Montech presents new conveyors and LT40 transport system

At Motek 2013, the Swiss conveyor technology specialist Montech is presenting new conveyors and the LT40 transport system in Hall 1, Stand 1180.

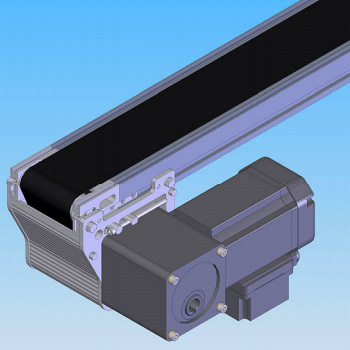

Montechís new TB30 and TB40 conveyors have efficiency-optimized drives and, compared to previous conveyors, are more efficient, offering higher power density with lower energy consumption.

Montechís new TB30 conveyor with efficiency-optimize end drive

Photo by Montech

The conveyor drive can be moved from the end to the middle of the unit, and vice versa, without changing the belt. With the same chassis width, the belt has a wider useful surface; the belt can be easily replaced. The new conveyors offer several variations and combinations: 45 to 800 mm width, up to 10 meter length and several drive variants.

More user friendly and more efficient

“Compared to previous models, the new conveyors are more user-friendly through their flexibility and more efficient thanks to their drive,” said Gianluca Aloisi, Director Sales at Montech. In addition, they have an attractive pricing and Montech offers three-year warranty, excluding wear parts.

Transport system LT40 Montech is also exhibiting the transport system LT40 in a configuration including lifts, lateral transport, positioning and placing devices, lifting/turning unit. According to Aloisi, this will show the compact and easy concept for the transport of workpiece carriers with products.

LT40 is comprised of a double belt system, which carries individual workpiece holders at a speed up to 20 m/min. The workpiece holders have a load capacity of 16.8 kg and can be provided with RFID, so that they can be identified at any time.

The peculiarity of the transport system LT40 is the fully integrated and compact drive. The drive, with 60 mm diameter, is integrated in the shaft, with no protruding parts, and operates the LT40 conveyors almost noiselessly.

The drive is driven by a motor with stepless speed variation. The operator can adjust speed ramps and change the transport direction. All components can be easily and quickly re-arranged thanks to the dovetail, normally without modifying the chassis.#

For mor information, please vist: http://www.montech.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech