KSB exhibited its BrauBeviale pumps solutions for hygienic applications at BrauBeviale Nuremberg

Photo by © KSB SE & Co. KGaA, Frankenthal

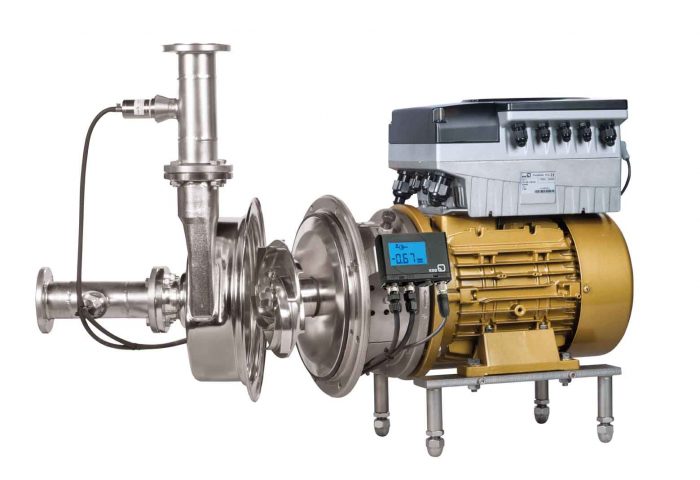

As a full liner for life sciences applications, the KSB Group showcased its comprehensive range of pumps and valves for sterile/hygienic applications and support processes in Nuremberg last November.

Naturally, the focal point of KSB’s presentation was the five hygienic food pump type series Vitachrom, Vitacast, Vitalobe, Vitaprime and Vitastage. Because of the large number of design variants the pumps are offered in, they are ideally suited for almost any pumping task in the fields of liquid or viscous food transport. The pumps’ excellent cleaning and steaming in place (CIP/SIP) capabilities are promoted by the almost complete lack of dead volume, the electropolished wetted components and the use of high-grade stainless steels. All pumps belonging to the Vita series have been awarded the certificates common to the industry, such as EHEDG, and their elastomer components conform to FDA standards

High-efficiency variable speed electric motors of the KSB SuPremE type series are available to drive the pumps. These motors meet the requirements of the highest efficiency class, IE5. Unlike conventional synchronous motors they do not contain any magnets, so the motors are manufactured without any rare earths, which are categorised as critical raw materials since their extraction causes severe environmental impacts in their countries of origin.

At last year’s BrauBeviale, KSB further presented a new pump monitoring system called KSB Guard. Networked vibration and temperature sensors fitted directly to the pump make availability at plant level transparent for the first time. The system ensures that changes in the operating behaviour of the machine are detected at an early stage, and maintenance work can be better planned, without having to be on site with the pump.

Representing the comprehensive valve programme was SISTO diaphragm valves and HERA gate valves as well as the BOA-H type series that is characterised by its energy-saving, flow-optimised hydraulic design.

AMTRONIC, the multi-functional pneumatic valve control unit was exhibited in combination with a butterfly valve of the type ISORIA. AMTRONIC is ideally suited for use in the beer and beverage industry. AMTRONIC incorporates functions ranging from simple open/close control of a pneumatic valve with open/closed position signalling to control tasks which are completed independently from a higher-level control station.

For more information, please visit http://www.ksb.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech