Piab’s Kenos® vacuum grippers help Steelgran improves its operating cycle by 35%

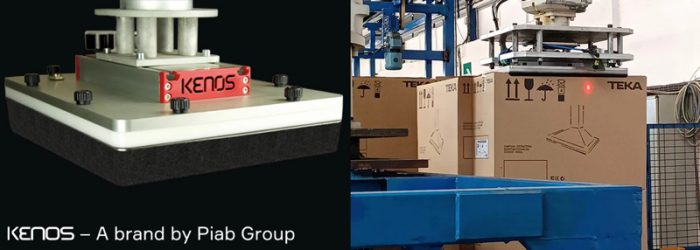

The change from a mechanical top gripper with suction cups to Piab vacuum foam gripper Kenos® KVGL has improved the operating cycle of end-of-line robots by 35% for Spanish company Steelgran Componentes S.A.

In any manufacturing process, time and costs are key factors, especially when there are sudden production increases. Steelgran Componentes S.A., manufacturer of Teka stove hoods in Spain, experienced bottlenecks due to peaks in the demand and decided to make a change in the gripping system of its end-of-line palletizing robot.

Steelgran has successfully worked with Piab’s partner in southern Spain, the Comercial Andaluza de Técnicas y Suministros S.L, (CATS), before and approached them again to find a suitable solution when this new challenge occurred.

“Steelgran needed a gripping solution that could handle different box formats and at the same time minimize product losses and increase speed”, explains José Juan Moncayo, sales engineer at CATS S.L.

The old gripping solution was used for the palletizing of fume hoods packed in different types of boxes. The latter come from three independent production lines out of which three types of cartons must be handled, one for each palletizing station. However, depending on the product, the boxes may vary between 25 different formats, weighing from 8 to 48 kg and ranging in size from 450 x 450 x 600 mm to 1080 x 495 x 1000 mm (length x width x height). This array of formats, some of which are particularly bulky and heavy, requires an extremely flexible solution capable of adapting to all models without having to change or adjust the gripping system.

The previous gripper was equipped with four suction cups and an extendable side arm to hold the side of the boxes and avoid load inertia. By having to open and close the arm whenever an adjustment was required, the handling and adjustment time of the gripper increased.

Moreover, at least one product was dropped during every production cycle forcing the production to stop. The maintenance of the robot, removal of the product, restart, and analysis of the fallen product claimed valuable time. In addition, the onwards palletizing speed had to be slowed down, which made the bottleneck even worse.

CATS were confident that the solution best suited for the project was Piab’s Kenos® grippers. As the relation to Piab is very close, CATS contacted Albert González, Field Product Manager of Piab’s Vacuum Automation Division in Spain and Portugal, to share all the technical details. Steelgran was soon offered the solution they needed:

“Kenos® vacuum foam grippers have proven to have optimal performance for carton palletizing applications. In addition, they provide high energy savings thanks to the COAX® technology,” Albert González says.

CATS soon confirmed the superiority of the solution which consisted of a 600 by 400 mm Kenos® KVGL with foam, equipped with six COAX® ejectors which provide the necessary flow rate and vacuum level to handle the full range of box formats. Piab’s system offers fast and safe gripping thanks to its high initial vacuum flow provided by the COAX® multistage ejectors. These are up to twice as fast as other ejectors and provide three times more flow than a conventional vacuum ejector with identical air consumption.

As Steelgran Componentes S.A. was already familiar with the performance and durability of Piab components, having Piab’s FCF friction cups and level compensators successfully installed in one production line with metal sheet handling for stamping, they decided to trust CATS’ proposal once again. Thanks to the unique COAX® multi-stage ejector technology, 85% of energy savings were achieved and depending on the box size and gripping time the cycle time was reduced to 15-40 s. Further, the required production speed to avoid bottlenecks was successfully realized.

“The change of gripping system on our end-of-line robot has far exceeded our expectations”, says Jesús Chica, Production and Maintenance Manager with Steelgran Componentes S.A. “With Piab Kenos® KVGL we have achieved 0 % product loss rate and have also reduced the noise level generated by the vacuum generation system by 50 %”, he concludes.

Piab’s Kenos® vacuum grippers simplify automated handling processes, ensuring reliable gripping on a wide variety of products with different shapes, surfaces, and dimensions. The grippers can be equipped with integrated vacuum generators or with external pumps if high suction capacity is required. For carton palletizing applications, the Kenos® KVGL series is best suited as a large-area vacuum gripper which, depending on the application, can be divided into separate vacuum zones and equipped with up to eight COAX® ejectors or an external pump.

For more information, please visit http://www.piab.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech