The New DTECT® Object 3D: The Future of 3D Object Detection

Introducing the DTECT® Object 3D, an industrial sensor that redefines object detection by merging the flexibility of a smart camera with the simplicity of a traditional sensor in a compact 3D detection solution. This next-generation device from SensoPart delivers reliable, real-time volume-based object information for demanding automation environments.

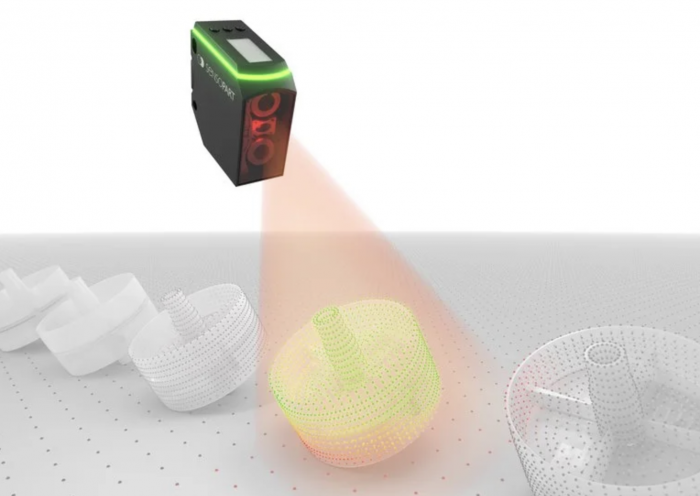

Innovative 3D Detection Technology

The DTECT® Object 3D uses patented active stereo technology with structured light to determine object volume and position independent of surface reflectivity. It can detect even dark or low-contrast objects with high precision, making it ideal for automated systems where traditional 2D sensors fall short.

Easy and Efficient Operation

Designed for users across automation fields, the sensor offers intuitive operation via an integrated color display and simple buttons, allowing quick configuration of the field of view and detection height — all without external software. After teach-in, the frame light instantly shows whether objects are detected as “good” or “bad.”

Versatile Application Performance

DTECT® Object 3D accelerates position control and completeness checks in various applications, from vibratory conveyors to assembly lines. It reliably determines part orientation (e.g., prone or supine) and identifies missing components without complex parameterization.

Two Versions for Application Flexibility

To suit different industrial setups, the sensor is available in two versions: a close-range model (up to 200 mm) for precision tasks like completeness checks in plastics and assembly tech, and a long-range model (up to 500 mm) for conveyor belt monitoring and packaging verification.

Powerful and Compact Design

Built for high-speed processes, DTECT® Object 3D supports up to 100 fps and integrates easily via a standard M12, 5-pin connector. Its robust F55 housing and patented depth imaging make it a reliable choice even in dynamic production environments.

Seamless Integration and Industrial Applications

With straightforward teach-in functionality and optional configuration through SensoTune software, this sensor enhances automation systems without the need for complex vision setups. Typical use cases include part orientation checks, presence detection, and completeness control across manufacturing and packaging lines.

For more information, please visit: https://www.sensopart.com/en/company/news/

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech