AUTOMHA’s LOG system offers semi-automatic intralogistic solution for efficient management and customizable warehouse

Photo by Automha S.p.A.

AUTOMHA, leader in creating systems for intralogistics, studies solutions and products to meet the needs of any industry.

Factory 4.0 is synonymous with technology, progress and traceability. But who says that these characteristics are verifiable only in completely automated and extremely complex systems?

AUTOMHA, leading company in creating systems for automatic storage, has wanted to create solutions of artificial intelligence suitable also to those realities that, for impossibility or needs, they chose a solution of semi-automation of its own internal logistics. This also allows companies until now considered excluded from the panorama 4.0 to make it more efficient quality management and processes at the production system level, logistic, traceability and data exchange.

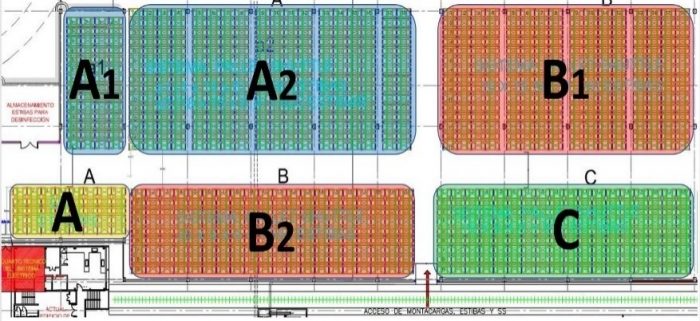

It is for this need that LOG was born, as logging, recording software which makes a warehouse served manually or by traceable AUTOSAT technology and efficient exactly as a system completely automatic. LOG holds track and manage all flows internal handling of the warehouse, processing all related information at the reception, at the deposit and to take out the goods.

Thanks to its hierarchical structure and modular, the LOG software it also allows to map and memorize accurately all the personal data related to load unit, such as production dates, type of content or quantity a warehouse. Peculiarities of LOG it is also its graphical interface, extensive but at the same user friendly and quick response time. The adoption of the software LOG of AUTOMHA allows therefore efficient management and customizable warehouse, mapped and rearranged anytime following the company logic. Among the good benefits of this software falls also traceability, understood as the ability to identify immediately the goods stored in lanes, activities, this, supported by the ability to extrapolate reports timely about the situation of warehouse in general. This reporting is developed with a predictive, finalized logic to preventive management ordinary maintenance o extraordinary. This allows to drastically lower the possibility to stop stock or data dispersion.

Maximum efficiency is given by the union of LOG with the AUTOSAT technology, the semi-automatic satellite for the intensive pallet storage in multi-depth invented and launched for the first time on the market by AUTOMHA in 2002 and today became the shuttle best-selling and appreciated at world.

For more information, please visit https://www.automha.it.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech