IVS introduces new machines for automated inspection of medical devices

All machines, installed and commissioned by Industrial Vision Systems, are fully validated to GAMP/ISPE protocols for medical device and pharmaceutical manufacturing.

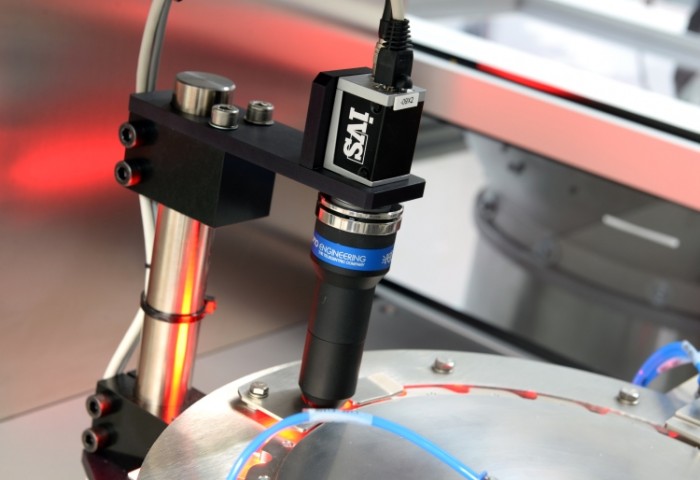

Photo by industrial vision

Industrial Vision Systems Ltd (IVS) has launched a number of new machines and systems which are now available for automated inspection of medical device products. The automated medical device inspection systems, which utilise machine vision, are supplied to various high-profile blue-chip medical device manufacturers for the programmed checking of components, sub-assemblies and packs.

Utilising a customisable dial plate which can be modified to suit varying sizes and shapes of parts, the Industrial Vision System machines use the latest generation IVS HD digital camera technology with telecentric optics to provide high speed inspection of medical device products at up to 300 parts per minute. The machines can accommodate up to six inspection camera stations each utilising different light and optics for varying quality checks. An integrated hopper and bowl supplies continuous feeding of parts allowing the vision system to provide 24/7 continuous inspection. Typical applications include inspecting for micron level mould defects in flash and shorts, checking key dimensional data on parts, syringe body inspection for inclusions, needle tip verification and measurement, plus medical device sub-assembly checks. The vision system includes integration with factory information systems and line controllers.

For more information, please visit http://www.industrialvision.co.uk.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech