ABB further enhances its Baldor-Reliance Food Safe motors with better performance and protection

- Food safety is the first priority of design

- Reliability in intense cleaning environments

- Increased sustainability with proven longer service life

Now, more than ever, it is vital that food and beverage companies choose supplier partners that understand their processes, helping to improve plant reliability, sustainability and achieve productivity goals.

For more than three decades, ABB has listened to equipment designers, operators and plant maintenance engineers to design and manufacture Baldor-Reliance Food Safe motors to perform reliably, at maximum efficiency, around the clock – and able to withstand rigorous cleaning and sanitation processes. Now ABB has underscored its commitment to uncompromised food safety and productivity with key enhancements in performance and protection to its Food Safe stainless steel motor line.

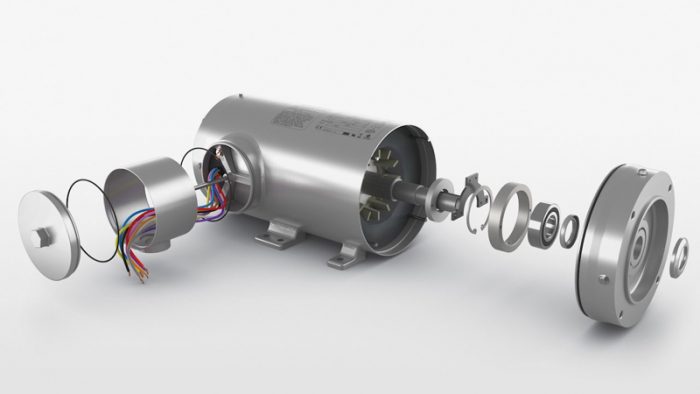

Enhanced design

- Bearing protection ring to reduce shaft currents

- 360-degree rotatable conduit box for ease of installation, operation and maintenance

- Plugged drain holes completely seal the motor to minimize water ingress

Features that have stood the test of time

- All stainless-steel construction – including housing, conduit box, drain plugs, hardware, fan cover and endplates – safeguards against corrosion to avoid costly downtime and repairs

- IP69 laser marked nameplate for readability throughout the life of the motor

- Hardened epoxy resin encapsulation provides an additional layer of internal protection against water and humidity

- Two-barrier mechanical shaft seals prevent water from entering at the shaft extension of the motor

- High-temperature Class H insulation with low-temperature (Class B) rise for longer insulation and bearing life

Baldor-Reliance Food Safe motors, designed with smooth contours and advanced sealing, exceed IP69 ingress protection ratings for washdown conditions to maximize motor life in high-pressure, sanitary cleaning environments. The product line covers single to three-phase ratings, with TEFC or TENV enclosures, in foot-mounted and footless configurations, providing OEMs and end users greater flexibility to choose the right product for their equipment and applications.

“We work closely with our customers to understand their needs and to stay informed on the emerging trends in the food industry. The top priorities in food production equipment right now are cleanability and durability,” said Matt Rodebush, Global Segment Manager, Food & Beverage, for ABB’s NEMA Motors Division “If a motor is easier to clean and maintain, we increase the safety of our food supply. It’s that simple. But our customers don’t just want equipment that’s easy to clean; they need motors that can stand up to those harsh cleaning conditions and keep going. We’ve addressed both requests with the enhanced design of our Food Safe stainless steel motors.”

When selecting the highest quality motor suitable for harsh washdown applications, it’s possible to achieve sustainability targets of food processing plants. High reliability means high productivity while reducing downtime, waste and CO2 – creating a safe, sustainable solution that protects the environment.

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation.

For more information, please visit http://www.abb.com/.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech