- Offer Profile

-

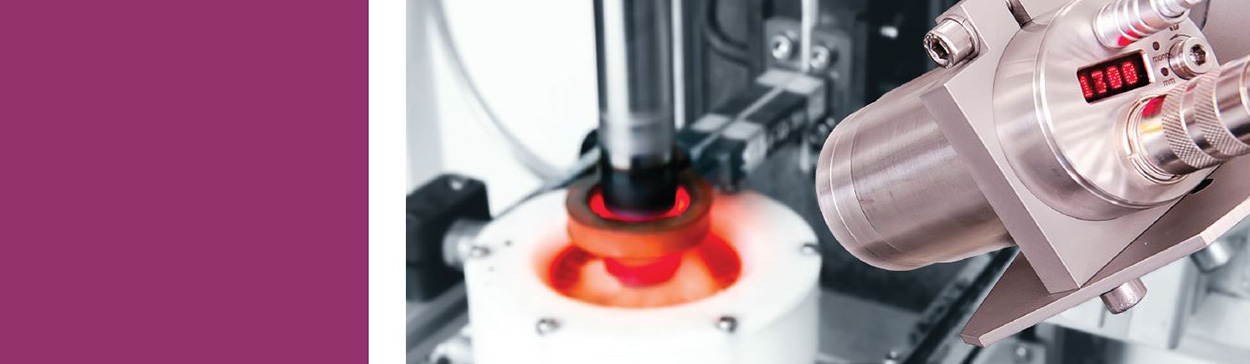

Highest Performance for Demanding Applications

Advanced Energy develops the world's most advanced power supplies and solutions for semiconductor and industrial customers. Get the precision, power and performance your applications require. Streamline your processes and boost productivity.

LumaSense Technologies, Inc., one of the most trusted providers of innovative temperature and gas measurement devices, was acquired by Advanced Energy in September 2018.

LumaSense infrared measurement sensors and products are now part of Advanced Energy's portfolio and complement a range of photonics-based measurement and monitoring solutions for Advanced Energy's leading precision, power and control technologies for semiconductor and industrial markets..

Temperature Measurement Products

Pyrometers

- Easily obtain the quality and accuracy you require. Our vast pyrometer portfolio is developed from years of research and customer contact. We provide infrared thermometer solutions for nearly every application request. And we can quickly adapt our solutions for unique application specifications.

Glass Applications Pyrometers

Benefit from Rugged and Precise Pyrometers Designed for Glass Applications

Choose from a wide range of non-contact pyrometers tailored to the glass industry's specific needs. Whether it be for flat glass or solar glass, container glassware, utility glassware, or technical glass, all of our products deliver fast and accurate temperature readings.

Impac IN 140/5 Series

Fast, Digital Pyrometer for Measurement of Glass Surfaces, 250 and 2500°C

The Impac® IN 140/5 digital pyrometers are ideal for non-contact temperature measurement of glass and quartz-glass surfaces between 250 and 2500°C.

The IN 140/5 series showcases very short response time and extremely small spot sizes. It has two model variations. The IN 140/5-L is equipped with a better field-of-view (optics 2-NL) and the high-speed IN 140/5-H has a short response time of only 10 ms.

- Short response times

- Small spot sizes

- Focusable optics

- Digital display

- Test current output

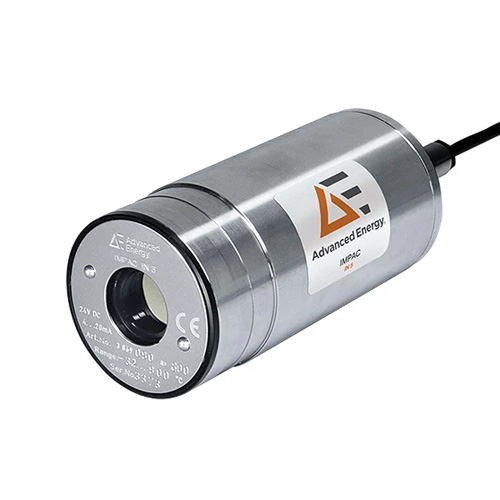

Impac IN 5/5 and IN 5/5 plus Series

-

Compact, Infrared Pyrometers for Temperature Measurement, 100 to 2500°C

Advanced Energy's Impac IN 5/5 and IN 5/5 plus series are specially designed pyrometers for non-contact temperature measurement of glass and quartz surfaces.

- Temperature Ranges: Between 100 and 2500°C

- Analog Output:

- IN 5/5: 4 to 20 mA (linear), several temperature ranges available

- IN 5/5 plus: 0 or 4 to 20 mA (linear), adjustable

- Small spot sizes (IN 5/5 = minimum 2.5 mm and IN 5/5 plus = minimum 1.1 mm)

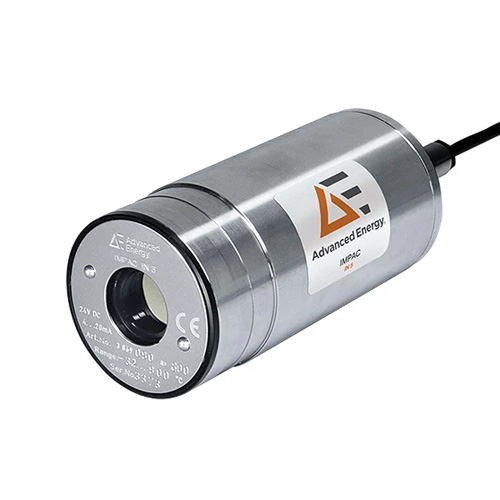

Impac IN 6/78

-

Accurate, Rugged, and Reliable Pyrometers for Non-Contact Temperature Measurement, 150 to 1100°C

Advanced Energy's Impac IN 6/78-L and IN 6/78-H are specially designed pyrometers for non-contact temperature measurement of thin glass sheets.

- Temperature Ranges:

- IN 6/78-L: 400 to 1100°C

- IN 6/78-H: 150 to 800°C

- Measurement of ultra-thin glass sheets with less than 1 mm thickness

- Easy installation and maintenance due to compact, rugged IP65 stainless steel housing designed for harsh environments

- Specially designed and coated high-end optics for high accuracy and excellent size of source effects

- Temperature Ranges:

Impac IPE 140/39

-

Digital Pyrometers with Focusable Optics for Metal and Glass Temperature Measurement, 20 to 1800°C

Advanced Energy’s Impac 140/39 allows you to measure temperature through flames and combustion as well as penetrate glass.

- 3.9 µm spectral range

- Focusable optics

- Small spot sizes

- Short response times

- Built-in digital display

- Precision mounting rail

Impac IS 50-LO/GL

-

Digital Infrared Thermometer with Fiber Optics, 600 to 1800°C

Advanced Energy's Impac IS 50-LO/GL is a specially designed pyrometer for temperature measurement in glass applications.

- Adjustable temperature ranges between 600 and 1800°C

- Robust fiber optic cable (up to 30 m) with a quick-release optical head

- Ambiance up to 250°C without cooling

Impac 8 pro Series

-

Portable, Digital Pyrometers for Non-Contact Temperature Measurement, 250 to 2500°C

Advanced Energy’s battery-driven Impac series 8 pro pyrometers offer wide temperature ranges and high accuracy. The series features Impac IS 8 pro, IGA 8 pro, and IS-8GS pro.

- Fully digital signal processing

- Integrated graphic display

- Bright, optimized viewfinder with exact spot indication

- Aluminum die-cast housing for harsh conditions

- Short response times and quick detection of temperature differences

Metal Applications Pyrometers

-

Increase Accuracy and Productivity

Increasing quality standards and higher energy costs demand more accurate and consistent temperature control in steel-making processes. Our pyrometers for metal applications provide cutting-edge technology, ease-of-use, and dependability.

Impac IN 5/5 plus Series Pyrometers

-

The Impac IN 5/5 plus compact pyrometers are specially designed for non-contact temperature measurement of glass and quartz glass surfaces with temperature ranges between 100 and 2500°C. These instruments are digital pyrometers equipped with a digital interface, enabling temperature indication and storage on a PC. A temperature subrange can also be configured and you can adjust parameters remotely. The version IN 5/5-L plus is equipped with optics for better fields of view for the measurements of small objects. The high-speed version IN 5/5-H plus has a shorter exposure time of only 10 ms and is suited for fast-measuring tasks.

- Adjust emissivity and exposure time directly in the instrument

- Remotely adjust instrument parameters and configure a temperature subrange

- Utilize various optics available for optimal matching of the instrument to the application

- Precisely align the pyrometer to the measuring object with a laser target light

- Operate in rough industrial environments

- Digitally store and process temperature data

Impac IS 6, IGA 6, and IGA 6/23 Advanced

-

Stationary, digital Pyrometers for Non-Contact Temperature Measurement, 50 to 3000°C

Advanced Energy’s Impac IS 6, IGA 6, and IGA 6/23 Advanced are digital and compact pyrometers for non-contact temperature measurement of metals, ceramics, or graphite.

- High-end optics with manual focus

- Unmatched accuracy and repeatability

- Wide temperature ranges and flexible process adaptation

- Fast response times

- Four-digit LED display

Impac ISR 6 Advanced

-

Digital Ratio Pyrometer with One-Color and Two-Color Modes for Non-Contact Temperature Measurement, 600 to 3000°C

Advanced Energy’s Impac ISR 6 Advanced is a digital, compact and fast two-color pyrometer for non-contact temperature measurement.

- Wide temperature ranges for flexible process adaptation

- High accuracy and repeatability

- Dirty-window warning

- Four-digit LED supply

- Fast response times

Impac ISR 6-TI Advanced

-

Stationary, Digital Hybrid Pyrometer with Built-In Thermal Imaging Camera, 700 to 1800°C

Advanced Energy’s Impac ISR 6-TI Advanced pyrometer combines the two-color method and thermal imaging in a single non-contact temperature measurement system.

- Built-in video camera with short wavelength infrared filter

- Thermal image auto-calibration

- Fast response times (2 ms)

- Dirty-window warning

- Robust, stainless steel sensor

Impac IGAR 6

-

Highly accurate digital ratio pyrometer with possible combination of 1-color and 2-color measurement, focusable optics and integrated display. Temperature ranges between 100 and 2550 °C.

The Impac® IGAR 6 Smart pyrometer can operate in one-color mode (100 to 2550 °C), two-color mode (250 to 2550 °C), or special smart mode.

In two-color mode (ratio method), two adjacent wavelengths are used for temperature determination. Temperature measurement is largely independent of the object’s emissivity and, in wide ranges, unaffected by dust and other contaminants. The measuring object can be smaller than the spot size. You also can measure through dirty-viewing windows up to a certain contamination point.

Impac IS 12 and IGA 12 Series

-

Digital, Infrared Thermometers for Non-Contact Temperature Measurement, 250 to 3500°C

Advanced Energy's Impac IS 12 and IGA 12 series pyrometers are robust, digital, and highly accurate for non-contact temperature measurement.

- Available with six fixed and three focusable optics that feature extremely small spot sizes

- Short Response Times:

- < 1 ms (IS 12, IS 12-S, IGA 12, IGA 12-S)

- < 1.5 ms, adjustable up to 10 s (IS 12-AI)

- 10 ms, adjustable up to 10s

- Distance ratio up to 900:1 (IS 12, IS 12-S, IGA 12, IGA 12-S)

Impac ISR 12-LO and IGAR 12-LO Series

-

Digital, Two-Color Infrared Temperature Sensors, 300 to 3300°C

Advanced Energy's Impac ISR 12-LO and IGAR 12-LO are digital two-color pyrometers with fiber optics for non-contact temperature measurement.

- Temperature Ranges: Between 300 and 3300°C

- Analog Output: 0 to 20 mA or 4 to 20 mA switchable, load 0 to 500 Ohm, test current 10 mA by pressing the test key

- Extremely fast exposure time

- Very small spot sizes

- Maximum value storage

Impac IS 12-TSP and IGA 12-TSP

-

Fully Digital, Extremely Precise Infrared Thermometer, 200 to 3000°C

Advanced Energy's Impac IS 12-TSP and IGA 12-TSP are fully digital, extremely precise transfer standard pyrometers for exact inspection of calibration sources.

- Temperature Ranges: Between 200 and 3000°C

- Analog Output: 0 to 20 mA or 4 to 20 mA, DC, switchable, load max. 500 Ohm

- Extremely fast exposure time

- Long-term stability

- Thermostatically-controlled detectors

Impac IS 50-LO plus and IGA 50-LO plus Series

-

Digital, Highly Accurate Infrared Thermometers, 50 and 3500°C

Advanced Energy's Impac 50-LO plus and IGA 50-LO plus series include pyrometers with fiber optics for non-contact temperature measurement on metals, ceramics, graphite, etc.

- Temperature Ranges: Between 250 and 3500°C

- Extremely short exposure time

- Very small spot sizes

- Built-in LCD display

- Test current output for diagnostics

Impac IS 140 and IGA 140 Series

-

Digital, Highly Accurate Infrared Thermometers With Optional Interfaces, 220 to 3500°C

Advanced Energy's Impac IS 140 and IGA 140 series includes pyrometers with focusable optics for non-contact temperature measurement.

- Temperature ranges between 220 and 3500°C

- Available with three different focusable optics

- Short response times <1 ms

- Extremely small spot sizes min 0.35 mm

- Available with Ethernet, Profinet, and Profibus interfaces

Impac IGA 140/23 Series

-

Digital, Highly Accurate Infrared Thermometers With Optional Interfaces, 50 to 1800°C

Advanced Energy's Impac IGA 140/23 series pyrometers are digital, highly accurate pyrometers for non-contact temperature measurement on metals, ceramics, graphite etc.

- Temperature ranges between 50 and 1800°C

- Available with three different focusable optics

- Short response times <1.5 ms

- Extremely small spot sizes min 0.5 mm

- Available with Ethernet, Profinet, and Profibus interfaces

Impac 8 pro Series

-

Portable, Digital Pyrometers for Non-Contact Temperature Measurement, 250 to 2500°C

Advanced Energy’s battery-driven Impac series 8 pro pyrometers offer wide temperature ranges and high accuracy. The series features Impac IS 8 pro, IGA 8 pro, and IS-8GS pro.

- Fully digital signal processing

- Integrated graphic display

- Bright, optimized viewfinder with exact spot indication

- Aluminum die-cast housing for harsh conditions

- Short response times and quick detection of temperature differences

Impac IPE 140

-

Digital Pyrometer with Focusable Optics for Non-Contact Metal Temperature Measurement, 5 to 1200°C

Advanced Energy’s Impac IPE 140 is a highly accurate and fully digital pyrometer. It features focusable optics and is ideal for metal, ceramic, and graphite temperature measurement.

- Short response times

- Small spot sizes

- Built-in digital display with temperature indication

- Optimized through lens view finder or laser targeting light

Impac IPE 140/39

-

Digital Pyrometers with Focusable Optics for Metal and Glass Temperature Measurement, 20 to 1800°C

Advanced Energy’s Impac 140/39 allows you to measure temperature through flames and combustion as well as penetrate glass.

- 3.9 µm spectral range

- Focusable optics

- Small spot sizes

- Short response times

- Built-in digital display

- Precision mounting rail

Impac IS 320, IGA 320, and IGA 320/23

-

Short Wavelength Digital Pyrometers for Non-Contact Temperature Measurement, 75 to 2500°C

Advanced Energy's Impac IS 320, IGA 320, and IGA 320/23 are short wavelength infrared thermometers. They are used for measuring metallic surfaces, graphite, and ceramics, etc.

- Internal digital signal processing for high accuracy and long temperature ranges

- Small housing dimensions for easy installation in confined spaces

- High-quality optics for measurement of small objects

- Built-in LED target light for easy alignment to the measuring object

Impac IGA 320/23-LO

-

Short Wavelength Digital Pyrometer with Fiber Optics for Non-Contact Temperature Measurement, 85 to 1200°C

Advanced Energy's IGA 320/23-LO is a short wavelength infrared measuring instrument with fiber optics and internal digital signal processing capabilities. This pyrometer is used for measurements of metallic surfaces, graphite, and ceramics, etc.

- Fiber optics

- Internal digital processing capabilities

- High-quality optics

- LED target light

Impac ISR 320 and IGAR 320

-

Stationary, Digital Ratio Pyrometer for Non-Contact Temperature Measurement, 300 to 2500°C

Advanced Energy's Impac ISR 320 and IGAR 320 pyrometers measure via the two-color (ratio) method.

- Internal digital signal processing for high accuracy

- Built-in LED target light for easy alignment

- Thermal intensity alignment

- Integrated dirty-window warning

Impac High Speed 740 Series

-

Stationary Pyrometers for Non-Contact, Metallic Surface Temperature Measurement, 160 to 3500°C

Advanced Energy’s Impac High Speed 740 series features stationary pyrometers for non-contact temperature measurement of metallic surfaces, graphite, ceramics, etc.

- Targeting light

- Very small spot sizes

- Variable or fixed optics

- Viewfinder

- Fast response times

Impac KTS 218 and KTG 218

-

Fast, Infrared Temperature Switches for Hot Object Recognition, 400 to 1500°C

Advanced Energy’s Impac KTS 218 and KTG 218 are infrared temperature switches that recognize hot objects within their field of views.

- 600 µs switch time

- Ten optics to choose from

- LED target light

- Stainless-steel housing

- Small dimensions

Mikron PhotriX Series

-

Best-in-Class Infrared Radiation Pyrometers, 30 to 2600°C

Advanced Energy's Mikron PhotriX pyrometers offer ultra-accurate, precise infrared temperature measurement with unmatched low-temperature capability.

- Unmatched signal-to-noise ratio

- Accuracy: ±1.5°C or 0.15% of reading

- Short wavelength, narrow bandwidth detectors

- Ambient temperature compensation to combat drift

- Unmatched, longterm stability and reproducibility

- Robust and flexible design allows for easy integration

Non-Metal Applications Pyrometers

Enable Critical Accuracy and Cost Savings

In industrial markets, accurate temperature measurement is critical for production monitoring. You need to keep costs down and product quality high. Advanced Energy is known for providing cutting-edge temperature management technology to meet stringent design requirements.

Impac 600 Series

-

Digital, Modular Infrared Thermometers for Non-Contact Temperature Measurement

Advanced Energy's Impac 600 series is a digital pyrometer series that provides a highly customizable design with easy installation and maintenance. The IN 600 is a digital pyrometer with exchangable sensor heads for non-contact temperature measurement of non-metallic or coated metallic surfaces.

- Suitable for measuring temperature ranges between -40 and 700°C

- High flexbility due to modular design

- Three different optics available with field of view 2:1, 10:1, or 20:1

Impac IN 300

-

Small, Stationary, Two-Wire Technique Pyrometer, -20 to 600°C

Advanced Energy's Impac IN 300 is a small, stationary pyrometer using a two-wire technique for non-contact temperature measurement of non-metallic surfaces.

- Temperature ranges between -20 and 600°C

- Adjustable emissivity of 0.4 to 1.0

- Analog output: 4 to 20 mA

Impac IN 5 and IN 5 plus Series

-

Infrared Thermometers for Non-Contact Temperature Measurement, -32 to 900°C

Advanced Energy's Impac IN 5 and IN 5 plus pyrometers have a solid and robust design for temperature measurement of non-metallic surfaces and painted, coated, or anodized metals.

- Temperature Ranges: Between -32 and 900°C Analog Output:

- IN 5: 4 to 20 mA (linear), several temperature ranges available

- IN 5 plus: 0 or 4 to 20 mA (linear), adjustable

- Small spot sizes (IN 5 = min. 2 mm and IN 5 Plus = min. 1 mm)

Impac IN 5/9 plus

-

Digital Pyrometer for Sapphire and Sapphire Wafer Temperature Measurement, 0 to 1500°C

Advanced Energy’s Impac IN 5/9 plus pyrometer is specially designed for non-contact sapphire and sapphire wafer temperature measurement. It features an analog output and digital interface.

- Analog output

- Digital interface RS232

- Laser target light

- Compact

- Adjustable exposure time

Impac IN 500 Series

-

Digital Infrared Thermometers for Non-Contact Temperature Measurement, -40 to 700°C

Advanced Energy's Impac IN 500 series includes the IN 510 and IN 520 and are digital pyrometers with miniature sensor heads for non-contact temperature measurement of non-metallic or coated metallic surfaces.

- Suitable for measuring temperature ranges between -40 and 700°C

- Sensor head and cable usable in ambient temperature up to 85 or 180°C without cooling, dependent on the type

- Field of View: 10:1 or 2:1

Impac IPE 140/34

-

Digital Pyrometer for Plastic Film Temperature Measurement, 50 to 500°C

Advanced Energy’s Impac IPE 140/34 is a highly accurate digital pyrometer with an extremely narrow spectral range.

- Spectral range 3.43 µm

- Focusable optics

- Two temperature ranges

- Short response times

Impac IPE 140/45

-

Digital Pyrometer for Flame and Combustion Gas Temperature Measurement, 400 to 2000°C

Advanced Energy’s Impac IPE 140/45 pyrometer features a specialized CO2 absorption band to accurately measure hot CO2 gas.

- Flame temperature measurement

- Combustion gas temperature measurement

- Focusable options

- Highly accurate digital pyrometer

- Available as a system for FEGT monitoring

Petrochemical Sensors

Benefit from Proven Experience

More than 550 refineries, gas plants, and petrochemical companies look to Advanced Energy’s E²T product line for accurate infrared temperature data. With over 1,700 installations worldwide, our petrochemical sensors deliver proven experience, superior performance, and cost savings. Benefit from dedicated support and E2T on-site product-service packages.

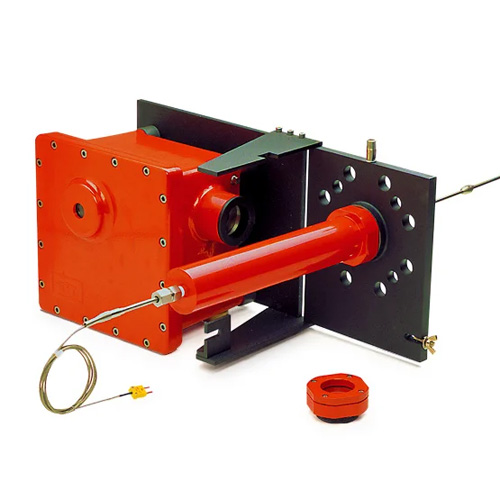

E²T Pulsar 4

-

Infrared Thermometry for Sulfur Reactors and High Temperature Furnaces

Advanced Energy's E2T Pulsar 4 instruments provide infrared thermometry for sulfur reactors and other high-temperature furnaces in temperatures between 350 to 2000°C.

- Single channel standard model programmable for gas or refractory measurement

- Two channel advanced model with simultaneous measurement of refractory and gas temperatures

- Explosion-Proof Certification II 2G Ex db IIB +H2 T4, IECEx, ATEX, FM (US and CDN) plus additional regional certifications

- Smart FMA™ Flame Measurement Algorithm (Pulsar 4 Advanced Only)

- RS485 Interface, HART protocol (Pulsar 4 Advanced Only)

E²T Quasar 2

-

Continuous Duty Flare Monitoring and Detection Instruments

Advanced Energy's E2T Quasar 2 instruments provide continuous monitoring and detection of pilot flame and flared gases from flares.

- Flame detection up to 400 m

- Detection of hydrocarbon and hydrogen flames

- Pilot and flaring signal level mA output

- Modular optoelectronic package for easy access and service

E²T Quasar M8100

-

Continuous Flare, Pilot, and Flare Monitoring Detection Instruments

Advanced Energy's E2T Quasar M8100 series instruments provide continuous monitoring and detection of flare stack pilot (PM), smoke (SM), and flares (FM).

- Flame detection up to 400 m away

- Detection of hydrocarbon and hydrogen flames

- CSA/US and ATEX explosion-proof housing

- Automatic gain control for adverse weather conditions

- Modular opto-electronic package for easy removal from housing

Semiconductor & Thin-Film Pyrometers

-

Access Field-Proven Temperature Measurement Technologies with Sekidenko Optical Pyrometers

Access field-proven temperature measurement technologies. Advanced Energy's Sekidenko line of optical fiber thermometers delivers real-time measurement via in-situ probes, optimizing process control.

Mikron PhotriX Series

-

Best-in-Class Infrared Radiation Pyrometers, 30 to 2600°C

Advanced Energy's Mikron PhotriX pyrometers offer ultra-accurate, precise infrared temperature measurement with unmatched low-temperature capability.

- Unmatched signal-to-noise ratio

- Accuracy: ±1.5°C or 0.15% of reading

- Short wavelength, narrow bandwidth detectors

- Ambient temperature compensation to combat drift

- Unmatched, longterm stability and reproducibility

- Robust and flexible design allows for easy integration

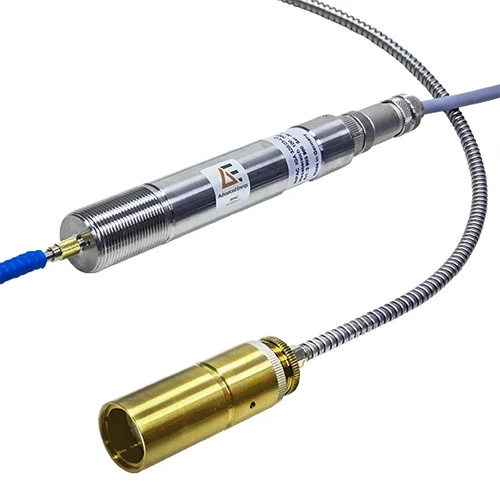

Sekidenko MXE

-

High-Speed, Non-Contact Optical Temperature Pyrometer with Integrated Reflectance Measurement and Emissivity Compensation

Advanced Energy’s Sekidenko MXE measures at ultra-high-speed sampling rates (up to 10 kHz) and offers combined temperature and active reflectance for precise control in dynamic processes.

- Precise temperature measurement enabling closed-loop process control

- Configurable wavelength based on material type and required temperature range

- Both analog and digital communications

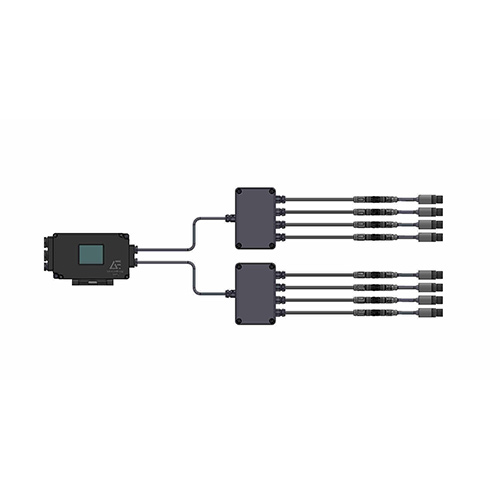

Sekidenko OR4000E

-

Multi-Channel, Non-Contact Optical Fiber Temperature Pyrometer that Supports Read Rates Up to 2 kHz

The Sekidenko OR4000E delivers precision temperature measurement, using active-emissivity compensation for accurate measurement and control under changing-emissivity conditions.

- Configurable wavelength based on material type and required temperature range

- Multi-channel measurement capabilities using remote lensed optical sensors or sapphire light pipes for in-situ measurement

- Both analog and digital communications with optional Fieldbus protocols for closed-loop control

Sekidenko OR4000T

-

Multi-Channel, Non-Contact Optical Fiber Temperature Pyrometer with Configurable Wavelength Range and Fixed-Emissivity Correction

The Sekidenko OR4000T is ideally suited to measure temperature in the most tightly controlled applications, where uniform, repeatable temperatures are required for process success.

- Configurable wavelength based on material type and required temperature range

- Multi-channel measurement capabilities using remote lensed optical sensors or sapphire light pipes for in-situ measurement

- Both analog and digital communications with optional Fieldbus protocols for closed-loop control

Sekidenko OR400M

-

Single-Channel Temperature Measurement Capability with Selectable/Fixed Emissivity

The Sekidenko OR400M offers the precise temperature measurement essential to semiconductor applications that require longer wavelengths.

- Configurable wavelength based on material type and required temperature range

- Integrated optical sensor

- Both analog and digital communications with optional Fieldbus protocols for closed-loop control

Sekidenko OR400T

-

Compact, Single-Channel Optical Fiber Temperature Pyrometer for High-Volume Semiconductor Applications

The Sekidenko OR400T delivers accurate, non-contact temperature and emissivity measurements in a compact, modular platform.

- Configurable wavelength based on material type and required temperature range

- Remote lensed optical sensors or sapphire light pipes for in-situ measurement

- Both analog and digital communications with optional Fieldbus protocols for closed-loop control

UV 400 and UVR 400

-

True Wafer Surface Temperature and Reflectance Measurement for GaN-based Epitaxy, 650 to 1300°C

Advanced Energy's UV 400 and UVR 400 pyrometers directly measure wafer surface temperature instead of the traditional susceptor/pocket temperature.

- Wide temperature range (650 to 1300°C) allows coverage of both main buffer growth and MQW growth

- Measure deposition thickness with the additional reflectometer at 635 nm on the UVR 400

- Adjustable emissivity, transmittance, and subrange

Thermal Imagers & Systems

- Advanced Energy’s turnkey thermal imagers and systems accurately measure temperature and use reliable infrared technology. These high-tech instruments can precisely determine the temperature and temperature distribution of small and fast-moving objects.

BoilerSpection MB

-

Mobile Infrared Camera for Clear Inspection of Boiler Tubes and Furnace Walls

Advanced Energy's BoilerSpection MB imaging system utilizes special mid-wave infrared detectors to see through flames. This unique feature means BoilerSpection MB can provide the clearest and most stable through-flame images in boilers, furnaces, kilns, or incinerators.

- Completely digital and IP-addressable camera system

- Built for mobile use

- Utilizes standard connections for viewing and recording real-time images

- Spectral wavelength: ~3.9 µm narrow band pass filter

- Measurement range: 500 to 1600°C (932 to 2912°F)

BoilerSpection SD

-

Turnkey Solution for Continuous Infrared Imaging inside Boilers and Furnaces

Advanced Energy's BoilerSpection SD imaging system provides clear, informative through-flame imaging. With BoilerSpection SD, you can proactively manage your boilers and vastly improve uptime. In fact, a return on investment study by customers found ROI measured in only a few months, not years.

- Resilient and robust for harsh environments

- Measurement range: 500 to 1600°C (932 to 2912°F)

- Stainless steel constructions with air cooling and purge

FlareSpection

-

Infrared Camera System for Continuous Pilot Flame and Flare Stack Monitoring

Advanced Energy's FlareSpection system provides pilot flame monitoring for applications with multiple flare tips. You can confirm flare operation remotely and detect differences in flare stack heat signatures.

- Continuous, remote, and automatic monitoring of pilot flames and flared gases

- High resolution 640 x 480 pixel thermal imager, providing unmatched spatial resolution

- Superior image quality

- Advanced software to enable automated and seamless integration with plant DCS

- Stainless steel enclosure designed for hazardous area

FurnaceSpection

-

Infrared Camera System for Continuous Reformer Tube Monitoring and Temperature Measurement Inside Furnaces

Advanced Energy's FurnaceSpection system provides real-time continuous temperature measurement to identify process abnormalities inside high-temperature furnaces in refining, metals, and glass production processes. It measures the temperature of product, refractory, and heat transfer surfaces inside natural gas-fired furnaces.

- Accurate 640 x 480 focal-plane array thermal imaging camera with sensitivity of 0.06°C

- Boroscope optics filtered at 0.85 μm wavelength to view through combustion gas and flames

- Rugged IP66, air or water cooled (SD), protective enclosure

- Standard (SD) with auto-retraction and Mobile (MB) versions available

- Radiometrically calibrated

Mikron MC320 Series

-

High-Performance, Infrared Camera for Demanding Real-Time Imaging Applications

Advanced Energy's Mikron MC320 series is a cost-effective, high performance non-contact infrared imager that serves a broad range of process monitoring applications.

- Temperature measurement accuracy: ±2°C or 2% of reading

- Focus range: 30 cm to infinity

- Several configuration options, including over network or mobile setup

Mikron MCL640

-

High-Performance, Infrared Camera for Temperature Measurement between -40 and 1600°C

Advanced Energy's Mikron MCL640 offers unparalleled accuracy for demanding industrial and manufacturing applications. This product is designed with advanced, maintenance-free electronics and industrial protective packaging.

- Designed to operate in harsh environments

- High resolution 640 x 480 pixel thermal imager for process control and monitoring

- Serves broad range of process control applications

Mikron MCS640

-

Short Wavelength Thermal Imagers for Temperature Measurement between 600 and 3000°C

Advanced Energy's Mikron MCS640 series offers short wavelength infrared (SWIR) thermal imagers with internal digital signal processing. The imagers are suitable for graphite, ceramics, and metallic-surface applications.

- Uncooled, fully radiometric detector (UFPA)

- Spectral range: NIR (short wavelength), customer specific adaptation on request

- Display of temperature at 307,200 measurement points (640 x 480 pixel)

ThermalSpection 724

-

Automated, Continuous Thermal Imaging System for Remote Fault Detection in Substations and Industrial Sites

Advanced Energy's ThermalSpection 724 allows you to remotely monitor multiple, distant substations from a central location.

- Remote fault detection and alarm generation

- Immediate analysis of dynamic conditions

- Complete turn-key system with protocols for data export

ThermalSpection CVM

-

Turnkey Solution for Monitoring Critical Vessels

Advanced Energy's ThermalSpection CVM system uses non-contact thermal imaging to provide real-time, continuous, automated fault detection and monitoring for your critical assets.

- Early fault detection to reduce risk, emergencies and unplanned outages

- Continuous, automated monitoring

- Easy integration into existing plant DCS and data historian

- Designed for hazardous area installations (ATEX, Class I Div 2)

Gas Sensors

Advanced Energy delivers innovative gas sensing instruments for numerous markets, including global energy, industrial materials, and advanced technologies. Our gas portfolio consists of gas modules and instruments that provide superior sensitivity over other gas detection techniques.Innova Gas Monitors and Samplers

Improve Process Efficiency and Reduce Waste

As a leader in trace and multi-gas monitoring, Advanced Energy delivers various NDIR and PAS gas solutions. Our gas monitors are ideal for all kinds of environments and applications and feature superior sensitivity.

Innova 1314i

-

Highly Accurate, Stable, Quantitative, and Remotely Controllable Gas Monitoring System

Advanced Energy's Innova 1314i is a highly accurate, reliable, and stable quantitative gas monitor. Its measurement principle is based on the photoacoustic detection method. Extremely versatile by design, the 1314i can measure at trace levels almost any gas that absorbs infrared light.

- Multi-gas monitoring of up to five different gases (+ water vapor) can be measured with excellent sensitivity and accuracy

- Suited for permanent monitoring tasks at low O&M costs

- Highest stability (low drift) makes calibration only necessary one to two times per year, and no carrier gas is needed

- Direct sampling

Innova 1403

-

Multipoint Sampler and Doser for Innova Photoacoustic Gas Monitors

The Advanced Energy Innova 1403 is a reliable, easy-to-use multipoint sampler and doser. It combines with the Innova 1512 photoacoustic gas monitor and a controlling computer featuring the Innova 7650 basic ventilation software to offer numerous monitoring capabilities.

- Increase area monitoring capabilities of the gas monitor by collecting air samples through tubing from up to six sampling points

- Full remote control from a PC with Innova ventilation software

- Factory calibrated dosing system includes automatic calculation of tracer-gas delivered to the dosing location

- Self-test function for verification of the unit's operation

Innova 1409

-

Multipoint Sampler Designed for Innova Gas Monitors

The Advanced Energy Innova 1409 is a reliable, easy-to-use multipoint sampler for gas sampling of up to 24 different locations. The Innova 1409 is designed to be remotely controlled from a PC using a USB interface in conjunction with an Innova Photoacoustic Gas Monitor to provide a flexible, sensitive, and accurate monitoring system.

- In conjunction with an Innova gas monitor, measure concentrations of up to five gases, water vapor, and air pressure in each sample

- Full remote control from a PC with Innova ventilation software

- Remotely control the instrument by using an Innova photoacoustic gas monitor or a PC

Innova 1512

-

Highly Accurate, Stable, Quantitative, and Remotely Controllable Gas Monitoring System

Advanced Energy's Innova 1512 is based on the photoacoustic infrared spectroscopy and delivers superior sensitivity in a very compact form factor. Extremely versatile by design, the 1512 is capable of measuring almost any gas that absorbs infrared light.

- Leverages the unique strengths of the photoacoustic sensor technique

- User-friendly, stable, reliable, and highly accurate

- Extremely low-volume flushing possible

Innova 3433i

-

Specially Configured Innova 1314i Multi-Gas Monitor for Automotive Emissions

The Advanced Energy Innova 3433i is a highly accurate and reliable multi-gas monitor with a special configuration for Exhaust Gas or SHED evaporative testing. The measurement system, based on the photoacoustic infrared detection method, is capable of measuring almost any gas that absorbs infrared light. Gas selectivity is achieved through the use of optical filters.

- Selectively measures a wide range of gases and vapors

- Linear response over a wide dynamic range

- Stable and reliable: ensuring a maximum of only two calibrations a year

- Compensates for temperature and pressure fluctuations, water vapor interference, and interference from other known gases

- Virtually no warm-up time necessary for quick operation

Innova 3750-2 / 3750-5

-

Tracer Gas Systems for Ventilation System Studies and Tests

The Advanced Energy Innova 3750-2 basic ventilation system (dual gas) and Innova 3750-5 basic ventilation system (multi-gas) offer fully integrated gas monitoring solutions. They enable accurate tracer gas methods and are ideal for ventilation performance studies or testing.

Tracer gas methods enabled:

• Concentration decay

• Constant injection

Innova 3751-2 / 3751-5

-

Tracer Gas Systems that Enable Constant Concentration Method

The Advanced Energy Innova 3751-2 basic ventilation system (dual gas) and Innova 3751-5 basic ventilation system (multi-gas) offer fully integrated gas monitoring solutions. They enable accurate tracer gas methods and are ideal for ventilation performance studies or testing.

Tracer gas methods enabled:

• Concentration decay

• Constant injection

• Constant concentration

Innova 3731

-

SF6 Leak Detection System for Enclosed GIS Substations

The Advanced Energy Innova 3731 SF6 leak detection system uses photoacoustic spectroscopy (PAS) technology. It offers highly accurate and stable quantitative gas detection.

- Available in 12- or 24-channel configuration to monitor large GIS installation

- Simple installation procedure

- Low cost of ownership

- Multipoint sampling

- Detection trending and automatic alarms

Andros OEM Gas Analyzers

Reduce Costs and Eliminate Field Calibration

Reduce gas measurement costs with modules that measure multiple gases and eliminate field calibration. Our Andros OEM gas modules lead the way in non-dispersive infrared (NDIR) gas analysis for automotive emissions and patient monitoring.

Andros 6500 and 6520

-

OEM Gas Analyzers for Auto Emissions

Advanced Energy’s Andros 6500 and 6520 gas analyzers offer unparalleled accuracy and performance via simplified design and implementation. Unlike analyzers that require moving components, the 6500 and 6520 use pulsed-infrared sources to achieve high accuracy and reliability.

- Highly accurate calibration

- High stability and rapid warm-up

- Unique optical architecture

- Comprehensive software architectures

Andros 6511

-

OEM Gas Analyzer for Greenhouse Gas Detection and Monitoring

Advanced Energy’s Andros 6511 gas analyzer offers unparalleled accuracy and performance. It’s designed to meet and exceed performance requirements for portable or fixed leak detectors of toxics or combustibles.

- Superior performance and reliability

- Enhanced optics and electronics

- Highly accurate calibration

- Extensive software architecture

- Rapid warm-up

Andros 6552

-

OEM Gas Analyzer to Detect Freon Refrigerants and Carbon Dioxide

Advanced Energy’s Andros 6552 gas analyzer is available with two gas channels and can be applied to any type or combination of refrigeration systems that employ FreonsTM and carbon dioxide.

- Ability to measure up to five gases

- Rapid warm-up

- Highly accurate calibration

- Simple and fast system integration

- RS232 or USB communications

Fiber Optic Temperature Sensors

- Advanced Energy’s Luxtron fiber optic temperature sensors set the standard for the energy, research, and medical industries. Based on Fluoroptic technology, each individual product can be configured for specific applications.

Luxtron ThermAsset2

-

Effective Fiber Optic Hot Spot Monitor and Controller for Power Transformers

Advanced Energy's Luxtron ThermAsset2 is designed to measure transformer winding hot spots in real time and activate control of the cooling system.

- Choice of two, four, six, or eight channels

- Direct, accurate, and real-time transformer winding hot spot and temperature monitoring

- Programmable setpoints and relays with individual LED alarm indicators

- Choice of two, four, six, or eight channels

Luxtron M-1000

-

FluorOptic Temperature Converter for measurements between -200 to 450 °C (-328 to 842 °F) in semiconductor applications.

Advanced Energy’s Luxtron® FluorOptic Temperature (FOT) Sensors use the principles of phosphorescence to deliver high-accuracy temperature monitoring for critical semiconductor applications such as plasma etch and plasma enhanced deposition. The sensors are immune to interference from RF and microwave sources, enabling the sub-1 °C process control required to achieve device performance and yield for leading edge semiconductor devices.

- Wide supported temperature range

- Low noise level with fast response rate

- Non-contact measurement to minimize the thermal offset

- Easy to install into OEM equipment

Fiber Bragg Grating Products

- Advanced Energy's WaveCapture™ Fiber Bragg Grating (FBG) spectral analyzers use innovative dispersive optics to provide excellent performance in a compact and robust package. This combination enables WaveCapture FBG Analyzers to enable real-world FBG sensing in challenging medical and industrial applications.

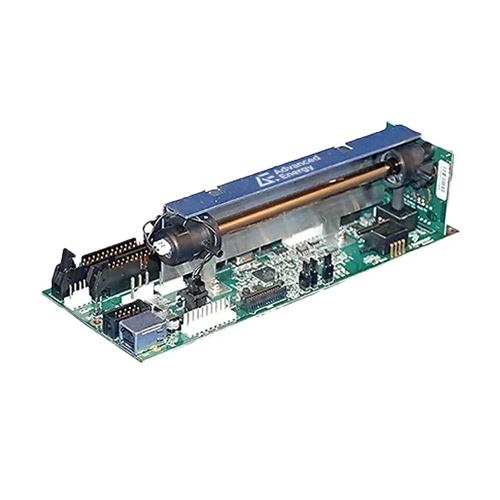

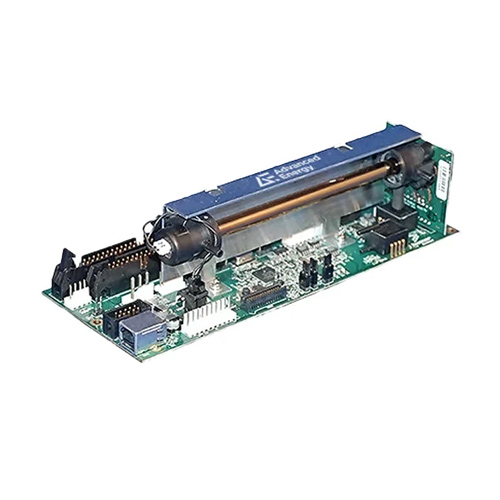

WaveCapture FBG Analyzer Series

-

Precise, Reliable, and Compact Spectral Analyzer for FBG Sensing

Advanced Energy's WaveCapture Fiber Bragg Grating Analyzer (FBGA) is an integrated spectral analyzer that serves as the heart of precise, fast, and reliable FBG sensing systems.

- High reliability with no moving parts

- Excellent wavelength repeatability, and resolution

- Ultra-fast response time (up to 5 kHz)

- Compact optical design

- Rugged design for field applications

- USB, Ethernet, or RS-232 interface

WaveCapture FBG Analyzer-IRS

-

Integrated Spectral Analyzer with an Internal Reference Source for Ultra Precise FBG Sensor Measurements

Advanced Energy's WaveCapture Fiber Bragg Grating Analyzer (FBGA) spectral analyzer with an internal reference source (IRS) serves as the heart of precise, fast, and reliable FBG sensing systems requiring increased precision. The addition of the IRS enables greater repeatability for FBG sensing systems or research requiring repeatability better than 2 pm.

- Ultra-reliable spectral analyzer grating with no moving parts

- Excellent wavelength repeatability and resolution

- Ultra-fast response time (up to 5000 Hz)

- USB 2.0 interface

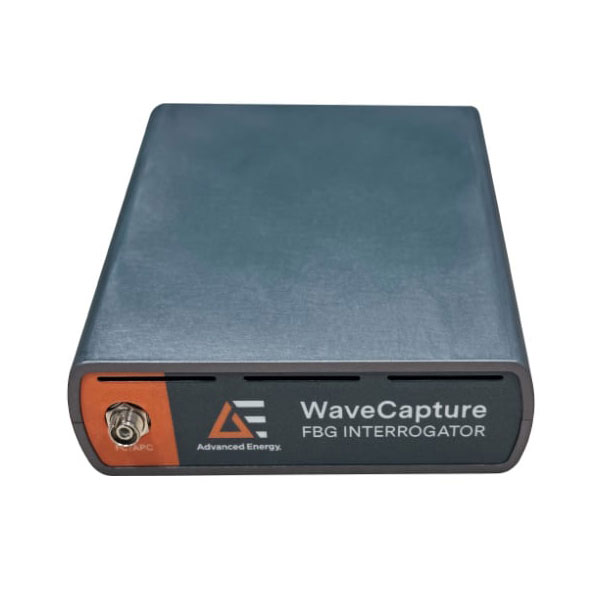

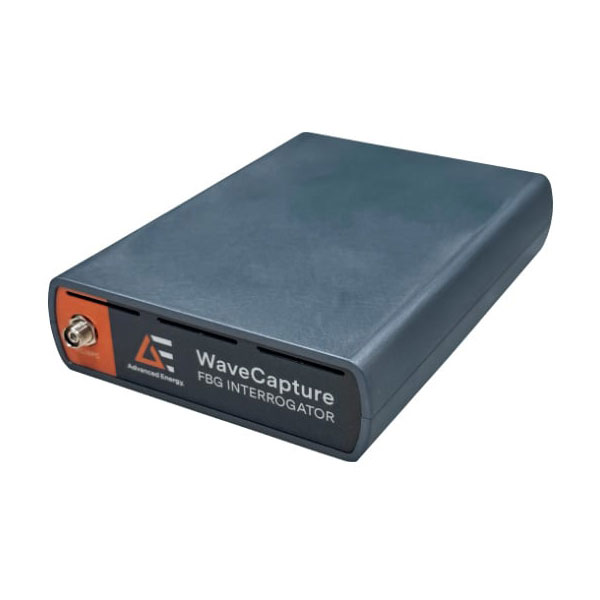

WaveCapture FBG Interrogator

-

Fiber Bragg Grating Interrogation System with Integrated Light Source

Advanced Energy's WaveCapture Fiber Bragg Grating Analyzer (FBGA) interrogation systems with an integrated light source provide complete systems for use with FBG sensors. Systems are available in 1, 4, and 16 channel models.

- High reliability with no moving parts

- Excellent wavelength repeatability and resolution

- Ultra-fast response time (up to 5 kHz)

- USB or RS-232 interface

SCR Power Controllers by Advanced Energy

Thyro Power Controllers

-

Flexibility and performance unite with Advanced Energy’s Thyro SCR power controllers. From simple to complex, ensure product quality with proven SCR operation, control modes, digital mains load optimization, and voltage sequence control.

Thyro-A+ Series

-

Precise, digital SCR power controller that supports currents up to 650 A and voltages up to 500 V

With an optional display and increased measuring accuracy, the Thyro-A+ digital SCR power controller series offers comprehensive operating and control modes to save system costs for resistive and transformer loads in various applications.

- Display or Thyro-Tool Pro software to easily visualize, commission or set parameters

- Increase performance control accuracy to maximize end process repeatability

- Easy fieldbus integration with optional BasicBus Module and available bus protocols

Thyro-A Series

-

Digital Thyristor Power Controller Supports Load Currents Up to 1500 A and Voltages Up to 600 V

Strike the perfect balance between price and performance. The Thyro-A SCR power controller delivers flexible application capabilities and industry-proven reliability. It is ideally suited for general heating applications.- Compact footprint with various applications for precise and reliable control of power and loads

- Low total harmonic distortion (THD) for improved power utilization

- Fully digital communications with optional fieldbus communication options

Thyro-PX Series

-

Advanced SCR Power Controller Supports Load Currents Up to 5000 A

Built for demanding thermal applications, our high-performance Thyro-PX SCR power controller supports multiple operating voltages and control modes.- Large 2.8 in (71.1 mm) LED graphic display with integrated process data recorder and SD card

- Digital and analog I/O options, with integrated memory for error tracking and energy consumption

- Mains-load optimization features dynamic digital control and power monitoring

Thyro-S

-

Thyristor Switch for General Heating Applications, Supports Load Currents Up to 350 A

Efficient yet powerful, the Thyro-S power controller is Advanced Energy’s most compact digital thyristor switch.

- Compact footprint with multiple operating voltages and current ranges

- Load monitoring, alarm relays, and power measurement

- Analog and digital communications with optional fieldbus communication options

Thyro-PX DC

-

Enhanced SCR Power Controller for All DC Rectifier Applications

Developed with the highest degree of reliability and state-of-the-art driven technology, the Thyro-PX DC series of digital SCR power controllers are designed for all DC rectifier applications. The series supports multiple operating voltages and control modes.

- Available up to 1800 amps DC Current

- Air-cooled rectifier type with modular 6 pulses stack (B6C) and extendable for 12 and 18 pulses parallel operation for higher power and less DC ripple

- Large 2.8 in (71.1 mm) LED graphic display with an integrated process data recorder and SD card

- Multiple I/O options, with integrated memory for error tracking and energy consumption