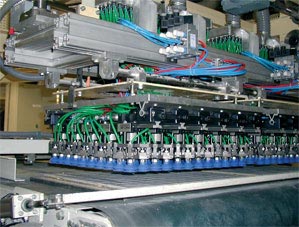

Guide systems in a die head for small size tiles

Guide systems that do not need lubrication, work reliably in dusty conditions and only take up little installation space – these are the requirements in the case of a new die head for small size tiles. The solution: maintenance-free DryLin® linear plain bearings from igus®. These take the place of the ball linings previously used, which failed after a short time due to the high level of dust. The die head made by Kautenburger GmbH, Merzig-Brotdorf, also attracted attention at the “manus®” competition with its much reduced servicing costs.

Photo by IGUS GmbH

Kautenburger GmbH has been making special machinery according to customer requirements for around 15 years. A new die head for small size tiles, which takes 240 small tiles each measuring 5 x 5 cm2 in one work step, is also attributed to the twelve employees currently working in the design, subassembly production and CNC chip removal departments .

This separates all the tiles whilst being transferred to a joint size of 2 mm and then deposits them in a grid. igus® linear bearings with polymer gliding elements support the suction heads (and the tiles) and help to move the individual suction heads. The current design of the die head, according to the design manager at Kautenberger, Christian Kautenberger, is completely different to its predecessors. “Similar tasks used to be done with ball linings, which failed to work after just a short time, however, due to the high amount of dust. The tiles also used to be transferred to the grid not by suction heads but plates; most of the tiles ended up not in the grid but on top of it, however, and had to be laboriously inserted by hand. The new automated die head now makes expensive manual labor superfluous. “

Dust and tightest installation space: “No need for maintenance”

In the case of the die head for small size tiles, a design needed to be developed that on the one hand can accommodate 240 suckers in the tightest installation space and on the other can move each individual sucker into position. Christian Kautenberger sees the biggest challenge in the amount of dust created when cutting the ceramic: “All guide systems that can only work when lubricated, will only last for a very short time here. DryLin® products, however, are maintenance-free and manage without lubricant. The line has been working in three-shift operation for several years without a great deal of wear. As maintenance is superfluous, we can save a lot of money on servicing. ” Besides the technical properties, the cost-effectiveness of a machine element represents a decisive selection criterion when it comes to the “manus®” competition. Whilst igus® acquires important information for future research activities here, the competitor benefits from the jury’s input. Kautenburger: “First of all it was interesting for us to see how outsiders judge our work. On the other hand an award means enhancing one’s image, which demonstrates our willingness to be innovative during talks with customers. “

For further information visit www.igus.de

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech