KNOLL provides specially coated screw pumps for difficult applications

Screw pumps are ideally suited for high-pressure applications of cooling lubricant on machine tools. But when there are especially abrasive particles in the pumping medium, premature wear threatens. The pump manufacturer KNOLL works against this in its KTS pump spindles with a unique hard material coating, thus prolonging the service life greatly.

KNOLL Maschinenbau ranks among the leading suppliers of systems for conveying and filtering chips and cooling lubricants in the metal machining industry. Furthermore, this Bad Saulgau company has also been able to call itself a renowned pump manufacturer for many years. The KTS screw pump has been a KNOLL success story for 30 years. Most KTS pumps are used in high-pressure systems for supplying cooling lubricant to machine tools.

Among other things, constant technical enhancement is responsible for their success. The current KNOLL KTS pumps, which are available in six different sizes, win people over with their performance (delivery rates between 5 and 1000 l/min, as well as pressures up to 150 bar) and quality. Even the standard models are extremely wear-resistant. Contributing to this, among other things, are that the spindle housing and the labyrinth seals on the pressure port housing are made of hard ceramic material (silicon carbide).

Hard material-coated spindles triple the service life

Given especially demanding applications, for example, grinding with corundum or CBN or processing scaled cast or steel cast parts, there can nevertheless be premature pump wear. This usually affects the spindles, which are normally made of hardened special steel. “If it is not possible to put filtration upstream, which removes these aggressive superfine particles,” explains Wolfgang Westphal, Team Manager R&D Pumps at KNOLL Maschinenbau, “these can get into the gap between spindle and housing and cause great damage.”

Since last year, KNOLL has offered a solution for such challenges: an optional special coating for the screw spindles, which distinguishes itself through its extreme hardness and outstanding sliding properties. “Thus, we have succeeded in increasing the life span of the pumps by two or three times,” emphasizes Westphal. Delivery rate, volume flow, and pressure remain unchanged as compared to the standard model.

The hard metal-coated spindle models are equally suitable for oil, emulsion, and even for washing solutions, where they – according to user experience – also ensure a significant extension of service life. In the end, it is not just abrasive superfine particles that clog the pumps, a high air portion in emulsions can also provide economic justification for the hard coating. KNOLL offers a true innovation for its screw pumps: they are available in-stock in all sizes.

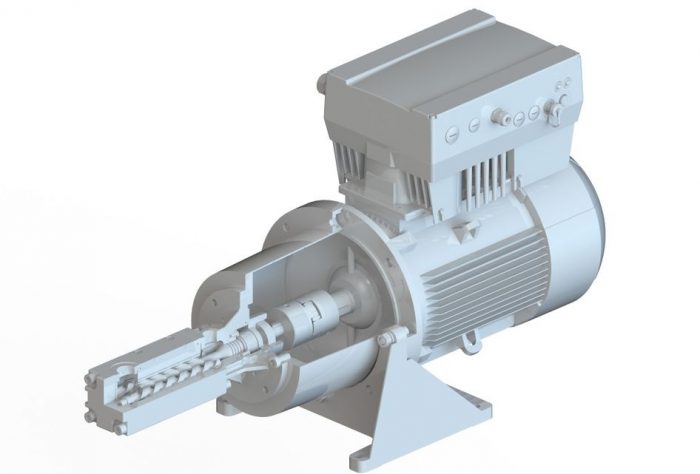

KNOLL screw pumps, type KTS

…are self-priming displacement pumps for lubricating and non-abrasive fluids. The pump essentially consists of 3 components: 1) the suction housing, 2) the spindle housing and 3) the pressure housing with throttle point, sealed shaft duct and external main bearing. The spindle housing consists of two ceramic shells embedded in steel (SIC); it contains a drive spindle and two running spindles, which also come with a hard material coating.

For more information, please visit: https://www.knoll-mb.de/en/news/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech