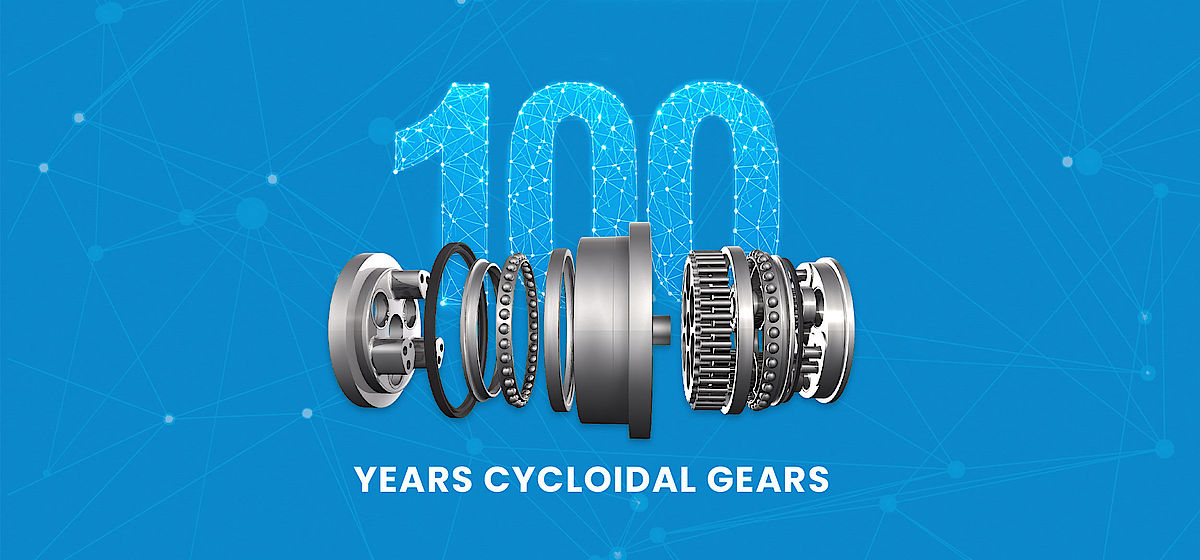

History: 100 years of cycloidal gears

In 2025, the cycloidal gear celebrates its 100th anniversary. Originally developed as a solution for use in cameras, this high-performance technology is now considered the ultimate in terms of precision, dynamics, and compactness. On the occasion of the 100th anniversary, we opened the history books to let the story come to life. Join us on a journey of discovery and find out how it all began.

While toothed gears were already known in ancient times, cycloidal gears are a relatively new technology. The first mention of the cycloid (a special shape of curve), from which the gears get their name, dates back to the early 16th century. But the invention of the cycloidal gear took another 400 years. In the late 1920s, the German engineer and entrepreneur Lorenz Braren developed an entirely new technology: the cyclo gear. For the transmission of forces, this type of gear used pins and rollers instead of the usual toothed gears – the cycloidal gear was born. In 1925, the technology was patented. This year therefore marks the 100th anniversary of the cycloidal gear.

100 years of cycloidal gears: An impressive success story

Compared to the millennia-long tradition of toothed gears, the 100-year history of the cycloidal gear appears at first to be relatively short – but the impressive success of the technology tells a different story. Originally, the invention was intended for use in cameras, but thanks to the outstanding properties – utmost precision, unique dynamics, exceptional load capacity, durability, compact design – its use in other areas of application was only a matter of time. Today,the innovative cycloidal gears are indispensable in robotics and other high-tech industries. They also cut a good figure in machine and plant engineering.

Two-stage reduction principle with external eccentrics

The world’s largest and most renowned manufacturer of precision cycloidal gears is Nabtesco Precision Europe GmbH. The company is the world market leader in the field of robotic gears and has a reputation as innovator and technology leader for cycloidal gears. A typical feature is the two-stage reduction principle with external eccentrics. This reduces vibrations, increases the fatigue limit, enables higher reduction rates, and achieves excellent performance with respect to dynamics and smooth operation, as well as excellent repeatability and path accuracy. As a result of standardisation, the cycloidal stage is consistent within a gear size; the different reduction ratios are achieved in the spur gear stage. The production of different, costly gear housings is eliminated, which is a big advantage in terms of cost-effectiveness.

Cycloidal gears and robotics

The first cycloidal gearbox from Nabtesco was manufactured in 1980. Used in excavator power drives, it was not yet a precision gear. The emergence of robot technology in Japan in the early 1980s marked the beginning of the great “career” of Nabtesco gears. The company collaborated with robot manufacturers from the very start. They required reliable, compact, and precise gearboxes – which led to the development of precision gears in the autumn of 1983. In 1985, the RV gearbox (RV stands for “rotor vector”) was launched – the first precision gear from Nabtesco with a cycloidal design. From the very beginning, these gears featured high torques, high rigidity, a compact design, and high precision – which made them ideal for robotics.

Optimised to perfection

Since then, Nabtesco has continued to optimise and perfect its cycloidal gears. The purely mechanical backlash is as low as 0.1 to 0.2 arcminutes. While the first cycloidal gearbox had no main bearing, this element was integrated in the late 1980s – today, 95% of Nabtesco gears sold feature an integrated main bearing, thus assuming a load-bearing function in the machine or robot. It also eliminates the need for external bearings. This has decisive advantages such as improved performance, more compact designs, reduced engineering costs, faster assembly, and lower costs.

The goal of these optimisations was and is still to boost performance. The advantages: smaller gearboxes, higher torque density, and the use of oil that is better suited to the particular application. Other central aspects are digitalization, integration, and sustainability.

Nabtesco – innovator and technology leader:

- Pioneer of cycloidal gear technology

- Inventor of the two-stage cycloidal gear with external eccentrics

- Number 1 supplier for robotics (60% market share in industrial robotics sector)

- Supplier for all major robot manufacturers in the industry

- Ready-to-use solutions for general machine and plant engineering

- Continuous advancement, research and transformation

For more information visit: nabtesco.de

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech