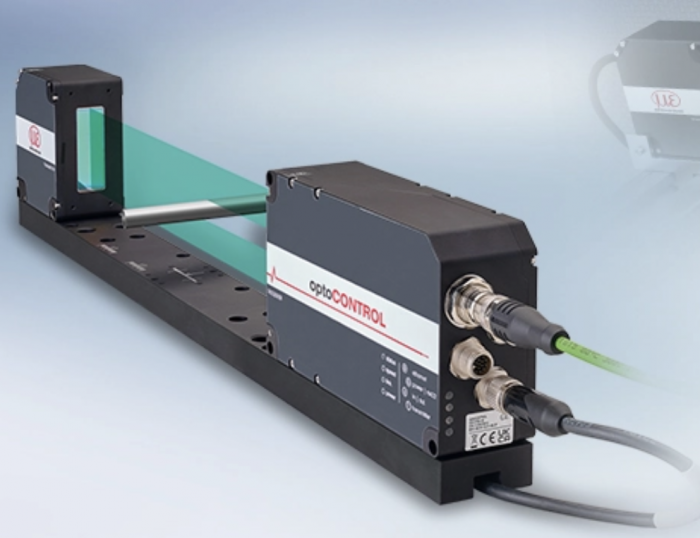

High-performance LED micrometer

The optoCONTROL 2700 is a compact, high-performance LED micrometer known for its outstanding precision, fast measurement rate, and user-friendly design. Available in two models with measuring ranges of 10 and 40 mm, it suits various automation and quality assurance applications. Its active tilt angle correction ensures accurate object detection, even at inclinations of up to 45°.

Configuration is done through an intuitive web interface, allowing the adjustment of video signals, filters, and various measurement modes. In setup mode, a shadow image assists with precise target alignment. The system is unaffected by ambient light, making it ideal for challenging environments and for measuring transparent or reflective objects. Additionally, the large measuring distance offers flexible integration into a wide range of applications.

Roller gap measurement during calendering

The highly accurate LED micrometer is used in quality assurance and machine monitoring. An important measurement task here is the monitoring of the roller gap in calender systems. The gap size is a key factor for controlling and monitoring the production of strip and sheet products. The optoCONTROL 2700 enables precise measurement of micro-gaps of less than 50 µm during the rolling process and thus ensures high-precision distance control in real time.

Due to the angle measurement, the position of the rollers in relation to each other is detected with absolute precision. This technology ensures constant material accuracy, even in the material width, and helps to avoid material waste. The micrometer is an efficient solution for optimizing rolling processes and ensuring consistently high product quality. The high-performance micrometer will soon also be available with a cable outlet for confined installation spaces. Thanks to the integrated controller, cabling and installation work is reduced to a minimum.

For more information, please visit: http://www.micro-epsilon.com/newsroom/news/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech