Navigation : EXPO21XX News » Material Handling » Warehousing vs. Storage: What’s the Difference?

Warehousing vs. Storage: What’s the Difference?

In modern logistics and supply chain management, businesses rely on warehousing and storage to keep their goods secure and accessible. While the two terms are often used interchangeably, they serve distinct purposes. Storage simply provides space to hold products, whereas warehousing integrates inventory management, automation, and order fulfillment to optimize logistics.

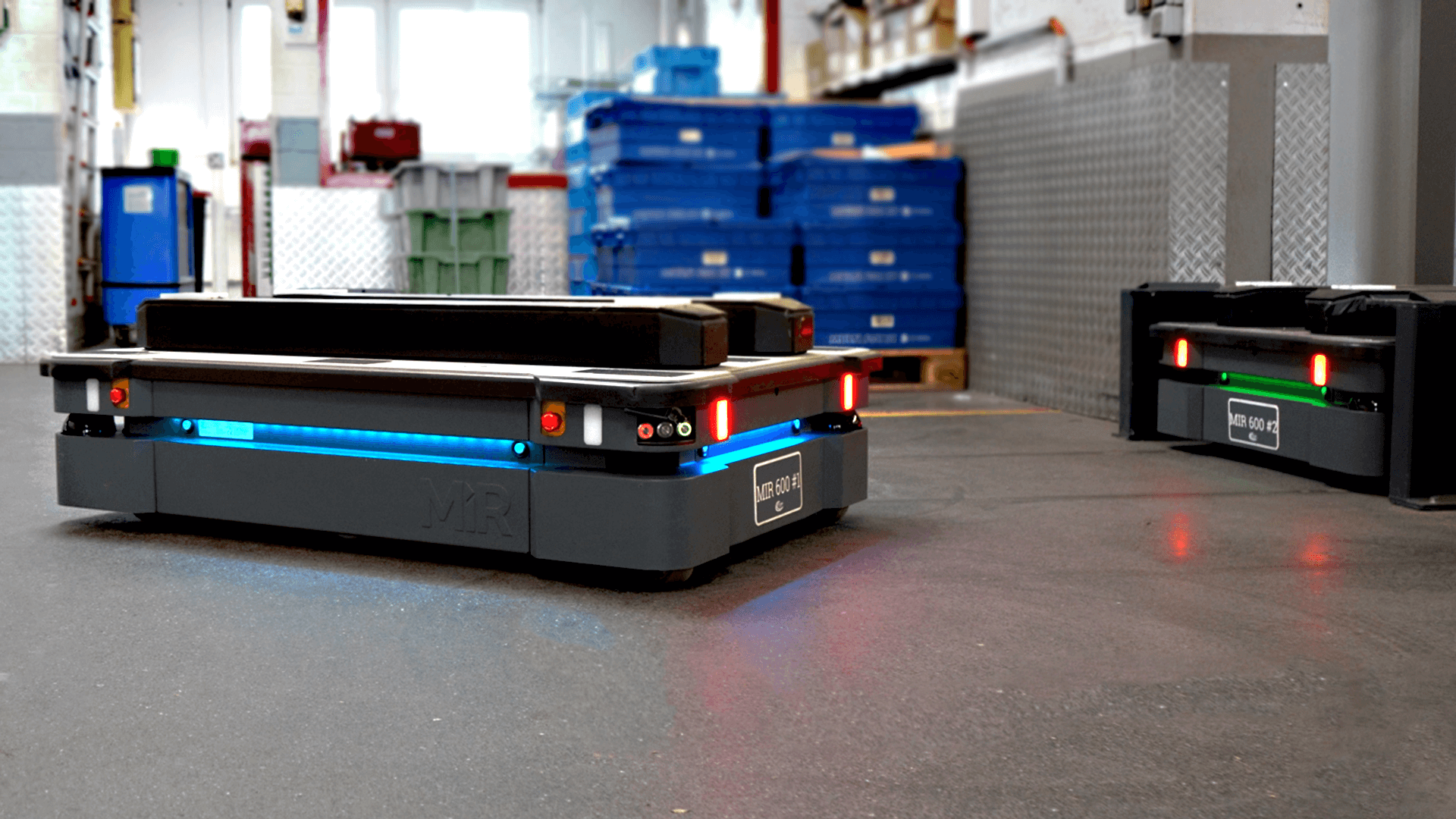

With robotics and automation, warehousing is evolving, enabling faster material handling, efficient inventory flow, and reduced costs. Understanding these differences helps businesses determine the best solution for their needs—especially when leveraging third-party logistics (3PL) services.

Key Differences Between Warehousing and Storage

Capacity

- Warehousing: Large-scale facilities designed to store bulk inventory, raw materials, and finished goods.

- Storage: Smaller units used for specific goods, often for personal or temporary business needs.

Duration

- Warehousing: Best for long-term storage, ideal for businesses handling seasonal goods or maintaining stock for extended periods.

- Storage: Typically short-term, suited for temporary inventory needs.

Cost

- Warehousing: Higher costs due to management software, labor, and transportation.

- Storage: More affordable, as it requires fewer operational resources.

Services

- Warehousing: Includes inventory tracking, picking, packing, and shipping, making it essential for supply chain efficiency.

- Storage: Primarily offers a secure space, without additional logistics services.

Security

- Warehousing: Equipped with surveillance, restricted access, and personnel monitoring for enhanced security.

- Storage: Some security measures may be in place, but typically less robust than warehouses.

Location & Accessibility

- Warehousing: Strategically located near distribution hubs for faster transportation and fulfillment.

- Storage: Can be located anywhere, sometimes even within warehouse facilities.

For further information visit: mobile-industrial-robots.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech

Related Expos

Tags

automation

digital cameras

drive system

factory automation

handling technology

industrial automation

industrial camera

industrial electronics

industrial robots

industrial sensor

industrial vision

Industry 4.0

intralogistic

intralogistics

laser applications

machine tool

machine vision

manufacturing process

materialhandling

material handling

measurement sensor

measurement systems

metalworking

motion control

motion drive

process industry

pumps

sensor technology

software

warehouse