RITMO

Videos

Loading the player ...

- Offer Profile

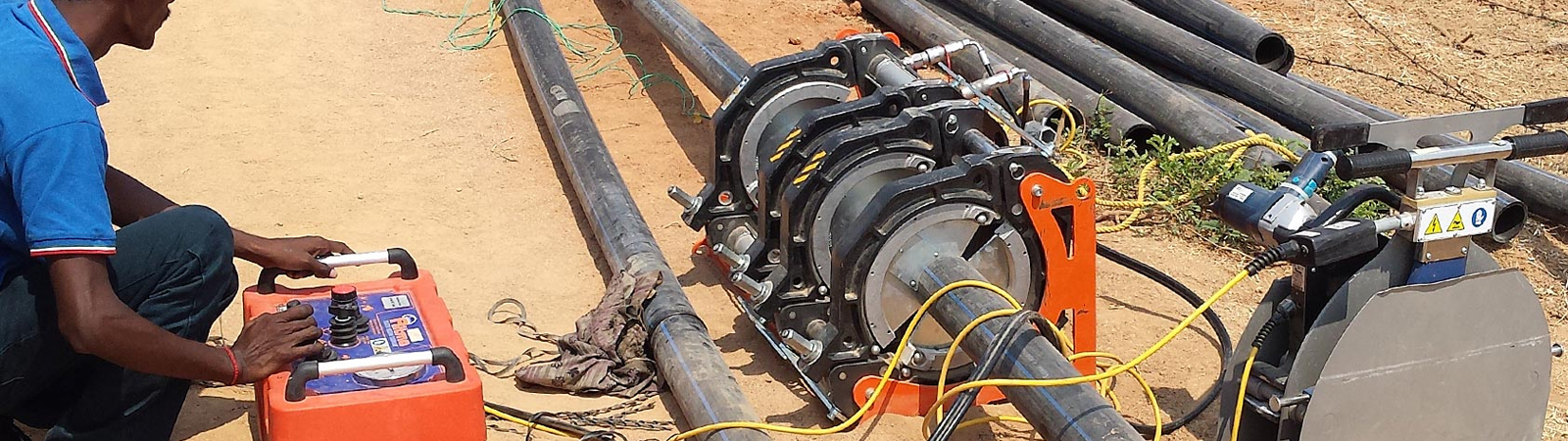

- RITMO S.P.A

is a world leader with over 35 years of experience in the manufacturing of plastic welding equipment.

All products are designed and built according to International standards and directives (UNI, ISO, CEE). Since the very beginning, quality and technology innovation are RITMO’s milestones, and time after time, this philosophy is always more recognized by the global market.

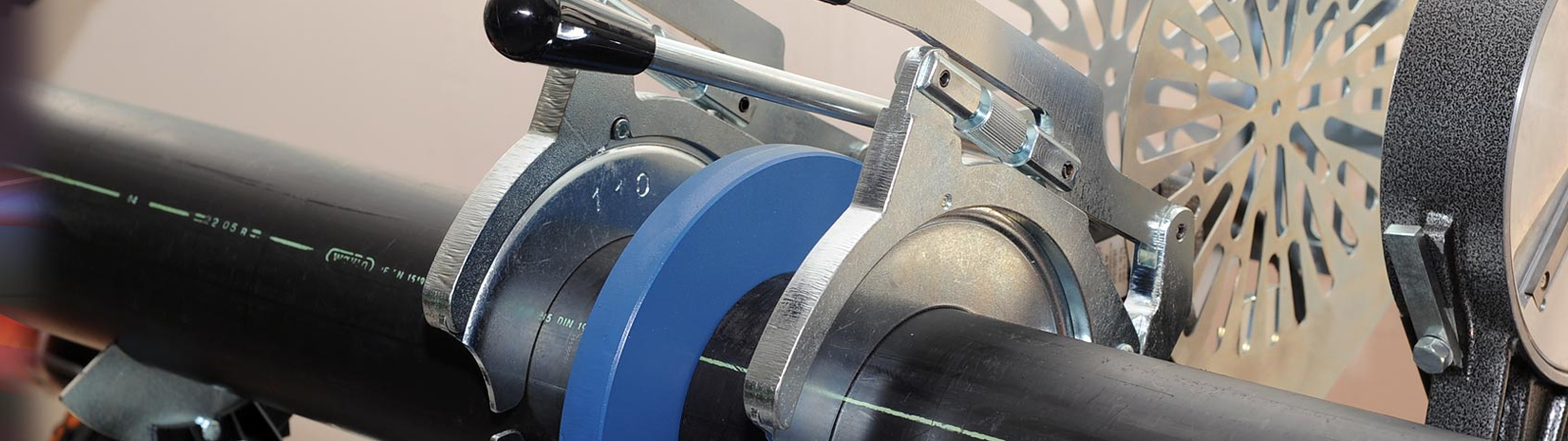

RITMO strong points are its ideas to design and produce accurate, fast, versatile, modular and easy-to-use welding machines. Products range includes butt fusion, electrofusion and extrusion equipment. Ritmo is also providing a complete line of accessories and useful instruments for pipe cutting and weld preparation such as the band saws.

RITMO’s regards towards the client has brought to the new-born “RITMO FUSION OPERATOR SCHOOL”, which is a welding school with the goal of building qualified personnel and spread the knowledge about the technical potentiality of RITMO’s equipment: TECHNOLOGY MADE IN ITALY

Product Portfolio

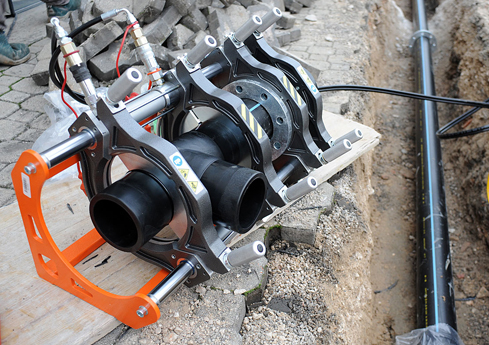

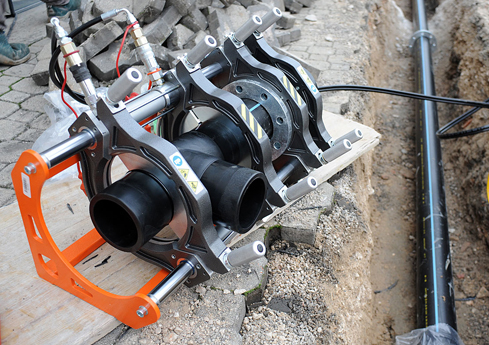

Butt Fusion For Pressure Pipe

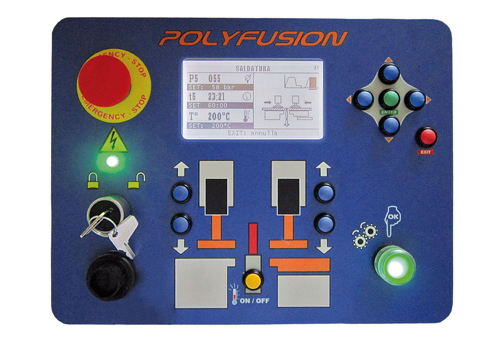

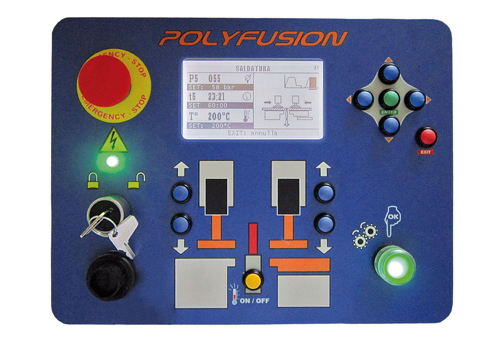

Easy Life - Automated Welding

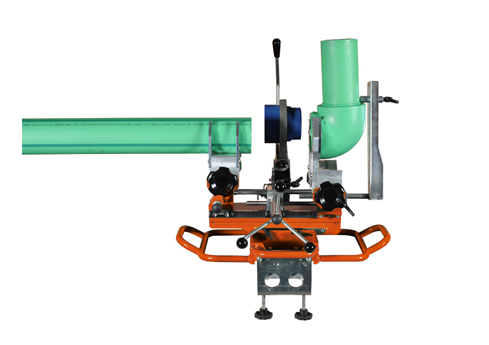

Basic 160 Easy Life

-

BASIC 160 EASY LIFE, thanks to a special gearcase, is able to manage the welding process in a semi-automatic way.

The electronic system guarantees the continuous repeat of the welding cycles and automatic control of the preset parameters, therefore the operator needs only to validate the welding phases. The user-friendly graphic display allows a quick setting of the desired parameters.

The EASY LIFE system can store up to 4000 welding cycles and sum them up into a PDF file. This report can be transferred to a PC/laptop through a USB port.

Possibility to pre-set 50 customized.

The EASY LIFE system data logging now shows the time!

BASIC 160 EASY LIFE is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase EASY LIFE

- A hydraulic hoses with non – drip quick couplings

- Adapters from Ø 40 to 140 mm

Basic 200 Easy Life

-

BASIC 200 EASY LIFE, thanks to a special gearcase, is able to manage the welding process in a semi-automatic way.

The electronic system guarantees the continuous repeat of the welding cycles and automatic control of the preset parameters, therefore the operator needs only to validate the welding phases. The user-friendly graphic display allows a quick setting of the desired parameters.

The EASY LIFE system can store up to 4000 welding cycles and sum them up into a PDF file. This report can be transferred to a PC/laptop through a USB port.

The EASY LIFE system data logging now shows the time!

BASIC 200 EASY LIFE is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase EASY LIFE

- A hydraulic hoses with non – drip quick couplings

- Adapters from Ø 63 to 180 mm

Basic 250 Easy Life

-

BASIC 250 EASY LIFE, thanks to a special gearcase, is able to manage the welding process in a semi-automatic way.

The electronic system guarantees the continuous repeat of the welding cycles and automatic control of the preset parameters, therefore the operator needs only to validate the welding phases. The user-friendly graphic display allows a quick setting of the desired parameters.

The EASY LIFE system can store up to 4000 welding cycles and sum them up into a PDF file. This report can be transferred to a PC/laptop through a USB port.

Possibility to pre-set 50 customized.

The EASY LIFE system data logging now shows the time!

BASIC 250 EASY LIFE is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase EASY LIFE

- A hydraulic hoses with non – drip quick couplings

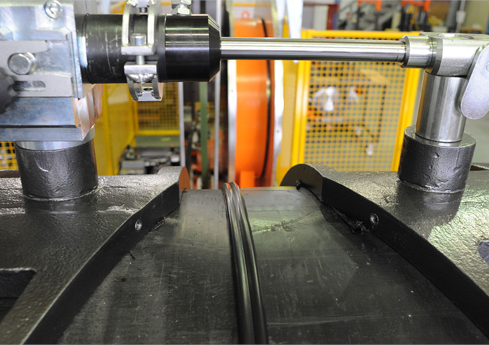

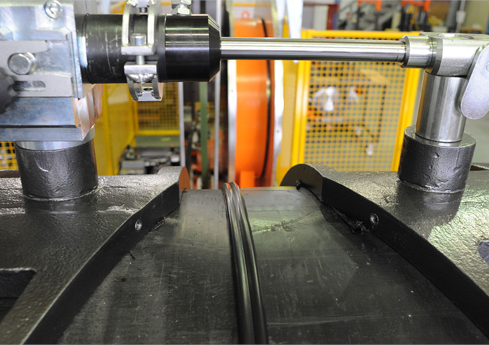

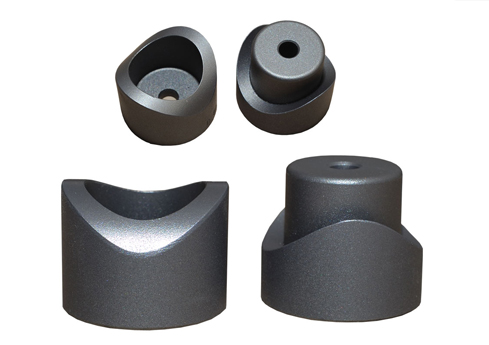

- Adapters SMARTLocK (RITMO patented) from Ø 75 to 225 mm

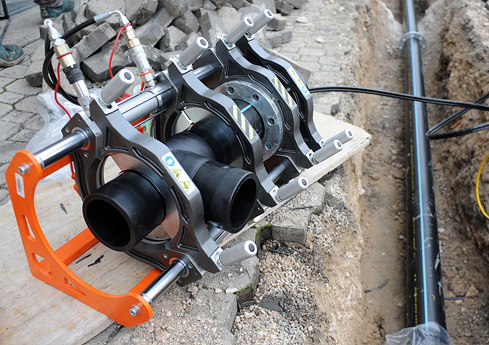

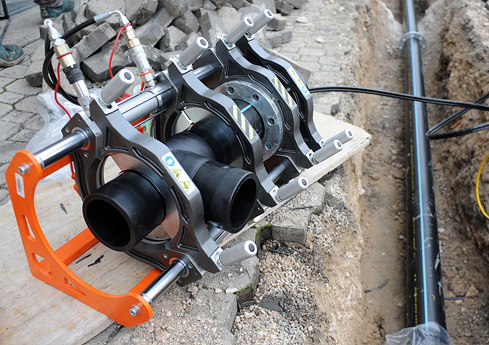

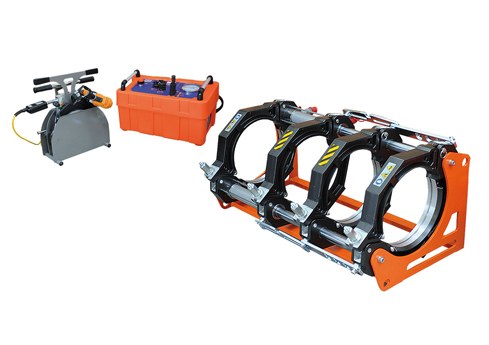

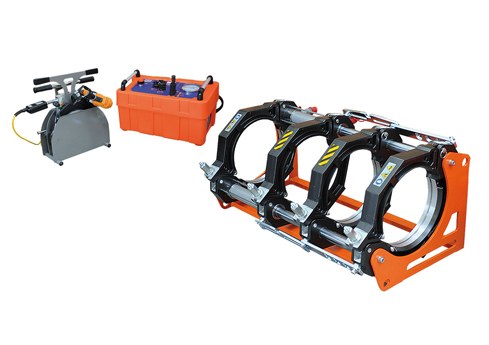

Basic 315 Easy Life

-

BASIC 315 EASY LIFE, thanks to a special gearcase, is able to manage the welding process in a semi-automatic way.

The electronic system guarantees the continuous repeat of the welding cycles and automatic control of the preset parameters, therefore the operator needs only to validate the welding phases. The user-friendly graphic display allows a quick setting of the desired parameters.

The EASY LIFE system can store up to 4000 welding cycles and sum them up into a PDF file. This report can be transferred to a PC/laptop through a USB port.

Se pueden crear un archivio personal de parámetros hasta 50 ciclos favoritos.

The EASY LIFE system data logging now shows the time!

BASIC 315 EASY LIFE is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase EASY LIFE

- A hydraulic hoses with non – drip quick couplings

- Adapters SMARTLocK (RITMO patented) from Ø 90 to 280 mm, Master adapters Ø 250 mm

Basic 355 Easy Life

-

BASIC 355 EASY LIFE, thanks to a special gearcase, is able to manage the welding process in a semi-automatic way.

The electronic system guarantees the continuous repeat of the welding cycles and automatic control of the preset parameters, therefore the operator needs only to validate the welding phases. The user-friendly graphic display allows a quick setting of the desired parameters.

The EASY LIFE system can store up to 4000 welding cycles and sum them up into a PDF file. This report can be transferred to a PC/laptop through a USB port.

Possibility to pre-set 50 customized.

The EASY LIFE system data logging now shows the time!

BASIC 355 EASY LIFE is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase EASY LIFE

- A hydraulic hoses with non – drip quick couplings

- Adapters SMARTLocK (RITMO patented) from Ø 125 to 315 mm, Master adapters Ø 250 mm

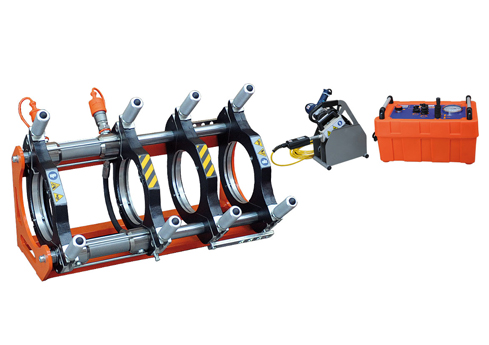

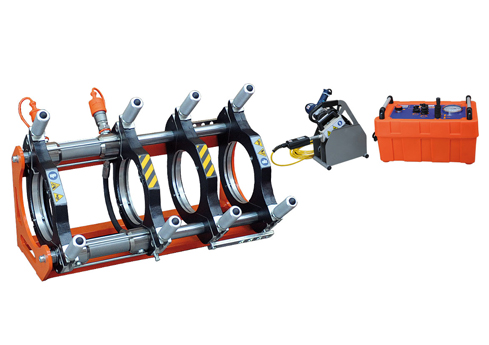

Delta 500 Easy Life

-

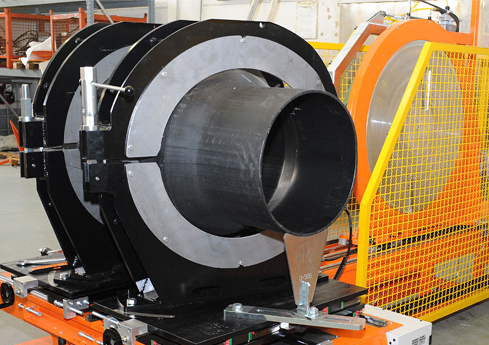

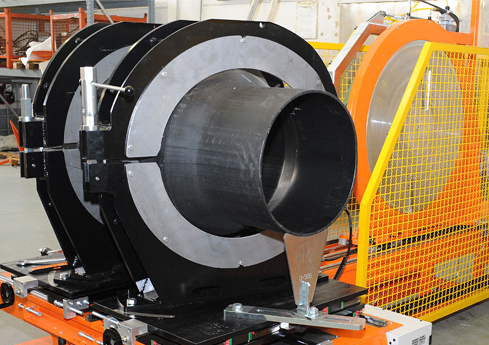

Thanks to a special gearcase, the DELTA 500 EASY LIFE is able to manage the welding process in a semi-automatic way from OD 200 to 500 mm.

With DELTA 500 EASY LIFE is possible to weld fittings such as elbows, tees, wyes and stub ends. This is possible because the 3rd clamp can be anchored to the 1st and 2nd (movable) and slide along with the pipe. The fitting have to be locked in the 4th clamp. Short neck stub ends can be welded with the help of a special tool (on request).

The electronic system guarantees the continuous repeat of the welding cycles and automatic control of the preset parameters, therefore the operator needs only to validate the welding phases. The user-friendly graphic display allows a quick setting of the desired parameters.

The EASY LIFE system can store up to 4000 welding cycles and sum them up into a PDF file. This report can be transferred to a PC/laptop through a USB port.

Possibility to pre-set 50 customized.

The EASY LIFE system data-logging now shows the time!

- A machine body with a steel bearing frame

- Clamps in steel

- Insert in steel with quick locking/unlocking system. No tools required

- Self detaching device: helps removing the heating plate during welding procedure

- An extractable heating plate with separate thermometer for reading the working temperature

- An extractable electric milling cutter with a safety microswitch and overload cutout

- Milling cutter’s plastic control box is protected by a metal frame

- Unlocking Milling Cutter, fast removing system to speed up the extraction from machine body

- An electrohydraulic gearcase EASY LIFE

- Digital electric connections box with the high precision (± 1°C) “Digital Dragon” temperature controller

- A milling cutter/heating plate support

Delta 630 Easy Life

-

With DELTA 630 EASY LIFE it is possible to weld fittings such as elbows, tees, wyes and stub ends. This is possible because the 3rd clamp can be anchored to the 1st and 2nd (movable) and slide along with the pipe. The fitting have to be locked in the 4th clamp. Short neck stub ends can be welded with the help of a special tool (on request).

Thanks to a special gearcase the DELTA 630 EASY LIFE is able to manage the welding process in a semi-automatic way from OD 280 to 630 mm.

The electronic system guarantees the continuous repeat of the welding cycles and automatic control of the preset parameters, therefore the operator needs only to validate the welding phases. The user-friendly graphic display allows a quick setting of the desired parameters.

The EASY LIFE system can store up to 4000 welding cycles and sum them up into a PDF file. This report can be transferred to a PC/laptop through a USB port.

Possibility to pre-set 50 customized.

The EASY LIFE system data-logging now shows the time!

The DELTA 630 EASY LIFE version has a useful trolley, easily maneuverable with its handgrip.

- A machine body with a steel bearing frame

- Clamps in steel

- Insert in steel with quick locking/unlocking system. No tools required

- Self detaching device: helps removing the heating plate during welding procedure

- An extractable heating plate with separate thermometer for reading the working temperature

- An extractable electric milling cutter with a safety microswitch and overload cutout

- Milling cutter’s plastic control box is protected by a metal frame

- Unlocking Milling Cutter, fast removing system to speed up the extraction from machine body

- An electrohydraulic gearcase EASY LIFE

- Digital electric connections box with the high precision (± 1°C) “Digital Dragon” temperature controller

- A milling cutter/heating plate support

All Terrain / Trailer

Delta 250 Trailer

-

DELTA 250 TRAILER: self-aligning hydraulic butt fusion machine, suitable for welding underpressure pipes for water, gas and other fluids up to Ø 250 mm (8" DISP). Built according to the International standards ISO 21307 HIGH PRESSURE (the clamps cylinders work with a pressure range that is three times and a half higher than the ISO Low Pressure ones. This enhances productivity, with a welding time saving of 60%).

DELTA 250 TRAILER is able to weld fittings like elbows, tees, Y-branches and flanges necks. Available in the 110 V and 230 V versions. Includes:

- A trailer-mounted machine body, easily removable from the trolley

- Fast-locking adapters system SMARTLocK RITMO Patented, thanks to which is possible to change adapters in few seconds

- An on-board electric milling cutter with a safety microswitch

- An extractable heating plate Teflon-coated (PTFE) equipped with an independent thermometer

- Two rollers

- An EASY LIFE control panel. It allows the operator to program and pilot all the welding duty cycle in an easy, fast and very intuitive way. It includes a data-logging system to store the welding data; report PDF file format.

Possibility to pre-set 20 customized. The EASY LIFE system can store up to 4000 joint reports

- A heating plate support which comes with a high-temperature-proof bag, which also avoid the heating element from being scratched

Delta 355 Trailer

-

DELTA 355 TRAILER welds HDPE, PP pipes and fittings for the transportation of gas, water and other fluids under pressure from 125 mm to 355 mm or from 4” IPS to 14” IPS. It is designed to work according to welding standard ISO 21307 High Pressure.

Machine composition:

- Removable control panel with data-logging, memory up to 4000 welding reports, GPS treacebility; USB port for welding report / data download / firmware upgrade. Easy-life welding control system: hardware and software have been developed to interact to each other sharing data during the entire workflow. Once set the welding parameters up, the system guarantees the repetition of the welding cycle, avoiding errors. The operator only have to confirm the work phases on the just pushing a button. Possibility to pre-set 20 customized

- Chassis is equipped with front steering wheels; parking brake, machine frame design for forklift lifting

- Removable machine body to work in tight spaces with shavings collection tray

- Dragging bar designed to weld between the 3rd and 4th clamp

- Ritmo patented insert quick release SMARTLOCK SYSTEM

- On-board electrical milling cutter with integrated locking handle system, safety switch-off device, motor thermic

protection and gas spring to easily lift/lower the facer

- On-board heating plate with protection frame and insulated protection bag; gas-spring for easy lift/lower the heating plate

- Heating plate and facer locking system for safe transportation

- Two hydraulic rollers for pipe loading and unloading

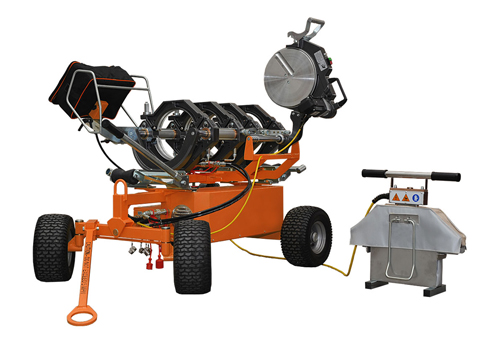

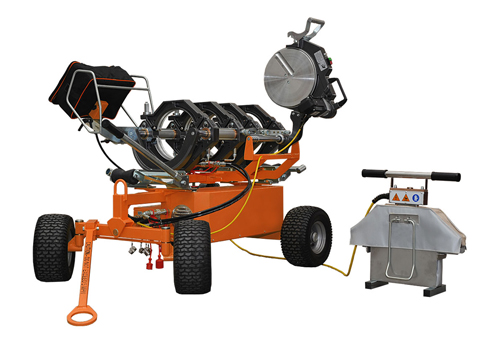

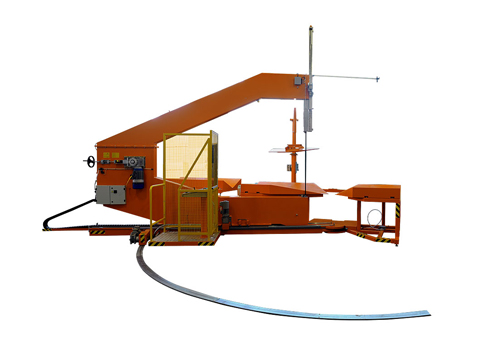

Delta 355 All Terrain

-

DELTA 355 ALL TERRAIN welds HDPE, PP pipes and fittings for the transportation of gas, water and other fluids under pressure from 125 mm to 355 mm or from 4” IPS to 14” IPS. It is designed to work according to welding standard ISO 21307 High Pressure. DELTA 355 ALL TERRAIN can be equipped with two types of engine: diesel low vibration and petrol.

The engine, like an electrical generator, indipendently gives the necessary power supply to the machine during all its

working and movement phases.

Machine composition:

- Removable control panel with data-logging, memory up to 4000 welding reports, GPS treacebility; USB port for welding report / data download / firmware upgrade. Easy-life welding control system: hardware and software have been developed to interact to each other sharing data during the entire workflow. Once set the welding parameters up, the system guarantees the repetition of the welding cycle, avoiding errors. The operator only have to confirm the work phases on the just pushing a button. Possibility to pre-set 20 customized

- Chassis is equipped with front steering wheels and rear traction; parking brake, machine frame design for forklift lifting

- Removable machine body to work in tight spaces with shavings collection tray

- Dragging bar designed to weld between the 3rd and 4th clamp

- Ritmo patented insert quick release SMARTLOCK SYSTEM

- On-board electrical milling cutter with integrated locking handle system, safety switch-off device, motor thermic

protection and gas spring to easily lift/lower the facer

- On-board heating plate with protection frame and insulated protection bag; gas-spring for easy lift/lower the heating plate

- Heating plate and facer locking system for safe transportation

- Two hydraulic rollers for pipe loading and unloading

- Kit for network power supply connection (upon request) excluding the machine engine and weld in closed enviroments

- 25 lt capacity tank for more than 12 working hours operating time

Delta 500 Trailer

-

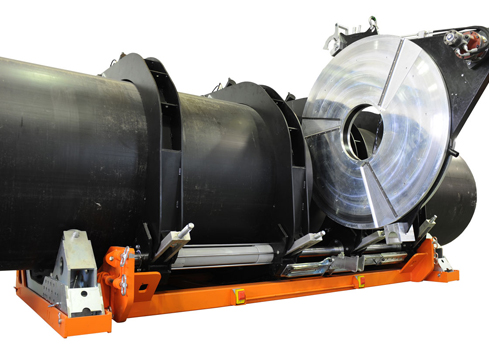

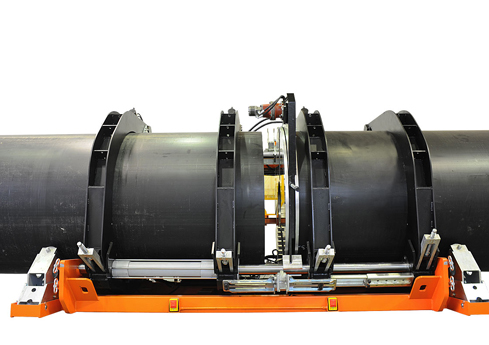

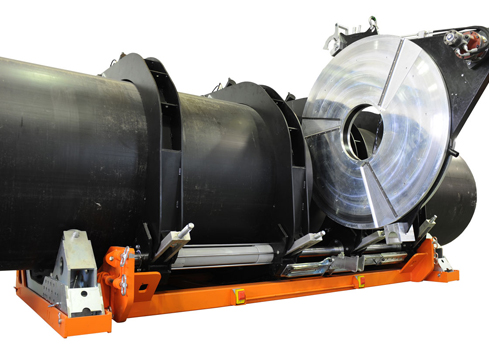

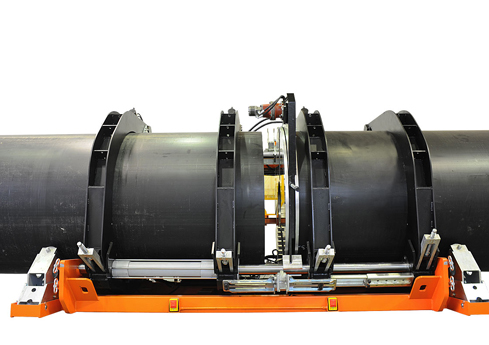

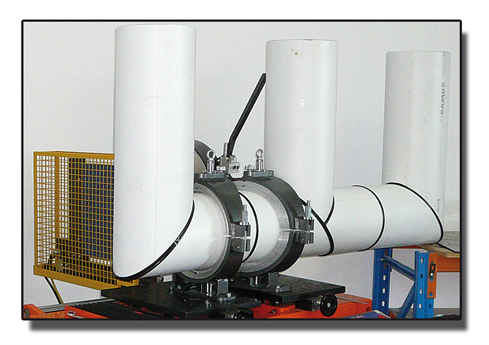

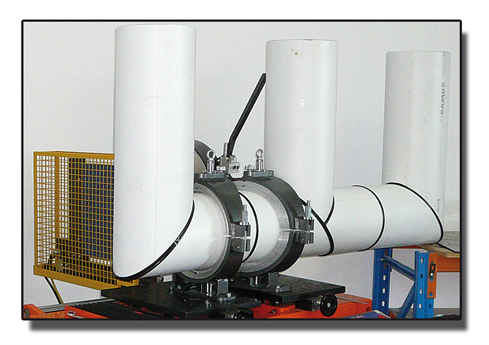

DELTA 500 TRAILER is a self-aligning fusion machine, suitable for welding thermoplastic pipes for the transport of water, gas and other fluids under pressure, up to Ø 500 mm.

Machine can fuse pipes according to the ISO 21307 High Pressure standard (pressure range is three times and a half higher than the ISO Low Pressure ones). This greatly enhances productivity allowing 60% time saving.

Standard machine features:

- Machine body mounted on a 4 wheeled chassis, easily removable for working in tight spaces

- New RITMO Patented assisted system to open/close/lift clamps-heater-facer

- Machine body with an automatic heating plate detaching device: helps removing the heating plate safely and fast

- Features the RITMO Patented fast-locking inserts, which allows to place and remove inserts in seconds

- 4 wheeled chassis with 2 steering wheels and a safety brake

- An on-board electric facer that is equipped with a safety microswitch to prevent from accidental starts, a thermal circuit breaker to protect motor and also features an ergonomic docking system and on/off switches

- An on-board heating plate Teflon-coated (PTFE) which comes with a high-temperature-proof bag, which also avoid the heating element from being scratched

- An EASY LIFE control panel with a large graphic display and GPS traceability, which is also removable from the machine body to be able to weld from outside the ditch. Allows the operator to program and pilot all the welding cycle in an easy, fast and very intuitive way. Includes a data-logging system to store full welding data, downloadable through a USB port straight into PDF files. The EASY LIFE system has the capability store up to 4000 joint reports.

Possibility to pre-set 20 customized.

- Two innovative lateral rollers that can be operated by a cordless drill

DELTA 500 TRAILER allows to easily weld fittings like elbows, tees, Y-branches and stub flanges.

Available in 230V single phase or three phase.

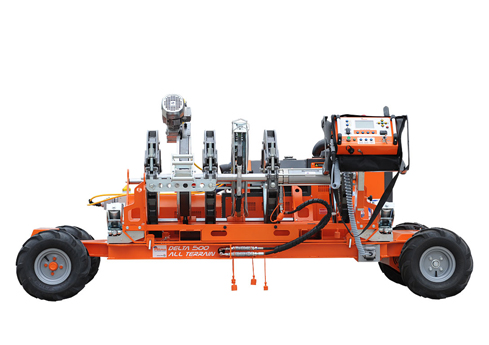

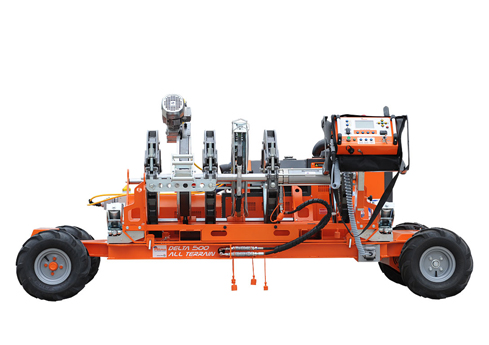

Delta 500 All Terrain

-

DELTA 500 ALL TERRAIN is powered by a low-vibration diesel engine and equipped with front steering wheels and rear traction. The machine is suitable for welding pressure pipes (HDPE, PP) for the transportation of water, gas and other fluids up to Ø 500 mm (20 "IPS).

Built according to the International standards ISO 21307 HIGH PRESSURE (machine works with a pressure range that is three times and a half higher than the ISO Low Pressure one. This enhances productivity, with a welding time saving up to 60%).

- Working range from Ø 200 to 500 mm (6" IPS ÷ 20" IPS)

- Welds fittings like elbows, tees, Y-branches and stub flanges

- New RITMO Patented assisted system to open/close/lift clamps-heater-facer

- Fast-locking system which allows to place and remove inserts in seconds

- Easy Life welding system

- GPS traceability

- Data-logging included

- Memory up to 4000 joint reports - downloadable straight into a PDF file

- Possibility to pre-set 20 customized

- USB port for firmware upgrade

- Intuitive control panel and large graphic display

- Machine body and on-board generator easily removable for working in tight spaces

- Machine can be powered using 230 V Three phase 50/60 Hz

- Wheeled chassis designed to be lifted using a forklift

- Two lateral rollers that can be operated by a cordless drill

- On-board electric facer that is equipped with a safety microswitch

- On-board generator removable for independent use

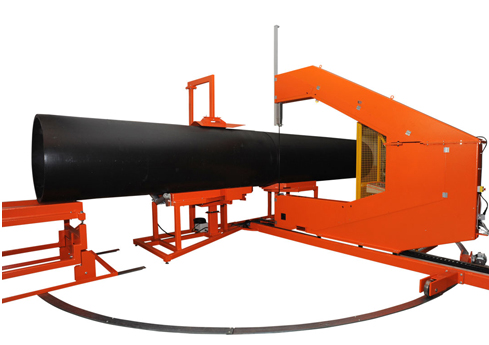

Delta 630 Trailer

-

DELTA 630 TRAILER is a self-aligning fusion machine, suitable for welding thermoplastic pipes for the transport of water, gas and other fluids under pressure, up to Ø 630 mm ( 24" DIPS)

DELTA 630 TRAILER allows to easily weld fittings like elbows, tees, Y-branches and stub flanges

Machine can fuse pipes according to the ISO 21307 High Pressure standard (pressure range is three times and a half higher than the ISO Low Pressure ones). This greatly enhances productivity allowing 60% time saving.

Standard machine features:

- Machine body mounted on a 4 wheeled chassis, easily removable for working in tight spaces; steel hydraulic clamping with the RITMO Patented fast-locking inserts, which allows to place and remove inserts in seconds; self detaching device: helps removing the heating plate during welding procedure

- 4 wheeled chassis with 2 steering wheels and a safety brake

- An on-board hydraulic electric facer that is equipped with a safety microswitch to prevent from accidental starts, a thermal circuit breaker to protect motor

- An on-board hydraulic heating plate Teflon-coated (PTFE) which comes with a high-temperature-proof bag, which also avoid the heating element from being scratched

- An EASY LIFE control panel with a large graphic display and GPS traceability, which is also removable from the machine body to be able to weld from outside the ditch. Allows the operator to program and pilot all the welding cycle in an easy, fast and very intuitive way. Includes a data-logging system to store full welding data, downloadable through a USB port straight into PDF files. Possibility to pre-set 20 customized. The EASY LIFE system has the capability store up to 4000 joint reports

- Two innovative lateral rollers that can be operated by a cordless drill

- Control panel for hydraulic movements

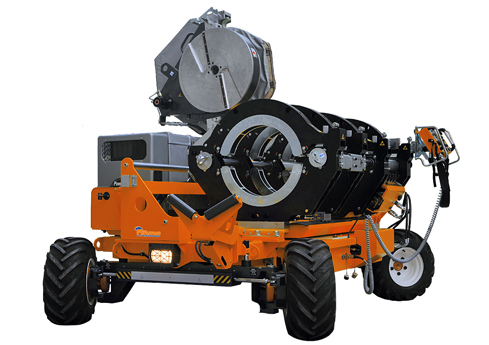

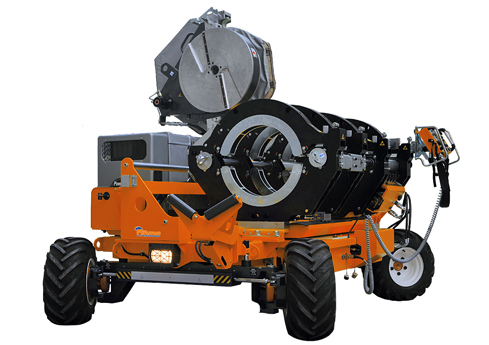

Delta 630 All Terrain

-

DELTA 630 ALL TERRAIN is the Pipe and Fittings FUSION Machine designed to face the toughest working conditions.

DELTA 630 ALL TERRAIN wants to mark a turning point to the world of Field Fusion. It stands out for being extremely easy to set up and work with. Take the heating plate and facer disconnecting system for example; the positioning / removal of the pipes is made without obstacles, giving the operator more time for what really matters.

Italian design, known for paying particular attention to details, gives DELTA 630 ALL TERRAIN many technical innovations that are indeed practical. Take the clamps hydraulic system, for instance - not only an aesthetical maneuver, but a protection against collisions while positioning the machine inside the trench. Take the low fuel consumption and soundproofing gear – protects the environment, your health and saves your money!

DELTA 630 ALL TERRAIN is available in 2 models:

DELTA 630 ALL TERRAIN CNC (automatic welding control system)

DELTA 630 ALL TERRAIN M (manual welding control system).

...and in two different settings, according to the welding regulation being used: ISO 21307 High Pressure vs ISO 21307 Low Pressure. When applying the first one, the clamps cylinders work with a pressure range that is three times and a half higher than the ISO Low Pressure ones. This enhances productivity, with a welding time saving of 60%.

Working range: Ø 225* - 630 mm; 8" IPS - 24" IPS; 8" DIPS ÷ 20" DIPS

*Ø 225 (from SDR 26 to SDR 7)

- 4 steering wheels drive

- Diesel-engine 2200 cc 22,7 Kw

- Self-contained with on-board generator

- Sliding 3rd CLAMP for fittings welding

- Automatic welding System “Easy Life”

- DATA-LOGGING with GPS

- Possibility to pre-set 20 customized

- Detachable Control Panel

- Remotely wire-controlled up to 12 m

- Trench-Friendly

- SmartLock Inserts

- Hydraulic Lifts

- Hydraulic-controlled Clamps and Milling cutter

- Climbs rough terrain up to 30%

Delta 1000 Trailer

-

DELTA 1000 TRAILER is a self-aligning fusion machine, suitable for welding thermoplastic pipes for the transport of water, gas and other fluids under pressure, up to Ø 1000 mm ( 36" IPS/DIPS).

Machine can fuse pipes according to the ISO 21307 High Pressure standard (pressure range is three times and a half higher than the ISO Low Pressure ones). This greatly enhances productivity allowing 60% time saving.

Standard machine features:

- Machine body mounted on a 4 wheeled chassis, easily removable for working in tight spaces; steel hydraulic clamping with the fast-locking inserts, which allows to place and remove inserts in seconds; self detaching device: helps removing the heating plate during welding procedure.

- 4 wheeled chassis with 2 steering wheels and a safety brake

- An on-board hydraulic electric facer that is equipped with a safety microswitch to prevent from accidental starts, a thermal circuit breaker to protect motor

- An on-board hydraulic heating plate Teflon-coated (PTFE) which comes with a high-temperature-proof bag, which also avoid the heating element from being scratched

- An EASY LIFE control panel with a large graphic display and GPS traceability, which is also removable from the machine body to be able to weld from outside the ditch. Allows the operator to program and pilot all the welding cycle in an easy, fast and very intuitive way. Includes a data-logging system to store full welding data, downloadable through a USB port straight into PDF files. The EASY LIFE system has the capability store up to 4000 joint reports.

Possibility to pre-set 20 customized

- Two hydraulic lateral rollers

- Control panel for hydraulic movements.

DELTA 1000 TRAILER allows to easily weld fittings like elbows, tees, Y-branches and stub flanges.

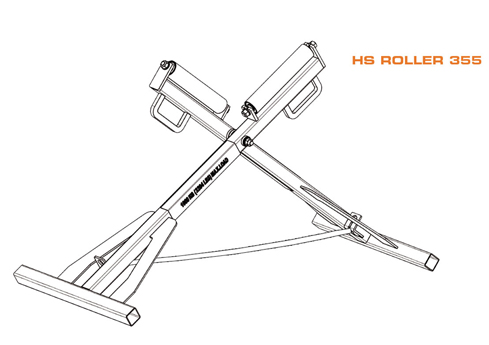

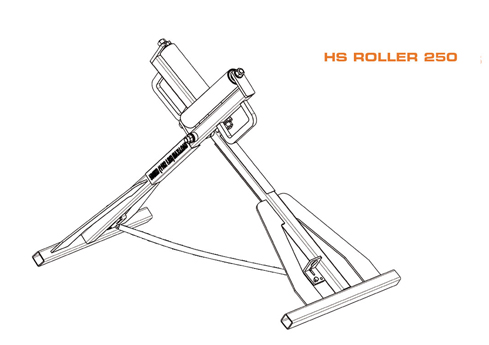

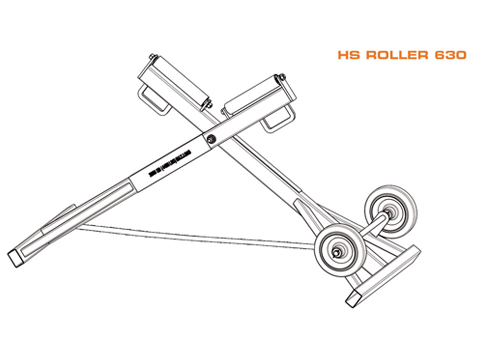

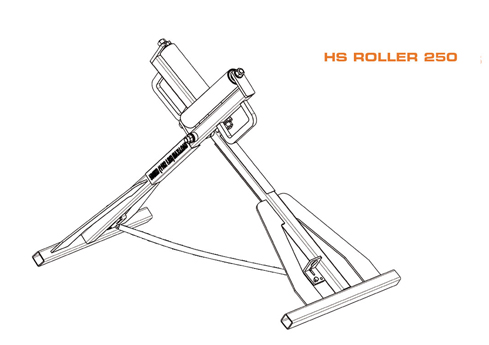

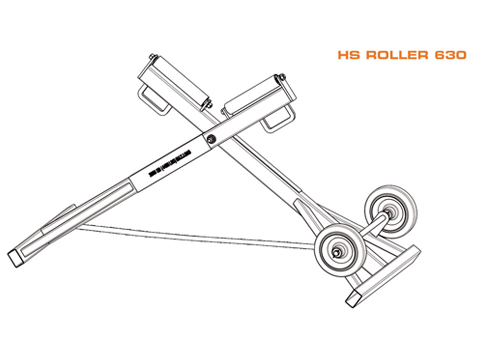

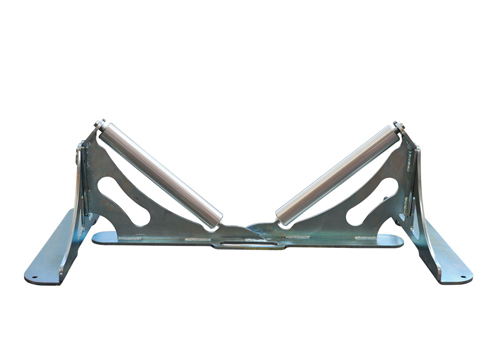

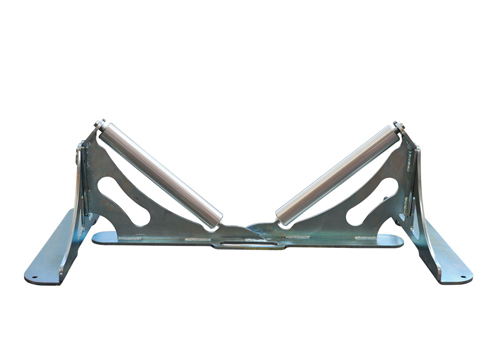

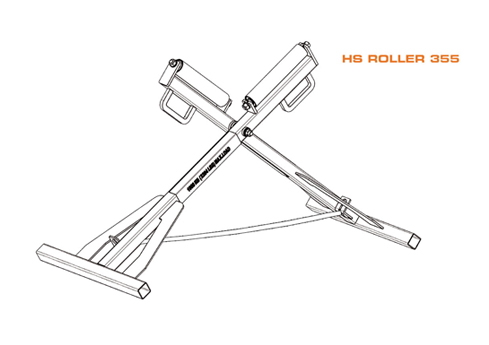

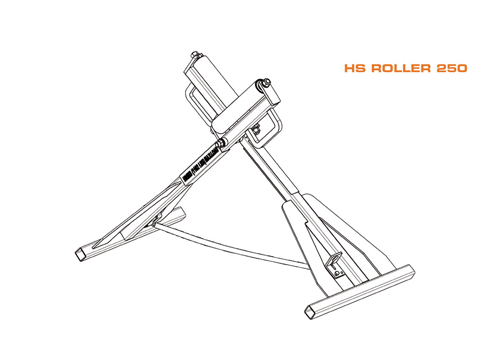

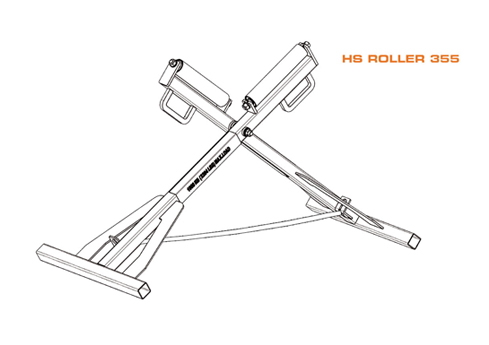

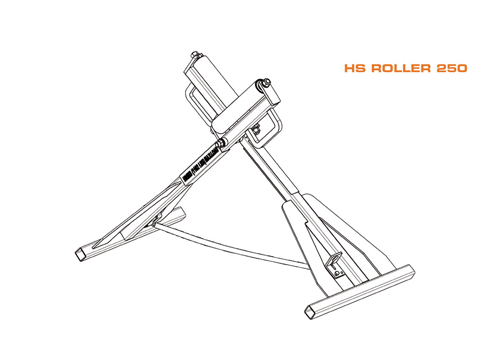

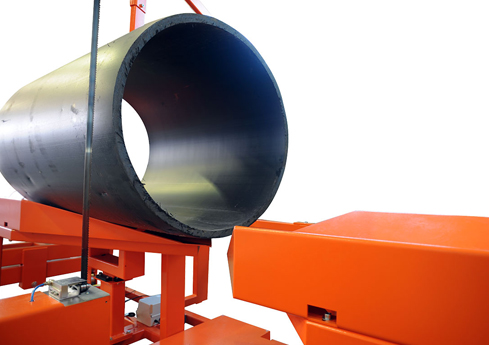

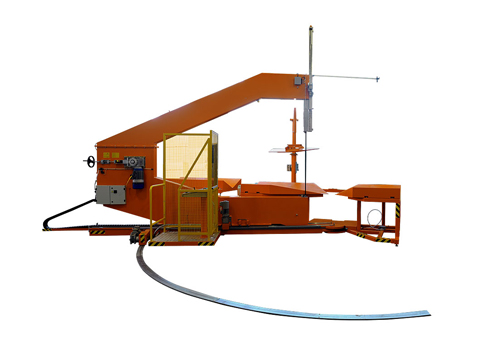

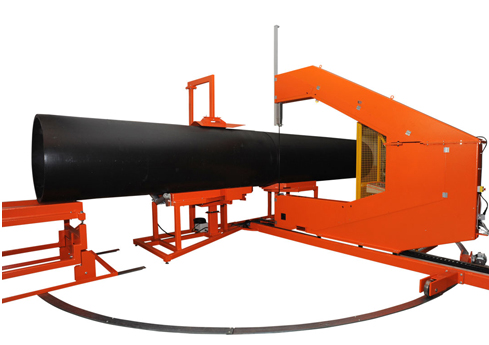

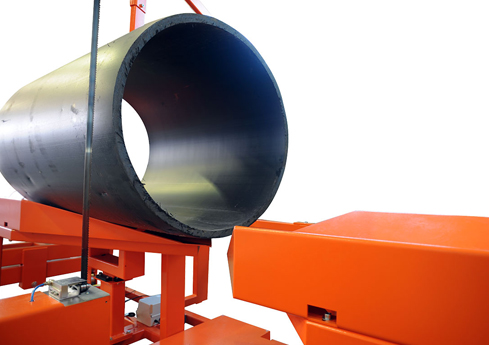

HS Rollers

-

ROLLER HS, this device is essential for supporting the pipes while they are being welded with the butt fusion machines. The rollers minimise pipe friction and drag force no matter which is the construction site condition.

Special design for ALL TERRAIN and TRAILER LINE.

This series features three different models:

- HS ROLLER 250 which can sustain pipes up to Ø 250 mm 8" IPS

- HS ROLLER 355 with a working range up to Ø 355 mm 14” IPS

- HS ROLLER 630 with a working range up to Ø 630 mm 24” DIPS

CNC - Fully Automatic

Delta Dragon CNC

-

Butt fusion welding can be managed automatically by using the DELTA DRAGON CNC system; this would eliminate any risk of error due to the operator.

It is available in two versions: SA with manual extraction of heating plate, FA with integrated mechanical extraction of heating plate.

The CNC system is available for the Delta Dragon 250 B and 315 B models.

The gearcase it is equipped with a compact and innovative plastic casing, which can resist to the most extreme job site working conditions; particular attention was paid to the connections as well, by applying military type plugs. An easy to use software and control panel allow to view the most widely used welding standards (ISO, GIS, DVS and other).

By selecting any one of the standard and pipe diameter/SDR, all the welding parameters (pressure, time, temperature) would be automatically calculated according to the standard itself. If the chosen welding cycle is not included in the standards listed above, it is possible to manually input the welding parameters (diameter, SDR, type of material, welding time and pressure…) by simply entering the “out of standard” mode. In both cases, the machine is able to automatically manage all the phases of the welding cycle, including milling and heating control.

At the end of the welding cycle, all data are stored in the in-built memory, up to 4000 records.

Serial ports enable the operator to connect the gearcase to a portable serial printer (to obtain an immediate report) or to a PC. The gearcase is equipped with a USB port for welding report in PDF and to firmware upgrade.

The complete configuration includes:

- a linear transducer applied to the machine body

- a extractable heating element SA or FA

- hydraulic hoses with non-drip quick couplings for connecting the gearcase to the machine body

- a milling cutter

- a transducer cable for connecting the gearcase to the machine body

- a milling cutter/heating plate support

Basic / Delta

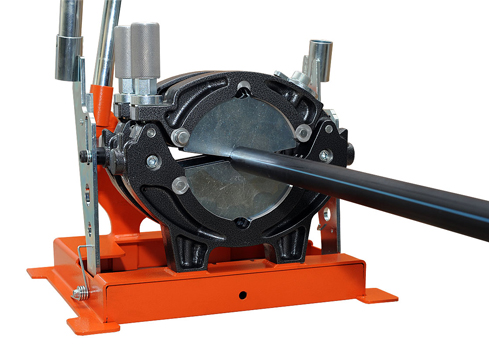

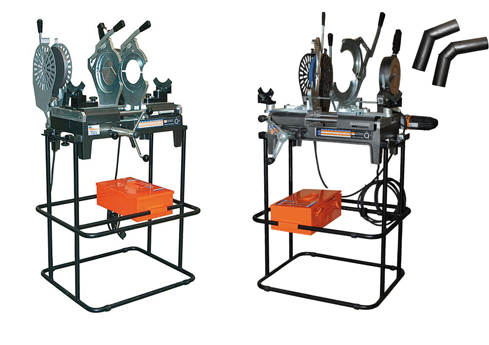

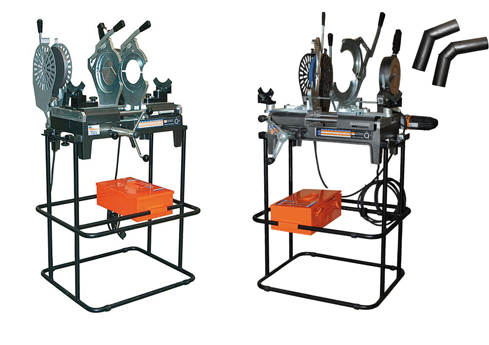

Basic 160

-

BASIC 160 is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate with DIGITAL DRAGON, high - precision electronic thermo-regulator

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase, with a clamp opening and closing lever

- A hydraulic hoses with non – drip quick couplings

- Adapters from Ø 40 to 140 mm

ON REQUEST (ACCESSORIES)

- Trolley

- Rollers

- THE INSPECTOR Data-logging

- Pre-insulated bag for heating plate

Basic 200

-

BASIC 200 is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate with DIGITAL DRAGON, high - precision electronic thermo-regulator

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase, with a clamp opening and closing lever

- A hydraulic hoses with non – drip quick couplings

- Adapters from Ø 63 to 180 mm

ON REQUEST (ACCESSORIES)

- Tool for flange necks

- Trolley

- Rollers

- THE INSPECTOR Data-logging

- Pre-insulated bag for heating plate

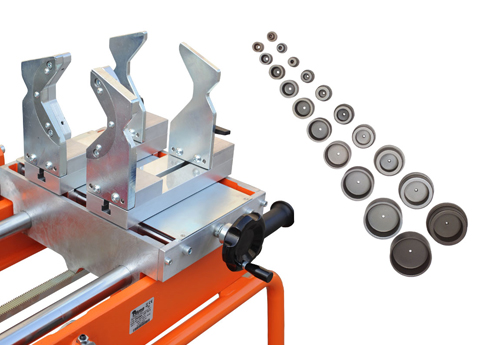

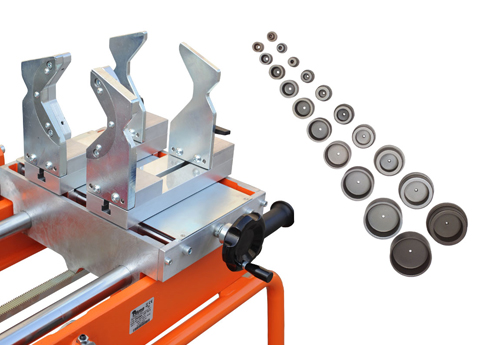

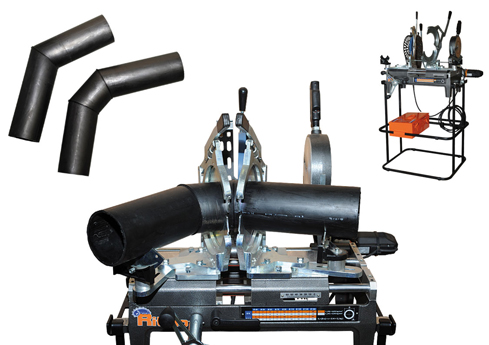

Basic 250

-

BASIC 250 is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate with DIGITAL DRAGON, high - precision electronic thermo-regulator

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase, with a clamp opening and closing lever

- A hydraulic hoses with non – drip quick couplings

- Adapters SMARTLocK (RITMO patented) from Ø 75 to 225 mm

ON REQUEST (ACCESSORIES)

- Tool for flange necks;

- Trolley;

- Rollers;

- THE INSPECTOR Data-logging

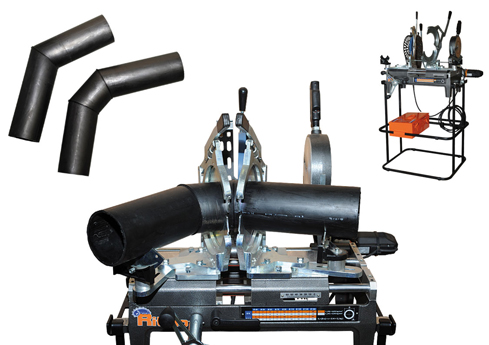

Basic 315

-

BASIC 315 is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate with DIGITAL DRAGON, high - precision electronic thermo-regulator

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase, with a clamp opening and closing lever

- A hydraulic hoses with non – drip quick couplings

- Adapters SMARTLocK (RITMO patented) from Ø 90 to 280 mm, Master adapters Ø 250 mm

ON REQUEST (ACCESSORIES)

- Tool for flange necks

- Trolley

- Rollers

- THE INSPECTOR Data-logging

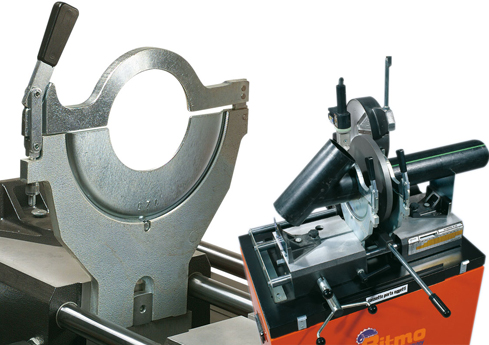

Basic 355

-

BASIC 355 is able to weld fittings such as elbows, tees, Y-branches and flange necks without any additional equipment by simply fixing the clamps’ drag bar.

- A machine body with 4 clamps and 2 hydraulic cylinders with fast non-drip couplings

- An extractable heating plate with DIGITAL DRAGON, high - precision electronic thermo-regulator

- An extractable milling cutter, with safety micro-switch

- An electrohydraulic gearcase, with a clamp opening and closing lever

- A hydraulic hoses with non – drip quick couplings

- Adapters SMARTLocK (RITMO patented) from Ø 125 to 315 mm, Master adapters Ø 250 mm

ON REQUEST (ACCESSORIES)

- Tool for flange necks

- Trolley

- Rollers

- THE INSPECTOR Data-logging

Delta 500

-

With DELTA 500 it is possible to weld fittings such as elbows, tees, wyes and stub ends. This is possible because the 3rd clamp can be anchored to the 1st and 2nd (movable) and slide along with the pipe. The fitting have to be locked in the 4th clamp. Short neck stub ends can be welded with the help of a special tool (on request).

Available in 230 V and 400 V.

- A machine body with a steel bearing frame

- Clamps in steel

- Insert in steel with quick locking/unlocking system. No tools required

- Self detaching device: helps removing the heating plate during welding procedure

- An extractable heating plate with separate thermometer for reading the working temperature

- An extractable electric milling cutter with a safety microswitch and overload cutout

- Milling cutter’s plastic control box is protected by a metal frame

- Unlocking Milling Cutter, fast removing system to speed up the extraction from machine body

- An electrohydraulic gearcase

- Digital electric connections box with the high precision (± 1°C) “Digital Dragon” temperature controller

- A milling cutter/heating plate support

ON REQUEST (ACCESSORIES)

- Clamps’ inserts from Ø 200 to 450 mm

- Tool for flange necks

- Electrical crane

- Special transport wooden case (DELTA 500 only)

- Special transport wooden case (machine body with trolley)

- Wooden case for inserts

- Machine body trolley

- Data-logging THE INSPECTOR

- Rollers

Delta 630

-

With DELTA 630 it is possible to weld fittings such as elbows, tees, wyes and stub ends. This is possible because the 3rd clamp can be anchored to the 1st and 2nd (movable) and slide along with the pipe. The fitting have to be locked in the 4th clamp. Short neck stub ends can be welded with the help of a special tool (on request).

Available in 230 V and 400 V.

- A machine body with a steel bearing frame

- Clamps in steel

- Insert in steel with quick locking/unlocking system. No tools required

- Self detaching device: helps removing the heating plate during welding procedure

- An extractable heating plate with separate thermometer for reading the working temperature

- An extractable electric milling cutter with a safety microswitch and overload cutout

- Milling cutter’s plastic control box is protected by a metal frame

- Unlocking Milling Cutter, fast removing system to speed up the extraction from machine body

- An electrohydraulic gearcase

- Digital electric connections box with the high precision (± 1°C) “Digital Dragon” temperature controller

- A milling cutter/heating plate support

ON REQUEST (ACCESSORIES)

- Clamps’ inserts from Ø 280 to 560 mm

- Tool for flange necks

- Electrical crane

- Special transport wooden case (machine body with trolley)

- Wooden case for inserts

- Machine body trolley

- Hydraulic rollers

- Data-logging THE INSPECTOR

- Rollers

Delta 800

-

With DELTA 800 it is possible to weld fittings such as elbows, tees, wyes and stub ends. This is possible because the 3rd clamp can be anchored to the 1st and 2nd (movable) and slide along with the pipe. The fitting have to be locked in the 4th clamp. Short neck stub ends can be welded with the help of a special tool (on request).

- A machine body with a steel bearing frame

- Self detaching device: helps removing the heating plate during welding procedure

- An extractable heating plate with separate thermometer for reading the working temperature

- An extractable electric milling cutter with a safety microswitch and overload cutout

- An electrohydraulic gearcase

- Digital electric connections box with the temperature controller

- A milling cutter/heating plate support

ON REQUEST (ACCESSORIES)

- Clamps’ inserts from Ø 500 to 710 mm

- Tool for flange necks

- Electrical crane

- Special transport wooden case (machine body with trolley)

- Wooden case for inserts

- Machine body trolley

- Data-logging THE INSPECTOR

- Rollers

Delta 1000

-

DELTA 1000 can weld fittings such as elbows, tees, wyes and stub ends. This is possible because the 3rd clamp can be anchored to the 1st and 2nd (movable) and slide along with the pipe. The fitting have to be locked in the 4th clamp. Short neck stub ends can be welded with the help of a special tool (on request).

- A machine body with a steel bearing frame

- Clamps and inserts in steel

- Self detaching device: helps removing the heating plate during welding procedure

- An extractable heating plate with separate thermometer for reading the working temperature

- An extractable electric milling cutter with a safety microswitch and overload cutout

- An electrohydraulic gearcase

- An electrical panel with power outlet for the heating plate and crane

- A milling cutter/heating plate support

ON REQUEST (ACCESSORIES)

- Clamps’ inserts from Ø 630 to 900 mm

- Tool for flange necks

- Electrical crane

- Machine body trolley

- Data-logging THE INSPECTOR

- Rollers

Delta 1200

-

DELTA 1200 can weld fittings such as elbows, tees, wyes and stub ends. This is possible because the 3rd clamp can be anchored to the 1st and 2nd (movable) and slide along with the pipe. The fitting have to be locked in the 4th clamp. Short neck stub ends can be welded with the help of a special tool (on request).

- A machine body with a steel bearing frame

- Clamps and inserts in steel

- Self detaching device: helps removing the heating plate during welding procedure

- An extractable heating plate with separate thermometer for reading the working temperature

- An extractable electric milling cutter with: Self detaching device, a safety microswitch and overload cutout

- An electrohydraulic gearcase

- Digital electric connections box with the temperature controller

- A milling cutter/heating plate support

ON REQUEST (ACCESSORIES)

- Clamps’ inserts from Ø 710 to 1100 mm; Master 1000 mm; 28" IPS ÷ 48" IPS

- Tool for flange necks

- Electrical crane

- Machine body trolley

- Data-logging THE INSPECTOR

- Rollers

Delta 1600

-

DELTA 1600 is a self-aligning welding machine with hydraulic clamps suitable for welding HDPE pipes for the transport of water and other fluids under pressure, up to Ø 1600 mm. The DELTA 1600 is designed in accordance to International standards (UNI 10565, ISO 12176-1). The DELTA 1600 can weld fittings such as elbows, tees, branches and flange necks.

- Robust machine body made of steel

- Steel hydraulic clamping

- Automatic detaching device of heating plate

- Raised platform deck for perfect monitoring of fusion process

- Easy to operate control panel

- INSPECTOR data logger compatible

- On board hydraulic control gearcase

- Pressure adjustment and pressure release valves for easy operations

- Hydraulically controller facer with safety microswitch

- Teflon coated heating plate with indipendent thermometer

ON REQUEST (ACCESSORIES)

- Hydraulic pipe lift rollers

- 4 wheeled trolley with extendable levellers for stabilization

- THE INSPECTOR data logging

- Steel inserts

- Electrical crane

Manual

Gamma 160

-

GAMMA 160 is a manual butt welding machine for HDPE and PP pipes up to Ø 160 mm.

GAMMA 160 features special jaws for manufacturing elbows.

Machine can also weld moulded fittings like bends, tees, wyes (Y) and flange necks up to Ø160 mm; short flange necks can be welded with the help of a stub end holder (on request), applied to the clamps. Machine body of GAMMA 160 is compact and easy to transport.

- A machine body with pressure regulating device of the bench vice closure

- A steel frame for the support of the machine body

- Steel sliding clamps with fast closing system

- An heating plate with an electronic temperature control device

- An electrically controlled milling cutter for levelling the ends of the pipe and/or fitting, with safety micro-switch against accidental starters

- A support for the milling cutter and the heating plate

- Steel adapters Ø 40, 50, 63, 75, 90, 110, 125, 140 mm

- A case for the adapters

ON REQUEST (ACCESSORIES)

- Tool for flange necks

- Thin single clamp

Delta 160 M

-

DELTA 160 M is a manual butt fusion welder for pipes up to Ø 160 mm.

Leading particulars are the restricted weight, minimum overall dimensions and versatility.

Featuring: a machine body, two clamps, an extractable electric milling cutter provided with a safety micro-switch, an extractable heating plate (with an independent thermometer to see the real working temperature and an electronic thermoregulator “Digital Dragon” with display), and two lateral supports on request.

DELTA 160 M have a locking device clamps - aligner RITMO Patented, that helps the operator to apply the necessary welding force. The welder is equipped with a clamp-aligner system patented by Ritmo, thus allowing the operator to apply the correct welding force.

The Digital Dragon is an high precision electronic thermoregulator (± 1° C accuracy) with digital display and regulating buttons. This new system includes Led indicators to check if the machine is working normally (live tension and working temperature), contingent probe’s failures and/or temperature anomalies.

ON REQUEST (ACCESSORIES)

- Clamps’ inserts from Ø 32 to 140 mm

- Lateral support

- Trolley for machine transportation and support

- Rollers

Accessories

App - Set & Go

-

“SET & GO” FREE APP developed by RITMO for its butt fusion machines.

“SET & GO” calculates the welding parameters in a simple, fast and useful way.

Through easy steps, like selecting the machine model, setting up the pipe data and choosing the welding standard, “SET & GO” tells you immediately your welding parameters!

The welding cycle is assisted and guided, step-by-step, by a handy timer with countdown function.

“SET & GO” … set to the future!

The Inspector

-

THE INSPECTOR - DATA LOGGING that controls, records and generates a PDF report of the entire welding process. The Inspector is an “open system” that can be used with Ritmo machines or others. The large graphic display allows an easy reading of welding reports. THE INSPECTOR is installed in a hard case made of PP, with protection degree IP 67. It is sold with a bag that contains the data logging and the battery charger with international adapters.

- Preloaded Major Welding Standard (ISO, DVS, and others)

- Memory of 1000 cycles - USB port for Welding Report in PDF

- Integrated GPS - Firmware upgradable via USB

- Battery operated (24 hr of operational work)

- Battery charger with international adapters

- Built-in plastic case in PP with IP67 protection class

- Transport bag

- Applicable to Ritmo machines and other

Standard composition

- THE INSPECTOR, transport bag, battery, charger and International adapters

On request

- Transducer connection cables; the cable and the transducer may vary according to the welder model (see price list for the correspondent codes).

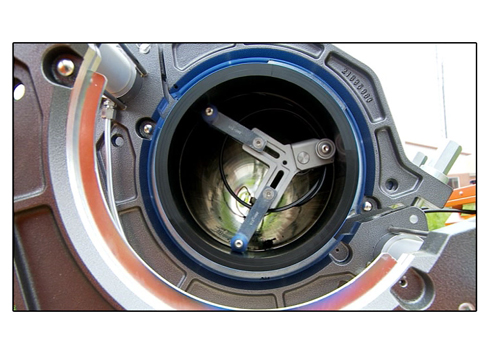

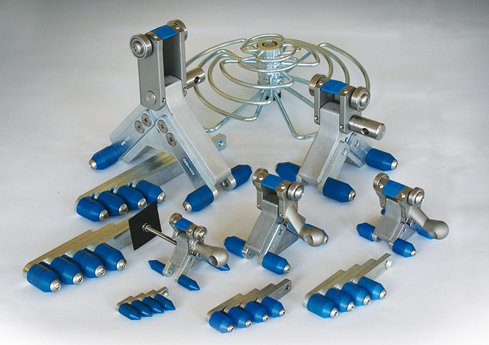

RID - Internal Debeader

-

Internal Debeader by RITMO S.p.A. covering a range from Ø 90 up to 500 mm!

ADVANTAGES: Intuitive and easy to use, accurate, versatile, composed of few parts.

A complete kit set is composto by:

- 6 pcs of alloy rods 2,15 mtr each (one is acting as turn handle)

- 5 pcs of center rings to ensure that the rods are in center of the pipe

- Alloy rods are delivered in a special carrying bag with a handle

- Internal Debeader Head 90 - 110 mm

- Internal Debeader Head 125 - 160 mm

- Internal Debeader Head 160 - 200 mm

- Internal Debeader Head 225 - 315 mm

- Internal Debeader Head 355 - 500 mm

Internal Debeader Heand can be ordered separately too.

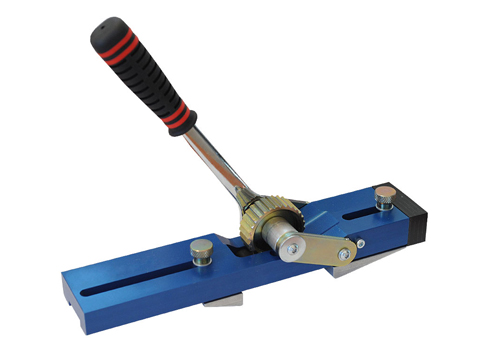

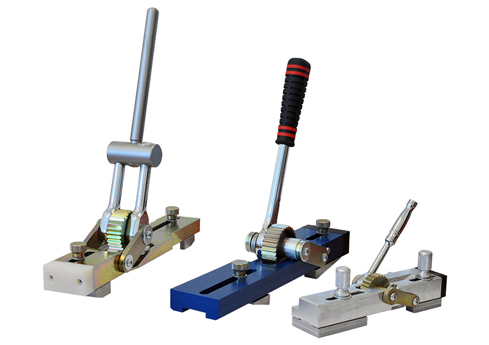

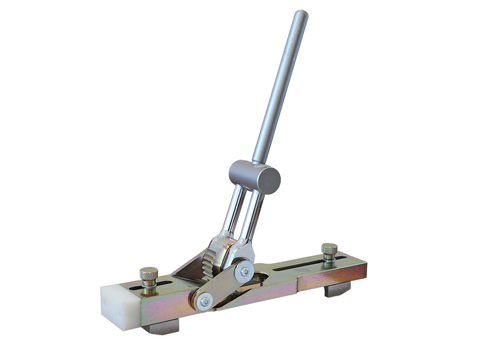

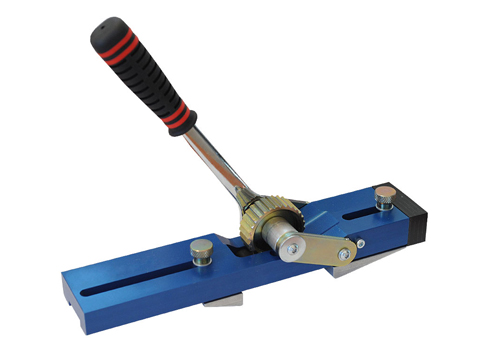

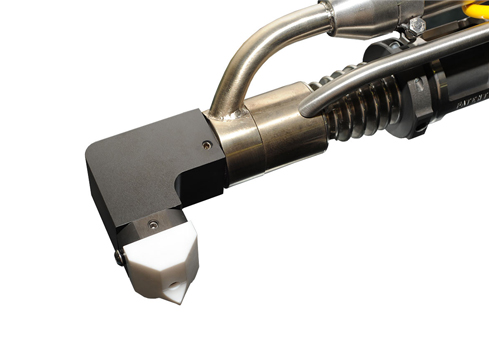

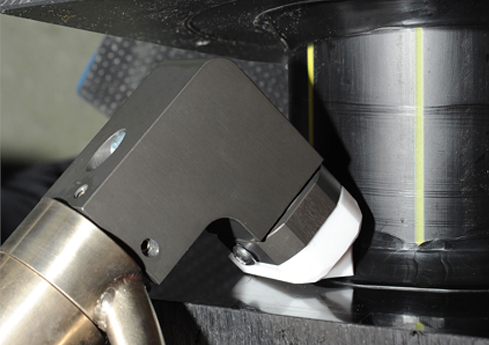

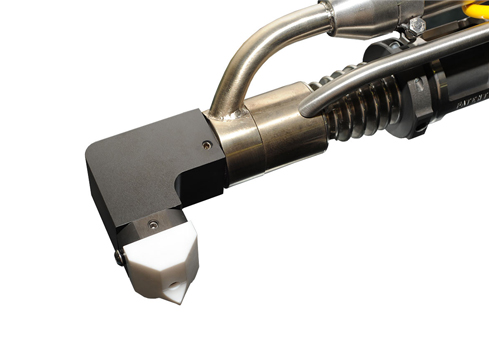

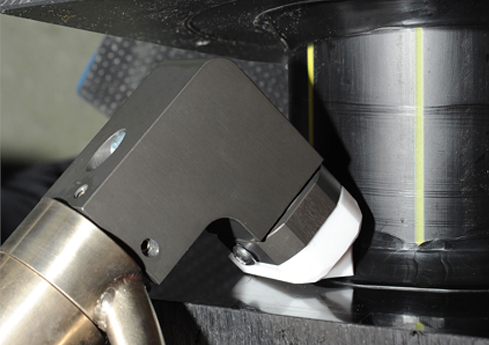

RED - External Debeader

-

RED - Ritmo External Debeader

Intuitive, Easy to use, Accurate, Versatile.

For pipes up to 1200 mm and sheets

External Debeader by RITMO S.p.A. covering a range from Ø 63 up to 1200 mm!

Designed to remove the external bead from a complete butt fusion welded joint.

The tool knocks onto the pipe bead, then alignment blocks slide against the pipe surface to guide it around the pipe

The blade cuts the under the bead and the handle helps pull the tool around the pipe, cutting the bead away.

RED works on flat surfaces too and removes the bead from plastic sheets without the guides for pipes.

Available in three different sizes

- RED 63 - 125

- RED 90 - 400

- RED 400 - 1200

Roller 355

-

ROLLER 355, this device is essential for supporting the pipes while they are being welded with the butt fusion machines.

The rollers minimise pipe friction and drag force no matter which is the construction site condition.

- ROLLER 355 which can sustain pipes up to Ø 355 mm. Easy to use and light.

Roller 1000

-

ROLLER 1000 is essential for supporting the pipes while they are being welded with the butt fusion machines.

The roller minimise pipe friction and drag force no matter which is the construction site condition.

- ROLLER 1000 which can sustain pipes from Ø 315 to 1000 mm. The structure is light weight, so it is easy to carry and use.

HS Rollers

-

ROLLER HS, this device is essential for supporting the pipes while they are being welded with the butt fusion machines. The rollers minimise pipe friction and drag force no matter which is the construction site condition.

Special design for ALL TERRAIN and TRAILER LINE.

This series features three different models:

- HS ROLLER 250 which can sustain pipes up to Ø 250 mm 8" IPS

- HS ROLLER 355 with a working range up to Ø 355 mm 14” IPS

- HS ROLLER 630 with a working range up to Ø 630 mm 24” DIPS

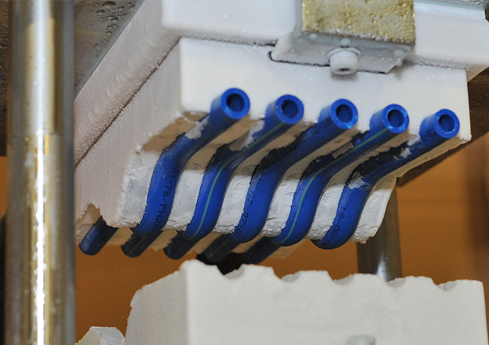

Electrofusion

High Pressure

Elektra Light

-

ELEKTRA LIGHT is an universal electrofusion machine, suitable for welding pipe/fittings for the transport of gas, water and for welding fire sprinkler system (HDPE, PP, PP-R couplings from 8 to 48 V).

The Elektra Light machine is made in compliance with international standards.

This is welding machine’s structure is light weight, so it is extremely easy to carry around.

Composed of:

machine body, an in built memory with 325 welding cycles - report PDF file - featuring the possibility of transferring data to a Pc/Laptop.

STANDARD COMPOSITION

- Elektra Light

- Universal adapter Ø 4,0 - 4,7 mm

- Laser scanner

- Trevira bag

- Manual scraper

ON REQUEST (ACCESSORIES)

- Data transfer adaptor DB9M/USB

Elektra 315

-

ELEKTRA 315 is an universal electrofusion machine, suitable for welding pipe/fittings for the transport of gas, water and for welding fire sprinkler system (HDPE, PP, PP-R couplings from 8 to 48 V).

The Elektra 315 machine is made in compliance with international standards. Composed of:

Machine body, intuitive control panel an in built memory with 500 welding cycles, featuring the possibility of transferring data to a Pc/Laptop and an laser scanner - barcode reading system that allows the automatic setting of the welding parameters. Report in PDF file.

STANDARD COMPOSITION

- Elektra 315

- Universal adapter Ø 4,0 - 4,7 mm

- Laser scanner

- Transport case

- Manual scraper

ON REQUEST (ACCESSORIES)

Kit for data transfer Machine to Pc/Laptop (adaptor DB9M/USB and Ritmo Transfer)

Elektra 500

-

ELEKTRA 500 is an high performance universal electrofusion machine, suitable for welding HDPE, PP, PP-R couplings (from 8 to 48 V).

Composed of:

- machine body surrounded by a tubular steel frame, thus creating a protective structure that gives to the welding design and functionality while also serving as transport handle and cable winding

- large graphic display that stands out for the size and resolution of the icons, making them easy to read in the setting and welding stages - intuitive control panel that simplifies and speeds up the setting of the welder

- universal connectors; no need of adapters

- GPS (on request) useful in jobsites where traceability is necessary

- a laser scanner - barcode reading system that allows the automatic setting of the welding parameters. There are nonetheless two manual settings available: by setting the welding tension/time parameters, and by introducing the numerical code indicated under the bar code, in order to recognize automatically the welding parameters

- internal memory of 4000 welds; the name of the operator among with the traditional welding data can be generated in PDF format. These reports can be downloaded to a PC through a USB port

- USB port allows updating the welder firmware, the reports download or a printer ESC-POS connection

STANDARD COMPOSITION

- Elektra 500

- Universal adapter Ø 4,0 - 4,7 mm

- Laser scanner

- Transport case

- Manual scraper

ON REQUEST (ACCESSORIES)

- GPS

- Printer ESC-POS

Elektra 1000

-

ELEKTRA 1000 is an high performance universal electrofusion machine, suitable for welding HDPE, PP, PP-R couplings (from 8 to 48 V).

Composed of:

- machine body surrounded by a tubular steel frame, thus creating a protective structure that gives to the welding design and functionality while also serving as transport handle and cable winding

- large graphic display that stands out for the size and resolution of the icons, making them easy to read in the setting and welding stages - intuitive control panel that simplifies and speeds up the setting of the welder

- universal connectors; no need of adapters

- GPS (on request) useful in jobsites where traceability is necessary

- a laser scanner - barcode reading system that allows the automatic setting of the welding parameters. There are nonetheless two manual settings available: by setting the welding tension/time parameters, and by introducing the numerical code indicated under the bar code, in order to recognize automatically the welding parameters

- internal memory of 4000 welds; the name of the operator among with the traditional welding data can be generated in PDF format. These reports can be downloaded to a PC through a USB port

- USB port allows updating the welder firmware, the reports download or a printer ESC-POS connection

STANDARD COMPOSITION

- Elektra 1000

- Universal adapter Ø 4,0 - 4,7 mm

- Laser scanner

- Transport case

- Manual scraper

ON REQUEST (ACCESSORIES)

- GPS

- Printer ESC-POS

Elektra Top

-

ELEKTRA TOP is a high performance universal electrofusion machine, characterized by its light weight and high efficiency, The machine is suitable to weld HDPE, PP, PP-R couplings (from 8 to 80 V) and has an approximate diameter working range* up to 1600 mm. (½” IPS - 63” IPS)

- Steel machine frame containing the newest Ritmo’s electrofusion technology. Safe transportation thanks to Elektra Top’s wide handle which enables a perfect grip and cable winding.

- 4000 welding reports memory.

- Welding reports can be downloaded directly in PDF file format, CSV, or BIN (Software Ritmo Transfer required) in to an external pen drive through the machine usb port, which allows also the welder firmware updating, or a printer ESC-POS connection.

- Large graphic display 6,5” LCD.

- Intuitive control panel.

- Universal connectors 90° 4 - 4,7 mm; no need of adapters.

- Laser scanner - barcode reading system that allows the welding parameters automatic setting. Possibility to set the welding parameters manually: by setting the welding tension/time, or by entering the fiitting’s numerical code indicated under the bar code. Traceability function ISO 12176.

- GPS (on request).

Elektra Top is available in 110 V with approximate diameter working range* Ø 20 ÷ 500 mm (½” IPS ÷ 20” IPS)

STANDARD COMPOSITION

- Elektra TOP

- Universal adapter Ø 4,0 - 4,7 mm

- Laser scanner

- Transport case

- Manual scraper

ON REQUEST (ACCESSORIES)

- GPS

Low Pressure / Drainage

Universal 315 V1

-

UNIVERSAL 315 V1 Electrofusion welding machine:

- Low pressure HDPE Ø 32 ÷ 315 mm;

- High pressure HDPE Rollmaplast and PP-R from 20 ÷ 315 mm (optional cables)

- Graphic display

- Auto recognition of fittings

- Memory with 350 welding reports

- Report in PDF File

- Serial/USB connector (optional)

- Self-compensation of the current supplied

(according to the ambient temperature)

- Transport case

- Firmware upgradable via USB

STANDARD COMPOSITION

- Carrying suitcase

- Welding cables * (A00, A01, A02, A03, A04, A00+)

- Welding extension cable

- Manual scraper

- Shoulder belt

ON REQUEST (ACCESSORIES)

- serial/USB adapter (welding data transfer)

- welding cable** (A05, A06, A07)

* WLDING CABLES - STANDARS COMPOSITION

A00 32 ÷ 160 mm Coes, Akatherm, Eurofusion, Geberit, Valsir, Wavin Vulcathene

A00+ 200 ÷ 315mm Wavin (Waviduo)

A01 200 ÷ 315mm Akatherm, Valsir, Wavin (Wavisolo), Eurofusion

A02 200 ÷ 315mm Geberit

A04 200 ÷ 315mm Coes (Coestilen)

** WLDING CABLES - ON REQUEST

A05 20 ÷ 63mm (PP-R) Coes (Coestherm not 8 - 48 V)

A06 20 ÷ 160mm (PE 80) Wavin/Rollmaplast (I) 20 ÷ 110mm (PE 100 - PP-R) Wavin/Rollmaplast (LI - Tigris Green) A07 125 ÷ 315mm (PE 100) Wavin/Rollmaplast (LI)

Mustang 160 V1

-

This electrofusion machine is suitable for welding electrofusion fittings in HDPE from Ø 32 to Ø 160 mm, for low-pressure conduits.

MUSTANG 160 V1 automatically detects connection to the fitting to be welded and compensates current supplied according to ambient temperature.

It is also capable of detecting any malfunction that could occur before or during welding procedures.

MUSTANG 160 V1 is made in compliance with the current safety standards and Directives, and the structure is light weight which makes it extremely easy to carry around.

STANDARD COMPOSITION

- Mustang 160 V1

- Cables with pins

- Transport case

- Manual scraper

Accessories

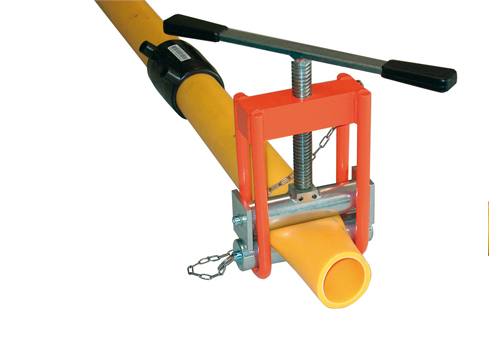

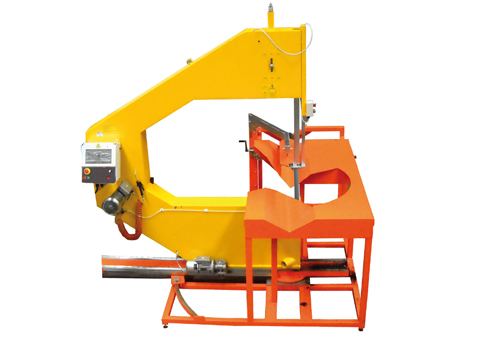

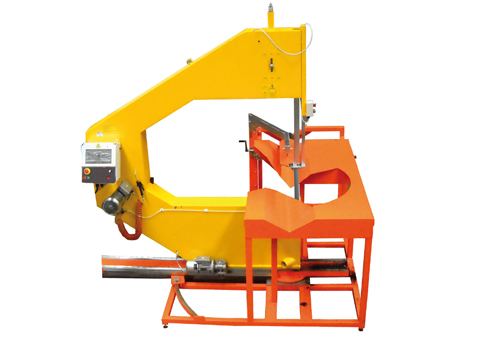

Pipe Cutters

-

PIPE CUTTERS are professional tools, essential for the manual cut of plastic pipes up to Ø 315 mm.

The TC 108, T1, TU 75, TU 140, T3 and T4 pipe cutters are made with the very best alloys, and are very manageable and practical to use.

The pipe cutters can be fitted with various special blades with appropriate cutting heights and penetration capacities to cut pipes of different materials. The TC 108 and T1 pipe cutters (with special blades) can cut Copper (Cu) and multilayer (PEx/Al,PPr/Al, etc.) pipes.

STANDARD COMPOSITION

- Pipe cutter with blade:

- TC 108 + blade Ø 22 mm + blade Ø 18 mm

- T1 + blade Ø 25 mm

- TU 75 + blade Ø 44 mm

- TU 140 + blade Ø 53 mm

- T3 + blade Ø 53 mm

- T4 + blade Ø 53 mm (HDPE 80 - HDPE 100: Ø 250 SDR 13>; Ø 315 SDR 17,5 >)

- Carrying case (for the T4 pipe cutter, only)

ON REQUEST (ACCESSORIES)

- Blades of different diameters and heights

Shears

-

SHEARS are professional tools, essential for the manual cut of plastic pipes, such as PP and PP-R up to PN 25; HDPE, PB and PVDF up to Ø 75 mm.

The C2 AC and C3 AC shears are entirely made in steel.

- C42

available green or orange color

- C2 AC

- C3 AC

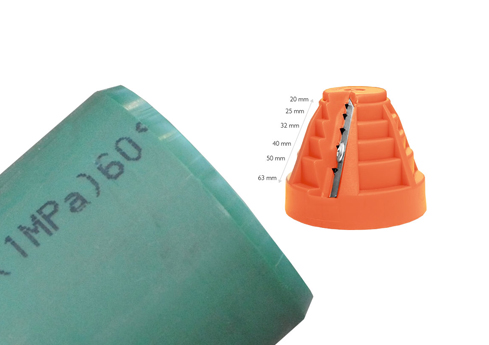

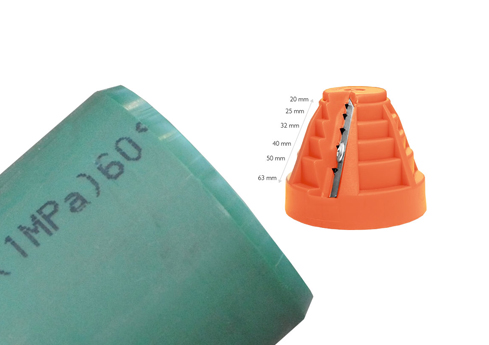

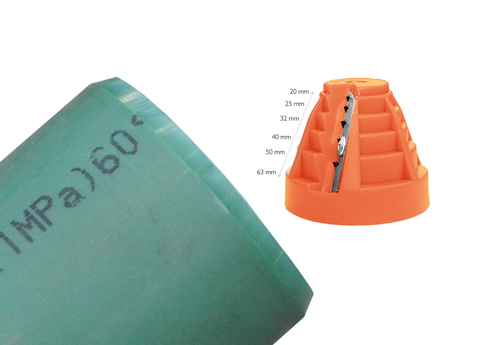

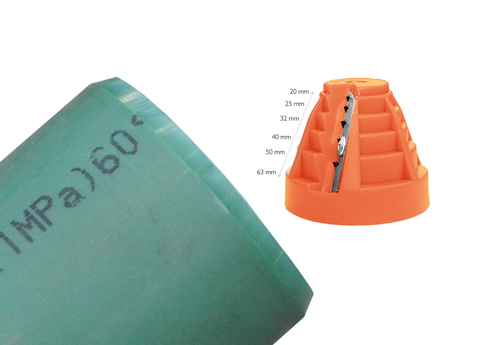

Turbo

-

TURBO is the innovative pipe scraper patented by RITMO for pipes and fittings ranging from Ø 20 to 63 mm SDR 6 to 11.

TURBO is simple and easy to use.

This incredible pipe scraper can work in confined spaces substantially reducing working times, especially during repair operations.

The rotating tool allows fast and precise scraping, without defects. Its blades also allow the perfect facing of the pipe ends which have been roughly cut due to a situation which makes the use of a pipe cutter difficult, like narrow spaces.

Six different sizes of the TURBO are available, according to the pipe size.

TURBO has to be used with a cordless driver.

MODELS

- 20

- 25

- 32

- 40

- 50

- 63

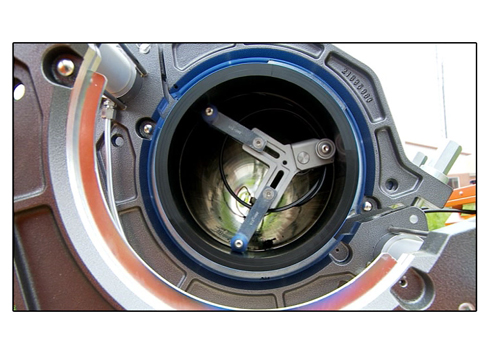

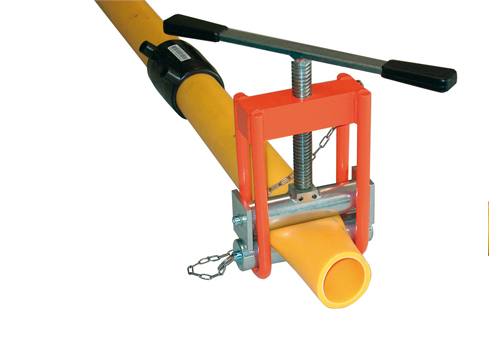

Pipe Scrapers PS

-

PS 180 and PS 400 are professional rotary scrapers, essential to prepare the plastic pipes and fittings before electrofusion welding.

The tools has an adjustable chuck covering all the Ø of the working range, and a blade holder orbital arm.

The PS series guarantees a constant and regular removal of the shaving.

The scrapers blade holder permits the scraping of the entire electrical sleeve's lenght, most useful when doing on site repairs.

STANDARD COMPOSITION

- PS 180 supplied with transport bag and spare blade

- PS 400 supplied with transport case and spare blade

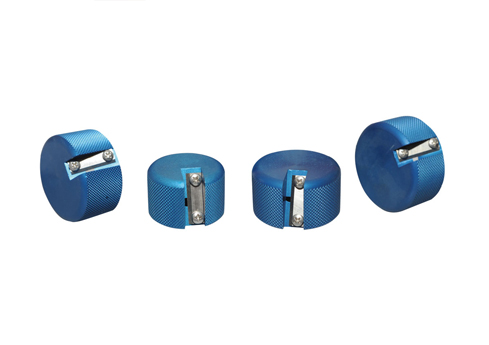

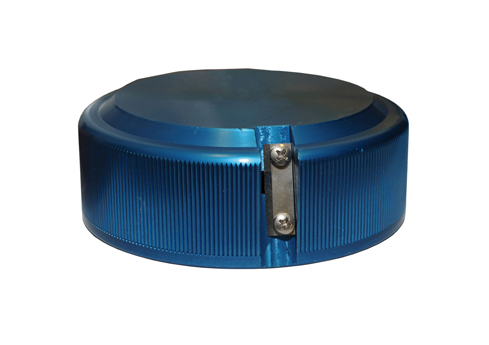

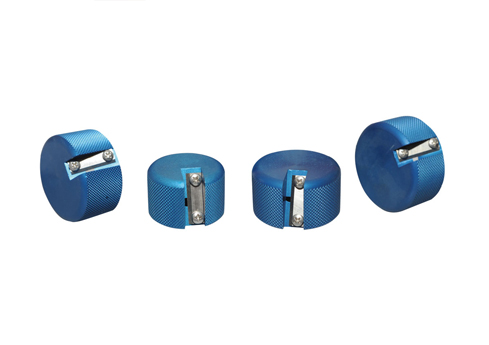

Pipe Scrapers RTC

-

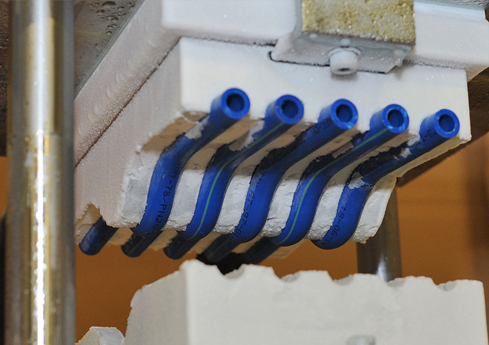

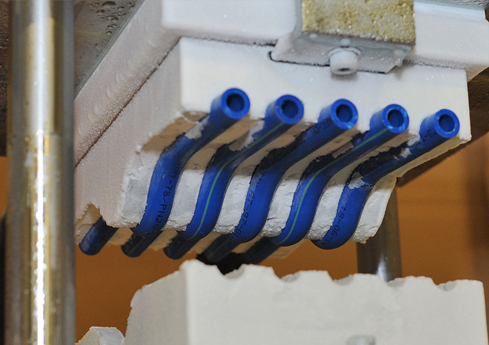

RTC 160 - 315 - 710

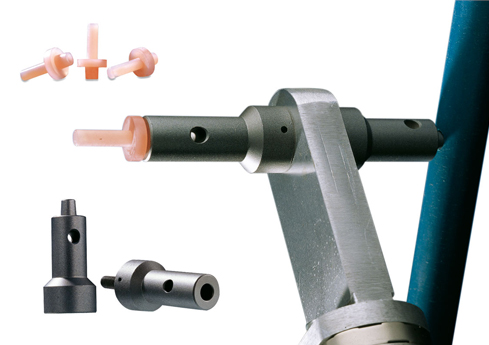

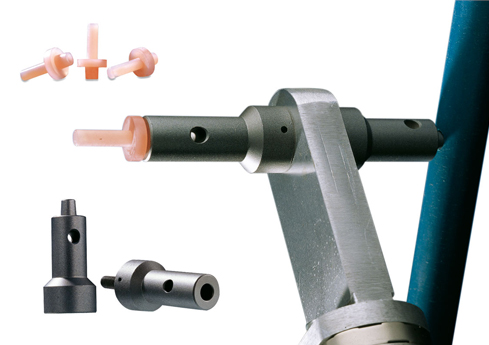

These professional rotary scrapers, designed and patented by Ritmo, are essential to prepare the plastic pipes and fittings before electrofusion welding.

Practical and handy, the pipe scrapers remove the oxidation layer caused by weather and ultraviolet rays. If not removed, the oxidation layer would severely compromise the quality of the joint. Among the main construction features there is a device that makes it possible to maintain the thickness of the continuous chip constant, even if the pipe is misshaped, and to adjust the length of the surface to scrape according to the depth of the electrical coupler.

The RTC 710 features an extendable arm to scrape the exact length of the electrical coupler, which is an advantage when having to perform maintenance/repair jobs in the building site. The main chuck has four extendable arms that clamps directly the inside diameter of the pipe.

STANDARD COMPOSITION

- Pipe scraper - Adapters kit (except for RTC 710)

- Spare blade - Handwheel key (for RTC 315)

- Aluminum transport case

- Screwdriver and small cutter

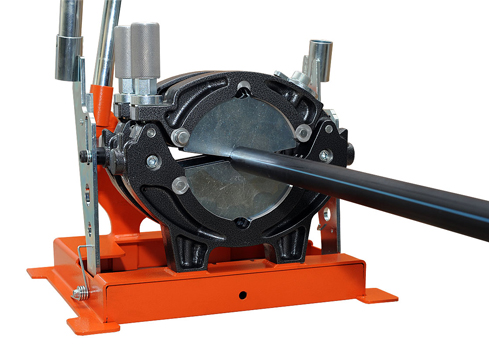

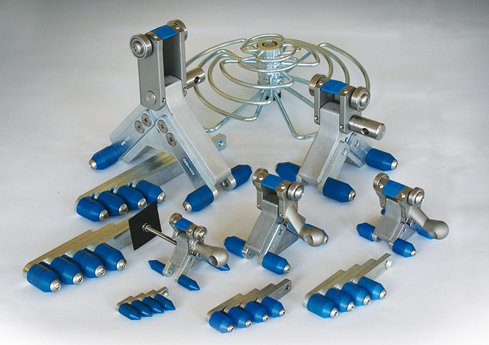

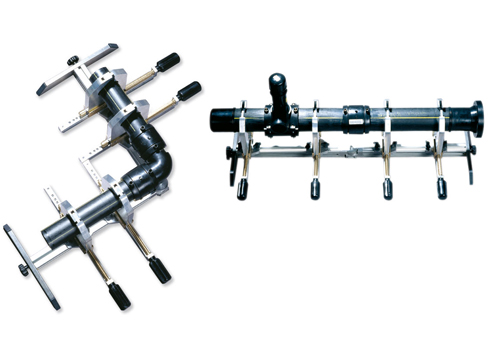

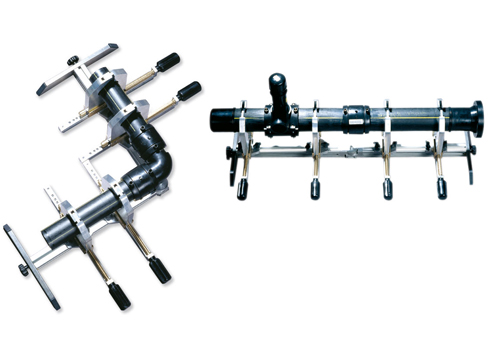

Aligner Eco 20-63

-

ALIGNER ECO 20-63 is composed by two aluminum axes on which are mounted self-centering clamps made of steel.

The clamps, can easily slide through the entire length of the axes.

A positioning plate allows to perform welds in line, 30 °, 45 °, 90 ° and T-branches in diameters between 20 and 63 mm.

The fixing of the pipes is done via cable ties (supplied) with fastener and quick release.

The aligner is versatile and easy to use.

Standard composition:

Aligner equipped with 4 cable ties.

Aligner 63

-

UNIVERSAL ALIGNER 63: professional tool is essential to hold pipes still and aligned during electrofusion.

The UNIVERSAL ALIGNER 63 is made almost entirely in a special Aluminium alloy and features a central joint for the fixed positions at 45° and 90°, four self-centring clamps that require no adapters.

The possibility to remove one part of the axis that carries the clamps and one clamp it self, allows the use of tapping tees during the fusion.

STANDARD COMPOSITION

- Aligner complete with four clamps, service spanner and transport bag

Aligner 160 Light

-

UNIVERSAL ALIGNER 160: professional tool is essential to hold pipes still and aligned during electrofusion (from Ø 63 to Ø 160 mm).

The UNIVERSAL ALIGNER 160 Light is made almost entirely in a special Aluminium alloy and features a central joint for the fixed positions at 45° and 90°, four self-centring clamps that require no adapters, and on request an additional axle complete with two clamps for welding the tees.

Its special quick release clamps grants a rapid extraction of the pipe once it has been welded.

STANDARD COMPOSITION

- Aligner complete with four clamps, transport bag or wooden transport case

ON REQUEST (ACCESSORIES)

- A 3rd axle complete with two clamps (for welding “Tees”)

Aligner Eco 63-180

-

ALIGNER ECO 63 – 180 is an essential and professional tool for the alignment and support of pipes during electrofusion from Ø 63 mm to 180 mm.

The ALIGNER is entirely made of steel, featuring a central adjustable joint and pipe fastening clamps fixed on axes.

The adjustable joint can be set on 4 different working positions to allow welding at preset angles such as 30°, 45°, 90°, “in line” and T welding.

Axes have V-shaped clamps positioned on them, which are equipped with pipe fastening belts. The system, along with fixing the pipe to the clamp, serves also as a centering device.

Each axis has 2 guides on which the clamps are able to slide.

The aligner is available in two configurations: 2 axes and 3 axes (to weld T fittings).

STANDARD COMPOSITION

- Aligner complete with four clamps, service spanner

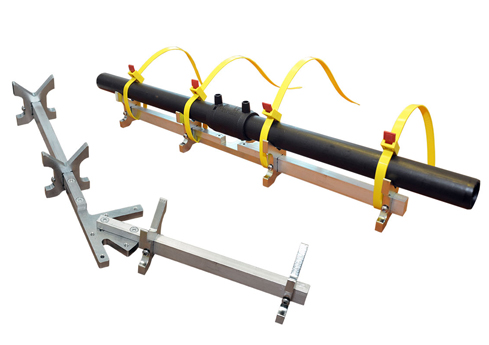

Aligner 125-500

-

ALIGNER 125 – 500 is an essential and professional tool for the alignment and support of pipes during electrofusion from Ø 125 mm to 500 mm.

The ALIGNER is entirely made of steel, featuring a central adjustable joint and pipe fastening clamps fixed on axes.

The adjustable joint can be set on 4 different working positions to allow welding at preset angles such as 45°, 90°, “in line” and T welding.

Axes have V-shaped clamps positioned on them, which are equipped with pipe fastening belts. The system, along with fixing the pipe to the clamp, serves also as a centering device.

Each axis has 2 guides on which the clamps are able to slide.

Practical side handles ensure an easy grip during movement and positioning, both during welding procedures, and preparation.

The aligner is available in two configurations: 2 axes and 3 axes (to weld T fittings).

STANDARD COMPOSITION

- Aligner complete with four clamps, service spanner

Rebounder

-

Rerounder the mechanical thread of these steel-made products help remodel the ends of ovalized pipes that need to welded by electrofusion.

The manual clamping of the tool stems pushes the ovalized end till its reshaping respects the ovalization range required by most standards, therefore allowing its insertion into an electrical coupling - and avoiding the cost of eliminating a good pipe.

The 3 rerounders cover the following diameters range:

250-400 model for OD from 250 to 400 mm;

450-560 model for OD from 450 to 560 mm,

630-800 model for OD from 630 to 800 mm.

Each one of them is sold separately, with a steel transport box.

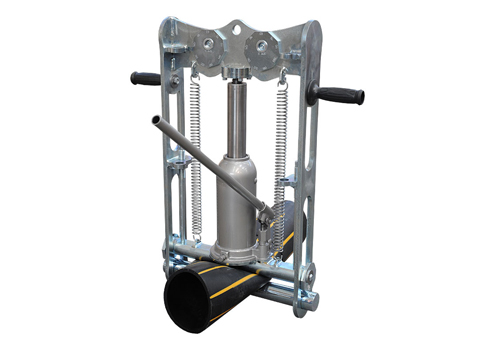

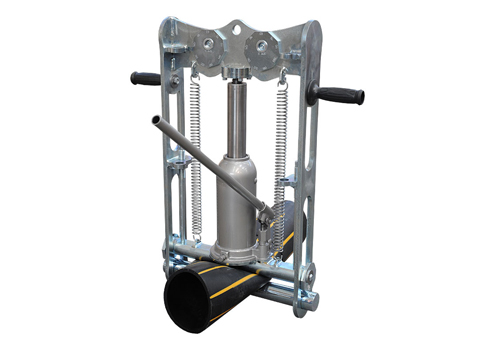

Squeezer 63-200 - Hydraulic

-

SQUEEZER 63-200 is an hydraulic squeezer, very effective and useful in the worksite, to stop the gas or water flow in the HDPE pipelines from Ø 63 to 200 mm - SDR 11, SDR 17.

Thanks to this all the works on the line can be done in the highest safety conditions. The squeezing action on the pipe is possible thanks to a hydraulic cylinder which is manually actuated by the operator with a pressing lever.

The resulting strength is transferred to two cylindrical rods which squeeze the pipe till the interruption of the flow. The SQUEEZER 63-200 is easy to transport thanks to two handles and its steel frame.

On its sides the SQUEEZER 63-200 is equipped with two metallic rods for safety protection in case of pressure losses or accidental impacts.

Moreover the standard configuration of the SQUEEZER 63-200 includes the stoppers for SDR 11 and SDR 17 to set according to the pipes diameter.

Squeezer 63

-

SQUEEZER 63 is a manual tool.

Easy and fast to apply, the SQUEEZER is useful in the worksite to stop the gas or water flow in the Polyethylene pipelines from Ø 16 to 63 mm / SDR 11; SDR 17.

The squeezing action runs by a movable cylindric bar and by an opposite one. The second bar can be removed to permit the pipe insertion. Two special stop templates with 4 positions (on the movable bar sides) assure a safe pipe squeeze on all working range diameters.

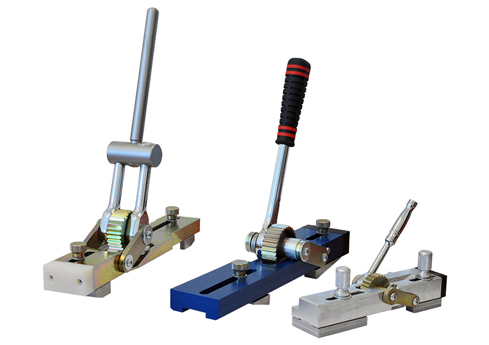

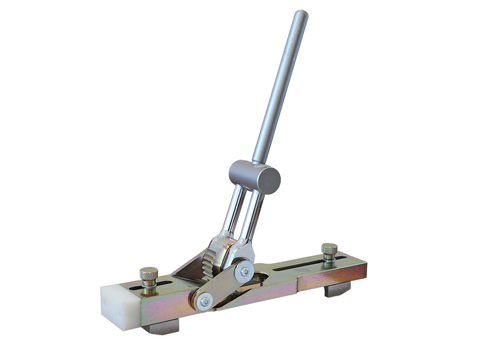

Chamfering

-

CHAMFERING tools are designed to make a bevel on the outside edge of a pipe end for socket fusion / electrofusion.

This Chamfer allows heater faces and socket fittings to be easily pushed onto the pipe end.

Bevelers

-

BEVELERS, these are professional tools for bevelling the ends of plastic pipes up to Ø 315 mm, that will be inserted into electrical couplers or plug-in joints.

The SME 1 and SME 2 PLUS bevelers are made in a special Aluminum alloy.

The special shape of the blades and the non-stick coating (PTFE) of the walls, allow a quick and easy bevel of the pipe.

STANDARD COMPOSITION

- Beveler body with blade

Maya 20-63

-

MAYA 20-63, manual tool for beveling the ends of plastic pipes for electrofusion, socket fusion, pipe connection. Maya 20-63 covers a range from 20 to 63 mm.

Compact and lightweight this chamfering tool proves to be a useful tool to always have in the toolbox.

Fitting Fabrication

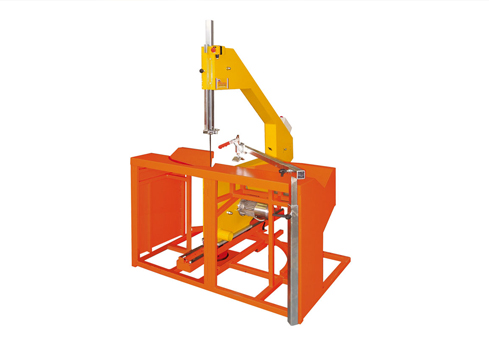

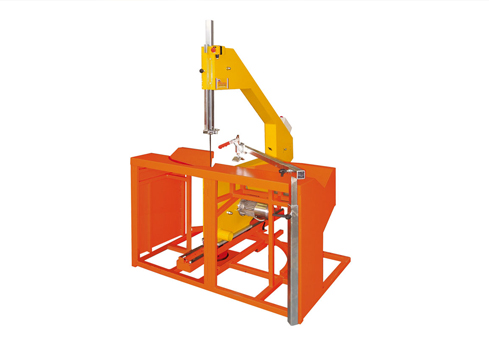

Omega

-

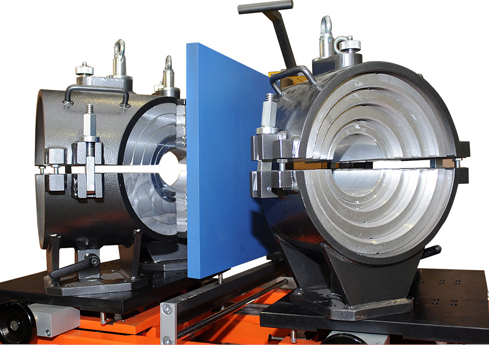

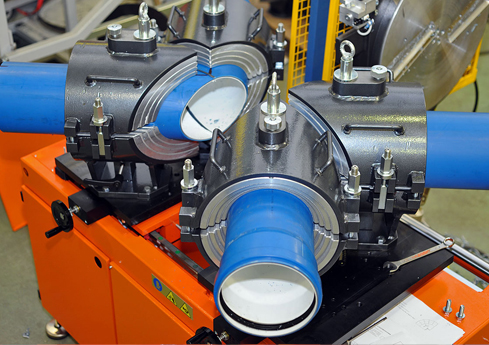

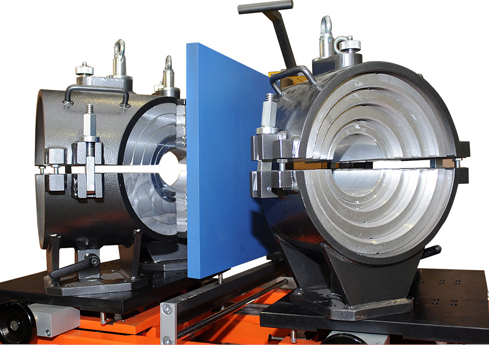

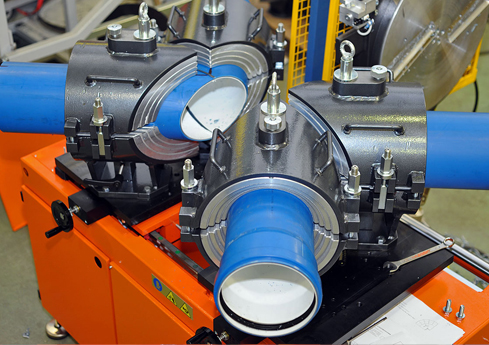

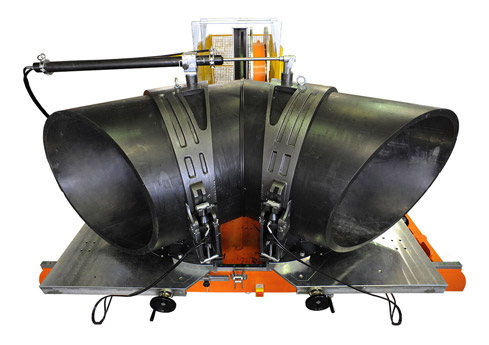

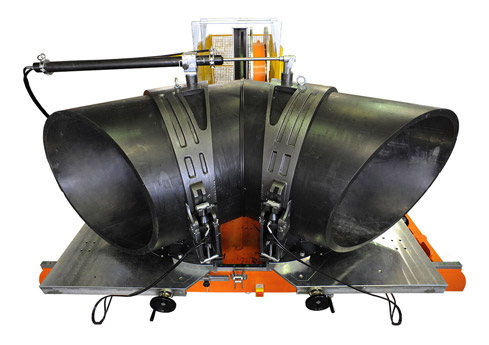

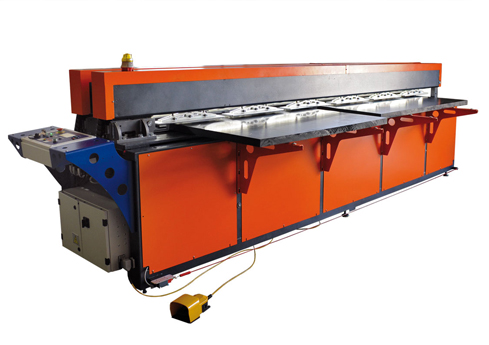

OMEGA 400 – 250 and OMEGA 630 - 250 are a fusion welding machines for in shop use for the manufacturing of special parts, such as reducing branches (Tees, Crosses) for the transport of water, gas and other fluids under

STANDARD COMPOSITION:

- Machine body with manual carriage for socket centring

- Hydraulic jaws for locking pipe & branches

- Side support for branches

- Quick release inserts - EASY LIFE control panel: allows a simple-easy-repeatable welding cycle, reducing the necessity of operator’s intervention

- A built-in memory records the welding cycles; the USB port and the software allow the transfer of data to a PC

- Hydraulic movement of heating plate that can host male/female sockets with heating plate detaching device

INTEGRATIVE SYSTEMS SIGMA 630 Pro with radial cutting kit

Alfa 200 CTB

-

ALFA 200 CTB - workshop welding machine designed to fabricate fittings by joining pipe segments with the help of special jaws:

Ebows up to Ø 200 mm 6" DIPS

Tees, Crosses, Wyes (Y) up to Ø 160 mm 6" IPS

The ALFA 200 CTB can also weld special and moulded fittings such as elbows, tees and flange necks, thanks to a different type of special jaws.

Composed of:

- A machine body with two carriages, one of which driven by a hydraulic system, and two lateral supports with inserts

- A control panel that features the Easy Life system, thanks to which it is possible to carry out a whole welding cycle in a simple, intuitive and repeatable way, so that the operator’s interference would be reduced to the minimum. An built-in memory allows the machine to store 4000 welding cycles (including the set diameters and SDR). Possibility to pre-set 50 customized. It is possible to transfer the welding data to a PC through a serial port (USB adaptor connector available) and data-management software. A printer can be connected to the serial port, to get a welding report at the end of each welding cycle.

- A heating plate with lifting sliding arm

- An electrically controlled milling cutter for levelling the ends of the pipes and/or fittings with built-in overload cutout and safety microswitch

- An upper cylinder, to be positioned on the jaws, for welding extra thick pipes and/or whenever it’s necessary to use high pressures

STANDARD COMPOSITION

- Machine body with control panel

- Heating plate

- Milling cutter

- Upper cylinder and service tools

ON REQUEST (ACCESSORIES)

- Elbows jaws Ø 200 mm with lateral support inserts from Ø 40 to Ø180 mm

- Tees/crosses jaws Ø 160 mm inserts from Ø 63 to Ø140 mm

- Wyes jaws jaws Ø 160 mm inserts from Ø 63 to Ø140 mm

- Right or left special jaws Ø 200 inserts from Ø 40 to Ø 180 mm

- Tool for flange necks

Alfa 400 Manual

-

ALFA 400 Manual Workshop welding machine designed to fabricate fittings by joining pipe segments, with the help of special jaws:

elbows: from Ø 90 mm to 400 mm

tees - crosses - wyes: from Ø 90 mm to 315 mm

The ALFA 400 Manual welding plastic materials such as: HDPE, PP.

Composed of:

- A machine body with two carriages, one of which driven by a hydraulic system

- A manual hydraulic control panel for the welding cycle

- A milling cutter

- A Teflon-coated heating plate, power supply 230 V 50/60 Hz

STANDARD COMPOSITION

- Machine body with manual control panel

- Heating plate

- Milling cutter

- Service tools

- Elbows jaws Ø 400 mm with lateral support inserts from Ø 90 to Ø 355 mm

ON REQUEST (ACCESSORIES)

- Tees/crosses jaws Ø 315 mm inserts from Ø 90 to Ø 315 mm

- Wyes jaws jaws Ø 315 mm inserts from Ø 90 to Ø 315 mm

- Right or left special jaws Ø 400 inserts from Ø 110 to Ø 355 mm

- Tool for flange necks

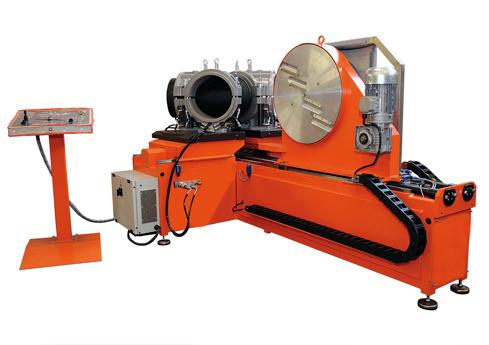

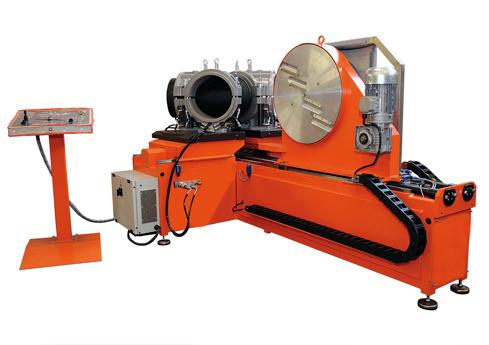

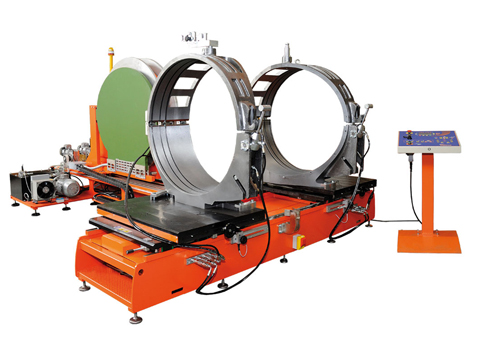

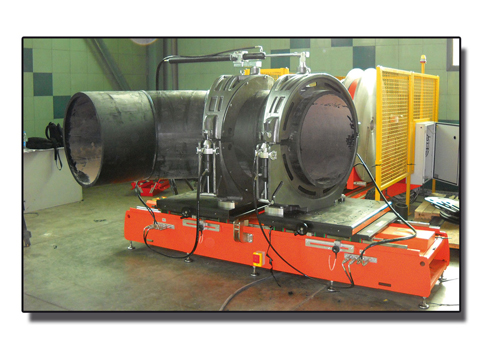

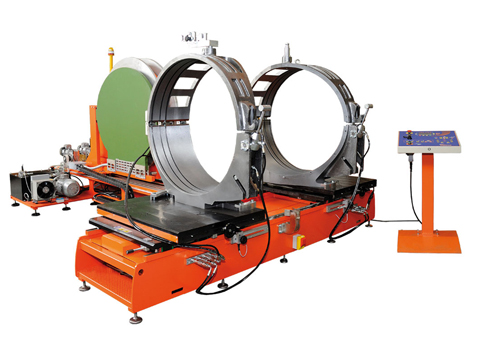

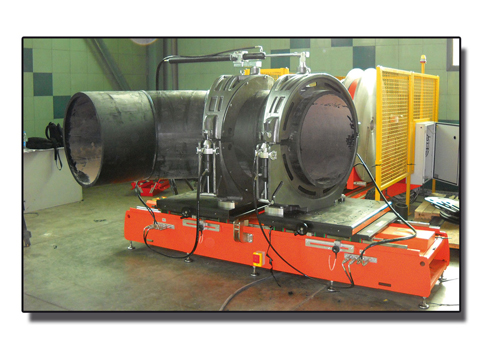

Alfa 400 Easy Life

-

ALFA 400 EASY LIFE workshop welding machine designed to fabricate fittings by joining pipe segments, with the help of special jaws:

elbows Ø 90 ÷ 400 mm (4" IPS ÷ 16" IPS)

tees - crosses - wyes Ø 90 ÷ 315 mm (4" IPS ÷ 12" IPS)

The ALFA 400 EASY LIFE can also weld special and moulded fittings such as elbows, tees and flange necks, thanks to a different type of special jaws.

Composed of:

- A machine body with two carriages, one of which driven by a hydraulic system; a control panel that features the Easy Life system, thanks to which it is possible to carry out a whole welding cycle in a simple, intuitive and repeatable way, so that the operator’s interference would be reduced to the minimum. An built-in memory allows the machine to store 4000 welding cycles (including the set diameters and SDR). Possibility to pre-set 50 customized. It is possible to transfer the welding data to a PC through a serial port (USB adaptor connector available) and data-management software. A printer can be connected to the serial port, to get a welding report at the end of each welding cycle.

- A heating plate featuring a new horizontal sliding system, automatically operated, which enables a fast side-sliding of the plate during the exchange period. The whole process is carried out with no need of disconnecting the upper cylinder, whenever it is in use.

- A milling cutter for levelling the ends of pipes and/or fittings that slides on recirculating ball slideways, with an electronic device for a soft start.

- An upper cylinder, to be positioned on the jaws, for welding extra thick pipes and/or whenever it’s necessary to use high pressures.

- Available in 230 V and 400 V.

STANDARD COMPOSITION

- Machine body with control panel EASY LIFE

- Heating plate

- Milling cutter

- Upper cylinder and service tools

- Elbows jaws Ø 400 mm with lateral support inserts from Ø 90 to Ø 355 mm

ON REQUEST (ACCESSORIES)

- Tees/crosses jaws Ø 315 mm inserts from Ø 90 to Ø 280 mm

- Wyes jaws jaws Ø 315 mm inserts from Ø 90 to Ø 280 mm

- Right or left special jaws Ø 400 inserts from Ø 90 to Ø 355 mm

- Tool for flange necks

Alfa 400 CTB

-

ALFA 400 CTB is a workshop welding machine designed to fabricate fittings by joining pipe segments, with the help of special jaws.

Elbows Ø 110 ÷ 400 mm (4" IPS ÷ 16" IPS)

Tees - Crosses - Wyes Ø 110 ÷ 355 mm (4" IPS ÷ 14" IPS)

Elbows and Wyes (Y) jaws opening/closing and locking movements are controlled hydraulically

Tees/Crosses jaws opening/closing movements are manual

The ALFA 400 CTB can also weld special and moulded fittings such as elbows, tees and flange necks, thanks to a different type of special jaws.

Composed of:

- A machine body with two hydraulically controlled carriages; a control panel that features the Easy Life system, thanks to which it is possible to carry out a whole welding cycle in a simple, intuitive and repeatable way, so that the operator’s interference would be reduced to the minimum. An built-in memory allows the machine to store 400 welding cycles (including the set diameters and SDR). It is possible to transfer the welding data to a PC through a serial port (USB adaptor connector available) and data-management software. A printer can be connected to the serial port, to get a welding report at the end of each welding cycle

- A Teflon-coated heating plate with hydraulic movement (in / out) on spherical bearings guides

- A milling cutter with hydraulic movement (in/out) on spherical bearings guides, operated by an electrical engine, provided with eight steel blades

- an upper cylinder, to be positioned on the jaws, for welding extra thick pipes and/or whenever it’s necessary to use high pressures

STANDARD COMPOSITION

- Machine body with control panel EASY LIFE

- Heating plate

- Milling cutter

- Upper cylinder and service tools

ON REQUEST (ACCESSORIES)

- Elbows jaws Ø 400 mm with lateral support inserts from Ø 110 to Ø 355 mm

- Tees/crosses jaws Ø 355 mm inserts from Ø 110 to Ø 315 mm

- Wyes jaws jaws Ø 355 mm inserts from Ø 110 to Ø 315 mm

- Right or left special jaws Ø 400 inserts from Ø 110 to Ø 355 mm

- Tool for flange necks

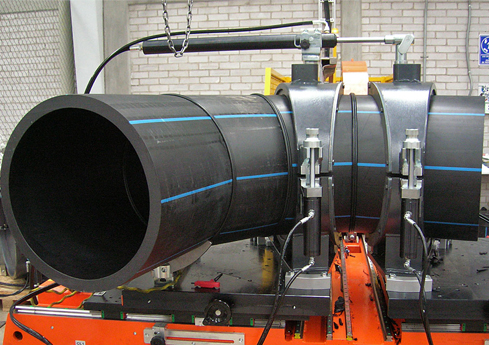

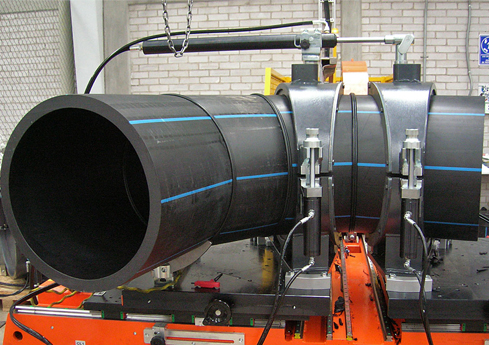

Alfa 630 T

-

ALFA 630 T is a workshop welding machine designed to fabricate fittings by joining pipe segments, with the help of special jaws.

Elbows - Tees - Crosses - Wyes Ø 225 ÷ 630 mm (8" IPS ÷ 24" DIPS)

All jaws movements are electro-hydraulically operated, both the open/close movement and the blocking mechanism.

The ALFA 630 T can also weld special and moulded fittings such as elbows, tees and flange necks, thanks to a different type of special jaws.

Composed of:

- A machine body with two hydraulically controlled carriages

- A control panel that features the CNC system, thanks to this would eliminate any risk of error due to the operator. The CNC incorporates a data-logging that can store up to 4000 cycles.

Possibility to pre-set 20 customized.

It is possible to download the data via USB slot; PDF report

- A Teflon-coated heating plate with electrical movement (in/out) on spherical bearings guides

- A milling cutter with electrical movement (in/out) on spherical bearings guides, operated by an electrical engine

- An upper cylinder, to be positioned on the jaws, for welding extra thick pipes and/or whenever it is necessary to apply high pressures.

STANDARD COMPOSITION

- Machine body with control panel CNC

- Elbows jaws complete with inserts from Ø 315 to Ø 630 mm

- Heating plate

- Milling cutter

- Upper cylinder and service tools

ON REQUEST (ACCESSORIES)

- Elbows jaws inserts from Ø 225 to Ø 280 mm

- Wyes - Tees - crosses jaws Ø 630 mm inserts from Ø 225 to Ø 630 mm

- Right or left special jaws (open manually) with inserts from Ø 315 to Ø 630 mm

Alfa 1000

-

ALFA 1000 is a workshop welding machine designed to fabricate fittings by joining pipe segments, with the help of special jaws.

Elbows Ø 400 ÷ 1000 mm (16" IPS ÷ 36" DIPS)

Tees - Crosses - Wyes Ø 400 ÷ 800 mm (16" IPS ÷ 30" IPS)

Composed of:

- A machine body with two hydraulically controlled carriages

- A control panel that features the CNC system, thanks to this would eliminate any risk of error due to the operator. The CNC incorporates a data-logging that can store up to 4000 cycles. It is possible to download the PDF data via USB slot. Possibility to pre-set 20 customized

- A Teflon-coated heating plate with electrical movement (in/out) on spherical bearings guides

- A milling cutter with electrical movement (in/out) on spherical bearings guides, operated by an electrical engine

- An upper cylinder, to be positioned on the jaws, for welding extra thick pipes and/or whenever it is necessary to apply high pressures.

STANDARD COMPOSITION

- Machine body with control panel CNC

- Elbows jaws Ø 1000 complete with inserts from Ø 400 to Ø 900 mm

- Heating plate

- Milling cutter

- Upper cylinder and service tools

ON REQUEST (ACCESSORIES)

- Wyes - Tees - crosses jaws Ø 800 mm inserts from Ø 400 to Ø 710 mm

Alfa 1200

-

ALFA 1200 is a workshop welding machine designed to fabricate fittings by joining pipe segments, with the help of special jaws.

Elbows Ø 630 ÷ 1200 mm (24" IPS ÷ 42" IPS)

Tees - Crosses - Wyes Ø 630 ÷ 1000 mm (24" IPS ÷ 36" DIPS)

Composed of:

- A machine body with two hydraulically controlled carriages

- A control panel that features the CNC system, thanks to this would eliminate any risk of error due to the operator. Possibility to pre-set 20 customized. The CNC incorporates a data-logging that can store up to 4000 cycles. It is possible to download the report PDF via USB slot

- A Teflon-coated heating plate with electrical movement (in/out) on spherical bearings guides

- A milling cutter with electrical movement (in/out) on spherical bearings guides, operated by an electrical engine

- An upper cylinder, to be positioned on the jaws, for welding extra thick pipes and/or whenever it is necessary to apply high pressures.

STANDARD COMPOSITION

- Machine body with control panel CNC

- Elbows jaws Ø 1200 complete with inserts from Ø 630 to Ø 1000 mm

- Heating plate

- Milling cutter

- Upper cylinder and service tools

ON REQUEST (ACCESSORIES)

- Wyes - Tees - crosses jaws Ø 1000 mm inserts from Ø 630 to Ø 900 mm

Alfa 1600

-

ALFA 1600 is a workshop welding machine designed to fabricate fittings by joining pipe segments, with the help of special jaws.

Elbows Ø 800 ÷ 1600 mm (30" IPS ÷ 63" IPS)

Tees - Crosses - Wyes Ø 800 ÷ 1200 mm (30" IPS ÷ 42" DIPS)

Composed of:

- A machine body with two hydraulically controlled carriages