The deTec4 Core safety light curtain: the logical solution for intralogistical plants

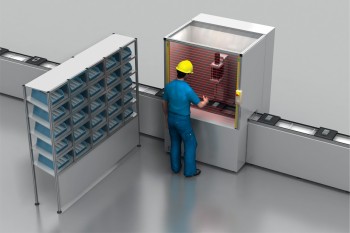

The new design-prize-winning deTec4 Core safety light curtain from SICK offers maximum possible safety for persons and machines during the operation of intralogistical plants. Resolutions for finger and hand detection, protective fields lacking blind zones, monitoring heights that prevent reaching over, and muting for automatic differentiation between persons and materials make the deTec4 Core the logical solution for numerous intralogistical areas of application.

Modern handling and warehousing systems, as well as powerful intralogistical systems and plants, would now be inconceivable without the greatest possible automation. Whether automated guided vehicles, conveyors and sorting systems, or upstream of and in high-bay warehouses – even if the processes are operating as if by magic, the plants themselves are not deserted. On the contrary: warehouse staff or service personnel can often be seen in the direct vicinity of the machines. Operated without protective measures, such machines in automatic mode pose risks to persons reaching into a hazardous point-of-operation or accessing a dangerous area for process-related reasons or for maintenance purposes. SICK’s range of protective devices includes numerous certified sensor and control solutions with which machines can be efficiently protected using effective, ergonomic and economical technology. This not only eliminates the risk of injuries to persons, but also liability risks for the management of companies that produce, place on the market or operate intralogistical machines and plant.

Photo by SICK AG

deTec4 Core: “curtain up” for pure safety

The new deTec4 Core is electro-sensitive protective equipment that meets the demands of Performance Level “e” according to EN ISO 13849 and SIL3 in compliance with IEC 61508. The safety light curtain thus offers the highest level of protection for humans and machines – for example, protecting the storage and retrieval tables of high-bay stackers; providing access protection for palletizing, depalletizing, strapping and pallet wrapping modules; monitoring the loading stations of monorail overhead conveyor systems; or protecting access in vertical stores. In all applications, the deTec4 Core first impresses during mechanical installation: the “QuickFix” standard mounting set supplied and, if necessary, the alignable “FlexFix” mounting, enable rapid and simple installation of the protective system – in combination with the integrated alignment indicator, with which the transmitter and receiver can be rapidly, easily and optimally positioned towards one another. At longer ranges, the optionally available AR60 laser alignment aid provides extra assistance.

Safety functions without frills

The functionalities that the deTec4 Core offers machine constructors and integrators in intralogistics focus on the essentials. The innovative design of the housing (just 34 x 31 mm²), which has won the iF Product Design Award 2013, is not only very robust, but also space-saving. The newly developed cable outlet prevents any blind zones above or below the protective field – regardless of whether the deTec4 Core is operated with a resolution for finger protection or a larger resolution for the reliable detection of a hand. The two range versions – 7 m with a resolution of 14 mm and 10 m with a detection capability of 30 mm – cover almost all tasks that are found in handling and warehousing systems. Depending on the particular machine and safety function, protective field heights of between 300 mm and 2,100 mm are available – graduated in 150 mm increments. At the maximum height, the deTec4 Core offers explicit protection against reaching over, in compliance with EN ISO 13855.

Sensor intelligence simplifies commissioning

Sensor intelligence simplifies commissioning

Commissioning of the safety light curtain is incomparably easy: no configuration is required because the sensor only operates in protective mode. Supplementary functions such as muting for reliable differentiation between persons and materials at entrances to hazardous areas, or the setting up of an automatic restart interlock, can be carried out via SICK’s UE48 safety relay or its Flexi Classic and Flexi Soft safety controllers. The deTec4 Core automatically and precisely adapts the range during commissioning. No optimization for operation at higher or lower ranges is therefore required. An easily visible red/green LED shows the current operating state of the safety light curtain. If there is a fault, the operating and alignment indicators on the safety light curtain show up to four error codes, simplifying diagnosis. Service data, such as the article number, serial number or type key, are engraved on the sensor (and therefore cannot be mislaid) and are still visible from the front when the device has been installed – another example of how the deTec4 Core simplifies work.

Suitable for every intralogistical environment

The innovations offered by the deTec4 Core are not restricted to the “classic” applications in stationary conveyor systems, picking and packaging lines, or high-bay warehouses. Its enclosure rating of IP 65 and IP 67, and operating temperature range from an arctic -30°C to +55°C, also permit use of the new safety light curtain in demanding environments, e.g. for protecting rotary tables and hoists, or the safety-oriented monitoring of robot stations, in deep-freeze stores – without the need for further measures such as heating or protective housings.

Visit www.sick.com for more information

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech