GIS Entertainment motors utilized in an innovative rigging system for CAMPUS SURSEE

Photo by GIS AG

Just in time for the 50th anniversary of CAMPUS SURSEE, the new multipurpose venue is opened. With an area of 800m2 and a modern infrastructure, it offers the perfect setting for a wide variety of events. An innovative rigging system combines maximum flexibility with highest safety. The cable-bound control system monitors the individual loads and lifting paths of the 24 GIS Entertainment motors. Data traffic is handled via TCP/IP and the system is conveniently controlled via a control panel with touch screen.

A wide variety of activities is held at short intervals at the Campus Sursee. For example, an association organizes an event lasting several days and combines it with an exhibition, an innovative electric car is presented to an expert audience, or music concerts take place. Both state-of-the-art audio/video technology and fully motorised rigging ensure maximum flexibility in the new event hall. The two companies B+T Bild+Ton AG, Rothenburg, as general contractor, and GIS AG, Schötz, realize this rigging system together.

Safe flexibility

A space of about 800m2 (27.5m length and 29m width) can be divided into soundproofed halves if necessary. The event hall is equipped with 12 longitudinal trusses, which are held by a total of 24 GIS LP500 D8Plus electric chain hoists. From the hall ceiling, the supply for each truss is provided by a foldable energy chain. The basic equipment includes lights and loudspeakers (AV technology).

Each GIS motor is suspended to the hall ceiling as a climbing hoist and can be controlled individually. Grouping them together enables the synchronous lifting and lowering of the trusses. Thanks to the excellent synchronization, their precise positioning is always guaranteed. The control system seamlessly monitors each individual load and logs all movements. In case of overload, lifting is blocked, but controlled lowering is still possible.

GIS motors in customised execution

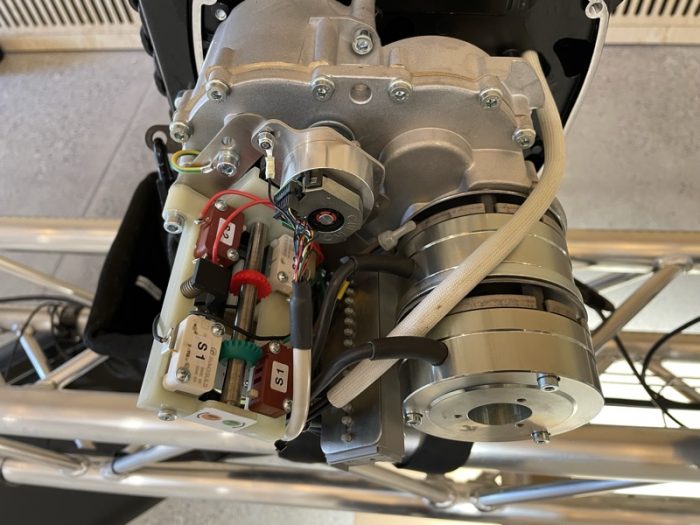

With the electric chain hoists used, in D8Plus version, people are allowed to stand under the resting load. An independent, second DC spring-loaded brake and a chain safety factor of 8:1 are essential for this. Two emergency stop contacts complement the geared limit switches for upper and lower hook positions. Each motor contains both, a load senor for load monitoring and an absolute encoder for measuring the lifting height. It has its own IP address and a TCP/IP communication interface integrated into the housing, with an external RJ45 socket.

Trouble-free communication

The brain of the rigging system is in an adjoining room, which includes a 19″ rack, with server, network switches and ports (POE) for the 24 motors. Thanks to cable-based communication, there is interference-free data traffic between the control panel, server and climbing hoists via the LAN. The system is operated on a tablet computer called “touch controller,” which is completed by an emergency stop switch and a green Go button. After its network cable is connected to one of three communication sockets in the hall, the motors are displayed with current lift height and load: For the entire event hall or only one of the two halves, depending on the socket selected.

Individually, as a group or all together, but always safe!

The target height for a single or a group of chain hoists is now entered on the touch controller. Five predefined combinations can be selected quickly and conveniently. However, the operator can also compose a group individually. In addition, scenes can be programmed. With the desired lifting heights, they can be easily called up later. After the presettings have been made, lifting or lowering is performed by keeping the Go button pressed.

Provisions for remote maintenance and a service contract with GIS ensure carefree operation of the rigging system for the future.

For more information, please visit http://gis-ag.ch.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech