New 4th Generation RoboCylinder RCP series with High-end Pulse Motor Controller from IAI

Market launch by IAI at MOTEK 2012

At MOTEK the Japanese volume manufacturer IAI will be presenting its new RoboCylinder series RCP4, the latest development in the highest selling RCP electric cylinder series. Since the product launch in 1999, axes of the RoboCylinder product line in the high six figure range have left the company’s domestic production plant in Shizuoaka in Japan. This year IAI, as longstanding “vendor of choice” to Toyota, received the coveted Exclusive Supplier Status for all of Toyota’s production sites worldwide – not least due to the best quality-price ratio of its successful RoboCylinder RCP series.

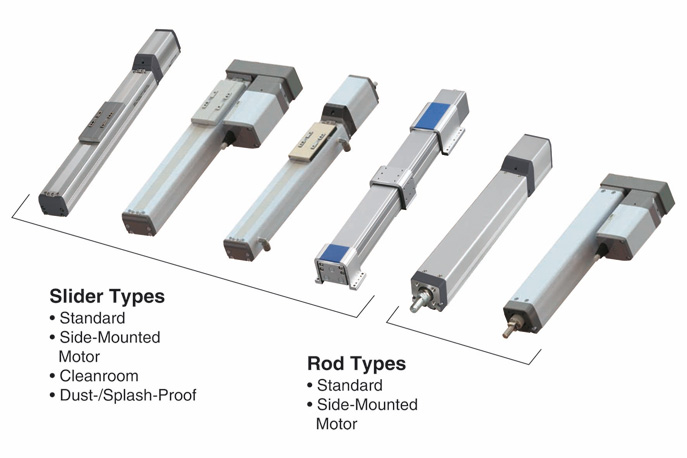

The new RCP4 series of 24 VDC electric cylinders from IAI is also designed as a replacement for pneumatic cylinders. The linear cylinders are available in two types, each in two variants: as directly driven slider or rod axis with the motor arranged as an extension of the cylinder’s longitudinal axis, or as short variant with a drive deflection in which the motor and axis are positioned parallel to one another. In addition, for special environmental conditions, IAI offers the slider axis in a special cleanroom series RCP4CR, suitable for cleanrooms of the ISO cleanliness class 4, as well as a special dust/splash-proof series RCP4W with protection degree of IP65.

For the market launch three sizes with widths of 52, 58 and 73 mm are available for the slider axes, and two sizes with an external diameter of 52 and 61 mm for the rod axes. The maximum permissible load extends from 370 to 673 and 1094 N with corresponding horizontal payloads of 20 to 80 kg. The maximum stroke extends from 50 to 800 mm for sliders and to 500 mm for the rods.

With the new corresponding high performance controller PCON-CA from IAI’s controller series PowerCon 150, with patent pending, the operator is provided with a range of options for automatically setting the optimal operating conditions as well as for service and maintenance work. The controller software, for which the IAI website guarantees continual updates, is equipped with new functions such as the control of production volume and utilisation rate, total travel monitoring with service reminder, fault recording with time protocol, cycle time minimisation or noise reduction.

A further feature of the software tool for the new pulse motor controller PCON-CA is the quick and easy commissioning. Software function modules are available for all standard controller manufacturers. In addition to CC-Link, DeviceNet, RS485 and pulse/direction interface, the Profibus DP field bus interface is also available for activation, parameterisation and diagnosis. In addition, the open interfaces EtherCAT, EtherNet/IP, and most recently Profinet, are also available for implementation in industrial Ethernet networks.

Visit www.iai-gmbh.de for more information

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech