Complete quality control and process optimization solutions by Isra Vision

ISRA VISION, global leader in surface inspection, presents a complete product portfolio with precisely customized solutions for quality and process management extended by innovative and efficient methods and procedures to increase the production efficiency. The systems are suited for 100% in-line inspection of all types of materials and processes including quality control, process optimization and yield management.

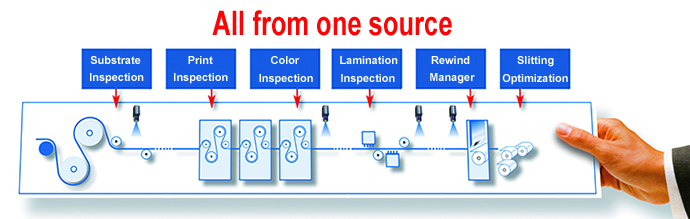

Beyond inspection: One platform for surface and print inspection to maximize process optimization

Photo by ISRA VISION

From extrusion to printing and further on to lamination and slitting – among the worldwide exacerbating competitive conditions there are no compromises concerning surface quality. Therefore manufacturers need reliable tools to get the best overview about all production steps. ISRA VISION offers 100% inspection systems for all substrates and materials, such as plastic film, film, paper, cardboard, composites, glass fibre, prepreg, printed flexible packaging, flexible printed circuits up to flexible solar cells.

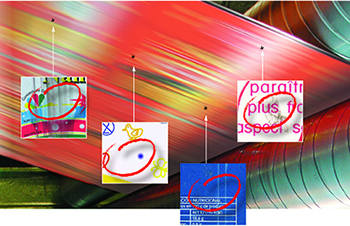

Reliable recognition of defects using SMASH in line inspection and classification technology to optimize process when manufacturing film and nonwovens

Photo by ISRA VISION

The SMASH surface inspection systems are used in all process steps. For example, they securely detect problems with substrates during extrusion or with coatings. The producer can quickly react to problems as they occur before valuable material is wasted. In order to achieve the highest level of quality, paper, film or metal is inspected during the coating process for all typical defects. The defects are reliably detected, classified as well as documented, and a protocol is created.

The PrintSTAR intelligent 100% print inspection solution makes a significant contribution to ensure correct print jobs and reduce production costs in the web printing industry. It functions with a scalable number of cameras – up to highest speed. By using the “Golden Master” principle, every repeat of the entire production run is inspected. Print inspection can also be extended to inspect additional added value applications, such as coating applications and front and backside print inspection.

ProofSTAR makes it possible to inspect everything that is important in sheet fed packaging printing with consistently high quality: the print itself, also hot foil or varnish, matt or glossy. The sophisticated 100% inspection can analyze all types of defects in text, image or graphics. BlankSTAR is an innovative 100% inspection solution for use in many of the various production steps in folding carton manufacturing and makes it possible to monitor all critical areas. Defective cartons are automatically rejected if these values are exceeded.

To be on the winning side: Exact 100% print inspection assures higher yield and better customer acceptance

Photo by ISRA VISION

The portfolio offers complete inspection solutions for the converting industry. The areas of use for these all-in-one camera-based inspection systems and their associated tools for production optimization are quite varied. These include any even finished surfaces with all substrates and material types. They are in use at all converting stages and are appropriate for many different installation sites, such as coating lines, re-winders and doctor machines. The range of inspected materials and applications covers a wide variety of markets such as the food, tobacco, hygienic and pharmaceutical industries.

With inspection solutions from ISRA users will benefit from a significant improvement in quality very early within the processing steps. This saves resources, minimizes scrap and guarantees constant quality with defined standards. As a result applicants profit from maximized yields.

For further information visit: www.isravision.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech