SICK partners with Sewio to offer indoor localization solutions based on ultra-wideband technology

Photo by Sick AG

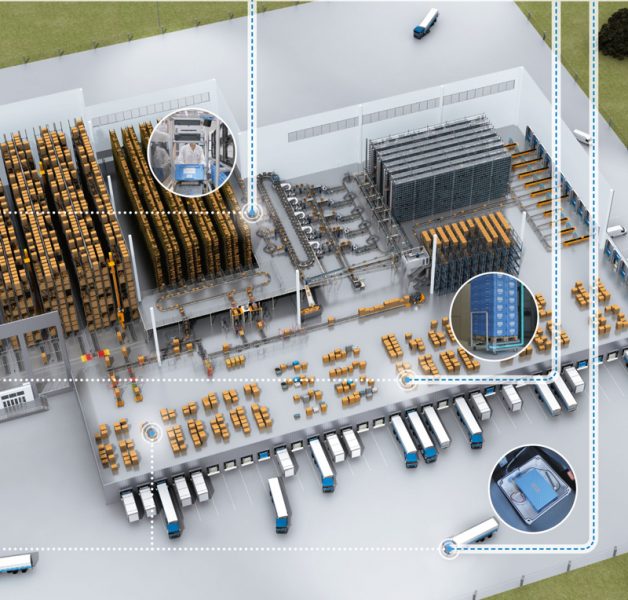

Sensor manufacturer SICK is expanding its range of localization products with support from Czech company Sewio, which is providing its extensive expertise with ultra-wideband (UWB) technology. This means that SICK can now offer its customers a complete portfolio of solutions for indoor localization for track & trace applications in non-automated or semi-automated areas.

In production halls and warehouses, a flurry of activity is a sign of success. Even more success is in store if it’s possible to determine where products, tools or autonomous vehicles are in real time. Tracking solutions based on UWB technology allow for more precise traceability than conventional methods have managed so far. On the one hand, they are more precise; on the other, they are more flexible. “Operators who want to benefit from the possibilities of indoor localization for Industry 4.0 applications can no longer get by without UWB-based tracking solutions,” explains Roland Avar, Head of Product Management Localization at SICK.

In order to speed up growth in the field of indoor localization, SICK is now announcing its strategic partnership with UWB specialist Sewio. The company, from the Czech Republic, has extensive market-specific knowledge about UWB technology on the one hand, and a wide range of UWB-based products on the other. The hardware required for localization, such as anchors or tags from Sewio, is the perfect complement to the products and services from SICK. “We have gotten to know Sewio and see its strengths in the field of research and development. From the existing partnership, we will be able to offer our customers complete solutions that enable full digitalization of material flows in no time. UWB is the ideal technology for closing the gap for real-time localization of industrial equipment,” is how Roland Avar describes the benefits of the collaboration. “We also see links which will help us develop important issues for the future such as asset tracking or asset monitoring, thus digitalizing the supply chain,” Avar continues.

“SICK provides its profound expertise in supply chain digitalization and offers complete solutions with professional support to customers all over the world. With our expertise in UWB-enabled RTLS technology, we are confident that this partnership will help us deliver complex industrial solutions and improve the safety and efficiency of smart factory operations,” explains Milan Simek, CEO and co-founder of Sewio.

Sensor-based complete indoor localization solution

SICK’s goal is to create a complete range of solutions for indoor localization for track & trace applications in non-automated or semi-automated areas, thus helping customers digitalize their supply chains. With the Tag-LOC system, SICK set the first milestone back in 2019 and developed a product that records real-time position data of assets such as vehicles, workpieces and materials. The Asset Analytics software analyzes this data so that completeness checks in picking areas can be carried out automatically, to name just one example.

In December 2021, SICK announced the integration of Croatian IT company MOBILISIS into SICK AG. With the acquisition, SICK is providing localization solutions for goods and merchandise outside halls using GPS. This also means that Bluetooth Low Energy (BLE) technology is available to the sensor manufacturer, which can be used to close the gap between RFID and UWB for indoor industrial applications.

Ultra-wideband technology (UWB)

Ultra-wideband is a technology that allows data to be transmitted over a wide bandwidth (> 500 MHz) via radio. UWB works with the so-called time-of-flight (ToF) of the signal (and not with RSSI (received signal strength indication)). This means that the technology measures much more precisely and makes very accurate distance measurements possible, even for fast-moving people and objects. UWB also works very well in industrial areas containing a lot of metal. Thanks to the transmission of data, existing processes can be linked to digital services and also made even more transparent, meaning they can be utilized for Industry 4.0 applications.

For more information, please visit http://www.sick.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech