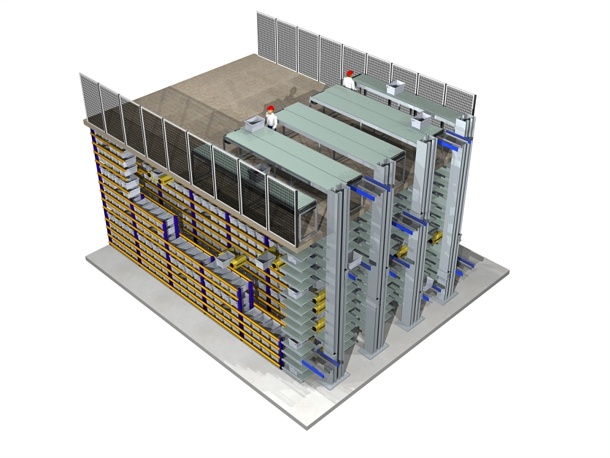

Next generation system for automated storage by DEMATIC

Dematic’s Multishuttle is the next generation system for automated storage and retrieval of cases, totes and trays.

Designed to enhance the interface between bulk stock and functions like picking, order assembly, and sequencing, the Dematic Multishuttle dramatically increases speed, accuracy and throughput.

Designed with simplicity in mind, the Dematic Multishuttle offers standard modular components and the flexibility to be scalable, especially for companies experiencing rapid growth and change in product demand profiles.

With sophisticated controls and performance enhancement software, the Dematic Multishuttle can interface with a wide range of storage media and handling containers. Its inherent flexibility enables it to be easily adapted to any shape or size building, including existing buildings with lower ceilings.

Photo by DEMATIC Europe GmbH

The Dematic Multishuttle extends the range of applications possible with automated storage systems, allowing a completely new range of automation solutions to be developed.

Dematic Multishuttle Captive

The Dematic Multishuttle “Captive” format is ideal for high throughput applications such as order picking and order consolidation buffers. A dedicated shuttle is used at each storage level in every aisle so that retrieval and put away are handled simultaneously with up to 600 double cycles per aisle per hour possible.

In Captive Systems, intelligent controls enable complex sequencing that contributes to flexibility and building store friendly orders.

Photo by DEMATIC Europe GmbH

For further information visit www.dematic.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech