TECHNOSOFT

Videos

Loading the player ...

- Offer Profile

- Technosoft is a leading DSP motion control technology company specialized in digital motion

control products and custom motion systems - intelligent servo drives and

motors - based on MotionChipTM, a motion control dedicated DSP.

Through embedded intelligence and easy high-level software programmability, Technosoft digital servo/stepper drives and motors offer ideal solutions for a large variety of applications ranging from medical, industrial, textile to semiconductors factory automation.

Product Portfolio

Intelligent Drives

- Technosoft's iPOS line of intelligent drives is based on a new design concept that has resulted in cost-effective, compact, modular solutions to the position, speed and torque control of rotary or linear brushless, DC brush, and step motors. Designed to cover both low-volume and high-volume applications, the iPOS intelligent drives integrate all basic motor control functions and motion control features in a single module. With the development of the new iPOS intelligent drives family, Technosoft has also extended the concept of distributed motion control. Now you can split the motion application between the iPOS drives and the EtherCAT or CANopen master. Using TML (Technosoft's motion programming language), you can build complex motion applications locally, on each drive, leaving only the high level of motion application on the EtherCAT or CANopen master, and thus reducing the network master complexity. The master supervises the entire motion application, while the specific tasks are executed by the iPOS drives.

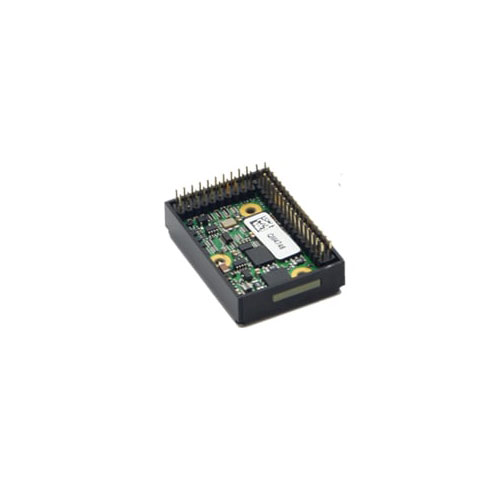

iPOS3602 VX-CAN 9-36V 2A 75W CANopen/EtherCAT

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply :9 – 36 VDC

- Output current: 2 A continuous; 3.2 A peak current

- Communication via RS232, CAN/CANopen (standard) or EtherCAT (optional)

- PCIe plug-in module with very high integration density

- Flexible integration on single or multi-axis motherboards

- Size (L x W x H): 46.5 x 19.2 x 8.5 mm

iPOS3602 MX-CAN 9-36V 2A 75W CANopen/EtherCAT

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 9– 36 VDC

- Output current: 2 A continuous; 3.2 A peak current

- Communication via RS232, CAN/CANopen (standard) or EtherCAT (optional)

- For soldering / plugging in with pin headers with a pitch of 2.54 mm

- Size (L x W x H): 55 x 26.4 x 13.1 mm

iPOS3602 BX-CAN 9-36V 2A 75W CANopen/TMLCAN

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 9 – 36 VDC

- Output current: 2 A continuous; 3.2 A peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- Closed-frame design, with retractable connectors

- Size (L x W x H): 80 x 55 x 16.3 mm

iPOS3602 HX-CAN 9-36V 2A 75W CANopen/TMLCAN

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 9 – 36 VDC

- Output current: 2 A continuous; 3.2 A peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- Closed-frame design with vertical retractable connectors

- Size (L x W x H): 73 x 45 x 16 mm

iPOS3604 VX-CAN 9-36V 4A 144W CANopen/EtherCAT

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 9 – 36 VDC

- Output current: 4 A continuous; 10 A peak current

- Communication via RS232, CAN/CANopen (standard) or EtherCAT (optional)

- PCIe plug-in module with very high integration density

- Flexible integration on single or multi-axis motherboards

- Size (L x W x H): 46.5 x 19.2 x 8.5 mm

iPOS3604 MX-CAN 9-36V 4A 144W CANopen/EtherCAT

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 9 – 36 VDC

- Output current: 4 A continuous; 10 A peak current

- Communication via RS232, CAN/CANopen (standard) or EtherCAT (optional)

- For soldering / plugging in with pin headers with a pitch of 2.54 mm

- Size (L x W x H): 55 x 26.4 x 13.1 mm

iPOS3604 BX-CAN 9-36V 4A 144W CANopen/TMLCAN

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 9 – 36 VDC

- Output current: 4 A continuous; 10 A peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- Closed-frame design, with retractable connectors

- Size (L x W x H): 80 x 55 x 16.3 mm

Micro 4804 MZ 7-48V 4ARMS EtherCAT or CANopen

-

- Intelligent, ultra compact and freely programmable motor controller

- Brushless rotary and linear motors, voice coils and DC brushed and stepper motors

- Motor supply / logic supply: 7 – 48 VDC / 6 – 48 VDC

- Output current: 6.3A (4.5ARMS) nominal; 16 A (11.3ARMS) peak

- Communication via RS232, USB + EtherCAT (MZ-CAT) or CAN/CANopen (MZ-CAN)

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 38.1 x 25 x 9.6 mm

Micro 4804 PZ 7-48V 5ARMS EtherCAT or CANopen

-

- Intelligent, compact and freely programmable motor controller

- Brushless rotary and linear motors, voice coils and DC brushed and stepper motors

- Motor supply / logic supply: 7 – 48 VDC / 6 – 48 VDC

- Output current: 8 A (5.7ARMS) nominal; 16 A (11.3ARMS) peak

- Communication via RS232, USB + EtherCAT (PZ-CAT) or CAN/CANopen (PZ-CAN)

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 38.1 x 25 x 9.5 mm

Micro 4804 CZ 7-48V 5ARMS EtherCAT or CANopen

-

- Intelligent, compact and freely programmable motor controller

- Brushless rotary and linear motors, voice coils and DC brushed and stepper motors

- Motor supply / logic supply: 7 – 48 VDC / 6 – 48 VDC

- Output current: 8 A (5.7ARMS) nominal; 16 A (11.3ARMS) peak

- Communication via RS232, USB + EtherCAT (CZ-CAT) or CAN/CANopen (CZ-CAN)

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 43.5 x 40 x 25.4 mm

iPOS4808 VX-CAN 11-50V 8A 400W CANopen/EtherCAT

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 50 VDC / 12 – 36 VDC

- Output current: 8 A continuous; 20 A peak current

- Communication via RS232, CAN/CANopen (standard) or EtherCAT (optional)

- Open-frame PCB with vertical plug-in design

- Size (L x W x H): 56 x 44 x 6.9 mm

iPOS4808 MY-CAN 11-50V 8A 400W CANopen/TMLCAN

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 50 VDC / 12 – 36 VDC

- Output current: 8 A continuous; 20 A peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- For soldering / plugging in with pin headers with a grid dimension of 2.54 mm

- Size (L x W x H): 60 x 43.6 x 12.4 mm

iPOS4808 MY-STO 11-50V 8A 400W CANopen/TMLCAN

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 50 VDC / 12 – 36 VDC

- Output current: 8 A continuous; 20 A peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- For soldering / plugging in with pin headers with a grid dimension of 2.54 mm

- Size (L x W x H): 60 x 43.6 x 22 mm

iPOS4808 MY-STO 11-50V 8A 400W EtherCAT

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 50 VDC / 12 – 36 VDC

- Output current: 8 A continuous; 20 A peak current

- Communication via RS232 or EtherCAT

- STO inputs with safety integrity level SIL3/Cat3/PLe

- For soldering / plugging in with pin headers with a grid dimension of 2.54 mm

- Size (L x W x H): 64 x 43.6 x 22 mm

iPOS4808 BX-CAN 11-50V 8A 400W CANopen/TMLCAN

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 50 VDC / 12 – 36 VDC

- Output current: 8 A continuous; 20 A peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design with retractable connectors

- Size (L x W x H): 88.5 x 77 x 16.4 mm

iPOS4808 BX-CAT 11-50V 8A 400W EtherCAT

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 50 VDC / 12 – 36 VDC

- Output current: 8 A continuous; 20 A peak current

- Communication via RS232 or EtherCAT

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design with retractable connectors

- Size (L x W x H): 88.5 x 77 x 16.4 mm

iPOS4810 MZ-CAN 11-50V 10A RMS 700W CAN/TMLCAN

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply / STO supply: 11 – 50 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 10 A RMS continuous; 28 A RMS peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 64 x 43.6 x 13.7 mm

iPOS4810 MZ-CAT 11-50V 10A RMS 700W EtherCAT

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply / STO supply: 11 – 50 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 10 A RMS continuous; 28 A RMS peak current

- Communication via RS232 or EtherCAT

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 64 x 43.6 x 13.7 mm

iPOS4810 XZ-CAN 11-50V 10A RMS 700W CAN/TMLCAN

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply / STO supply: 11 – 50 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 10 A RMS continuous; 28 A RMS peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 64 x 43.6 x 13.7 mm

iPOS4810 XZ-CAT 11-50V 10A RMS 700W EtherCAT

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply / STO supply: 11 – 50 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 10 A RMS continuous; 28 A RMS peak current

- Communication via RS232 or EtherCAT

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 93 x 43.8 x 32 mm

iPOS4815 MZ-CAN 11-50V 15A RMS 1kW CAN/TMLCAN

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply / STO supply: 11 – 50 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 15 A RMS continuous; 28 A RMS peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 64 x 43.6 x 13.7 mm

iPOS4815 MZ-CAT 11-50V 15A RMS 1kW EtherCAT

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply / STO supply: 11 – 50 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 15 A RMS continuous; 28 A RMS peak current

- Communication via RS232 or EtherCAT

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 64 x 43.6 x 13.7 mm

iPOS4815 XZ-CAN 11-50V 15A RMS 1kW CAN/TMLCAN

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply / STO supply: 11 – 50 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 15 A RMS continuous; 28 A RMS peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 64 x 43.6 x 13.7 mm

iPOS4815 XZ-CAT 11-50V 15A RMS 1kW EtherCAT

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply / STO supply: 11 – 50 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 15 A RMS continuous; 28 A RMS peak current

- Communication via RS232 or EtherCAT

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 93 x 43.8 x 32 mm

iPOS4850 BX-CAN 11-60V 64A 3kW CANopen/TMLCAN

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 60 VDC / 9 – 36 VDC

- Output current: 64 A (45ARMS) nominal; 90 A (64ARMS) peak

- Supports various feedback options including absolute encoders

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design, with retractable connectors

- Size (L x W x H): 139 x 93.9 x 24.6 mm

iPOS4850 BX-CAT 11-60V 64A 3kW EtherCAT

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 60 VDC / 9 – 36 VDC

- Output current: 50 A continuous; 90 A peak current

- Supports various feedback options including Sin / Cos and absolute encoders

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design, with retractable connectors

- Size (L x W x H): 139 x 93.9 x 24.6 mm

iPOS8010 BX-CAN 11-80V 10A 800W CANopen/TMLCAN

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 60 VDC / 9 – 36 VDC

- Output current: 10 A continuous; 20 A peak current

- Supports various feedback options including Sin / Cos and absolute encoders

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design, with retractable connectors

- Size (L x W x H): 139 x 94.2 x 24.5 mm

iPOS8010 BX-CAT 11-80V 10A 800W EtherCAT

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 60 VDC / 9 – 36 VDC

- Output current: 10 A continuous; 20 A peak current

- Supports various feedback options including Sin / Cos and absolute encoders

- Communication via RS232 or EtherCAT

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design, with retractable connectors

- Size (L x W x H): 139 x 94.2 x 24.5 mm

iPOS8020 BX-CAN 11-80V 20A 1.6kW CANopen/TMLCAN

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 80 VDC / 9 – 36 VDC

- Output current: 20 A continuous; 40 A peak current

- Supports various feedback options including Sin / Cos and absolute encoders

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design, with retractable connectors

- Size (L x W x H): 139 x 94.2 x 24.5 mm

iPOS8020 BX-CAT 11-80V 20A 1.6kW EtherCAT

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 11 – 80 VDC / 9 – 36 VDC

- Output current: 20 A continuous; 40 A peak current

- Supports various feedback options including Sin / Cos and absolute encoders

- Communication via RS232 or EtherCAT

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design, with retractable connectors

- Size (L x W x H): 139 x 94.2 x 24.5 mm

iPOS8015 MZ 12-80V 15ARMS 1kW CANopen or EtherCAT

-

- Intelligent, compact and freely programmable motor controller

- For brushless rotary and linear motors, voice coils, DC brush and step motors

- Motor supply / logic supply / STO supply: 12-80 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 21.2A (15ARMS) nominal; 40A (28.3ARMS) peak

- Communication via USB, LV-TTL UART, EtherCAT, RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 64 x 43.8 x 15.7 mm

iPOS8015 XZ 12-80V 15ARMS 1kW CANopen or EtherCAT

-

- Intelligent, compact and freely programmable motor controller

- For brushless rotary and linear motors, voice coils, DC brush and step motors

- Motor supply / logic supply / STO supply: 12 – 80 VDC / 9 – 36 VDC / 18-40VDC

- Output current: 21.2A (15ARMS) nominal; 40A (28.3ARMS) peak

- Communication via USB, LV-TTL UART, EtherCAT, RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 93 x 43.8 x 32 mm

iGVD71 BX-CAN 11-80V 100A 8KW CANopen/TMLCAN

-

- Intelligent, compact and freely programmable motor controller

- For brushless and DC brush motors

- Motor supply / logic supply / STO supply: 11 – 80 VDC / 9 – 36 VDC / 18 – 36 VDC

- Output current: 100 A (71ARMS) nominal; 130 A(92ARMS) peak current

- Supports various feedback options incremental and absolute encoders

- Communication via RS232 (micro USB port), TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design, with retractable connectors

- Size (L x W x H): 104.2 x 95 x 47.1 mm

iGVD71 CAN-STO 11-80V 100A 8KW CANopen/TMLCAN

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply / STO supply: 11 – 80 VDC / 9 – 36 VDC / 18 – 36 VDC

- Output current: 100 A continuous; 140 A peak current

- Supports various feedback options including incremental and absolute encoders

- Communication via RS232, TMLCAN and CANopen interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design, with retractable connectors

- Size (L x W x H): 104.2 x 95 x 47.1 mm

iGVD71 BX-CAT 11-80V 100A 8KW EtherCAT

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush motors

- Motor supply / logic supply / STO supply: 11 – 80 VDC / 9 – 36 VDC / 18 – 36 VDC

- Output current: 100 A (71ARMS) nominal; 140 A (100ARMS) peak current

- Supports various feedback options including incremental and absolute encoders

- Communication via RS232 (micro USB port), EtherCAT interfaces

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Closed-frame design, with retractable connectors

- Size (L x W x H): 104.2 x 95 x 47.1 mm

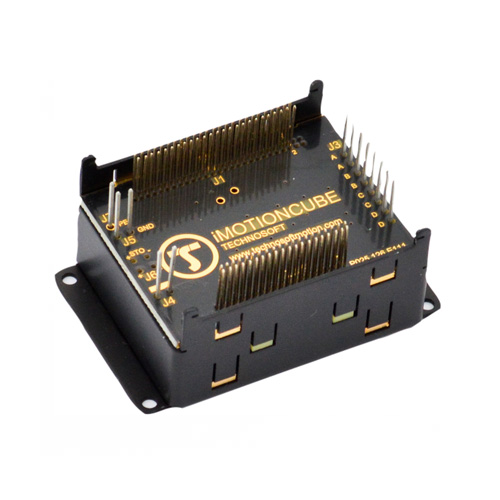

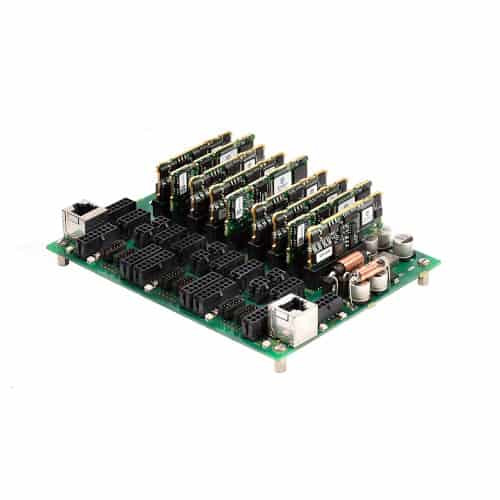

IPOS360X SX MULTI-AXIS MOTION SYSTEM

- Motion system with up to 4 iPOS360x VX-CAN drive controllers

- For DC brushless, DC brush, stepper, linear, and voice coil motors

- Power voltage: 9-36 VDC; Logic voltage: 7-36 VDC

- Up to 4 A continuous, 10 A peak per drive

- CAN communication between axes

- RS-232 and Ethernet for setup

- Size (L x W x H): 98 x 100.3 x 21.2 mm

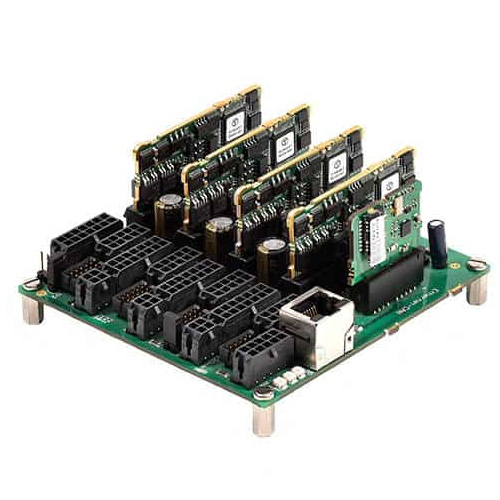

iPOS360x SY-CAN 6-Axis Motion System CANopen/EtherCAT

- Motion system with up to 6 iPOS360x VX-CAN drive controllers

- For DC brushless, DC brush, stepper, linear, and voice coil motors

- Power voltage: 9-36 VDC; Logic voltage: 7-36 VDC

- Up to 4 A continuous, 10 A peak per drive

- CAN/CANopen (CiA301, 305 & 402) or EtherCAT (CoE)

- RS-232 and Ethernet for setup

- Size (L x W x H): 160 x 122 x 22 mm

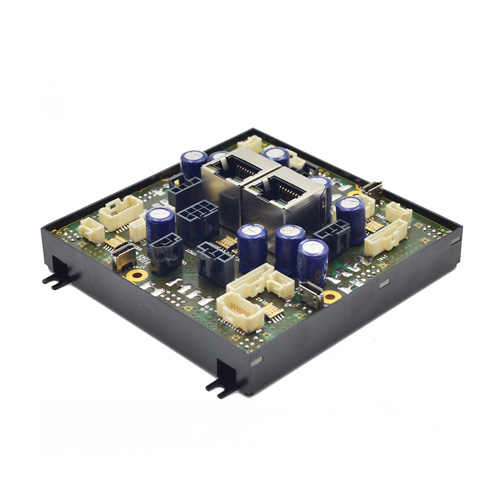

Micro 4804 Multi Axis System CANopen or EtherCAT

-

- Motion system with 3 or 4 Micro 4804 MZ drive controllers

- Brushless rotary and linear motors, voice coils , DC brushed and stepper motors

- Motor supply / logic supply: 7 – 48 VDC / 6 – 48 VDC

- Output current: 5.7 A (4ARMS) nominal; 16 A (11.3ARMS) peak

- Communication via RS232, USB, CAN/CANopen (standard), EtherCAT

- STO inputs with safety integrity level SIL3/Cat3/PLe

- Size (L x W x H): 71,4 x 118,2 x 21,7 mm

iPOS3604 HX-CAN 9-36V 4A 144W CANopen/TMLCAN

-

- Intelligent, compact and freely programmable motor controller

- For brushless, DC brush and step motors

- Motor supply / logic supply: 9 – 36 VDC

- Output current: 4 A continuous; 10 A peak current

- Communication via RS232, TMLCAN and CANopen interfaces

- Closed-frame design with vertical retractable connectors

- Size (L x W x H): 73 x 45 x 16 mm

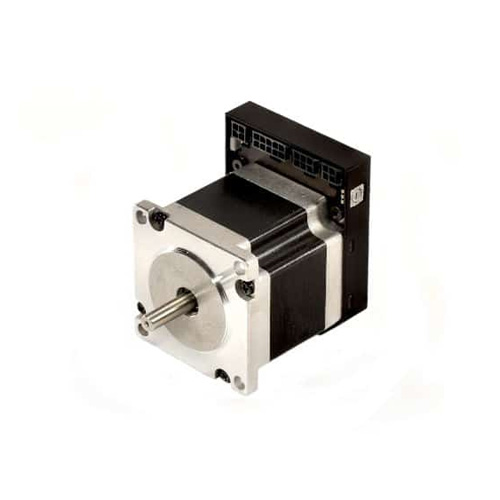

Intelligent Motors

- The iMOT line of intelligent brushless and step motors combines an intelligent drive, a motor and a position sensor into a single unit. The result is a compact cost effective solution that translates motion commands received through a communication channel into mechanical motion.

iMOT172S XM-CAN 12-48V 300 mNm Stepper motor CANopen/TMLCAN

- Stepper motor with embedded drive and motion controller

- Stepper motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 300 mNm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: Molex Micro-Fit

IMOT17XS TM-CAN 300 MNM TMLCAN & CANOPEN

- Stepper motor with embedded drive and motion controller

- Stepper motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 300 mNm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: M8 / M12

iMOT172S TM-CAT 12-48V 300 mNm Stepper motor EtherCAT

- Stepper motor with embedded drive and motion controller

- Stepper motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 300 mNm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: EtherCAT and RS232

- Connector system: M8 / M12

iMOT171B XM-CAN 12-48V 80 mNm Brushless motor CANopen/TMLCAN

- Brushless motor with embedded drive and motion controller

- Brushless motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 80 mNm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: Molex Micro-Fit

iMOT171B TM-CAN 12-48V 80 mNm Brushless motor CANopen/TMLCAN

- Brushless motor with embedded drive and motion controller

- Brushless motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 80 mNm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: M8 / M12

IMOT171B TM-CAT 100-300 MNM ETHERCAT

- Brushless motor with embedded drive and motion controller

- Brushless motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 80 mNm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: EtherCAT, RS232

- Connector system: M8 / M12

iMOT172B XM-CAN 12-48V 160 mNm Brushless motor CANopen/TMLCAN

-

- Brushless motor with embedded drive and motion controller

- Brushless motor with integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 160 mNm

- Magnetic singleturn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: Molex Micro-Fit

iMOT172B TM-CAN 12-48V 160 mNm Brushless motor CANopen/TMLCAN

- Brushless motor with embedded drive and motion controller

- Brushless motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 160 mNm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: M8 / M12

iMOT172B TM-CAT 12-48V 160 mNm Brushless motor EtherCAT

-

- Brushless motor with embedded drive and motion controller

- Brushless motor with integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 160 mNm

- Magnetic singleturn absolute encoder with 4096 I / rev. (12 bit)

- Interface: EtherCAT, RS232

- Connector system: M8 / M12

iMOT173B XM-CAN 12-48V 240 mNm Brushless motor CANopen/TMLCAN

-

- Brushless motor with embedded drive and motion controller

- Brushless motor with integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 160 mNm

- Magnetic singleturn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: Molex Micro-Fit

iMOT173B TM-CAN 12-48V 240 mNm Brushless motor CANopen/TMLCAN

- Brushless motor with embedded drive and motion controller

- Brushless motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 160 mNm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: M8 / M12

iMOT173B TM-CAT 12-48V 240 mNm Brushless motor EtherCAT

-

- Brushless motor with embedded drive and motion controller

- Brushless motor with integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 160 mNm

- Magnetic singleturn absolute encoder with 4096 I / rev. (12 bit)

- Interface: EtherCAT, RS232

- Connector system: M8 / M12

iMOT232S XM-CAN 12-48V 1.0 Nm Stepper motor CANopen/TMLCAN

- Intelligent stepper, NEMA 23

- Embedded drive and motion controller

- Continuous torque: 1.5 Nm

- Motor supply: 12.5-48 V; logic supply: 12.5-36 V

- Integrated position sensor: 4096 counts/rev

- Inputs: 5 digital, 1 analog. Outputs: 2 digital

- TMLCAN & CANopen communication

- Rectangular connectors

iMOT232S TM-CAN 12-48V 1.0 Nm Stepper motor CANopen/TMLCAN

- Intelligent stepper, NEMA 23

- Embedded drive and motion controller

- Continuous torque: 1.5 Nm

- Motor supply: 12.5-48 V; logic supply: 12.5-36 V

- Integrated position sensor: 4096 counts/rev

- Inputs: 4 digital, 1 analog. Outputs: 2 digital

- TMLCAN & CANopen communication

- Circular connectors, M8 and M12

IMOT232S TM-CAT 1.0-1.5 NM ETHERCAT

- Intelligent stepper motor, NEMA 23

- Embedded drive and motion controller

- Continuous torque: 1.0mNm (iMOT232S)/1,5Nm (iMOT233S)

- Motor supply: 12-48 V; logic supply: 12-36 V

- Position sensor: 4096 counts/rev, absolute single-turn

- Inputs: 4 digital, 1 analog. Outputs: 2 digital

- Circular M8 and M12 connectors

- EtherCAT communication with CoE protocol

iMOT233S XM-CAN 12-48V 1.6 Nm Stepper motor CANopen/TMLCAN

-

- Stepper motor with embedded drive and motion controller

- Stepper motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 1.6 Nm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: Molex Micro-Fit

iMOT233S TM-CAN 12-48V 1.6 Nm Stepper motor CANopen/TMLCAN

- Stepper motor with embedded drive and motion controller

- Stepper motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 1.6 Nm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: CANopen / TMLCAN, RS232

- Connector system: M8 / M12

iMOT233S TM-CAT 12-48V 1.6 Nm Stepper motor EtherCAT

-

- Stepper motor with embedded drive and motion controller

- Stepper motor with an integrated freely programmable servo controller

- High dynamics and efficiency through field-oriented control (FOC)

- Operating voltage: 12 – 48 V / nominal torque: 1.6 Nm

- Magnetic single-turn absolute encoder with 4096 I / rev. (12 bit)

- Interface: EtherCAT, RS232

- Connector system: M8 / M12

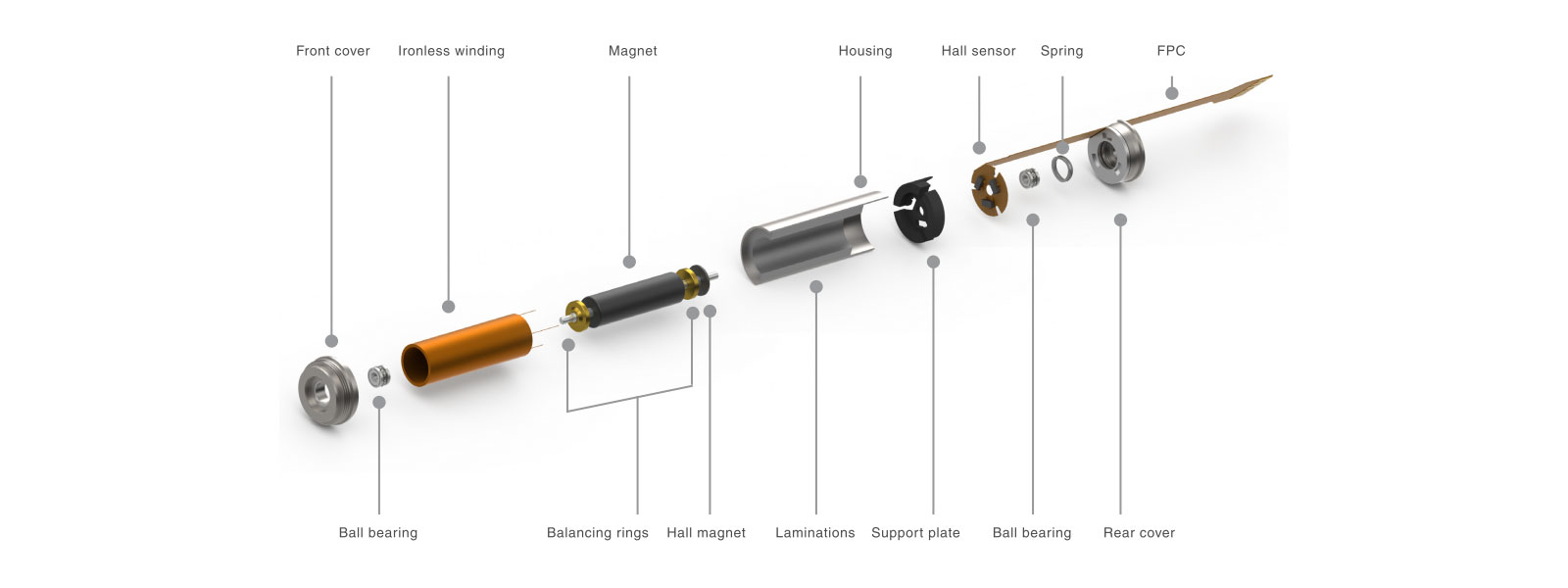

Micro Motors - Slotless Brushless DC Motors

- Innovative and independent patented ironless motor winding design delivers high power in a compact size. The brushless motors are manufactured in two versions to match wide application requirements: the TSU version is dedicated to standard speed and torque applications, and the TSH models have been optimized for higher speeds. Furthermore, the motors exhibit low noise, low inertia, and short response time to satisfy any dynamic application. The stator of a typical brushless motor is constructed using slots and the stator winding is shaped around them, this technology is very known and the issues that come with it aren’t to be neglected. The main issue is cogging torque which is a challenge in applications that require fast response, fast acceleration, and smooth operation.

- Smooth control

- Small Size (Ø13, Ø16 and Ø22 mm)

- High Torque

- High Speed

- Modular design

- No cogging torque

- Low weight

- Cost effective

TSU13026

- Slotless BLDC Motor, F13mm, 2.8mNm, 20000rpm

TSU13038

- Slotless BLDC Motor, F13mm, 5.5mNm, 20000rpm

TSU16036

- Slotless BLDC Motor, Ø16mm, 9.4mNm, 14000rpm

TSH16056

- Slotless BLDC Motor, F16mm, 13.2mNm, 46000rpm

TSU22048

- Slotless BLDC Motor, F22mm, 33.1mNm, 17000rpm

TSH22045

- Slotless BLDC Motor, F22mm, 21.2mNm, 37000rpm

TSH22060

- Slotless BLDC Motor, F22mm, 33.8mNm, 36000rpm

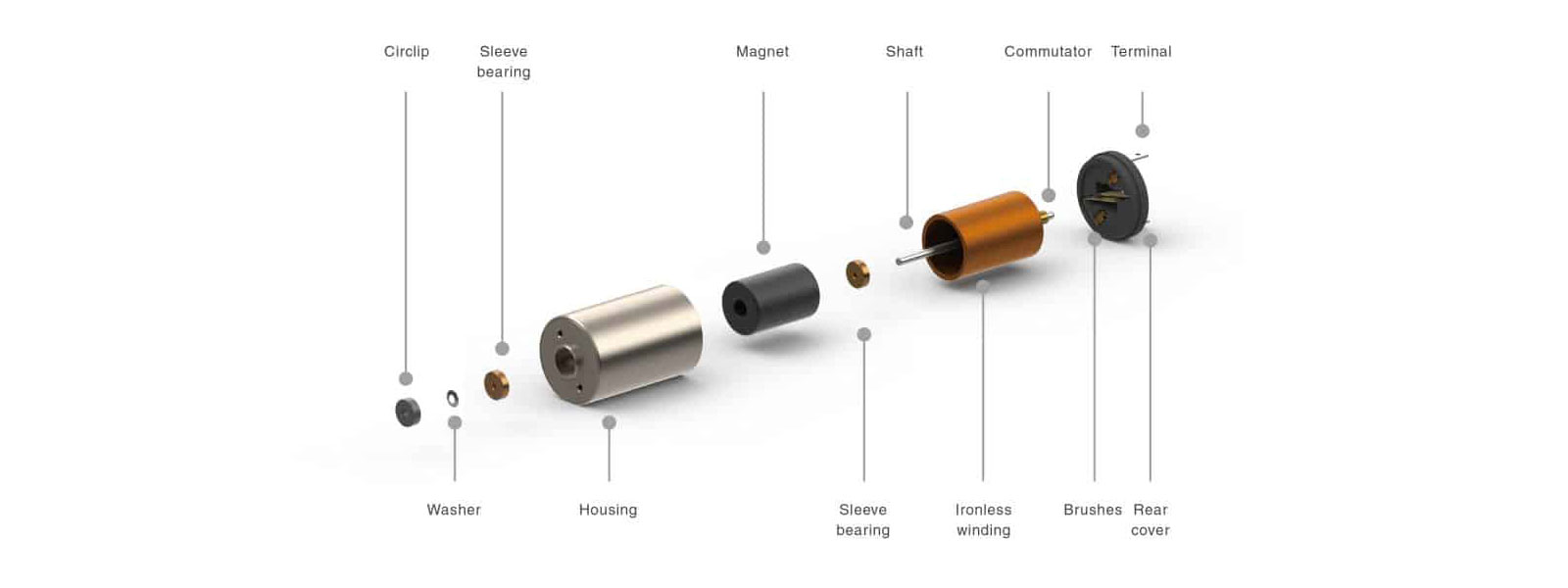

Coreless Brushed DC Motors

- Innovative and independent patented ironless motor winding design delivers high power in a compact size. The brushless motors are manufactured in two versions to match wide application requirements: the TSU version is dedicated to standard speed and torque applications, and the TSH models have been optimized for higher speeds. Furthermore, the motors exhibit low noise, low inertia, and short response time to satisfy any dynamic application. The stator of a typical brushless motor is constructed using slots and the stator winding is shaped around them, this technology is very known and the issues that come with it aren’t to be neglected. The main issue is cogging torque which is a challenge in applications that require fast response, fast acceleration, and smooth operation.

- Ironless Winding

- Small Size (Ø13, Ø16 and Ø22 mm)

- High Torque

- High Speed

- Modular design

- Long operational lifetime

- Cost effective

- Silent operation

Motor Applications:

- Robotics

- Medical surgical tools

- Laboratory Automation

- Factory Automation

- Semiconductor Equipment

- Textile

TCU08017

- Coreless Brushed DC Motor, Ø8mm, 0.6mNm, 5400rpm

TCU10017

- Coreless Brushed DC Motor, Ø10mm, 0.71mNm, 5000rpm

TCU10025

- Coreless Brushed DC Motor, Ø10mm, 1.63mNm, 6700rpm

TCU13020

- Coreless Brushed DC Motor, Ø13mm, 1.83mNm, 8600rpm

TCU13028

- Coreless Brushed DC Motor, Ø13mm, 3.48mNm, 7900rpm

TCU16025

- Coreless Brushed DC Motor, Ø16mm, 2.23mNm, 8100rpm

TCU17025

- Coreless Brushed DC Motor, Ø17mm, 3.89mNm, 8200rpm

TCU17035

- Coreless Brushed DC Motor, Ø17mm, 7.72mNm, 9000rpm

TCU24032

- Coreless Brushed DC Motor, Ø24mm, 10.92mNm, 8000rpm

Industries

- The iMOT line of intelligent brushless and step motors combines an intelligent drive, a motor and a position sensor into a single unit. The result is a compact cost effective solution that translates motion commands received through a communication channel into mechanical motion.

Medical

-

Technosoft`s benchmark contributions with custom motion solutions are a part of leading medical applications such as:

- Clinical diagnosis

- Surgical instruments and robots

- Centrifugal pumps

- X-Ray Equipment

- Biomechatronics

- Ophthalmology equipment

When it comes to manufacturing components for the medical industry, a quality-controlled fabrication process is an absolute requirement for the series production and use of components. For this reason, our development team has focused intensively on expanding the process monitoring systems. Technosoft is certified according to ISO 9001:2008.

Instrumentation & Optics

-

Technosoft`s benchmark contributions with custom motion solutions are a part of leading instrumentation & optics applications such as:

- Digital microscopes

- Laser measuring systems

- Aerial view cameras

- Photometry

- Lens shaping and polishing

- Auto focus & auto zooming

Robotics

-

Motion control solutions for robotics

- Robots and cobots

- Exoskeletons

- Grippers

- Automated guided vehicles (AGVs)

- Warehouse automation

Laboratory Automation

-

Motion control solutions for laboratory automation

- Analysis equipment

- Pipetting

- Liquid handling systems

Factory Automation

-

Motion control solutions for factory automation

- Pick and place robots

- Cartesian robots

- Welding robots

- Printing equipment

- Bonding systems

- Laser marking

- Wafer inspection

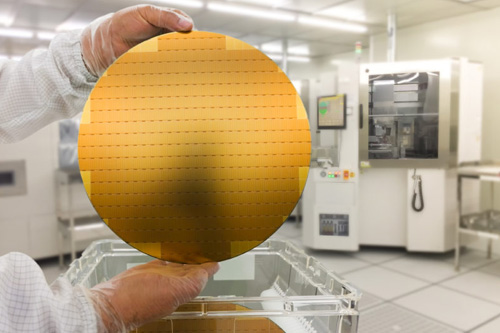

Semiconductor Equipment

-

Motion control solutions for Semiconductor Equipment

- Flexible automation

- Atomic layer etching

- Trim and form

- Pick and place handler

Packaging

-

Motion control solutions for Packaging markets

- Bottling machines

- Labeling machines

- Gluing machines

- Package printing

- Material dosing

Industrial Equipment

-

Motion control solutions for

- Elevators

- Elevator doors

- Solar cells

- Hydraulic pumps

- Solar trackers

- Photo voltaic panels

Textile

-

Motion control solutions for Textile

- Weaving

- Warping

- Knitting

- Tufting

- Traverse control