- Offer Profile

- „Engineered and Made in Germany“

– As a medium-sized development, production and sales company, we have committed ourselves to this quality feature.

DRUCK & TEMPERATUR Leitenberger offers a longstanding experience in the fields of measurement-, testing- and calibration technology. We ensure our customers an excellent quality by the latest production technologies and a very high vertical range of manufacture.

Our innovative spirit as well as a steady further development of our product range, offers a fast and flexible reaction towards individual customer requests. Our company success is supplemented by an extensive know-how in various industrial sectors and a strong service availability towards our customers. We see our responsibility in assisting our customers as a competent partner on all matters regarding measurement, testing and calibration of pressure, temperature, torque and force.

New: Instruments with IO-Link interface

LPT 533-IO Pressure transmitter - IO-Link

-

Interface: IO-Link version 1.1 (Slave)

Data transmission: COM 2 / 38.4 kbits/s

Mode: SIO / IO-Link

Standard: IEC 61131-2 / IEC 61131-0Stainless steel sensor

Pressure ranges from 0...100 mbar to 0...400 bar

Accuracy ±0.35% FS / optional ±0.25% FS

• Perfect thermal behaviour

• Excellent long term stability

LDS 350-IO - Electronic pressure switch - IO-Link

-

Interface: IO-Link version 1.1 (Slave)

Data transmission: COM 2 / 38.4 kbits/s

Mode: SIO / IO-Link

Standard: IEC 61131-2 / IEC 61131-0Stainless steel sensor

Nominal pressures from 0...100 mbar to 0...600 bar

Accuracy ±0.5% FS / ±0.35% FS, optional ±0.25% FS

Indication of measured values on a 4-digit LED display

Rotatable and configurable display module

Pressure

Pressure Measurement

Pressure Transmitter

- Gauge and absolute pressure,

differential pressure

Standard output signals

Plug-on displays, field displays- For gauge pressure, vacuum and absolute pressure measurement

- Pressure ranges 0...10 mbar to 0...6000 bar

- Differential pressure transmitter 0...6 mbar to 70 bar

- Plug-on displays, field displays

Based on different sensor technologies, combined with housing materials of stainless steel and various plastics, the industrial pressure transmitters are suitable for almost all industrial gases and fluids.

Our industrial pressure transmitter may be adapted to almost any application due to a variety of electrical and mechanical connections.

Accuracy values in below table according to IEC 60770.

Bourdon Tube Pressure Gauges

- Dry or with glycerine filling.

Wetted parts in brass.

also Welding pressure gauges.

also FREON pressure gauges.- Bourdon tube pressure gauges (C- or spiral shape)

- Standard, industrial or robust exeuctions

- Dry or Glycerine filled (other dampening fluids on request)

- Wetted parts in copper-alloy/brass

- Case in steel or stainless steel

- Pressure connection: BSP, optional NPT or other

All stainless steel bourdon tube pressure gauges

- Dry or with glycerine filling.

Wetted parts in stainless steel.

also SOLID FRONT safety execution

also HIGH PRESSURE up to 7000 bar.- All wetted parts made in stainless steel

- optional SOLID FRONT safety excecution "S3"

- optional HIGH PRESSURE execution up to 7,000 bar (100,000 psi)

- Dry or glycerine filled (other dampening liquids on request)

- Wetted parts made in stainless steel Window in tempered safety glass Pressure connection: BSP (or NPT, other on request)

Capsule Pressure Gauges

- mbar pressure ranges.

Wetted parts in brass or stainless steel

. Without liquid filling (dry, no glycerine).

Suitable for gaseous media only.- Standard version: wetted parts in copper-alloy/brass

- Stainless steel version: wetted parts in stainless steel

- Case with bayonet ring or snap-in window in stainless steel or ABS plastic Pressure ranges from 25 mbar to 1000 mbar pressure/vacuum/compound

- Pressure connection BSP (optional NPT or other)

- Capsule pressure gauges cannot be delivered with glycerine filling

- Capsule pressure gauges are suitable for gaseous media only

Diaphragm Pressure Gauges

- Wetted parts in steel

or stainless steel.

Dry or glycerine filled.

Threaded or flanged connection- Standard execution: wetted parts in steel and copperalloy

- All stainless steel execution: wetted parts in stainless steel

- Ranges from 10 mbar to 25 bar pressure and vacuum and compound

- Bajonet type case in steel or stainless steel

- Pressure connection with thread or flange

Laboratory test pressure gauges

- Analogue reference pressure

gauges with high accuracy.

Cl. 0.6 / Cl. 0.25 / Cl. 0.1

for test and calibration purposes- Analog bourdon tube pressure gauges with particularly high measuring accuracy

- For test and comparison measurements

- Accuracy ±0.6% FS or ±0.25% FS or ±0.1% FS

- Accuracies from ±0.6% FS to ±0.1% FS

- Scale with fine graduation, balanced knife pointer

Differential Pressure Gauges

- Measure differential pressure.

Membrane, diaphragm, capsule

and magnetic picston system

from 6 mbar to 250 bar delta p- Analogue differential pressure gauges with membrane, diaphragm, capsule or magnetic piston system

- Differential pressure ranges from 0...6 mbar to 0...250 bar

- Static pressure up to 400 bar (depending on model)

- For measurement of differential pressure in filters, pumps, vents, cooling systems, piplines, clean room technology, medical technology, etc.

- Models for gaseous and fluid media

- Some models can be equipped with reed contacts

Pressure gauges with electric contacts

- Pressure gauges with

electric contacts:

Magnetic snap-, inductive-

or elektronic contacts- Dial pressure gauges with electric contacts

- ...with magnetic snap-action contact(s), or

- ...with inductive contact(s) (also ATEX), or

- ...with electronic contact(s), e.g. for SPS

- Housing without or with dampening fluid filling

- Bourdontube in brass or stainless steel

- Diaphragm in steel or stainless steel

- Case diameter DS 100 or DS 160

- For gasoeus or fluid media

Digital handheld manometers

-

Our digital handheld manometers (pressure gauges) are portable hand-held gauges for accurate measurement of pressures, vacuum, differential pressures and also absolute pressures.

- Precision handheld measuring device for pressure, vacuum, differential pressure, absolute pressure as well as torque and force/weight

- Handheld pressure, vacuum and differential pressure gauges

Digital Pressure Gauges

- Digital pressure gauge

Very accurate and robust

Selectable pressure units

Some models with interface

- Digital pressure reading instruments

- Several models and accuracies

- Very accurate and robust

- Selectable pressure units

- Models with USB or RS232 interface available

- Models with WIRELESS data transmission available

- Accuracy from ±0.5% FS to ±0.05% FS

- Very good readable LC display

- Suitable also for calibration and test purposes

Pressure Switches

- Electronic pressure switches

with or without digital display,

Mechanical pressure switches

very robust

- Electronic pressure switches with up to 4 contacts

with or without digital display (LED)

Due to the simple handling as well as the variety of software features (switching points and hysteresis freely configurable, delay function, Min/Max value data storage, display and analogue output signal scalable, etc.) the electronic pressure switches of DRUCK & TEMPERATUR Leitenberger GmbH is expecially suitable as intelligent pressure switches for general plant and machine construction and the processing industry. - Mechanical pressure switches with up to 2 contacts

with diaphragm or bourdon tube

Highly robust - Models with IO-Link interface

- Electronic pressure switches with up to 4 contacts

Diaphragm Seals

- For seperation of pressure medium,

e.g. hygienical applications or

for highly viscous media

Large selection of materials

In order to isolate the measuring elemtent of pressure gauges, pressure switches and electronic pressure transmitters from corrosive, vicous and sedimentary process fluids, diaphragm seals are placed in between the measurement point and the instrument. Diaphragm seals must often be made of special high-strength materials.

Diaphragm seals are manufactured to DIN or ANSI standards.

Depending on model, following materials are available for the wetted parts:- Stainless steel AISI 316

- Stainless steel AISI 316 with PTFE coating

- Monel 400

- Hastelloy C276

- Hastelloy B2

- Tantalum

- Icolloy 825

- Inconel 600

Accessories

- Valves, Cocks, Syphons,

Overpressure protection,

Rubber caps, Adapters,

Gaskets, Cooling tower

We offer large number of accessories for pressure gauges, pressure transmitters and pressure switches:- Pressure gauge Valves

- Pressure gauge Cocks

- Syphons

- Overpressure protection devices

- Rubber protection caps

- Threaded adapters

- Gaskets Cooling tower

Pressure Calibration

Portable Pressure Test Pumps

-

Pressure test pumps serve as a portable manual test pressure source for the calibration of pressure measuring instruments by means of comparative measurements

- Simple manual operation

- Pneumatic (with ambient air)

- Hydraulic (with oil or water)

- Simple and sensitive test pressure adjustment via built-in fine adjustment valve

- Including connection for reference device and connection (via hose) for test item

Pressure Comparison Test Pumps

- Manual hydraulic spindle pumps

for generation of pressure

pneumatic or hydraulic

max. 7000 bar- Manual generation of test pressure for test, adjustment and calibration purposes.

- Pneumatic hand lever pump (with ambient air), or

- Hydraulic spindle pump (with water or oil, depending on model).

- Make also high pressure values with very low force.

- Fine pressure adjustment with sensitive volume variator.

Electronic Pressure Calibrators

- High accuracy reference pressure

reading instruments,

documenting process calibrators,

combined calibration instruments- Pressure Calibrators

Pressure reference standard for checking, adjustment and calibration of all kind of pressure reading instruments. - In addition, documenting process calibrators measure mA and V and save calibration data of units under test.

- Some models have data logging functionality.

- Normally, in addition a calibration pressure source is needed (e.g.

Pressure Test Pumps or Pressure Comparison Pumps).

Exception: Model LR-Cal LPK 300-PP comes with integrated electric pump -0.8...+20 bar. - Optional the pressure calibrators can be supplied with DAkkS certification.

- Pressure Calibrators

Pressure Calibration Kit - LR-Cal LPP-KIT pressure calibration kits

- LPP-Kit: portable pressure

source (test pump) PLUS

pressure reference instrument

as KIT in a case

Pressure source (test pump) and reference pressure gauge / calibrator in portable case.

Content of pressure calibration kits LR-Cal LPP-KIT:- Pressure test pump

- Reference pressure gauge or pressure calibrator (standard)

- Set of threaded adapters Rigid transit case with custom foams

The portable pressure calibration kits LR-Cal LPP-KIT allow a comfortable, efficient and very accurate testing, adjusting and calibrating of pressure measuring devices in the field, as well as in laboratories and workshops.

Digital Handheld Manometer

-

The portable pressure calibration cases LR-Cal LPP-KIT contain calibration pressure source, reference and accessories (adapters/seals) in a sturdy case.

Composites:

- Pressure test pump(s) with test hose(s)

- Reference pressure gauge (comparison standard, pressure calibrator)

- Thread adapter set (and seals)

- Rigid case with molded foam inserts

Pressure Controller

- Motorized automatic

pressure source and

pressure reference reading

in ONE unit

- Automatized generation of pressure and vacuum, high accurate reference included.

- Due to the high accuracy and control stability, the pressure controllers are especially suitable as references for production lines and laboratories, in order to carry out automatic testing and/or calibration of all types of pressure reading instruments.

Deadweight Tester Pressure balances

-

Deadweight tester also called pressure balances, piston manometers or pressure test stands with weighted pistons, are primary standards for the measurand pressure. They include both a calibration pressure source and a reference and are therefore self-sufficient.

- Rigid basements with integrated manual test pressure generation (spindle pump)

- Extremely high reproducibility

- Measurement uncertainties mathematically calculable

- Accuracy data in % of the measured value (not of the FS full scale value)

- Basic mechanical-physical principle

Hydraulic diagnostics

-

Diagnostic equipment and cases for testing hydraulic and working hydraulic applications

- Diagnostic device pressure + flow + temperature

- Hydraulic test case

- Hydraulic test case for working hydraulics

- Digital pressure gauge without and with USB interface

- Pneumatic test cases (test kits)

Marine calibration cases (pressure + temperature)

- Everything for testing and calibrating pressure gauges and temperature measuring instruments of all types in a splash-proof case.

Temperature

Temperature Measurement

Bimetal dial thermometer

- for process industry,

all stainless steel or

industrial executions,

for heatings or for air ducts,

with coiled spring or bar magnets- Models for Process and Chemical Industry

- Industrial and Standard executions Models for Heatings

- Models for Air ducts

- Model for touching measurement with coiled spring

- Model for touching measurement with bar magnets

Inert gas dial thermometer

- All stainless steel, for

process and chemical industry

Without or with capillary

Bottom or back connection

or every angle connection- All stainless steel construction

- Without or with capillary (for remote reading)

- Process connection radial buttom, or

- Process connection axial back, or

- Every angle process connection

- For food industry, pharmaceutic industry, chemical and petrochemical industry

Temperature probes, temperature transmitter and digital thermometer

- For industrial applications

or handheld instruments

High accuracy, comfortable and easy handling- High accuracy

- Simple operation

- Very large, clear visible display

- For industrial applications

- Handheld instruments

- Measures temperature of fluids, gases, materials, surfaces

Temperature Calibration

Multifunction Calibrators

- Measure and simulate

temperature, mV, mA,

resistance, TCs, RTDs

Loop Calibrators- Multifunctional calibrators:

Measure and supply of thermocouples, resistance thermometers, resistance, current, voltage. - Calibrate temperature and pressure with one instrument

- Multifunctional calibrators:

Precision Reference Thermometer

- High precision reference

thermometer

Reference RTD probes,

Reference Thermocouples- very high accuracy

- as reference for comparison measurements of temperature for calibration purposes

- preaged

- handhelds with probe, or reference RTDs and TCs

Temperature calibration baths

- Micro Baths for temperature

calibration

Portable and stationary

models

- Models for portable use (e.g. on site) or stationary use (e.g. in laboratory)

- Controlled temperature source for calibration purposes

- Models from -40°C to +300°C

- Accuracy up to 0.15°C

- Stability up to ±0.02°C

Dry block temperature calibrator

- Portable

Metal Dry Block

Temperature

Calibrators

- Models for portable usage, e.g. on site

- Controlled temperature source for calibration purposes

- Models from -24°C to +1100°C

- Accuracy up to 0.15°C

- Stability up to ±0.03°C

- Block diameters from 35 mm to 60 mm

- Insertion depths from 104 mm to 275 mm

Black Body Temperature Calibrator

- complete kit

Dry block temperature calibrator

and

precision handheld thermometer

- Model for portable use, e.g. on site

- Controlled temperature source for calibration purposes

- with "Black Body" insert for checking and calibrating non-contact measuring infrared thermometer

- Range +24°C...+650°C

- incl. handheld reference thermometer with probe

Marine calibration cases (pressure + temperature)

- Everything for testing and calibrating pressure gauges and temperature measuring instruments of all types in a splash-proof case

Level - Niveau

LLS 150 Level limit switch

-

Brief description:

- Level limit switch for liquid media

- Aseptic measuring point due to G 1/2" process connection thread for modular weld-in socket and process connection system (see accessories)

- EHEDG-compliant, food-safe materials

- No PC required for commissioning and calibration

- Defined position of the screw connection

Your benefits:

- Aseptic sealing system

- Food-safe materials, EHEDG-compliant

- Independent of the conductivity of the medium

- Quick teach-in possible via teach-in button

- Robust stainless steel head with protection class IP 69K

LLS 250 Level limit switch (rod version)

-

Brief description:

- Level limit switch for liquid media

- Ideal as an alternative to the tuning fork

- Aseptic measuring point thanks to 1/2" BSP process connection thread for modular weld-in socket and process connection system (see accessories)

- EHEDG-compliant, food-safe materials

- No PC required for commissioning and calibration

- Defined position of the screw connection

Your benefits:

- Aseptic sealing system

- Food-safe materials, EHEDG-compliant

- Independent of the conductivity of the medium

- Quick teach-in possible via teach-in button

- Robust stainless steel head with protection class IP 69K

- Reliability even with adhesive and viscous media

LRP 150 Level probe with 1 rod

-

Brief description:

- Level rod probe as single-rod probe for conductive level measurement

- Aseptic measuring point due to 1/2" BSP process connection thread for modular weld-in socket and process connection system (see accessories)

- EHEDG-compliant, food-safe materials

- Defined position of the screw connection

- Rod can be freely shortened

Your benefits:

- Aseptic sealing system

- Food-safe materials, EHEDG-compliant

- Rod can be shortened as required

- Resistant to media adhesion with PFA coating

- Robust stainless steel head with protection class IP 69K

- Optionally with integrated LAM 2 evaluation electronics

LRP 250 Level rod probe with 2 rods

-

Brief description:

- Level rod probe as dual rod probe for conductive level measurement

- Aseptic measuring point due to 1" BSP process connection thread for modular weld-in socket and process connection system (see accessories)

- EHEDG-compliant, food-safe materials

- Defined position of the screw connection

- Rods can be freely shortened

Your benefits:

- Aseptic sealing system

- Food-safe materials, EHEDG-compliant

- Rods can be shortened as required

- Resistant to media adhesion with PFA coating

- Robust stainless steel head with protection class IP 69K

- Optionally with integrated LAM 2 evaluation electronics

Accessories for LLS 150+LLS 250+LRP 150+LRP 250

-

Weld-in sleeves, sealing plugs and process connections

for LLS 150 + LLS 250 + LRP 150 + LRP 250- Dead space and elastomer-free process adaptation

- Hygienic installation in containers and pipelines

- EHEDG and FDA compliant

- Material stainless steel 1.4404 (AISI 316L), others on request

- With material certificate on request

- Process connections: Milk pipe, DIN 11851, Varivent, DRD flange

Connection cables, plugs and connectors

for LLS 150 + LLS 250 + LRP 150 + LRP 250- with pre-assembled M12 circular plug connector

- 4-pole version

- Stainless steel union nut

- PVC cable

- Various lengths

LLD 200 Level device

-

Brief description:

- Level device for top-hat rail mounting in the control cabinet

- Channel 1: simple tank/level control

- Conductive measuring method

- Adjustment of sensitivity and time delay via potentiometer

- Channel 2: Overflow or dry run protection (separate from channel 1)

- 2 relay outputs (2 changeover contacts) or active electronic output for PNP

- 2 status LEDs on the front panel

Your advantages:

- Slim housing design 22.5 mm

- 2-channel device (level control and full/empty signal)

- Adjustable time delay

- 2 status LEDs on the front

- Integrated pump control with 3-rod probe

Optical Level Switch Model FS-18S

- Light source: LED (red light)

- Measurement: Switch

- Response time: 10 ms

- Process temperature: -25°C...+55°C

- Process pressure: -0,5 bar...+16 bar

- Process connection: 1/2" BSP male

- Supply voltage: 10...30 VDC

- Electrical connection: M12x1, 4-pin

- Signal output: PNP or NPN

- MEDIA: Fluids (with max. low density foam)

Immersion probe Model LMP 307

- Stainless steel sensor

- Accuracy ±0.35 (optional 0.25/0.1)% FS

- Nominal pressure: 0...1 mH2O to 0...250 mH2O.

-

Output signals: 4...20 mA (2-wire),

0...20 mA (3-wire), 0...10 V (3-wire). -

Special characteristics:

• Diameter 26.5 mm

• Small thermal effect

• High accuracy

• Good long term stability - MEDIA: Water, fuel, oil

- OPTIONS: IS-version, SIL-2 version, drinking water certificate (DVGW and KTW)different kinds of cables and elastomers, petrol-version - welded pressure sensor and housing, mounting with stainless steel pipe.

Immersion probe Model LMK 307

- Ceramic sensor

- Accuracy: ±0.5% FS

- Nominal pressure: 0...4 mH2O to 0...250 mH2O

- Output signals: 4...20 mA (2-wire),

0...20 mA (3-wire), 0...10 V (3-wire) - Special characteristics:

• Diameter 27 mm

• Good linearity

• Excellent long term stability

• Easy handling - MEDIA: Water, sewage, fuel, oil

- OPTIONS: IS-version, SIL-2 version, different kinds of cables and elastomers, customer specific versions.

Immersion probe Model LMK 382

- Ceramic sensor

- Accuracy: ±0.35 (optional ±0.25)% FS

- Nominal pressure: 0...40 cmH2O to 0...200 mH2O

- Output signals: 4...20 mA (2-wire),

0...10 V (3-wire) - Special characteristics:

• Diameter 39.5 mm

• Especially for sewage, viscous and pasty media - MEDIA: Water, sewage, fuel, oil

- OPTIONS: IS-version, mounting with stainless steel pipe, flange version, diaphragm 99.9% Al2O3, different kinds of cables and elastomers.

Screw-in probe Model LMK 331

- Ceramic sensor

- Accuracy: ±0.5% FS

- Nominal pressure: 0...400 mbar to 0...60 bar

-

Output signals: 4...20 mA (2-wire),

0...20 mA (3-wire), 0...10 V (3-wire) -

Special characteristics:

• Pressure port 3/4" BSP flush for pasty and impurity media

• Pressure port PVDF for aggressive media - AREAS OF USE: Plant and machine engieneering, energy industry, environmental engineering, medical technology.

- OPTIONS: IS-version, SIL-2 version, customer specific versions.

Screw-in probe Model LMK 351

- Ceramic sensor

- Accuracy: ±0.35 (optional ±0.25)% FS

- Nominal pressure: 0...40 mbar to 0...20 bar

- Output signals: 4...20 mA (2-wire),

0...20 mA (3-wire), 0...10 V (3-wire) - Special characteristics:

• Pressure port PVDV for aggressive media

• Pressure port 1 1/2" BSP male for pasty and plluted media - AREAS OF USE: Plant and machine engineering, environmental engineering.

- MEDIA: Fuil, oil, viscous and pasty media

- OPTIONS: IS-version, diaphragm 99.9% Al2O3, customer specific versions.

Torque and Force Calibration

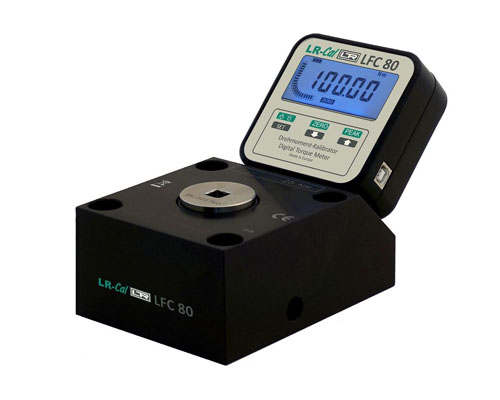

Torque Meter (bench type) - LFC 80

- Digital Torque Meter for benches

optional with mechanical support with dual linear guide for calibration of torque wrenches

for test and calibration purposes- Ranges from 0...0.5 Nm to 0...2000 Nm

- You can select from 9 torque measuring units

- Accuracy ±0.20% FS

- Incl. ACCREDIA (DAkkS) certificate from 1/10 of range for clockwise direction,

Total uncertainty <=1% FS

(Ranges 0...0.5 Nm and 0...2.5 Nm incl. factory certificate) - Optional additional ACCREDIA (DAkkS) Zertifikat for counter-clockwise direction

- PEAK function for exact detection of the "snap-point"

(clockwise and counter-clockwise direction) - Programmable "First PEAK" Function, makes calibration more easy

- Optional: with data logging functionality

- With optional support LR-Cal LFC-ATCplus suitable for calibration as per ISO 6789-1 and ISO 6789-2.

Professional handheld indicator - LHM

- High accuracy handheld indicator for force/weight, torque and pressure

PEAK function with programmable "First Peak" detection, internal and external sensors

USB interface, optional WIRELESS

Data logger, rechargeable Li-Ion battery

for force/weight, torque and pressure- With internal force or pressure sensor or without internal sensor.

- External sensors for pressure and torque.

- Rigid aluminium housing, portable.

- Up to 4800 measurements per second, programmable.

- Data logger (130,000 values).

- USB interface.

- PEAK function, positive and negative.

- "First PEAK" detection, programmable.

- Programmable filter and average functions.

- Chargeable Li-Ion battery, incl. USB charger.

- 15 pressure units, 9 force/weight units, 8 torque units.

- Up to 7 external sensors, also mixed, automatic sensor recognition.

- Possibility of linearisation and calibration of the sensor(s).

- Optional WIRELESS data transmission.

Reference Pressure & Force Gauge - DFP

- Digital Reference Pressure Gauge, scalable conversion to force & weight

Perfect for checking pressure gauges at hydraulic presses

- Accuracy ±0.1% FS

- Pressure ranges up to 2000 bar

- 1 year autonomy without recharging (battery operated)

- Pressure unit "bar", conversion to Force (daN, KN) or Weight (to, kg)

- PEAK function (positive and negative)

- Digital filter (adjustable)

- Pressure connection: 1/2" BSP male

- Clear and easy to read LCD with large figures and bargraph

Datalogger

LDL 540 and LDL 550

- Extremely robust data loggers for external sensors, for

- Temperature

- Pressure

- Pulse

- Digital

- Norm signals

BS

- Mechanical Line Strip Recorder for pressure and/or temperature Writing width 100 or 120 mm Several recording speeds available Also as double recorder Portable or for wall mounting

LDL 650

-

Graphic display

2 alarm contacts

For external sensors

1, 4 or 8 analog channels- Temperature Pt 100, Pt 500, Pt 1000

- standard signals

- Digital RS485 interface, Modbus RTU

Incl. Windows PC software

LDL 700

-

Multi-channel process value display TFT

with switching and analog outputs

Option: with data logger- Touchscreen

- 8 integrated PD/PI/PID controllers

- RS-485 interface, Modbus RTU

- USB host port + USB device port

- Assignment of max. 60 channels by inputs, outputs, mathematical/logical functions, controllers, profiles and virtual outputs

LR SMART TECH Hydraulic

Hydraulic Diagnostic Device - HD 01

- Pressure & Flow & Temperature

2 measuring channels, each channel displays 3 physical values: pressure, flow and temperature.

Logging and storage of measured data via USB interface on USB stick.

Clear, easy readable LC display with backlight option.

Ranges:- 0...250 bar + 7.5...78 l/min + 0...125°C

- 0...400 bar + 15...300 l/min + 0...125°C

- 0...400 bar + 40...600 l/min + 0...125°C

All sensors supplied with factory certificate of calibration.

Chargeable Li-Ion battery.

Option: Volume flow controller MBV, for simulation of a load on the hydraulic pump

Hydraulic Test Kits - HPKD and HPK

- Enable quick and reliable diagnostics of all kind of hydraulic systems

Test kits with digital or analogue reference pressure gauges, hoses and adapters

Pressure ranges: 25 bar / 100 bar / 400 bar / 600 bar- Test kit HPKD: with 1 to 3 digital pressure gauges DM 80

- Test kit HPKD-UMS: with 1 to 3 digital pressure gauges DM 80-UMS with data storage and USB

- Test kit HPK: with 1 to 3 analogue pressure gauges DS 63

Digital Pressure Gauge with Data storage and USB interface - DM 80-UMS

- Accuracy ±0.5% FS as per IEC 60770, incl. factory certificate of calibration

Pressure ranges from -1...+16 bar to 0...1000 bar

Pressure units: mbar, bar, PSI, kPa, MPa

Large LCD with bargraph and backlight option

Min- and Max PEAK function

Supply: built-in chargeable Li-Ion battery

Digital Pressuere Gauge - DM 80

- Accuracy ±0.5% FS as per IEC 60770, incl. factory certificate of calibration

Pressure ranges from -50...+50 mbar to 0...2500 bar

Pressure units: mbar, bar, PSI, kPa, MPa

Large LCD with bargraph and backlight option

Min- and Max PEAK function

Supply: 2 batteries 1.5 V VDC LR6-AA

Low-cost Digital Pressure Gauge - DM 80-S

- Accuracy ±0.5% FS as per IEC 60770

Pressure ranges from von -1...+3 bar to 0...60 bar

Pressure units: bar, PSI

Battery operated

TESTKIT in transit case with Pressure test pump LR-Cal LPP 40 for manual generation of test

- pressure -0.95...+40 bar and

Digital Test Pressure Gauge DM 80

or

Digital Pressure Gauge and Data Logger DM 80-UMS

incl. factory certificate of calibration

and set of BSP, NPT and metric threaded adapters.

Marine Calibration Kits

Marine Calibration Kits

- Every ship has a large number of measuring devices and sensors for the measurands pressure and temperature on board.

A regular calibration of the accuracy of these gauges and sensors is mandatory by the classification societies.

The calibrators should be easy to operate, particularly robust and reliable. The accuracy of this test equipment must be documented by certificates.

This is exactly the purpose for which we offer our LR-Cal Marine Calibration Kits.

The LR-Cal Marine Calibration Kits enable the user to perform pressure and temperature tests and calibrations for all types of pressure and temperature insturments.

They contain a dry block temperature calibrator as well as a complete pressure test set (test pressure source and certified reference device).

Both, the pressure and the temperature calibration components are supplied with factory calibration certificates.

All components are housed in a waterproof and robust marine case.

INDUSTRIES

Pharmaceutical Industry

- The manufacture of pharmaceutical products require the highest level of qulity and product safety. With our measuring, testing and calibration instruments freedom from contamination and safety of your production processes can be guaranteed in accordance with all hygienic requirements.

To meet the standards of the pharmaceutical industry, our devices can be delivered with the following approvals:- FDA (Food & Drug Administration)

- ATEX (Intrinically safe for potentially explosive environments)

In order to ensure safety and hygienic requirements, we can deliver our devices with the following process connections, i.e.:- Threaded connections, e.g. in stainless steel

- Clamp connections

- VARIVENT connection

- Threaded connections with flush diaphragm

Oil and Gas Industry

- The treatment and extraction of oil and gas over longer distances constantly requires new demands and the highest standards for the installed measuring technology. Our measuring, testing and calibration devices (depending on the model) are tested extensively under extreme conditions for both, the onshore and the offshore area, and therefore are applicable for the use even under the most severe environmental conditions.

To meet these high standards, our devices can be delivered with the following approvals and according to the following standards:- ATEX approval (for use in potentially explosive environments)

- NACE standard 01.03

In order to ensure safety and stability under extreme conditions, we can deliver our devices with the following material, i.e.:- Wetted parts made of Stainless Steel

- Wetted parts made of Hastelloy

- Wetted parts made of Monel

- Wetted parts made of PVDF or PVC

Chemical and Pertochemical Industry

- Since the chemical and petrochemical industry are subject to strict international guidlines such as the PED and ATEX, the requirements for the devices used in the process are very high. The installed measuring, testing and calibration instruments must ensure a smooth workflow and the protection of the system and operators. In addition, the devices must be continously stable, even in aggressive environments and in potentially explosive atmospheres.

Hydraulic Diagnostic

- Hydraulically operated systems in the stationary as well as in the mobile hydraulic must be checked periodically in order to ensure the product quality. Our LR SMART TECH test and diagnostic devices are especially developed for hydraulic applications and guarantee an easy handling during test and diagnostic works and fast readout of the measurement data.

For all kind of hydraulic applications, our pressure transmitter (model dependend) and glycerine filled bourdon tube pressure gauges are ideal.

Food Industry

- The industrial production of food and beverage requires the highest standards of hygiene and safety. Protection against the formation of germs and bacteria is elementary in order to guarantee a smooth and contamination-free production process. To ensure that, our measuring, testing and calibration devices (depending on the model) meet the respective requirements with regard to material, process reliability, contamination protection and process connection technology.

To meet these high standards, our devices can be delivered with the following approvals:- FDA (Food & Drug Administration)

- ATEX (Intrinsically safety in potential explosive environments)

To ensure all safety and hygienic requirements, we can deliver our devices with the following process connections, i.e.- Stainless steel threaded connections

- Clamp connections

- VARIVENT connection

- Threaded connections with flush diaphragm

Marine - Onshore and Offshore

- Due to the extreme conditions at sea, the marine industry demands the highest requirements on technology and materials. Measuring, testing and calibration instruments are exposed to a wide variety of loads such as shocks, aggressive medie, cold or heat.

We offer suitable measurement, testing and calibration technology for the use on board, which ensures safe operation and quality.

Medical Engineering

- Inspections and check-ups at medical facilities require a high level of quality, reproducibility and safety. Pressure and temperature measurements must be checked regularly, storage conditions e.g. for medication must be documented.

Calibration Labs and Quality Assurance

- All industrial sectors require the highest standards on process-relevant measuring equipment in order to guarantee the quality and safety of machines, systems, facilities and operators. Since measuring devices are exposed to various influences such as heat, cold, shocks, pulsating pressures or aggressive media, we recommend an annual inspection and recalibration.

For these applications we offer you particularly well-suited devices and systems, namely for the following physical measures:- Pressure

- Temperature

- Torque

- Force

Our testing and calibration devices are not only suitable for laboratory uses, but (depending on the model) also portable on site, directly at the measuring point. Since the ambient conditions have to be documented during a calibration, we also offer particularly suitable data loggers for the ambient temperature, relative air humidity and barometric air pressure (e.g. required to calculate the air density).