Turck’s new capacitive sensors offers detection of extreme values for conveyer line application

Photo by Hans Turck GmbH

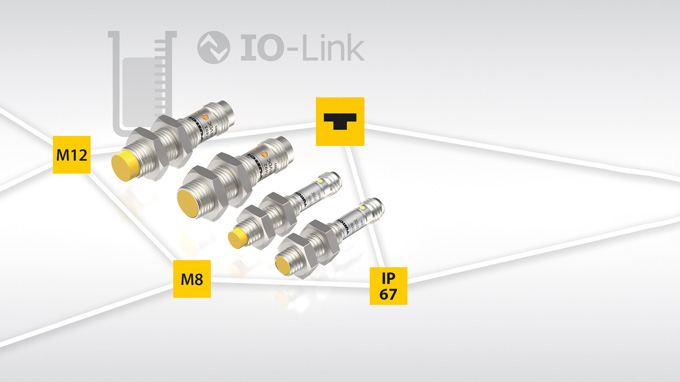

Turck is presenting new capacitive sensors in the M8 and M12 metal housing for flush or non-flush mounting. The robust IO-Link devices with protection to IP67 are compact and offer versatile use, particularly for detecting objects in production, logistics or pharmaceutical applications. Their dynamic teach function simplifies setup during the ongoing process. The sensors can thus detect the extreme values of passing objects on conveyor lines and independently determine the ideal switch point. An integrated counter function enables the implementation of autonomous counting applications without the need for a PLC.

Additional information for condition monitoring

The sensors provide a large amount of additional information for condition monitoring systems for the monitoring of machine states: process values, operating hours, actual internal or maximum temperature, number of switching operations or the actual device status can be called up directly via the interface.

Easy commissioning via Turck’s IO-Link master

The IO-Link sensors are commissioned by the usual IO-Link process. The easiest way to do this is with Turck’s IO-Link masters, which enable direct access to all parameters via their web server. Users therefore neither have to download an IODD nor an IODD interpreter such as Pactware.

INDUSTRIES

- Manufacturing industry

- Logistics

- Pharmaceutical industry

KEY FUNCTIONS

- Dynamic Teach for in-process sensor teach-in

- M8 and M12 metal housing with IP67 protection class

- IO-Link

- All-round visible LED

For more information, please visit http://www.turck.com.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech