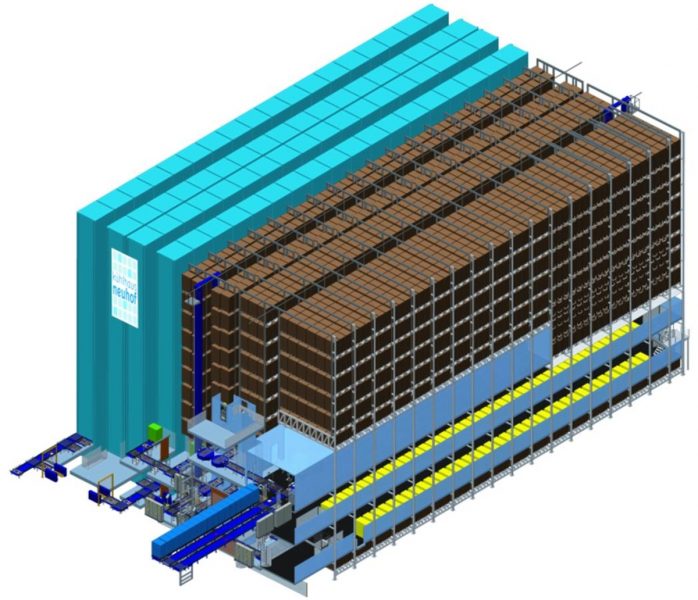

Gilgen Awarded Contract to Expand Deep-freeze Warehouse

Gilgen Logistics AG has been commissioned with this expansion of the deep-freeze warehouse. The capacity of the existing high-bay storage facility is going to be increased from 5,780 to more than 13,100 pallet spaces, with two additional storage aisles (one double-deep stacker crane / one multiple-deep stacker crane, with shuttle). Photo by Gilgen Logistics GmbH

A warehouse operator in the deep freeze sector, Kühlhaus Neuhof AG was founded in 1977 in Gossau, Switzerland. It specializes in the storage of meat, processed potatoes, semi-finished vegetables and all types of foodstuffs. In 2010, it constructed a new building with around 5,780 pallet places that went into operation in 2012. Gilgen Logistics supplied its pallet conveyor technology as well as the truck docking stations.

Primarily, services in the foodstuffs storage and transshipment sector are provided at this deep-freeze warehouse. Various customers (partners and third parties) make use of these logistics services to outsource their production volumes and for interim storage of raw materials. Opposite to expectations, the doubling of capacity realized upon a construction of the new building was already reached around the end of its second year of operation. This meant it became possible to meet the business partners’ storage requests only to a limited degree. In just five years, the facilities are going to be around one and a half times the size of the existing building.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech