More productive and reliable mechatronic drive solutions by Lenze

The finely graduated range of gearboxes has a level of efficiency that is higher than 94 % over the entire transmission range.

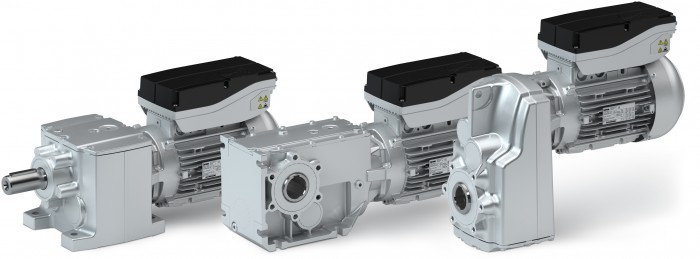

Photo by Lenze SE

The basis of this drive solution is provided by the new, finely graduated g500 range of gearboxes, which have been specially designed to convert motor speed into torque as intelligently and precisely as possible. The efficiency achieved over the entire transmission range is higher than 94 %.This provides a clear plus factor in terms of energy efficiency. “We looked closely and critically at the familiar, traditional solutions, asking ourselves what applications were out there and what they actually needed – in order to benefit the machine builder and plant operator. The result is something that the market has never seen in this form. It shows that we are not interested in offering customers run-of-the-mill solutions: we are providing special solutions tailor-made to meet their needs,” explains Rune Friis-Knutzen, responsible for strategic product development in electromechanics at Lenze. Because the gearbox losses are so low, the motor does not have to generate as much energy, and at the end of the day this improves the efficiency of the entire system. The combination of the Lenze Smart Motor and the g500 provides a perfectly dimensioned drive for horizontal materials-handling technology. And the customer is only buying just as much functionality as he actually needs. Also, a lower level of heat is generated, and this increases the overall service life. What has made these successes possible? In the development phase, Lenze made use of the most up-to-date calculation and simulation procedures.

With its g500 range of gearboxes, Lenze is continuing its steady focus on the same goals that are behind the Lenze Smart Motor: keeping the solution as easy-to-operate as possible – along the lines of an AC motor, for example – while at the same time achieving impressive levels of performance and efficiency. One attractive feature resulting from this broad mechatronic perspective is that the speed settings in the Lenze Smart Motor can be easily adjusted on site with a smartphone app and near field communication (NFC). This means that motor speeds from 500 to 2,600 revolutions per minute with a constant torque can be covered by just one single variant.

The new g500 gearboxes represent another step forward, adding yet another advantage to the broad range of speeds available from the Lenze Smart Motor: now, one single variant of motor and gearbox can replace the many different variants that machine builders still need to use today. On top of that, the high levels of efficiency achieved by the Lenze Smart Motors and gearboxes are also very beneficial in terms of energy efficiency. In addition to being used in combination with the Lenze Smart Motor, the g500 gearboxes can also be combined with Lenze’s MH range of IE2 three-phase AC motors, its inverter-optimised MF motors, and its MCA and MCS servo motors to create intelligent application-related packages.

The helical, helical-bevel and shaft-mounted helical gearboxes will be coming onto the market in two phases. Lenze is starting with the smaller sizes of 45 to 600 Nm in a newly designed aluminium housing. They will be followed about one year later by the higher power ratings up to 13,000 Nm, produced in cast iron.

For more information, please visit http://www.lenze.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech