessories and therefore select the a individual drum pump set from JESSBERGER.

DRUM PUMP SETS FOR FLAMMABLE MEDIA

-

From JESSBERGER are the perfect assistents for fast and safe filling and transferring or emptying of drums and containers

Drum pump sets stainless steel 316 Ti are used for all neutral, slightly aggressive liquids such as diluted acids, alkalies or detergents and thin fluid food. In addition the pump tubes provide a special safety for conveying or transferring flammable liquids of different hazard classes (up to temperature class 4) in the ex zone 0 and when pumping low-viscous neutral or slightly aggressive media in ex zones 1 and 2.

Drum pump, hose and pump nozzle were perfectly matched based on our decades of experience and guarantee therefore an immediate usability and durability of our drum pumps.

Each of our drum pump sets consists of an electric or air operated drum pump motor, a pump tube suitable for the application, two meter media-proof dispensing hose and a nozzle, which facilitates filling and transferring.

Outside of hazardous areas you can combine each pump tube with each drum pump motor and corresponding accessories and therefore select the a individual drum pump set from JESSBERGER.

DRUM PUMP SETS STAINLESS STEEL FOR DILUTED CHEMICALS

-

From JESSBERGER are the perfect assistents for fast and safe filling and transferring or emptying of drums and containers.

Drum pump-Sets Stainless steel are suitable for neutral, slightly aggressive liquids such as diluted acids, alkalis or cleaning agents.

Drum pump, hose and pump nozzle were perfectly matched based on our decades of experience and guarantee therefore an immediate usability and durability of our drum pumps.

Each of our drum pump sets consists of an electric or air operated drum pump motor, a pump tube suitable for the application, two meter media-proof dispensing hose and a nozzle, which facilitates filling and transferring.

Outside of hazardous areas you can combine each pump tube with each drum pump motor and corresponding accessories and therefore select the a individual drum pump set from JESSBERGER.

DRUM PUMP SETS STAINLESS STEEL FOR FOOD

-

From JESSBERGER are the perfect assistents for fast and safe filling and transferring or emptying of drums and containers.

Drum pump-Sets Stainless steel suitable for thin-viscous foods like malic acid, pineapple juice, protein solutions, dextrose (grape sugar), juice, oils, cider, etc.

Drum pump, hose and pump nozzle were perfectly matched based on our decades of experience and guarantee therefore an immediate usability and durability of our drum pumps.

Each of our drum pump sets consists of an electric or air operated drum pump motor, a pump tube suitable for the application, two meter media-proof dispensing hose and a nozzle, which facilitates filling and transferring.

Outside of hazardous areas you can combine each pump tube with each drum pump motor and corresponding accessories and therefore select the a individual drum pump set from JESSBERGER.

SMALL FILLING PLANT

-

Filling made easy - for acidic and basic solutions

Numerous companies from the filling, chemical or packaging industry would like to fill thin-liquid to slightly viscous media at the push of a button from barrels or containers in manually fed canisters as quickly as possible.

The filling system was specially designed for the own drum pumps. However, it is also possible to use other pumps. In combination with a scale, this ensures a clean, accurate and safe filling even with foaming media.

Advantages- For easily filling of empty or partial filled containers.

- Also for foaming media.

- The filling control is done by a scale (0-30 kg, accuracy ± 20 g).

- The required quantities are set on the evaluation unit.

- With index system or with stop for the container.

- The fill tube can be put manually into the container. (No automatic mode).

- The filling process does not begin until the container and the pump tube are in position.

- Plant made of stainless steel.

- Electronic components IP67. Easy to use.

ACCESSORIES FOR DRUM PUMPS

- Extensive range of accessories for drum pumps and pump systems.

ELECTRONIC FLOWMETER

-

According to the measuring principle of the turbine wheel and oval wheel meter. Pulse output or volume presetting for controlling a pump, a solenoid valve or a ball valve as an option.

The turbine wheel counter is a volume meter. The speed is proportional to the flow rate. Oval wheel counters belong to the group of direct volume meters for liquids with movable partitions (displacement meters).

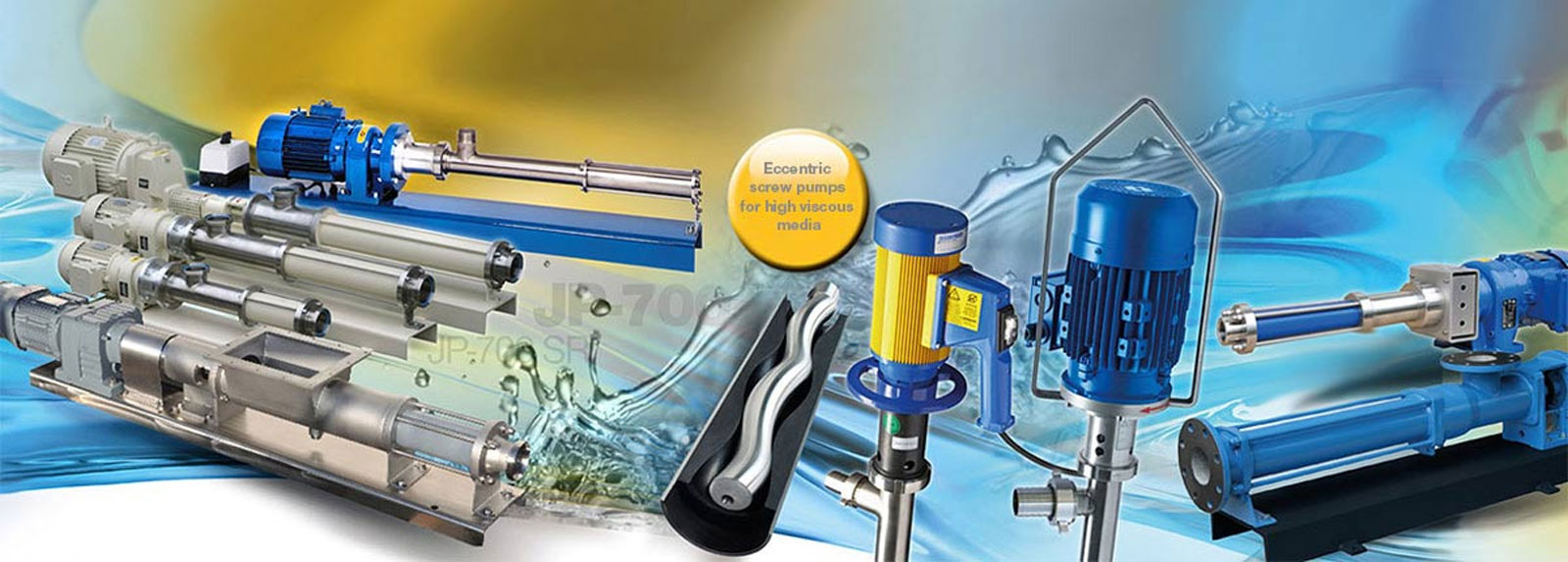

ECCENTRIC SCREW PUMPS

-

FOR PUMPING HIGH-VISCOUS, STILL FLOWABLE MEDIA, WE OFFER A COMPLETE RANGE OF ECCENTRIC SCREW PUMPS.

With electric motor or air operated motor, they are used to transfer thin liquids and viscous substances up to 100,000 mPas, preferably stationary, used in continuous operation.

The flow rates are standard at 12, 25 or 50 liters/min, thefunding pressures on 6 or 12 bar.

The pump tubes are made of stainless steel 316Ti, the stators of NBR, NBR light, FKM, EPDM, EPDM light or PTFE.

ECCENTRIC SCREW DRUM AND CONTAINER PUMPS JP-700 SR (speed reducer)

-

Drive with electric or air operated motor and planetary gear

- Particularly for intermittent operation.

- For gentle and almost pulsation free transferring of low viscous to highly viscous, thixotropic, gassy, solids and fibres containing, aggressive and neutral media.

- Pump tube will be driven by electric universal or air operated motors.

- All pump parts are made of stainless steel 316Ti.

- The stators are adapted to the medium and available in NBR, NBR light, FKM, EPDM, EPDM light, PTFE.

- Discharge pressure 6 bar at the single-stage and 12 bar with the two-stage pump tubes.

- The maximum viscosity of the medium is 10,000 mPas at the SR version.

- Medium temperature up to 160°C.

- Special lengths up to 2,000 mm on request.

- Easy disassembling and therefore optimal cleaning. Weight 12 kg.

- Special version for food, cosmetic and pharmaceutical products can be delivered: polished surfaces, either open or encapsulated pin joints, no dead spaces in the pump, easy disassembling and therefore easy cleaning, milk thread connection DN 11851, CIP connections as an option, stator and sealing materials in food grade FDA, also PTFE stators available.

PUMP TUBES FOR ECCENTRIC SCREW PUMPS JP-700 SR (SPEED REDUCER)

-

- For direct connection to electric universal motors JP-280 respectively JP-480 and to air driven motors JP-AIR 2 and JP-AIR 3.

- Suction tube Ø 54 mm, at discharge male thread connection G 1½”.

- Optional hose connection 1″, 1¼” or 1½”.

- Planetary gear (SR speed reducer) reduces speed from 8.000–12.000 rpm to 550–800 rpm.

- Suitable for 200 liter drum with 2″- bung-hole.

- All parts of the pump that will get in contact with pumped medium are made of stainless steel or identical to the material of the stator. Shaft seal by stuffing box packing or single acting mechanical seal Chrome/Carbon/FKM. At discharge side male thread R 1½” made of stainless steel

ECCENTRIC SCREW DRUM AND CONTAINER PUMPS JP-700 DR

-

With electric or air operated motor and planetary gear

- The pumps of the series JP-700 DR are versatile, robust and powerful pumps.They are used for pumping thin fluid to highly viscous substances up to 100,000 mPas, preferably used stationary and in continuous operation.

- JP-700 DR-Version drive through three-phase, single-phase, gear or air operated motors.

- Wide range of accessories such as pump mounting bracket, double-sided handle, bypass or dry running protection available as an option.

- The weight of the pump depends on suction tube length and the drive 25-35 kg.

- The pump is also available as a food version (see JP-700 SR version) or as a dosing pump (lower flow rate, smaller suction tube diameter).

Motors- Drive with three-phase or air operated motor is directly coupled with flexible coupling, beared shaft ball.

- Drive with three-phase or air operated motor directly coupled with extended motor shaft.

PUMP TUBES FOR ECCENTRIC SCREW PUMPS JP-700 DR, -FK

-

Pump tubes JP-700 DR with rigid and flexible coupling

All parts of the pump that will get in contact with pumped medium are made of stainless steel or identical to material of stator.

Shaft seal by stuffing box packing or single acting mechanical seal stainless steel/carbon/FKM. At discharge side male thread R 1½” made of stainless steel.

Suction tube Ø 54 mm, at discharge male thread connection G 1½”.

Optional hose connection 1″, 1¼” or 1½”.

The stators are adapted to the medium and available in NBR, NBR light, FKM, EPDM, EPDM light, PTFE.

ECCENTRIC SCREW CONTAINER PUMP JP-700.80-300

-

JP-700.80.1, 80.2, 200.1, 200.2, 300.1 and 300.2

Drive with three-phase or air operated motor directly coupled with extended motor shaft.

Gentle and nearly pulsation free pumping of low to high viscous, thixotropic, gaseous, solids and fibers containing, aggressive and neutral media.

Suction tube, pump parts and rotor made of stainless steel 316Ti.

Pump and motor directly coupled.

Encapsulated pin joints or joint-free.

Easy disassembly.

Various discharge connections.

Materials of the shaft seal: mechanical seal SS / Carbon / FKM or SiC / SiC / FKM. O-rings made of FKM or FEP. Alternatively stuffing box made of PTFE.

Driven by three-phase, gear- or air operated motors.

Wide range of accessories such as pump mounting bracket, double-sided handle, bypass or dry running protection available as an option.

Special features of the food version: Polished surfaces, easy disassembly and thus easy to clean at the discharge milk thread DIN 11851, stator and seals in food grade version according to FDA, PTFE stators also available.

PUMP TUBES FOR ECCENTRIC SCREW CONTAINER PUMPS JP-700.80-300

-

Pump tubes JP-700.80-300 with direct coupling

Flow rates 80, 200 or 300 l/min.

Discharge pressure 6 and 12 bar.

Pump tube lengths 1,000, 1,200 and 1,400 mm (special lengths available).

Suction tube diameter 89 mm (JP-700.80), 105 mm (JP-700.200) and 130 mm (JP-700.300).

Hose connection DN 40, DN 50–65, DN 65–80.

JP-700 H / -HL

-

Drive with three-phase or air operated motor, directly coupled, pump shaft ball-bearing

These eccentric screw pumps enable a gentle, almost pulsation free transport of thin to high viscous, thixotropic, gaseous, solids and fibres containing, aggressive and neutral media.

Stainless steel execution SS 316Ti

Pump and drive directly coupled

Pressure stages 6 and 12 bar

Flow rates up to 3.000 l/h

Connections male thread G 1½” on suction and female thread G 1¼” on discharge side

Totally enclosed pin joints, Rotor SS 316Ti

Stator material adapted to the pumped medium (NBR, NBR food grade, FKM, EPDM, EPDM light and PTFE are available)

Shaft seal by single-acting mechanical seal or stuffing box

Base plate as an option (in steel or stainless steel)

Driven by three-phase motor, gear motor or variable gear motor, IP 55

DOSING PUMPS JP-7032-7120.2

-

for thin fluid to high viscous media

Type JP-7032 up to JP-7120.2. Almost pulsation free transport and small quantity dosing of thin to high viscous, thixotropic, gaseous, solids and fibres containing, aggressive and neutral media in nearly all industries.- High dosing precision

- Flow rate adjustable by the speed of the motor

- Stainless steel execution SS 316Ti

- Pump and motor directly coupled

- Space-saving design

- Flow rates from 0,6 up to 1200 l/h

- Pressure stages 6, 12, 18 and 24 bar

- Thread connections on suction side G 1” and G ½” on discharge side G 1”

- Totally enclosed pin joints

- Rotor SS 316Ti

- Stator material adapted to the pumped medium (NBR, NBR light, FKM and EPDM, EPDM light; PTFE is only available at types JP-7115.1 and JP-7115.2)

- Shaft seal by single-acting mechanical seal or stuffing box

- The JESSBERGER high viscosity dosing pumps are supplied as standard with either a for operation with frequency inverter drive suitable gear motor or with an adjustable manually control gear motor. The pumps currently do not yet have ATEX approval and should therefore not be used for pumping flammable media.

ECCENTRIC SCREW PUMPS - BLOCK PUMPS

-

Industrial pumps in horizontal mounting form

In addition to the shown standard pumps we can quote further sizes:- Flow rate: up to 200 m³/h:

- Pressure stages: 6, 12, 18 and 24 bar

Block pumps in horizontal mounting form

A low priced alternative are pumps in block construction.

These pumps are directly flanged to the drive. Due to saving of bearing pedestal, elastic coupling and if necessary also base plate briefer mounting forms and cheaper versions can be realised.- Flow rate: up to 200 m³/h:

- Pressure stages: 6 and 12 bar

ECCENTRIC SCREW PUMPS JP-700 PB / JP-700 PS

-

For pumping thin to high viscous, thixotropic, solid and fibrous, aggressive and neutral media in almost all branches of industry, agriculture and biogas industries.

- Motor with three-phase or air operated motor and planetary gear.

- Pulsation free transport, gentle product treatment

- Drive directly coupled or with bearing housing and flexible coupling.

- Flanges DIN 2501 or ANSI

- Self-priming

- Reversible pumping direction.

- Pump housing in cast iron or stainless steel.

- Rotating parts in stainless steel.

- Sealed universal joints.

- Shaft seal stuffing box or mechanical seal.

- Stators in NBR, EPDM, FPM, PTFE.

- Base plate in steel or stainless steel.

- Horizontal or vertical mounting.

- Gear motor, suitable for operation with frequency converter or variable speed gear motor.

DRY-RUNNING PROTECTION FOR ECCENTRIC SCREW PUMPS

- Prevents reliable damage of the pump

The dry running of an eccentric screw pump can be costly. Repairs and plant downtimes are the result. The Jessberger dry run protection prevents this timely and reliable during operation or startup of the pump. The pump only starts when the medium is actually transferred.

Up to 6 digital sensors can be connected for monitoring.

Analog evaluation on request.

Control components made in Germany.

Ready for connection; there is no connection in the control box necessary.

ACCESSORIES FOR ECCENTRIC SCREW PUMPS

-

In addition to an extensive range of eccentric screw pumps, we also offer our customers a range of accessories from our own production.

When removing media from an open 200 liter drum or 1000 liter IBC container with eccentric screw pumps, the use of a traverse offers a locking option for safe operation with optimal emptying.

The stainless steel travers can be easily assembled with adjustable handles.

MULTI COMPONENT SYSTEM

-

DESCRIPTION

In the case that thin to viscous media should be volumetrically filled into small containers, in addition to a gentle and low-pulsation delivery an accurate dosing is imperative.

This follows not only from the facts, but also the EU-condition with regard to the filling of packaging in order to avoid penalizing consumers. In the final packaging directive is normalized, the extent to which the mass or volume of the contents of a box may differ from the print on the package. The standardized requirements were met there are implemented by our designers with the following filling plants.

MULTI-COMPONENT FILLING AND DOSING SYSTEM

For dispensing of low-viscosity to medium viscosity media according to specified recipes a Multi-Component Filling and Dosing System was supplied that is based on the principle of own eccentric screw pumps and the different media can reliably and accurately be filled and dispensed.

TASK AND STARTING POINT

According to the customer‘s application, three different components should be dosed according to pre-selected recipes from storage containers in manually supplied container. Starting point in developing a solution proposal were initially the own eccentric screw pumps. They have a rotating screw conveyor made of stainless steel 316Ti (rotor) and a counter-rotating, stationary elastomeric stator of the available materials NBR, NBR light, FKM, EPDM or EPDM light. Due to the different slope and transfer coefficient of the two conveying elements create cavities that mutually open and close due to the rotation of the rotor and whose volume is always the same. The gentle and pulsation-free delivery with extremely low shear eccentric screw pumps are therefore ideally suited for dosing.

The dripping of medium is prevented by entering a withdrawal value. By reversing the direction of rotation in the filling nozzle is at the end of dosing a minimal amount of product in the dispensing nozzle sucked back, therefore a filling valve will not be needed.

The input of the recipes with the dosing of the individual components is done via an input display, which is housed in a central control cabinet. The central control cabinet, is due to the customer‘s specifications, in a separate room. In order to ensure process safety, the changing of parameters and recipes is only possible by password and therefore protected from changes.

Another control cabinet, made of stainless steel, with digital display of the currently selected recipe is located at the bottling plant. To start the filling process is first necessary to calibrate sample expenditure for each of the components. This is done by entering the nominal quantities and the calculated actual quantities of the sample output.

The shown Multi-Component Filling and Dosing System was designed very user-friendly due to the easy disassembly and cleaning. In addition to a precise dosage it ensures low pulsation, gentle product handling without dripping. Beyond a large flow rates and application area, also a password-protected prescription and conveying volume prefix was implemented. Due to its modular design it can be used for many other applications in the field of dosing technology.

MOBILE SINGLE-COLUMN BARREL EMPTYING PLANT

-

ELECTRIC OR PNEUMATIC POWERED LIFTING DEVICES ARE USED IN MANY INDUSTRIES FOR LIFTING AND POSITIONING HEAVY SUPPLIES. IN CONNECTION WITH AN ECCENTRIC SCREW PUMP, ALSO BARRELS WITH HIGHLY VISCOUS MEDIA CAN BE EMPTIED QUICKLY, SAFELY AND SEMI-AUTOMATED.

Numerous customers from the bottling, manufacturing or packaging industry need to empty highly viscous liquids from a variety of 200 liter barrels quick, clean and as simple as possible. In many of these applications, it is no longer enough for a pump manufacturer to offer only a single pump.

The barrel pump manufacturer JESSBERGER has, therefore, developed in the field of eccentric screw pumps, as the company logo and the text „pumps and systems“ shows from a pure pump manufacturer to a system supplier who can offer complete solutions in the field of automation, dosing and control technology in addition to pumps. In recent months, numerous special designs have been supplied to renowned German companies. An example of a semi-automated barrel emptying highly viscous media is the mobile single-column barrel emptying plant.

STATIONARY SINGLE-COLUMN BARREL EMPTYING PLANT

-

STARTING POINT FOR THE STATIONARY SINGLE-COLUMN BARREL EMPTYING PLANT WITH FOLLOWER PLATE WERE THE OWN ECCENTRIC SCREW PUMPS

This additional special construction by JESSBERGER was delivered to a customer, who wanted to fill a high-viscosity preservative agent from 200 liter barrels by means of a type grease gun with follower plate and a scale in small containers.

The solution proposed by our designers in the field of eccentric screw pumps presented is a stationary single-column barrel emptying plant with follower plate. This plant was designed for the almost complete emptying of medium to high viscosity and viscous media of cylindrical smooth wall or corrugated barrels with 200 liter capacity.

OPERATING PRINCIPLE

A eccentric screw pump with follower plate and elastic sealing lip is mounted vertically with a boom to a lifting device.

By means of a double-acting pneumatic cylinder the pump is lifted into the upper end position. The barrel to be emptied, is pushed to the bottom plate and centered under the pump and locked.

The pump is then lowered so with the help of the pneumatic cylinder into the barrel until the follower plate touches the surface of the medium.

The air between the barrel edge and medium escapes through a hand-operated vent valve in the follower plate. Once a small amount of medium escaping through the vent valve, the vent valve is closed, the pneumatic cylinder is depressurized and the pump switched on.

The eccentric screw pump with follower plate, submerge by the low pressure produced by the pump, slowly into the barrel. Before reaching the bottom of the barrel the pump is turned off by a magnetic limit switch on the pneumatic cylinder. Thus, a prolonged dry running of the pump is prevented. The remaining residue in the barrel amount is about 1% of the barrel volume.

The pneumatically operated vent valve (pinch), mounted on the follower plate, will supply compressed air from about 0.5 bar between barrel base and follower plate. The resulting lifting force transports the eccentric screw pump as far out from the barrel until the follower plate has reached the barrel edge. Then the vent valve is shut off.

By means of lift cylinder the pump with follower plate is lifted into the upper end position.

BOTTLING PLANT WITH HOPPER

-

MANUAL FEED OF THE BOTTLES, CUPS OR CANS. ANOTHER PLANT WITH A FUNNEL-SHAPED STORAGE CONTAINER FOR FILLING IN BOTTLES, CUPS OR CANS ALSO BASES UPON THE PRINCIPLE OF ECCENTRIC SCREW PUMPS.

DEFINITION OF TASK

At the customer‘s application thin to viscous media should be bottled by pressing a button and on a gram exactly in manually supplied container, so that in view of the EU pre-packaging directive repeatable dosing had to be absolutely sure.

OPERATION PRINCIPLE AND CONSTRUCTION

The heart of the system is a vertical eccentric with a funnel-shaped storage container. With each revolution of the rotor, a defined volume is delivered so that the filling quantity is determined by the number of revolutions.

DOSING CONTROL

The dosing control Jessfüll-01 consists essentially of a memory programmable controller (PLC), an LCD display for parameter input and the power unit for driving the pump. The dosing control can be used for the control of different pump sizes, whereby a further portion of the filling quantity is also possible.

To start the filling process initially a trial issue is to calibrate. This is done by entering the nominal capacity and the determined actual amount of the sample output. Then the continuous filling can begin. Occasional checks to deviations of capacity from the nominal value are required. Any discrepancies can be corrected manually at the control box.

The bottling plant was completely made of stainless steel 316Ti and is thus suitable for many industries and applications.

In addition to chemical resistance with respect to the conveying medium, care was taken in the design of the plant with regards to the compatibility with respect to any cleaning agents as well as the expected temperatures in the cleaning process

The bottling plant can be used both in stand-alone mode as well as be involved operated in a master control unit and allows in this particular case of the customer a valveless, subsequent dripping free filling of different media in bottles, cups or cans. In addition to the user-friendly design (easy disassembly, fast product change) particular attention was paid to a high dosing accuracy, a gentle product handling and a pulsation free bottling. In addition to an FDA compliant version, also CIP cleaning can be offered as an option.

Due to the requirements set out in the EU pre-packaging directive aspects can be considered from a legal perspective, that the bottle plant based on the principle of eccentric screw pumps by JESSBERGER with probability bordering on certainty takes these requirements into account and the filled volumes consequently always be within the permissible tolerance range.

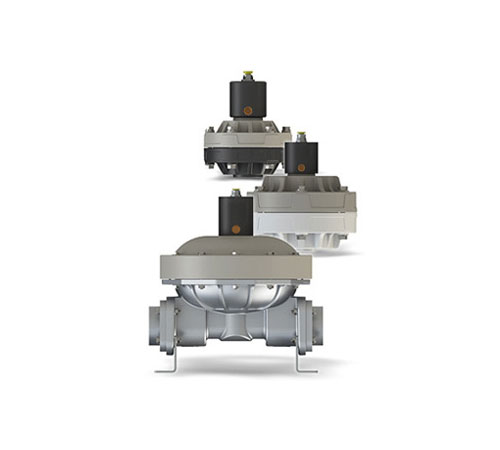

AIR OPERATED DIAPHRAGM PUMPS SERIES JP-810

-

AIR OPERATED DIAPHRAGM PUMPS HAVE LONG BEEN RECOGNIZED AS THE MOST FLEXIBLE PUMPS OF THE INDUSTRY FOR HANDLING DIFFICULT LIQUIDS AT RELATIVELY LOW PRESSURES AND FLOWS.

Due to the large range of possible installations, diaphragm pumps can be used in numerous applications.

Almost every type of liquid from highly corrosive acids through high viscosity paints and adhesives, to food and drink products can be pumped.

JP-810.8

-

Technical data:

Fluid connection

1/4″ BSP

Air connection

4 mm

Flow rate

8 l/min

Air pressure

8 bar

Delivery head

80 m

Suction lift dry

3 m

Suction lift wet

9,8 m

Solids

2,5 mm

Noise level

62 dB

Viscosity

6.000 mPas

All values are maximum values

DIAPHRAGM PUMPS FOR THE FOOD SECTOR JP-810

-

Technical data:

Fluid connections

Tri-Clamp ¾”

Air connections

6 mm

Flow rate

20 l/min

Air pressure

7 bar

Viscosity

10.000 mPas

Dimensions W x H x D

148 x 153 x 92 mm

Material:

Stainless steel electro-polished

All values are maximum values

ACCURATE JP-810 AC

-

This diaphragm pump was developed for external control, as required for demanding applications in dosing. With a direct electrical interface that uses electrical impulses to control the pump, the JP-810 AC ACCURATE offers a variable stroke rate that can be easily controlled if required.

Applications- Chemical industry

- Flexographic printing industry

- Paints & varnishes

- Sewage engineering Printing inks.

DRUM JP-810 D

- The products are produced for emptying drums and containers and offer an economical and robust alternative to other pump systems. Due to the different materials of the pumps, a wide variety of media can be transferred. The pump can be mounted on the drum quickly and easily. The drum can completely emptied with a suction tube.

Applications- Chemical industry

- Disposal technology

- Automotive industry

- Food industry

TWIN JP-810 T

-

The products are mainly used in the textile and paper processing industries. These TWIN pumps are able to convey two media independently of each other and at the same time. This is achieved by using separate connections on the suction and discharge ports. This prevents undesired mixing.

Application- Paints & varnishes

- Sewage engineering

- Printing inks

- Flexographic printing industry

PULSATION DAMPENER FOR DIAPRAGHM PUMPS JP-810

-

The active pulsation dampener is the most efficient way to remove pressure variations on the discharge of the pump.

JESSBERGER pulsation dampener works actively with compressed air and a diaphragm, automatically setting the correct pressure to minimize the pulsations.

Pulsation dampeners require minimum maintenance and are, subject to the requirements of the application, available in the same housing and diaphragm materials as the pump.

Applications- Metering/Injection/Dosing

- Equalizes discharge pressure spikes, increasing accuracy

- Filter press/Inline filters

- Increases filter efficiency and life by providing a smooth flow

- Spraying

- Smooth, consistent spray pattern

- Filling

- Eliminates inconsistent filling and splashing.

- Eliminates harmful water hammer, preventing pipe and valve damage

COMPRESSED AIR CONTROL UNIT FOR DIAPHRAGM PUMPS

-

A compressed air control unit regulates and filters the compressed air and catches dust, dirt or rust.

- Compressed air control unit in a complete set. Ideally suited for use with air operated diaphragm pumps.

- This significantly improves the performance and service life of the air operated motors.

ACCESSORIES FOR DIAPHRAGM PUMPS

- Extensive range of accessories for air-operated diaphragm pumps JP-810.

AIR OPERATED DIAPHRAGM PUMPS SERIES JP-800

-

DIAPHRAGM PUMPS ARE CHARACTERIZED BY HIGH OPERATIONAL SAFETY, AS WELL AS THEIR DIVERSITY. THE COMPRESSED AIR DIAPHRAGM PUMPS CAN BE USED FOR ALMOST ALL LOW-VISCOUS TO HIGH-VISCOUS MEDIA.

A wide range of different pump materials ensures optimum chemical resistance to the media be pumped, and the optimum thermal resistance with a view to the liquid or ambient temperature.

Because of their design principle, the air operated diaphragm pumps are qualified for a variety of difficult applications, especially in damp or hazardous locations.

JP-800.5

-

AIR OPERATED DIAPHRAGM PUMP JP-800.5, 1/4″ 5 l/min

STANDARD:

II 3/3 GD C IIB T135 °C (EX ZONE 2)

CONDUCT:

II 2/2 GD C IIB T135 °C (EX ZONE 1)

Technical data:

Delivery/suction connection

G 1/4″

Air connection

G 1/8″

Max. dry suction lift*

3 m

Max. flow rate*

5 l/min

Max. head*

70 m

Solids

–

Max. air supply pressure

7 bar

Construction material

PP

Net weight

0,5 kg

*Depending on construction materials

All threads are female threads

All values shown are approximate and not binding

AIR OPERATED DIAPHRAGM PUMPS FOR FOOD JP-800

-

In addition to th e standard diaphragm pumps of the JP-800 series, JESSBERGER also offers special versions for the food sector.

Due to the material used (stainless steel, electropolished), the Food series can be used to cover many tasks in the pharmaceutical and food industry.

Standard:

II 3G Ex h IIB T4 Gc (Ex Zone 2)

II 3D Ex h IIIB T135°C Dc (Ex Zone 2)

Conductive:

II 2G Ex h lib T4 Gb (Ex Zone 1)

II 2D Ex h IIIB T135°C Db (Ex Zone 1)

Technical data

Delivery/suction connection

G 1/2″*

Air connection

G 1/4″

Max. dry suction lift

6 m

Max. flow rate

30 l/min

Max. head

70 m

Max. air supply pressure 7 bar

Solids

Ø 2 mm

Dimensions

177 x 170 x 120 mm

Construction material

Stainless steel/electro-polished

PULSATION DAMPENERS FOR JP-800

-

A diaphragm pump can not produce a continuous flow rate, as opposed to a centrifugal pump. If, however, a very exact delivery speed and quantity is required, a pulsation dampener is used.

The following models can be used for various types of air operated diaphragm pumps from our JP-800 series.

Advantages- High-viscosity media have a continuous flow rate.

- The pumps are relieved by the dampener.

- A dosing system is much quieter.

- Pressure surges in the systems are damped or avoided.

COMPRESSED AIR CONTROL UNIT FOR DIAPHRAGM PUMPS

-

A compressed air control unit regulates and filters the compressed air and catches dust, dirt or rust.

- Compressed air control unit in a complete set. Ideally suited for use with air operated diaphragm pumps.

- This significantly improves the performance and service life of the air operated motors.

HORIZONTAL CENTRIFUGAL PUMPS

-

These horizontal centrifugal pumps are operated by a direct-drive motor (max. 3.000 rpm). They are especially suitable for a fast transfer of chemicals when emptying containers or tanks as well as for applications when a

medium has to be pumped in circulation.

The JP-840 series offers several pump sizes with flow rates from 6 to 75 m³/h and head from 7,2 to 38 m. Their special construction with an open-impeller allows even the pumping of extremely dirty liquids or media containing small solids.

The maximum viscosity for these centrifugal pumps is 500 mPas (at 20°C) and the maximum temperature of the medium 65°C at PP or 95°C at PVDF. Depending on the application there are two versions available with different internal seals (lip seal or bellow-type seal).

The availability of different materials of construction – depending on chemical and thermal resistance of medium or environment – guarantees an absolute reliability of operation and a long life time of pump.

JP-840.80

-

Technical data:

Max. flow rate

6 m³/h

Max. head

7,2 m

Max. viscosity

500 mPas

Solids

Ø 5 mm

Suction side

G 1½” or DN 40 Flange

Discharge side

G 1″ or DN 25 Flange

Motor power

0,37 kW

Seal

Lip seal or bellow-type seal

Dimensions

328 x 140 x 175 mm

Weight

PP 8,5 kg, PVDF 9,5 kg

Material

PP / PVDF

JP-840.100

-

Technical data:

Max. flow rate

9 m³/h

Max. head

10,5 m

Max. viscosity

500 mPas

Solids

Ø 7 mm

Suction side

G 1½” or DN 40 Flange

Discharge side

G 1″ or DN 25 Flange

Motor power

0,55 kW

Seal

Lip seal or bellow-type seal

Dimensions

328 x 140 x 175 mm

Weight

PP 8,5 kg, PVDF 9,5 kg

Material

PP / PVDF

JP-840.110

-

Technical data:

Max. flow rate

20 m³/h

Max. head

15 m

Max. viscosity

500 mPas

Solids

Ø 2 mm

Suction side

G 2″ or DN 50 Flange

Discharge side

G 1½” or DN 40 Flange

Motor power

1,1 kW

Seal

Lip seal or bellow-type seal

Dimensions

406 x 203 x 191 mm

Weight

PP 16 kg, PDVF 17 kg

Material

PP / PVDF

JP-840.120

-

Technical data:

Max. flow rate

25 m³/h

Max. head

16 m

Max. viscosity

500 mPas

Solids

Ø 6 mm

Suction side

G 2″ or DN 50 Flange

Discharge side

G 1½” or DN 40 Flange

Motor power

1,5 kW

Seal

Lip seal or bellow-type seal

Dimensions

426 x 203 x 210 mm

Weight

PP 20 kg, PDVF 21 kg

Material

PP / PVDF

JP-840.130

-

Technical data:

Max. flow rate

30 m³/h

Max. head

20 m

Max. viscosity

500 mPas

Solids

Ø 6 mm

Suction side

G 2″ or DN 50 Flange

Discharge side

G 1½” or DN 40 Flange

Motor power

2,2 kW

Seal

Lip seal or bellow-type seal

Dimensions

448 x 203 x 210 mm

Weight

PP 22,5 kg, PDVF 23,5 kg

Material

PP / PVDF

JP-840.140

-

Technical data:

Max. flow rate

40 m³/h

Max. head

21 m

Max. viscosity

500 mPas

Solids

Ø 12 mm

Suction side

G 2″ or DN 50 Flange

Discharge side

G 1½” or DN 40 Flange

Motor power

3 kW

Seal

Lip seal or bellow-type seal

Dimensions

505 x 203 x 227 mm

Weight

PP 29 kg, PDVF 30 kg

Material

PP / PVDF

JP-840.150

-

Technical data:

Max. flow rate

42 m³/h

Max. head

25 m

Max. viscosity

500 mPas

Solids

Ø 2 mm

Suction side

G 2½” or DN 65 Flange

Discharge side

G 2″ or DN 50 Flange

Motor power

4 kW

Seal

Lip seal or bellow-type seal

Dimensions

505 x 203 x 227 mm

Weight

PP 44 kg, PDVF 47 kg

Material

PP / PVDF

JP-840.155

-

Technical data:

Max. flow rate

45 m³/h

Max. head

28 m

Max. viscosity

500 mPas

Solids

Ø 3 mm

Suction side

G 2½ or DN 65 Flange

Discharge side

G 2″ or DN 50 Flange

Motor power

5,5 kW

Seal

Lip seal or bellow-type seal

Dimensions

619 x 300 x 312 mm

Weight

PP 60 kg, PDVF 63 kg

Material

PP / PVDF

JP-840.160

-

Technical data:

Max. flow rate

55 m³/h

Max. head

32 m

Max. viscosity

500 mPas

Solids

Ø 9 mm

Suction side

G 2½ or DN 65 Flange

Discharge side

G 2″ or DN 50 Flange

Motor power

7,5 kW

Seal

Lip seal or bellow-type seal

Dimensions

645 x 300 x 310 mm

Weight

PP 70 kg, PDVF 73 kg

Material

PP / PVDF

JP-840.180

-

Technical data:

Max. flow rate

75 m³/h

Max. head

38 m

Max. viscosity

500 mPas

Solids

Ø 9 mm

Suction side

G 2½ or DN 65 Flange

Discharge side

G 2″ or DN 50 Flange

Motor power

11 kW

Seal

Lip seal or bellow-type seal

Dimensions

695 x 300 x 310 mm

Weight

PP 96 kg, PDVF 99 kg

Material

PP / PVDF

VERTICAL CENTRIFUGAL PUMPS

-

ESPECIALLY SUITABLE FOR HIGH AGGRESSIVE MEDIA LIKE ACIDS AND ALKALIES

These vertical centrifugal pumps are operated by a direct-drive motor (max. 3.000 rpm) and have high performance data regarding flow rate (6 to 75 m³/h) and head (7,5 to 38 m). They are especially suitable for a fast transfer of chemicals when emptying containers or tanks.

Centrifugal pumps of series JP-820 will be mainly used for fixed installations while the pump column is immersed directly in the tank. The special construction of these pumps avoids the use of internal mechanical seals (that often have to be replaced) and ensures that any leakages will be collected in the tank.

The open impeller allows even continuous pumping of extremely dirty liquids or media containing small solids. The maximum viscosity for these centrifugal pumps is 500 mPas (at 20°C) and the maximum temperature of the medium 65°C at PP or 95°C at PVDF.

The availability of different materials of construction – depending on chemical and thermal resistance of medium or environment – guarantees an absolute reliability of operation as well as a long life time of the pump.

JP-820.80

-

Technical data:

Max. flow rate

6 m³/h

Max. head

7,5 m

Max. viscosity

500 mPas

Solids

Ø 7 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 1½”

Discharge side

G 1″ or DN 25 Flange

Motor power

0,37 kW

Dimensions

300 x 220 x 419 + L mm

Pump tube lengths

250, 500, 800 mm

JP-820.90

-

Technical data:

Max. flow rate

9 m³/h

Max. head

10,5 m

Max. viscosity

500 mPas

Solids

Ø 10 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 1½”

Discharge side

G 1″ or DN 25 Flange

Motor power

0,55 kW

Dimensions

300 x 220 x 419 + L mm

Pump tube lengths

250, 500, 800 mm

JP-820.95

-

Technical data:

Max. flow rate

16 m³/h

Max. head

14 m

Max. viscosity

500 mPas

Solids

Ø 6 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 2″

Discharge side

G 1½” or DN 40 Flange

Motor power

0,75 kW

Dimensions

360 x 300 x 419 + L mm

Pump tube lengths 500, 800, 1.000, 1.250 mm

JP-820.110

-

Technical data:

Max. flow rate

20 m³/h

Max. head

15 m

Max. viscosity

500 mPas

Solids

Ø 6 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 2″

Discharge side

G 1½” or DN 40 Flange

Motor power

1,1 kW

Dimensions

360 x 300 x 419 + L mm

Pump tube lengths 500, 800, 1.000, 1.250 mm

JP-820.120

-

Technical data:

Max. flow rate

25 m³/h

Max. head

16 m

Max. viscosity

500 mPas

Solids

Ø 6 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 2″

Discharge side

G 1½” or DN 40 Flange

Motor power

1,5 kW

Dimensions

360 x 300 x 446 + L mm

Pump tube lengths

500, 800, 1.000, 1.250 mm

JP-820.130

-

Technical data:

Max. flow rate

30 m³/h

Max. head

20 m

Max. viscosity

500 mPas

Solids

Ø 6 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 2″

Discharge side

G 1½” or DN 40 Flange

Motor power

2,2 kW

Dimensions

360 x 300 x 467 + L mm

Pump tube lengths

500, 800, 1.000, 1.250 mm

JP-820.140

-

Technical data:

Max. flow rate

40 m³/h

Max. head

21 m

Max. viscosity

500 mPas

Solids

Ø 12 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 2″

Discharge side

G 1½” or DN 40 Flange

Motor power

3 kW

Dimensions

360 x 300 x 507 + L mm

Pump tube lengths

500, 800, 1.000, 1.250 mm

JP-820.150

-

Technical data:

Max. flow rate

42 m³/h

Max. head

25 m

Max. viscosity

500 mPas

Solids

Ø 2 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 2½”

Discharge side

G 2″ or DN 50 Flange

Motor power

4 kW

Dimensions

480 x 380 x 532 + L mm

Pump tube lengths

500, 800, 1.000, 1.250 mm

JP-820.155

-

Technical data:

Max. flow rate

45 m³/h

Max. head

28 m

Max. viscosity

500 mPas

Solids

Ø 2 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 2½”

Discharge side

G 2″ or DN 50 Flange

Motor power

5,5 kW

Dimensions

480 x 380 x 682 + L mm

Pump tube lengths

500, 800, 1.000, 1.250 mm

JP-820.160

-

Technical data:

Max. flow rate

55 m³/h

Max. head

32 m

Max. viscosity

500 mPas

Solids

Ø 9 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 2½”

Discharge side

G 2″ or DN 50 Flange

Motor power

7,5 kW

Dimensions

480 x 380 x 702 + L mm

Pump tube lengths

500, 800, 1.000, 1.250 mm

JP-820.180

-

Technical data:

Max. flow rate

75 m³/h

Max. head

38 m

Max. viscosity

500 mPas

Solids

Ø 11 mm

Max. temperature

at PP 65°C, at PVDF 95°C

Suction side

G 2½”

Discharge side

G 2″ or DN 50 Flange

Motor power

11 kW

Dimensions

480 x 380 x 752 + L mm

Pump tube lengths

500, 800, 1.000, 1.250 mm

MAGNETIC CENTRIFUGAL PUMPS

-

Magnetic centrifugal pumps are magnetically coupled centrifugal pumps in which the drive motor and the actual pump are mechanically separated.

The pump is driven by contactless magnetic force transmission. This construction eliminates the shaft seal required in conventional centrifugal pumps, which regularly causes leakage problems. The pump casing is hermetically sealed by the construction of the magnetic centrifugal pump, thus guarantees a high operating safety as well as a long service life.

The essential feature of these centrifugal pumps is therefore their seal-free design, which does not allow leaks.

The materials used for the JESSBERGER magnetic centrifugal pumps are characterized by a high chemical and thermal resistance and thus guarantee a long service life.

In addition to the standard polypropylene version, which is already suitable for a large part of the applications, a large proportion of the pumps are also available in ECTFE.

All sizes are available with hose or thread connections.

THE SPECIAL ADVANTAGES

Compact and robust design, sealless design, no leakage problems.

Absolute operational safety, suitability for continuous operation, high efficiency.

High chemical and thermal resistance, versatile usability.

Optimal price / performance ratio, environmentally friendly construction.

Easy maintenance.

NH-PX | NH-PI

-

Drive with non-contact magnetic force transmission. Leakage free construction.

Features

Magnetic centrifugal pump with a small flow rate and an integrated single-phase motor or 24-VCC DC motor.

Aimed at OEM‘s for liquid fertilizer, ice machines, vending machines, water cooling, water testing equipment etc.

NH-PS

- Drive with non-contact magnetic force transmission. Leakage free construction.

Features

Magnetic centrifugal pump with medium flow and integrated AC or three-phase motor.

Aimed at OEMs for liquid fertilizer, ice machines, food industry, water cooling, water treatment, etc.

NH-PW

-

Drive with non-contact magnetic force transmission. Leakage free construction.

Features

Industrial pump for chemicals, with possibility of Atex certification for ETFE models.

For industrial use, general chemical processes, loading and unloading of tanks, absorption towers etc.

NH-PW-N

-

Drive with non-contact magnetic force transmission. Leakage free construction.

Features

Self-priming industrial pumps for the chemical industry. Derived from the PW series.

For the industrial sector, emptying tank trucks, pumping of tanks (underground).

NH-PW-H

-

Drive with non-contact magnetic force transmission. Leakage free construction.

Features

High lift head industrial pump for chemicals, with possibility of Atex certification for ETFE models.

NH-PW-C

-

Drive with non-contact magnetic force transmission. Leakage free construction.

Features

Industrial pump for tough environments. The inner ETFE body is reinforced with a thick cast iron housing, increasing its mechanical strength and resistance to elevated temperatures.

Pump is suitable for outdoor installation or demanding environmental conditions. Atex certification possible.

DIESEL PUMPS

Protank 30

-

for refilling of agricultural machinery, tractors, excavators, caterpillar, trucks, etc.; the pumps are not suitable for other media and therefore not for oils, gasoline or water.

Protank 25, non-self-priming pumps for diesel and heating oil of hazardous class A III in 230 V, 12 V or 24 V

Features- Wear-resistant, smooth-running centrifugal pump.

- Suction stage for manual pre-pumping or for emergency operation.

- Safety by means of integrated heel protection (outflow protection).

- Thermal fuse High flow rate at low weight.

- Suction hose length 1,6 m

- Suction filter F20/1

- Perbunan tubing with anti-kink spring.

- Standard nozzle ZP19 or automatic nozzle.

- 230 V: cable with Schuko plug.

- 12 V oder 24 V: cable with low-voltage plug.

Protank 50

-

Protank 50, self-priming pumps for diesel and heating oil of hazardous class A III in 230 V, 12 V or 24 V

FEATURES- Pump: Vane pump selfpriming with bypass valve

- Construction: Robust design fulfilling the hardest tasks.

- Siphon protection: Permanently effective, acc. to law.

- Delivery head: 9 to 17m, up to 2 m self priming.

- Motor protection: Overload protection by a thermal circuit breaker, self-resetting.

- Handling: Discharge hose can be easily disassembled from pump.

- Material: Pump housing and impeller made of cast iron.

- Suction hose: Length 1,6 m, 1″, with strainer.

- Discharge hose: Length 4 m, 1″

- Nozzle: Standard nozzle or automatic nozzle included in set.

- Flowmeter: Mechanical flowmeter as option depending on version, see program.

- Package: Non returnable package.

ELECTRONIC FLOWMETER

-

ACCORDING TO THE MEASURING PRINCIPLE OF THE TURBINE WHEEL AND OVAL GEAR COUNTER

Pulse output or quantity preset for controlling a pump, a magnetic valve or a ball valve as an option.

The turbine wheel counter is a volume meter. The speed is proportional to the flow rate.

Oval wheel counters belong to the group of direct volume meters for liquids with movable partitions (displacement meters).

OVAL GEAR METER ORZ-I

-

FOR OILS, TRANSMISSION FLUIDS, COOLANTS, BRAKE FLUIDS AND WIPER LIQUIDS

DESCRIPTION

The oval gear meter with electronic counter has been designed to measure motor oils (S.A.E. 5-50), gear oils (S.A.E. 80-240), transmission fluid, coolents (ethylene glycol), brake fluids and wiper fluids. The meter has a modular construction, cost-effective and robust but lightweight.