Eaton to demonstrate its latest electro-hydraulic solutions at Hannover Messe 2015

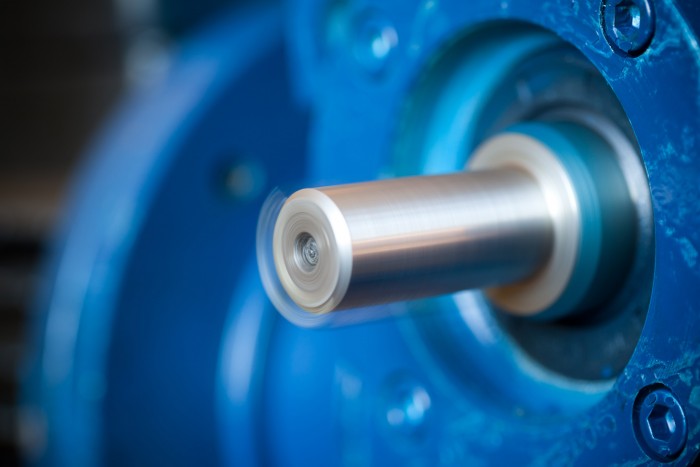

Photo by Eaton Corporation

Power management company Eaton will showcase its latest generation of fully integrated electro-hydraulic solutions at Hannover Messe 2015 to enable machine builders to see how it is possible to deliver higher levels of accuracy, speed, energy efficiency, reliability and safety. Visitors to Hall 21, Stand F03, in the Motion, Drive & Automation section of the fair, will also get the chance to see Eaton’s latest hydraulics and filtration innovations, which focus on machine diagnostics and condition monitoring as well as increasing energy efficiency and reducing production costs.

As part of its vision of a fully integrated industrial future, Eaton will demonstrate a working model of an innovative variable speed drive (VSD) pump system capable of providing machine and system builders with energy savings of up to 70% (machine duty cycle dependent). The fully integrated electro-hydraulic system represents a flexible solution for machine automation and control and is comprised of high efficiency variable speed electric motor drives that provide for reduced hydraulic power unit operating costs of up to 40%. The integration of vane and piston pump options can enable machine builders to further reduce operating costs by up to 20%. In addition, the system provides for extended machine life by lowering heat generation and improves operator safety and comfort by reducing pump noise levels.

Combining the power density and proven performance of Eaton’s pump systems with the smart control functionality of variable frequency drives, the system can achieve power-on-demand in a more energy efficient way than a conventional constant speed pump system. To demonstrate this, the VSD pump system will be set up to operate in both fixed and variable speed mode to highlight differences in energy consumption.

In combination with Eaton’s comprehensive automation offering including HMI/PLCs and the innovative SmartWire-DT communication and wiring technology, setting up the monitoring and control for force, direction and speed of the proportional pressure relief valve system is fast and easy. Additionally, by visiting Eaton’s Electrical sector stand C63/69 in Hall 11 visitors will find out how to interact remotely with the VSD pump system.

Visitors will also be able to learn about other innovations from Eaton’s Hydraulics business including the LifeSense hydraulic hose condition monitoring system. This tracks the health of hydraulic hose assemblies in real time and detects internal fatigue and external damage to provide advanced notification if the hose is approaching the end of its life. In addition, there will be the opportunity to see one of Eaton’s recently launched Hydre-MAC low-speed, high torque (LSHT) direct drive, radial piston motors that offer maximised uptime for optimal application efficiency and reduced total cost of ownership.

Moreover, on Stand F03, Eaton’s Filtration Division will be showcasing its IFPM fluid purifier system that enables operators to extend fluid life while improving the performance and safety of the entire system. The improved, fully automated, mobile IFPM system removes damaging foreign substances – water, particulate contamination and dissolved gasses – from hydraulic and lubrication systems to increase capacity and enhance efficiency in demanding applications.

For more information, please visit http://www.eaton.eu.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech