Lenze’s FAST technology module offers easier and more productive handling system

Photo by Lenze SE

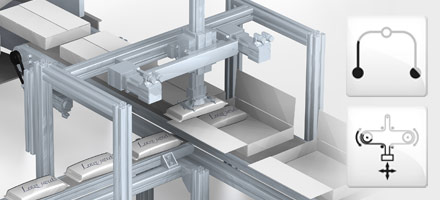

Fully fledged robot functions in simple gantry systems and automatic stackers that are used to handle materials? With the new robotics module in the FAST application software toolbox, Lenze is paving the way for easily configurating coordinated motion along several axes. This solution from the specialist in drives and automation systems is a powerful pick & place module that has everything engineers need for fast, productive and most flexible handling systems.

In the areas of intralogistics, packing technology, assembly and material handling systems, gantry systems are mainly used for stacking and moving wood, metals, plastic or glass. The gantry units are often driven on single axes by PLC-controlled positioning drives. A more elegant way of doing things, i.e. with gantry-robot kinematics and coordinating multiple axes, has not been possible up to now due to the complicated and time-consuming programming it would involve. This is exactly where the new FAST technology module comes in; it clusters the robotics together to create an easy-to-parameterise drive solution with a robotics core on the inside. This is just as easy to parameterise as a single positioning axis.

“The FAST technology module is so easy to use that PLC-controlled gantries can be very effectively replaced with sequential motion commands,” explains Alexander Schlegel, who works in the Business Development department of Lenze Sales. This has tangible advantages; soft intrinsically synchronous travel profiles result in substantially less wear on the mechanical parts of a machine than point-to-point positioning. They can also be designed to be considerably more efficient and operate faster with smaller drives and less power overall. Thanks to the open standards used, namely PLCopen Part 1/2/4 and the IEC 61131 programming environment, FAST can be used to perfectly integrate additional drive tasks. For example, upstream and downstream conveyor drives are easy to engineer with the same controller and drive controllers from the same i700 family.

Even complex drive systems with multiple-axis coordination are easy to use without any special knowledge of robot programming thanks to the prepared and intensively tested software solution. Lenze is convinced that this solution will make companies more willing to use robotics, especially in view of the fact that they considerably improve the efficiency and productivity of their plants. Thanks to the simplification of the engineering process, engineers have more time to optimise processes and the actual functions of the machines they build. All in all, this improves the competitiveness of OEMs as they no longer need to concentrate on motion control.

For more information, please visit http://www.lenze.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech