SICK introduces Lector®65x – the new image-based code reader

Time for some real talent to step up to the line: SICK completes its portfolio of identification solutions for long reading distance in logistics and factory automation, laser scanners, line cameras, RFID systems, and – the recent novelty – the high-resolution LECTOR®65x matrix camera.

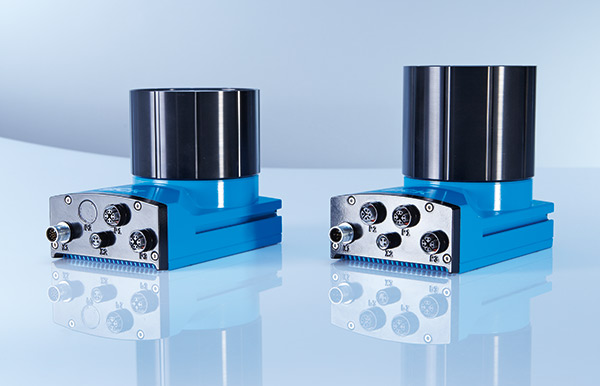

Process reliability from two perspectives: Dynamic Focus and Flex

The image-based code readers of the LECTOR®65x product family are available in two focus types. The “Flex” version adapts to the most diverse tasks with individually selectable lighting and standard C-mount lenses. In the “Dynamic Focus” model, the LECTOR®65x constitutes the innovation on the market of high-resolution, matrix-based code readers. In fractions of a second, the focus position adjusts in the optimum way to changing reading distances and object heights. In this way, the code reader always has the best possible focus position from one package to the other – and therefore a sharp picture of the code throughout.

In both variant types, the LECTOR®65x provides integrated high-performance LED lighting and imagers with a resolution of two or four megapixels. The latter make it possible to reliably identify a 1D code customary in the market with a line width of 0.5 mm in a “wide-angle” reading field of almost 500 mm x 500 mm. Moreover, powerful decoding algorithms ensure that even codes with poor contrasts or destroyed sections are detected and evaluated reliably.

Photo by Sick AG

Adapted perfectly throughout – the system solution

When it comes to flexible and modular designing of reading gates, the LECTOR®65x Dynamic Focus for Systems means that one now has a device model available that allows networking several code readers using only one cable per device. One can extend a single reading gate by one camera at a time, thus adapting it in the best possible way to a conveyor belt width and to the corresponding field of view required.

Simple operation and network integration

In terms of set-up, function keys and auto-setup guide the user to the optimum setting. Optical and acoustic feedback signals and an integrated target laser help aligning, thus enhancing ergonomics and throughput in semi-automated identification processes. “Easy integration” is a given for LECTOR®65x code readers. Serial interfaces, I/Os, USB, CAN, and EtherNet-based fieldbusses such as TCP/IP, EtherNet/IP are already integrated into the code readers. Other fieldbusses, e.g. PROFIBUS and PROFINET, are available as connection modules.

Typical areas of use for the LECTOR®65x code readers can be found in logistics related to automated sorting processes or as a presentation camera for manual sorting. In factory automation, the code readers use their potential in, among other things, identification of tires or in the “end-of-line” area of packaging installations.

For more information, please visit www.sick.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech