The Solid3D Case Study on Tamron Vision’s Machine Vision Implementation

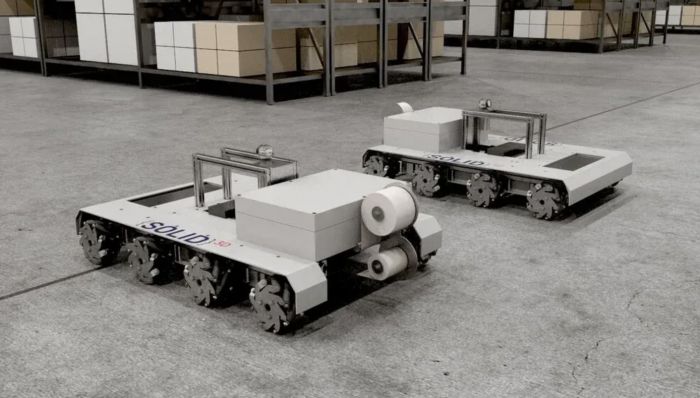

Industrial automation and robotics increasingly rely on advanced vision systems to enable autonomous operations with precision and reliability. A compelling example of this trend is the collaborative application of Tamron’s industrial optics in the Solid3D warehouse robotics solution, demonstrating how optical technology enhances machine vision performance in real-world environments.

Integrating Tamron Optics into Autonomous Warehouse Robots

In this case study, the robotic system developed by Solid3D leverages a vision setup that combines an industrial camera with a high-precision Tamron lens to enable accurate object detection and positioning. Tamron’s lens selection was driven by requirements for compact size, superior optical performance, and compatibility with the camera sensor — factors critical for mobile robotics sensors operating in dynamic warehouse environments.

Vision System Architecture and Component Synergy

The core of the vision system comprises a USB industrial camera paired with a Tamron lens that captures high-resolution images for processing and analysis. This image data feeds into Solid3D’s proprietary vision software running on embedded computing hardware, enabling precise measurement and localization tasks necessary for autonomous navigation and positioning applications in logistics automation.

Precision Imaging for Automated Marking and Navigation

One of the standout use cases demonstrated in the study involves floor marking and positioning within warehouses. The integration of Tamron optics ensures that visual data used for robot navigation meets stringent accuracy standards, with image clarity that supports sub-millimeter precision in automated tasks. This level of optical performance is a cornerstone of reliable machine vision in industrial mobile robots.

Benefits of Industrial Lens Technology in Machine Vision

Tamron’s industrial lenses contribute to robustness and adaptability in challenging operational contexts. Their compact design minimizes weight and power consumption — both crucial for autonomous systems — while delivering consistently sharp imagery across varying lighting conditions and motion scenarios. Together with Solid3D’s software, this creates a vision solution capable of supporting complex automated workflows.

Future Trends in Vision-Driven Industrial Automation

This case underscores a broader industry shift toward integrating high-quality optical components with advanced vision processing to improve efficiency and autonomy in industrial applications. As robotics solutions evolve, the demand for precision lenses and optimized imaging pipelines will continue to grow, making partnerships between optics manufacturers and machine vision developers increasingly strategic.

For more information, please visit: https://tamron.vision

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech