Large-area grippers are setting new standards in the field of automated vacuum handling

Photo by Schmalz GmbH J. Förder- und Handhabungstechnik

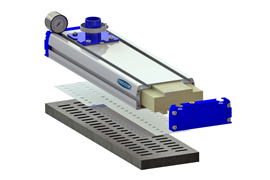

The new large-area gripping system FMP from Schmalz features over 86 percent more holding force than the competition, higher flexibility and increased energy efficiency. The third gripper generation is thus setting new standards in automated handling processes.

Wide range of applications

The new large-area gripping system FMP makes it possible to handle workpieces made of various materials such as wood, metal sheet, glass, cardboard or plastic with different shapes, surfaces and dimensions with ease. The workpieces can even be picked up from an imprecise position. The new system ensures process-safe handling of both porous workpieces and workpieces with gaps. The system is particularly suitable for use in the timber and furniture industries for handling coated or unplaned wooden workpieces such as boards, beams or panels. The new generation FMP also demonstrates its strengths in packaging processes and is ideal for automated palletizing and depalletizing of cardboard boxes, bags and film packaging or shrink-wrapped products.

86% more suction force

Schmalz has equipped the gripping system with a special insert element and leak-free check valves to optimize flow. Comparing it to the top products from competitors further highlights the gripper’s strengths: The FMP generates an impressive 86 percent more suction force on average when used on unplaned workpieces and 87 percent more suction force on workpieces with smooth surfaces.

Photo by Schmalz GmbH J. Förder- und Handhabungstechnik

Your benefits:

- Process-safe handling of porous workpieces

- Fast evacuation for shorter cycle times

- Improved energy efficiency

- Cost-efficient system design

Modular design

The main body of the large-area gripper consists of a single-chamber extruded aluminum section and has a connector for external vacuum generation. The FMP is available with a suction area equipped with plug-in bellows suction pads or highly flexible sealing foam. The optimized adhesive foil, which is used to attach the sealing foam to the valve module, is also new. When the sealing foam begins to show signs of wear, it can be removed without leaving behind any residue. Since this will eliminate the need for complicated sheet cleaning, the amount of work required to replace the foam is reduced by 90%. An innovative valve film makes it possible to quickly change the valves when different types and sizes are required. This means that the gripper system can be quickly and easily adapted to changing requirements. Even the check valves can be quickly installed or removed. Grooved strips on the sides of the body are used to attach sensors for part present detection and cycle-time optimization.

Overall, Schmalz was able to reduce the weight of the gripper system by 25%, which makes it possible to reduce cycle times and speed up production processes.

Minimum maintenance, maximum availability

During operation, the large-area gripping system proved to be exceptionally maintenance and service friendly. For example, the single-chamber section means that seals no longer need to be changed and that the flow technology can be switched at any time if the handling requirements change. Schmalz has tested its new sealing foams against the top competitors’ foams as well as against standard PU foam. The result: The wear limits of the other foams were already reached at 200,000 and 800,000 cycles, respectively. The sealing foam from Schmalz, on the other hand, was able to perform over 2 million cycles before reaching its wear limit. This guarantees increased availability by minimizing the maintenance times and system downtimes, thereby resulting in a quick return on investment.

The FMP series will be available from the third quarter of 2013. Efficient production processes at Schmalz ensure short delivery times.

For further information visit www.schmalz.de

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech