Zebra’s Fetch mobile robots can be deployed without extensive planning

Deploying mobile robots for material movement might be simpler than we might think.

Planning and deploying new technology for automation can sometimes seem intimidating. Today many operations across the supply chain from warehouses, fulfillment, and distribution are looking to modernize and optimize by adding Autonomous Mobile Robots (AMR). Since mobile robots move around facilities among people, people may think that it requires extensive planning or infrastructure updates for deployment.

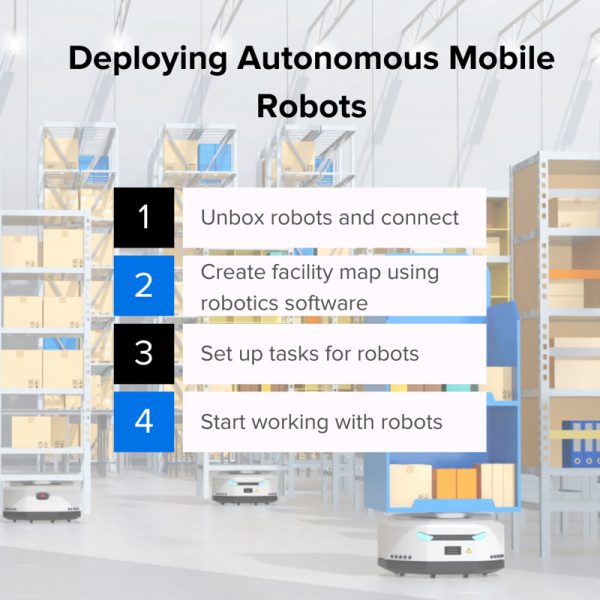

But while autonomous mobile robots can solve complex challenges, getting them up and running is likely easier than imagined. Here is a common step-by-step process to deploy Zebra’s Fetch mobile robots:

1. Unbox robots and connect

The first step is to simply unbox the robots and connect them to the Wi-Fi network through the robotics software. If the software is cloud-based, it can easily connect with any network.

2. Create facility map using robotics software

To help robots navigate, users need to create a map on the software. Robots use this information to perform tasks and navigate their environment. At this step, users can even specify preferred robot travel paths and keep-out zones.

3. Set up tasks for the mobile robots

Users can set up their workflows using drag-and-drop features on the software. Depending on users needs, they can put the robots to any task in their facility — from optimized picking to automated material handling.

4. Start working with mobile robots

Once the workflows are set up, users can start using these mobile robots. They can have multiple applications, and these can be updated as and when they want.

By using mobile robots, companies can significantly improve efficiency and enable teir employees to focus on value-added activities around the warehouse.

Unblock warehouse space

Mobile robots can also help in decluttering and unblocking customers’ warehouse. Whether they are looking at their returns, packing, kitting, or shipping processes, there is a lot of material that clogs up their facility. Although there are workers who remove this trash, these roles have high turnover and remain expensive to fill in an already worker-strapped market. Heavy-load mobile robots can schedule pick up of bulk containers filled with packaging material and garbage without the need of a forklift or a manually moved cart.

Eliminate unnecessary walking

Introducing mobile robots in warehouses reduce walking time for workers and in turn allows them to focus on higher-level tasks that both increase warehouse productivity rates and improve efficiency. Automation of material handling for heavy loads also translates to workers spending less time tired and sore as back and knee injuries are very common due to repetitive lifting and the hours of walking involved.

Reasons why mobile robots can be easy to deploy

1. Customers don’t need to make any infrastructure changes

Legacy material handling equipment, like AGVs and conveyors, require fixed paths and infrastructure changes before they can be deployed. This can mean a significant upfront cost as well as a delay in deployment until the upgrade is complete. Mobile robots can be up and running without any infrastructure changes.

2. Customers aren’t required to involve their IT team

They can deploy entire AMR fleets with cloud-based robotics software, so there’s no requirement for complex programming. They can even add or remove robots easily as their needs change with time.

3. Customers won’t need to interrupt operations for deployment

AMRs can be deployed within hours, unlike other automation solutions. Since conveyors or AGVs require infrastructure and IT updates before deployment, a portion of customers’ facility may have to be shut down pre-deployment. With AMRs, they don’t have to make any changes to their facility.

Autonomous mobile robots can be set up in just hours and the process is much simpler than customers might think.

For more information, please visit http://www.zebra.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech