Franke’s wire race bearings helps Risomat optimizes its manufacturing capabilities

Photo by Risomat GmbH & Co. KG

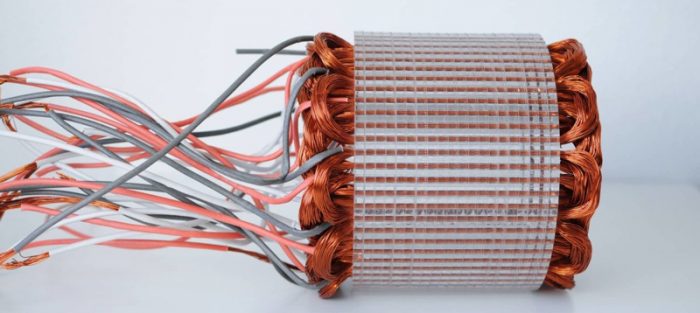

Whether in an electric toothbrush, in an e-car or in the generator of an emergency power unit – electric motors of all different sizes move our world and their number is constantly growing. With the production systems of Franke’s customer Risomat, electric motors and generators can be manufactured in a highly automated way. Risomat uses specific wire race bearings from Franke for its special machines.

The company Risomat in Baienfurt, Upper Swabia, develops and builds production solutions for the electrical industry: from individual production cells to complete production lines. Risomat has been driving automation in the production of electric motors since the 1980s. And Risomat has been building complete production lines for e-car traction motors since 2010.

Family business with prospects

Risomat is owned and managed by Hubert Halder and his son Christian Halder. The son joined the family business one and a half years ago. Neither was born an entrepreneur: When Risomat arranged the succession in 2007, Hubert Halder was a salaried operations manager at Risomat. To ensure the continuous development of the company, he decided to take over the business.

The Halders attach great importance to solid planning for the future. With Christian Halder, 31, the succession in the company has already been arranged. “With a project duration of several months to years and a service life of usually more than 10 years, the customer is naturally already thinking: ‘Where do I buy my machine?'” he says. The company’s new building in Baienfurt, which was completed in 2019, also sets a sign towards the future. Almost four million euros were invested in the new location. All areas of the company are now under one roof.

E-cars and many more applications

Currently, the spacious production areas are mainly used to manufacture production lines for e-traction motors. Risomat has already equipped many German car manufacturers and suppliers: E-motors in vehicles from VW, Audi, BMW and Bosch, among others, are manufactured on Risomat lines. However, Risomat’s portfolio is not limited exclusively to e-traction motors. In cars alone, there are numerous other e-motors that can be efficiently produced with Risomat machines. Electric motors are also installed in generators, pumps, fans, cranes and conveyor systems, for example, which are manufactured on Risomat equipment. The electrical manufacturing professionals even offer suitable solutions for narrow niches. Siemens Healthineers, for example, uses Risomat coil-winding machines to produce the coils for its MRI equipment.

“Wherever there is little installation space available, the compact Franke bearings are very suitable.”, said Christian Halder, CEO of Risomat.

Matching bearing solutions from Franke

Individual bearing solutions from Franke are used at various points in Risomat’s manufacturing solutions. As a central rotary bearing for coil winding, for example, as the main bearing in rotary indexing tables or in modules for automated parts handling. On the one hand, Risomat uses super-slim Franke bearing elements, which enable the machine builder to design the enclosing construction according to his individual ideas. On the other hand, Risomat obtains complete bearing assemblies that are custom-designed by Franke – for example, with external gearing. The bearing assemblies offer Risomat the advantage that the manufacturing effort can be outsourced to the bearing specialist, which streamlines and accelerates its own production.

Photo by Risomat GmbH & Co. KG

Advantages of Franke wire race bearings

The Franke principle of inserted wire raceways has several advantages for Risomat: “Wherever there is little installation space available, the compact Franke bearings are very well suited,” Christian Halder explains. The adjustable preload of Franke bearings is particularly useful for Risomat in manually operated stations. How difficult or easy it is to turn a workpiece carrier, for example, can be precisely adjusted during assembly to find the ideal balance between backlash-free precision and ease of movement.

Another important argument in favour of Franke bearings is their low weight. Among other things, Risomat uses Franke wire race bearings with a diameter of over half a metre. Despite this size, they only weigh around one kilogram, which in turn benefits the dynamics and saves energy. Last but not least, the economic feasibility of large diameters and the free choice of bearing diameter speak in favour of Franke. Christian Halder sums it up like this: “Special machine construction requires special bearing solutions”.

“Franke offers a high-quality product. In addition, we appreciate the fact that they respond flexibly and innovatively to our wishes and challenges and look for solutions together with us.”Hubert Halder, CEO

Photo by Risomat GmbH & Co. KG

Birds of a feather flock together

Risomat and Franke are similar in their focus on individual requirements. Hubert Halder: “The main advantage for our customers is that we respond precisely to their problems and their product. We adapt every little sub-process individually so that the customer can manufacture his product perfectly.” In addition, they are very familiar with their customers’ products and can therefore advise them on manufacturability and design.

And there are also parallels in the emphasis on innovation. Hubert Halder sees the most important task for his company in maintaining the technological lead. “This means that we adapt and further develop the processes and machines to the new types of drive concepts.” Franke as a supplier fits Risomat very well in this respect: “Franke offers a high-quality product. In addition, we appreciate that they respond flexibly and innovatively to our wishes and challenges and look for solutions together with us.”

For more information, please visit http://www.franke-gmbh.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech