Stauff enhances its U-bolts with its ACT concept

Photo by STAUFF

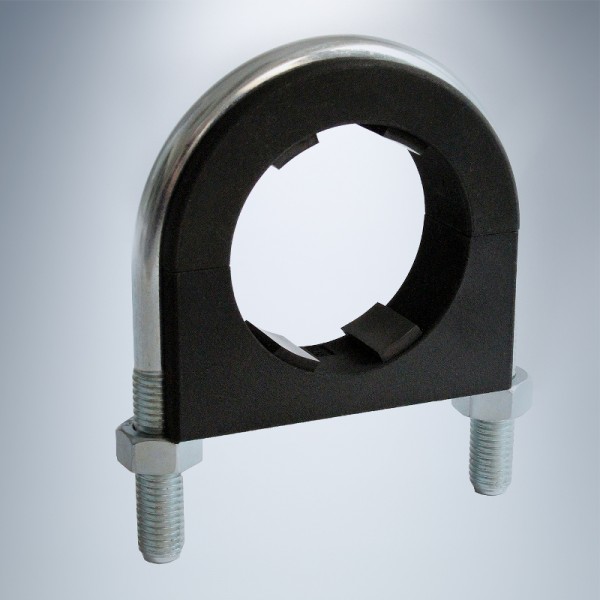

Round steel U-bolts of the RBD series as per DIN 3570 (form A) from Stauff are designed for surface or hanging installation of pipelines with outer diameters and nominal widths of more than 500 mm. They are usually made of zinc plated steel or stainless steel and are popular with tube installers, who greatly appreciate the space-saving design and easily implemented installation principle in addition to their wide range and quick availability.

In some industry branches and applications, contact corrosion can occur due to the direct contact with the metal pipes and adverse environmental conditions. The catalyst for this process is generally a corrosive medium between the two metals, such as seawater or everyday humidity. For decades, the formation of this type of corrosion on pipelines has been observed, closely examined and documented in process applications, on seagoing vessels and in the offshore industry. Corrosion is the reason for time-intensive and therefore cost-intensive service and maintenance procedures for plant operators and, in extreme cases, represents a high safety risk for humans, machines and the environment.

At the SMM trade fair this year, Stauff unveiled round steel U-bolts which were made using the company’s innovative ACT concept. In this case, ACT (Anti-Corrosion Technology) refers to a two-piece insert made of flame-retardant plastic material, which is placed between the U-bolt – designed in compliance with DIN requirements – and the pipe. The integrated elastomer strips – two in each half – clamp the line without allowing the component to have contact with metal, and therefore effectively prevent the formation of corrosion. This design also avoids the accumulation of seawater and other corrosive media in the gap between the insert and the pipeline.

In case that the round steel U-bolts are manufactured from stainless steel, the solution meets all market requirements as (for example) defined in the Norwegian Offshore Standard Norsok Z-010 (Revision 3) from October 2000 (Section 7.3: Tubing installation).

In addition to the standard components, Stauff also offers round stainless steel U-bolts and hexagon lock nuts with enhanced corrosion resistance by practically excluding metallic and non-metallic impurities during production, processing and handling. To guarantee optimal corrosion resistance even after installation in the plant, the company also recommends storing the components separately, with no risk of contact with normal steel or other metals, as well as the use of suitable assembly tools.

For more information, please visit http://www.stauff.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech