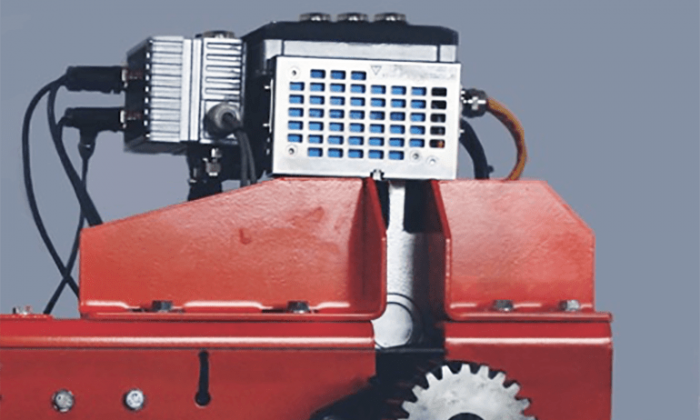

NORDAC FLEX SK 205E offers efficient processing in handling and positioning applications

Thanks to its wide selection of functions and direct mounting, on the drive or close to the drive, the decentralised NORDAC FLEX frequency inverter is especially suitable for positioning applications or moving and rotating tasks in handling technology.

NORDAC FLEX inverters are mounted directly on the motor or close to the motor. This means that only short motor and encoder cables as well as minimal length cabling for directly connected application sensors and actuators are required. The installation topology provides for linear supplies for mains voltage, 24 V control voltage and field bus systems/Industrial Ethernet. With the NORDAC FLEX SK 205E, dynamic movements with short start/stop times or cyclic operation can be implemented thanks to high overload and optional braking resistors. The operation of highly efficient synchronous motors is possible, as is the use of brake motors and encoder feedback, e.g. for position-controlled handling systems. Also vertical movements, e.g. for lifting systems with higher performance requirements and loads can also be operated in the same system. All power and communication connections are optionally available as plug-in versions. Options such as functional safety via PROFIsafe complete the package, making the NORDAC FLEX SK 205E a flexible all-rounder in this market segment.

Control up to four synchronised axes

Due to the internal PLC and the POSICON position control for relative and absolute positioning, the NORDAC FLEX can synchronise several NORD drives in master-slave mode. The integrated POSICON functionality ensures that the inverters are able to determine the current position of the master drive and transmit it to the following slave axes as setpoint position. As a result, functions such as synchronised movement and “flying saw “ can be executed quickly and precisely. Up to three slave inverters can be controlled by one master inverter. A higher level control is not necessary. NORD drives self-sufficiently ensure smooth processing in many different handling and positioning applications.

For more information, please visit http://www.nord.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech