Humidity sensors by Sensirion increases the safety of electric vehicles

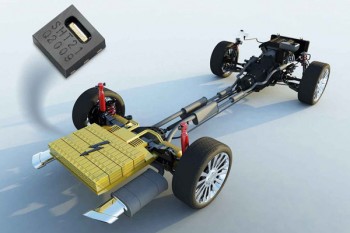

The safety of electric vehicles and hybrid electric vehicles is highly dependent on the battery. The lithium ion batteries predominantly used in such vehicles are a source of various potential hazards for the occupants. A sophisticated battery management system is necessary to address these hazards. Among other tasks, it manages ambient conditions for the battery and ensures proper battery maintenance and replacement. This considerably reduces the risk of malfunction and overheating.

Overheating during battery charging or operation under diverse ambient conditions, proper maintenance, secure replacement, preventing malfunctions, and the risk of electric shock in the event of an accident are among the factors addressed by a properly designed battery management system. For this reason, vehicle batteries have developed into diagnostic systems equipped with sensors for the constant monitoring of battery voltage, current, temperature and internal pressure. Other sensors detect factors such as acceleration, the ground orientation of the vehicle, and humidity. When specific sensors detect that a monitored value is outside specified limits, the battery is immediately disconnected from the vehicle to ensure safety.

The proper use of humidity sensors in green cars can increase the safety of vehicle batteries, reduce their power consumption and increase their lifetime. Modern humidity and temperature sensors are based on proprietary CMOSens® Technology, which combines the sensor element and signal processing circuitry on a single semiconductor chip. The Swiss sensor manufacturer Sensirion is the technological market leader in this area and produces sensors of this sort in the millions. These sensors have been widely adopted by vehicle manufacturers. The advantages of CMOSens humidity and temperature sensors are direct and economical integration into the battery management system, a digital interface for effective data transmission on the CAN bus and sensor network, and communication diagnostics to ensure reliable operation.

Avoiding short circuits and saving energy

The battery is actively cooled by air or water to prevent battery overheating during vehicle operation. If an electric vehicle is operated under humid conditions in tropical regions or on rainy days, a considerable amount of humidity can accumulate inside the battery. If the temperature of the air inside the cooled battery reaches the dew point, moisture condenses on the inside of the battery. This water film increases the risk of short circuits, which can lead to battery shutdown and potential damage to the battery. Humidity accumulation can easily be prevented by ventilating the battery housing with dry air from the vehicle’s air conditioning system.

To avoid constant battery ventilation and the unnecessary use of energy, the humidity of the air inside the battery can be monitored, so that the ventilation process is only initiated when the humidity exceeds a specified critical value and condensation is possible. This strategy minimizes the power consumption of the air conditioning system and improves the overall efficiency of the vehicle while increasing battery safety.

Prolonging lifetime

Excessive humidity accelerates the corrosion of various electrical contacts and connectors in the battery. These parts are especially prone to corrosion because they are heated during operation by the high current load. To reduce the risk of corrosion damage to electrical parts, a humidity-controlled ventilation strategy with dry air can be implemented as previously described. This allows a major reduction in maintenance effort and expense by avoiding excessive humidity in the battery.

Monitoring battery aging

Another issue in battery management is battery aging due to moisture penetration. Vehicle battery cases may be fitted with vents to equalize variations in atmospheric pressure. These vents are usually made from water-repellent fabric. Although this is essentially watertight, in the course of time a small amount of moisture penetrates the fabric and enters the battery. Due to the long service life of a vehicle, the amount of moisture penetration can lead to problems because the water reacts with the electrolyte and lithium electrodes. This chemical interaction results in gases inside the battery cells, which degrade the characteristics of the electrolyte. The end result is reduced cell capacity and lifetime.

For more information visit www.sensirion.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech