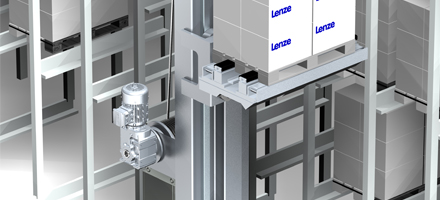

Lenze presents its new fully rounded SRU solution package

Photo by Lenze SE

Enhanced system performance, reduced commissioning times and lower energy consumption – these are the main requirements for next-generation storage and retrieval units (SRUs). Lenze has now brought a fully rounded SRU solution package onto the market. The new automation solution has intelligent hardware and software in-side and is tailored to the requirements of modern SRUs. It offers sophisticated safety functions, simplifies engineering and improves system availability. The benefits are increased productivity, lower energy consumption and better use of space for logistics tasks.

The travelling and hoist drives and load handling device axes are controlled by a Motion Controller as the central control. The new machine module for storage and retrieval units from the Lenze FAST application software toolbox, which controls all SRU functions, is integrated into it. Like all FAST software modules the focus is on setting parameters instead of programming. Intuitive user guidance using a graphical user interface (GUI) and prepared visualisation of the storage and retrieval unit facilitate all engineering tasks.

In addition, the integrated online identification of payloads enables automatic dynamic feedforward adjustment of the servo controller to constantly changing loads during SRU operation. The tendency to oscillate is thus reduced and the load handling device can reach its exact position faster.

Given the high speed requirements, every second before the engineering inside the storage and retrieval unit stops the oscillation counts. Lenze has therefore developed a special function for SRUs: the exclusively software-based control system uses counter-pulses to reduce any residual boom oscillation after feedforward controlling. This solution smooths the way to high travelling drive acceleration speeds without time-consuming S-rounding. As the reduced boom oscillations die down faster, the telescopic arm of the load handling device can be run out faster, thus additionally increasing SRU productivity.

When it comes to SRU safety, the question is immediately posed as to how the controller behaves in the event of power failure. Lenze has developed a drive power failure control that guides the drives to a halt without immediately applying the mechanical brakes. Power failure is detected within 5 milliseconds, potential energy consumers are switched off and the travelling drive switched to operation in generator mode. The storage and retrieval unit kinetic energy can thus be stored for reuse in the servo inverter DC bus until the storage and retrieval unit has dissipated its kinetic energy. Only then are the brakes applied with the advantage of less wear and tear due to reduced friction work.

A safety system integrated into the drive and reliable Ethernet-based field buses form the basis of the modern safety concept for SRU motion control. All safety-relevant functions of the storage and retrieval unit can thus be solved without an inline safety control.

Productivity also includes using available space to its best advantage, so reducing the buffer area at the end of the aisles to create more storage space. This is possible thanks to reliable position-based speed monitoring, allowing Lenze to reduce the speed of the travelling drive as it gets closer to the end of the aisle.

Last but not least, the solution package significantly improves energy efficiency. On the one hand energy is saved by reusing the energy recovered from the hoist or travelling drive to raise the load handling device or accelerate the travelling drive.

Smart energy-efficient coordination of travelling and hoist drives is integrated into the Lenze FAST SRU machine module. The solution package also includes a new power recovery system, which due to its very compact dimensions and low weight, is ideal for use in the mobile control cabinet of the SRU and promises energy savings of up to 30 percent.

For more information, please visit http://www.lenze.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech