Temposonics® MH-Series XTERNAL MOUNT: Field-Serviceable Position Sensing for Extreme Off-Highway Applications

Temposonics LLC has introduced the MH-Series XTERNAL MOUNT, a new magnetostrictive linear position sensor designed specifically for off-highway machinery operating in extreme environments. The solution addresses a long-standing challenge in mobile hydraulics: maintaining reliable position feedback while enabling fast, simple service without opening hydraulic cylinders.

Designed for Serviceability in the Field

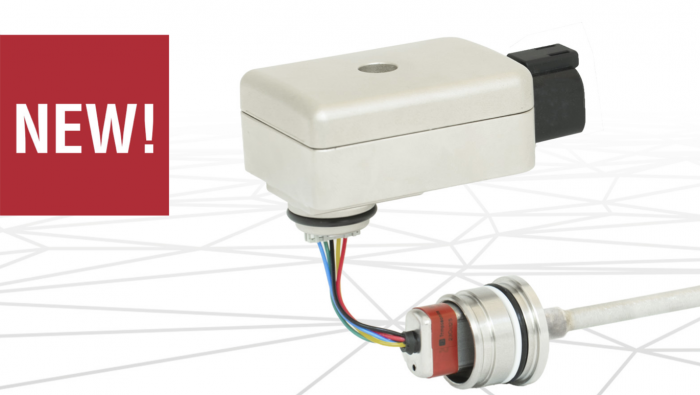

A defining feature of the MH-Series XTERNAL MOUNT is its innovative dual-housing architecture. The sensing element is installed inside the hydraulic cylinder, while the electronics module is mounted externally. This separation allows technicians to replace the electronics directly in the field by loosening a single screw and disconnecting an internal cable. No recalibration or reprogramming is required, enabling immediate return to operation and minimizing machine downtime.

This approach is particularly valuable in applications where equipment operates continuously under harsh conditions, such as construction, mining, agriculture, and material processing. In these environments, serviceability can be as critical as durability.

Built for Extreme Operating Conditions

Temposonics brings decades of experience in mobile hydraulics to the XTERNAL MOUNT design. The sensor is engineered for demanding off-highway use cases where exposure to shock, vibration, dirt, and temperature extremes is unavoidable. By keeping the sensitive electronics accessible outside the cylinder, the system simplifies maintenance while preserving robust internal sensing performance.

The design reflects real-world feedback from customers who require long service life and rapid repairs rather than complex maintenance procedures.

Flexible Configuration for Mobile Hydraulics

The MH-Series XTERNAL MOUNT is available with a wide range of options to support different machine and cylinder designs. Output signals include voltage, current, and CANbus interfaces such as J1939 and CANopen, allowing seamless integration into modern vehicle control architectures.

For internal installation, the sensing pipe is available in multiple dimensions, including 5 mm outer diameter pipes up to 1000 mm in length and 7 mm outer diameter pipes up to 2500 mm. The sensor is compatible with standard off-the-shelf magnets, reducing complexity for integrators and cylinder manufacturers. The external electronics module includes an integrated Deutsch-style connector for reliable electrical connections in mobile environments.

Global Manufacturing and Customer-Centric Support

Beyond the technical design, Temposonics emphasizes its global manufacturing footprint and customer support capabilities. With production facilities in both the United States and Europe and support teams worldwide, the company offers reliable supply chains and localized assistance for OEMs and integrators.

Whether applied to rock crushers, agricultural machinery, or other off-highway equipment with limited internal space, the MH-Series XTERNAL MOUNT is positioned as a future-ready solution for precise motion control and reduced lifecycle costs.

For more information, please visit: https://www.temposonics.com/NewsEvents

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech