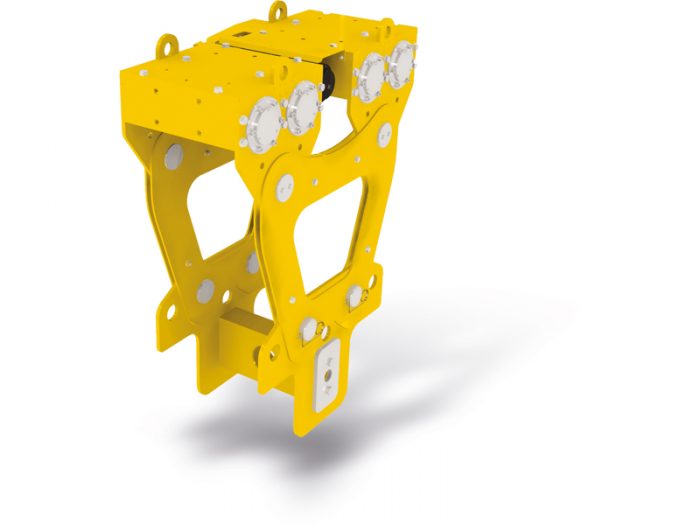

Enerpac equipped its telescopic gantry range with new fixed lifting lugs and modular side shift units

Heavy lifting product specialist, Enerpac Heavy Lifting Technology, has expanded the hydraulic gantry lifting options for industrial movers. In addition to fixed lifting lugs, it now offers modular electric powered, header beam side shift units for its entire telescopic gantry range from the SL100 through SBL1100.

The modular side shift units allow gantry users to customize the ‘below the hook’ distance to suit header beam dimensions and project requirements. It also requires less space above the header beam compared to hydraulic powered side shift units.

“Customers tell us that space is critical during industrial moves. By reducing the space requirements above the header beam and the available lifting distance below the header beam we’re equipping our customers with the lifting flexibility they are looking for,” says Pete Crisci, Product Line Director, Enerpac Heavy Lifting Technology.

Controls for the electric side shift are integrated within the gantry base units and wireless control system. The side shifts are available with extension bars and sling guides providing more lifting options. All side shift systems ship in dedicated storage frame for ease of handling.

Other Gantry and Hoist Applications

The Enerpac powered side shift can also be used on other manufacturer’s gantry systems and fixed beam lifting and hoist systems by using a stand-alone electrical panel with pendant control. “By opting for an electrically powered side shift we’re able to offer other gantry users, and those companies with an in-house fixed beam hoist, the ability to easily add a compact, modular side shifting function to their lifting systems,” notes Crisci.

For more information, please visit http://www.enerpac.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech