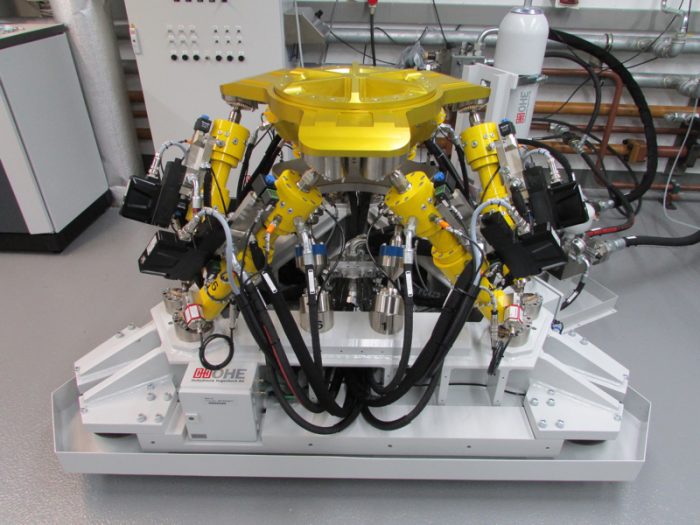

Oelhydraulik Hagenbuch utilized Eaton’s Aeroquip Triple Crown high-performance hoses for its Hexapod test benches

Photo by Eaton Corporation

Dynamic movements in drive cylinder in all six degrees of freedom, test frequency of up to 100 hertz, a tight installation area: installing hydraulic hoses in Hexapod test benches to be used by automotive manufacturers to test suspension elements is a challenge. Oelhydraulik Hagenbuch AG therefore uses flexible high-performance hoses from Eaton’s Aeroquip Triple Crown product range.

Background – Dynamic testing of suspension elements

A crucial factor for driving comfort and safety within motor vehicles are suspension components. A renowned automotive manufacturer therefore tests each component thoroughly at its research centre. Within the facility the company operates state-of-the-art test rigs, including a Hexapod test bench: The characteristics of suspension elements as well as their transmission function are determined here. What’s more, test bench can also be used for long-term vibration testing.

“The Hexapod concept allows dynamic movements in all six degrees of variance and thus a realistic simulation of environmental conditions. We also generate defined vibrations in order to determine component characteristics,” explains Claudia Giesser-Meyer, head of marketing at Oelhydraulik Hagenbuch AG, manufacturer of Hexapod test benches. The company was founded in 1955 and is a traditional Swiss family-owned company from Ebikon in the Canton of Lucerne. The 50 employees focus primarily on drive technology with oil hydraulics. Experience gathered over decades has been utilised directly in the construction of the Hexapod test benches. Hagenbuch builds versions for a wide variety of applications – for example, heavy load platforms for the assembly of aeroplane modules, for the simulation of ship movements in towing channels, or as shakers/simulation systems.

Challenge – Vibration, torsion and high pressures

In the automotive manufacturer’s research centre, the Hexapod provides highly flexible load settings, as the forces and paths can be individually programmed. “The suspension elements can be tested at a frequency of up to 100 hertz,” explains Daniel Roher, head of the service centre at Hagenbuch. “The upper platform can also be rotated by 90 degrees.” The tests run for several weeks, 24 hours a day. In doing so, both the suspension elements being tested and the Hexapod components can be subjected to enormous loads. The operating conditions are particularly tough on the hydraulic hoses, which supply oil to the six drive cylinders. “The Hexapod has six degrees of variance, meaning the drives move in every direction. So the hoses are inevitably exposed to torsion forces,” Rohrer explains. Exposure to torsion forces significantly reduce the life of standard hydraulic hoses. “In addition, the installation space in the Hexapod is severely limited and the hoses obviously cannot touch any of the other components, as doing so would quickly wear them out. “We therefore need a hose with the shortest possible bend radius. It also needs to withstand pressures of up to 200 bar,” says Daniel Rohrer.

Solution – A more flexible rubber hose with low bend radii

Oelhydraulik Hagenbuch has been using the high-performance hoses in the Eaton Aeroquip Triple Crown range for years – starting with the first Hexapods. “When we started developing the Hexapod, we sat down together with Eaton specialists and selected the best possible hoses for this application. Since then, we have generally been working with Type GH793 hoses.” The hose has a synthetic rubber inner core and dual wire weave, making it highly resistant to temperature and pressure. What’s more the hose can be used in a temperature range of -40 °C to +127 °C. The version used by Hagenbuch has an interior radius of 19 millimetres and is designed for operating pressures of up to 276 bar. It’s also important to note that the GH793 rubber hose is extremely flexible: the minimum bend radius for the 19-millimetre hose is 200 millimetres. The hose is designed for hydraulic systems based on mineral oil/water emulsions and for general industrial applications. A synthetic Dura-Tuff rubber cover provides additional protection which is more wear-resistant than standard covers. The hoses need to prove their high-performance capacity before they reach the customer: instead of the 200,000 impulse cycles for standard hoses, Eaton tests the Aeroquip Triple Crown hoses with up to one million impulse cycles.

User friendly, one-piece fitting

However, a hose is only as good as its connection. The hydraulic experts at Hagenbuch therefore use TTC fittings for the GH793: This fitting is a one-piece, nipple and rim therefore on a single body and crimped without using shells. “The fitting is quickly crimped and very user-friendly,” says Rohrer. “We also experimented with a screw crimp in order to reduce torsion, but they are too large and we couldn’t install them in the Hexapods. In addition, the resistance is too great by several magnitudes.”

Result – Proven durability and seal integrity

The combination of Aeroquip Triple Crown GH793 and TTC fittings provide Hagenbach with a solution that can be installed in very compact spaces thanks to the flexibility of the hose lines. The automotive manufacturer can use the test bench constantly for a year. Daniel Rohrer’s conclusion: “We have had very good outcomes in terms of service life and seal integrity. We have had no problems with the hoses despite the tough conditions.”

For more information, please visit http://www.eaton.eu.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech