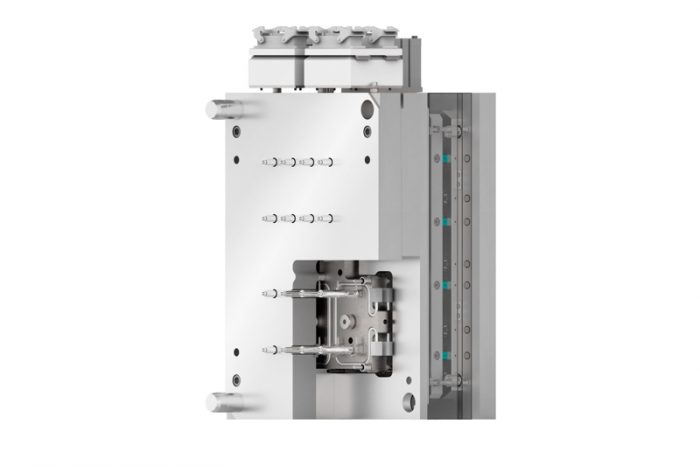

Meusburger’s powerMOVE lifting plate offers ideal force-speed ratio for pins movements during injection moulding process

Photo by Meusburger Georg GmbH & Co KG

The powerMOVE lever operated lifting plate is an integral part of the hot half in Meusburger’s range of valve gate systems. Matched to the sizes in the plates range, various standardised powerMOVE units are available, which are customised according to the individual requirements. The arrangement of the nozzles can be freely configured.

The powerMOVE lifting plate from Meusburger is a cleanroom compatible and self-lubricating pin actuation system. The lever mechanism ensures ideal force and speed for the opening and closing of the pins during the injection moulding process. With no additional control system necessary, consistent high quality of injection moulded parts is ensured.

FUNCTIONALITY & PROPERTIES

- Maximum closing force and low speed when plunging the pins into the gate

- Increasing speed when opening the valve pin

- Minimal force loss compared to other actuation mechanisms

- Lifting frame is mounted on roller bearings

- Rolling friction means 20 times less friction than sliding friction

- Stepless height adjustment of each individual valve pin

- Shutdown of individual pins without opening the mould

- Close spacing of pins possible

- Smallest cavity distance and high number of cavities

HOW CUSTOMER BENEFIT – AT A GLANCE

- Ideal force / speed ratio for the pin movement

- Self-lubricating and cleanroom compatible

- Standardised design matches the Meusburger range of plates

For more information, please visit http://www.meusburger.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech