Yaskawa added three new direct drives and a servo amplifier to its Sigma-7 servo system

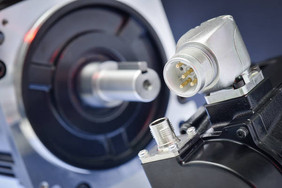

Removable plugs, made in accordance with European standards, allow quick and easy wiring.

Photo by Yaskawa Electric Europe GmbH

Additional direct drives and motion controllers in accordance with IEC 61131-3

Yaskawa expands the current Sigma-7 servo system with new components and functions, including three new direct drives and a servo amplifier with integrated motion controller in accordance with the IEC 61131-3 standard. In addition, the performance classes 6 – 7.5 kW and 11 – 15 kW for the 400 V variant are now ready for the market.

The recent expansion of the Sigma-7 portfolio includes 200 V and 400 V amplifiers and motors in the 50 W to 15 kW performance class. New to the product range are three additional direct drives with high-resolution encoder (either absolute or incremental) in the torque range from 1.3 Nm to 240 Nm.

Thanks to the 24 bit encoder, the control properties are significantly improved compared to the previous Sigma-5 series. The advantage of direct drives is the elimination of gearboxes, which in turn saves space and increases performance. In addition, these motors are designed for maximum torque stability with the highest level of precision. All motors have the option of central cable insertion and are thus ideally suited for handling applications of all kinds.

The three new direct drive models SGM7D, SGM7E and SGM7F are specially tailored to different applications: The external iron-coated rotor of the SGM7D ensures a high permissible mass moment of inertia for applications with large loads or load fluctuations at a rated torque of 1.3 Nm to 240 Nm. The internal and therefore more compact SGM7E with a rated torque of 4 Nm to 200 Nm offers a higher speed with maximum torque stability for applications with high machining frequency. Where low inertia is required, the internal iron-free rotor of the SGM7F offers particularly quiet and ripple-free operation due to its motor structure. Its rated torque is 2 Nm to 35 Nm.

Single-axis amplifier programmable in accordance with the IEC 61131-3 standard

In some applications, intelligent individual drives are required. The Sigma-7 servo system can be easily adjusted, e.g. in dosing and labeling applications. With the introduction of the Sigma-7Siec, there is now also a variant designed specifically for the European market. With its IEC development interface, it ensures simple, fast, and user-friendly programming in accordance with the IEC 61131-3 standard. Using additional, standardized protocols such as Ethernet/IP and Modbus TCP, the system can be extended with external I/Os or operator terminals.

Sigma-7C dual-axis model with integrated controller

The Sigma-7C dual-axis model with integrated controller is also available on the market. As the model does not require a separate controller, the configuration becomes more compact – thus saving space in the switching cabinet or the system. There is also no need to add a bus cable between the controller and servo amplifier. The module uses up to 16 percent less space in the switching cabinet compared to conventional solutions, and significantly less wiring work is required. In addition to the existing two axes, MECHATROLINK-III can be used to control or synchronize up to four additional external axes via the integrated controller.

In terms of reaction speed, the integrated controller offers significant advantages: The combination of two internal axes reduces the command/response delay to a minimum. The system also offers a speed controller bandwidth of 3.1 kHz in the drive, allowing higher machine throughputs. In addition, the system does not require a battery that is specific to the controller, which simplifies maintenance.

Enhanced safety functions

In line with the latest additions to the portfolio, the servo system now offers enhanced safety features and meets the requirements of EN IEC 61508 SIL 3 and PL-e. The STO function (Safe Torque Off) is integrated as standard in all servo amplifiers in this series. Fulfilling legally mandated safety standards is therefore no problem. For higher safety requirements, the SS1, SS2 and SLS safety functions are available as optional modules for various Sigma-7 models.

Removable plugs and compact motors

Like the Sigma-7 servo drive series, the new components and functions are also designed to ensure that the systems can always be started up quickly and easily and to maximize machine output with high precision.

Removable plugs, made in accordance with European standards, allow quick and easy wiring. Devices can also be connected directly from one to the next, known as daisy-chain wiring. The book-style housing supports gap-free, side-by-side installation of several amplifiers in a small space. This makes it possible to realize a high performance density inside the switching cabinet.

Sigma-7 also offers significant advantages over comparable previous motor models. In particular, the components boast high efficiency: While offering equivalent performance to previous models, Sigma-7 servo motors are up to 20 percent smaller in length and produce considerably less heat. The extremely high encoder resolution of 24 bit is up to 16 times higher than conventional solutions. When combined with the amplifiers, the servo motors meet the highest demands for synchronization and accuracy.

For more information, please visit http://www.yaskawa.eu.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech