igus Introduces High‑Performance Components for Industrial Systems

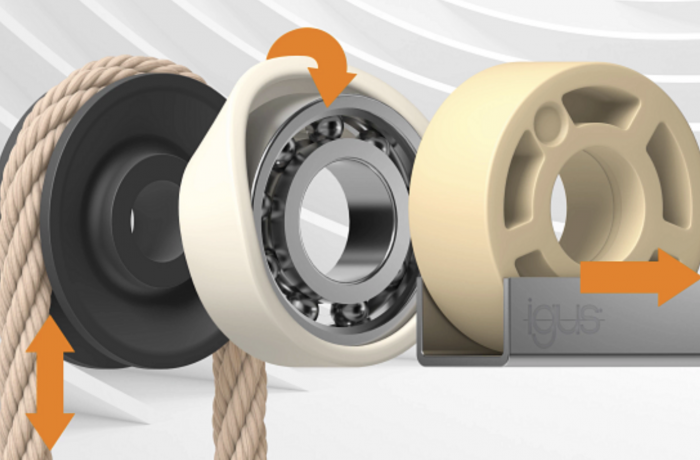

igus has announced that its new high‑performance plastic components—including skate wheels, pulleys and roller adapters—have entered series production and are now widely available for industrial automation applications. These components are designed to be durable, maintenance‑free and cost‑effective compared to conventional metal alternatives.

Advanced Materials Improve Durability and Operational Efficiency

The newly launched pulleys made from iglidur JB are built to run directly on shafts without additional lubrication, significantly reducing dirt‑sensitivity and maintenance requirements. Laboratory tests indicate they achieve around four times the wear resistance of POM pulleys. The skate wheels crafted from iglidur J offer up to six times the wear resistance compared with previous POM versions, and their lubricants‑free plastic design offers lighter construction, improved corrosion resistance and gentler operation on rails.

Roller Adapters Reduce Noise and Protect Running Rails

In addition to the pulleys and skate wheels, igus now offers roller adapters made from iglidur P360. These adapters allow existing metal skate wheels to run on plastic mounts, rather than metal‑on‑metal contact, which reduces wear on running rails, cuts maintenance cycles and delivers quieter operation. Tests show up to three times greater wear resistance compared to conventional PA adapters.

Applications Across Automation, Medical Devices and Mobile Systems

These new components are ideal for a wide range of use‑cases, including height‑adjustable workstations, compact lifting systems and mobile medical equipment. Their lightweight, lubrication‑free and maintenance‑free attributes make them particularly suited to environments where contamination or frequent use pose challenges.

For more information, please visit: https://press.igus.eu

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech