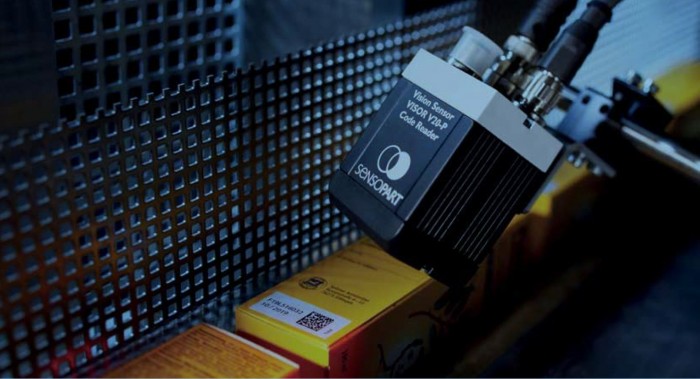

Sensopart’s Vision Code Reader VISOR® V20 For Patient Safety

Counterfeit medicines products with ineffective or incorrectly dosed active ingredients can cause considerable harm to patients. A new EU directive therefore stipulates by 2017 that all medicines with prescription are to be given a unique identifier . High-capacity Vision code readers such as VISOR® V20 from SensoPart Industriesensorik ensure that the codes are correctly printed and are of good readable quality.

Many counterfeit medicines are sold online and mainly concern expensive lifestyle product such as the famous blue pills. Whilst cases of counterfeiting are indeed rare in the legal supply chain, from pharmaceutical companies to wholesalers and pharmacies, the branch does, however, fear an increase over coming years. To exclude counterfeits, an identification system called “securPharm” was developed in anticipation of the EU anti-counterfeit directive, which will come into effect in 2017. It was tested in a successful pilot project which was completed in May 2013. The system is now to be introduced worldwide by 2017.

The new unique identifier on pharmaceutical packaging checked with the aid Vision code reader VISOR® V20

Photo by SensoPart Industriesensorik GmbH

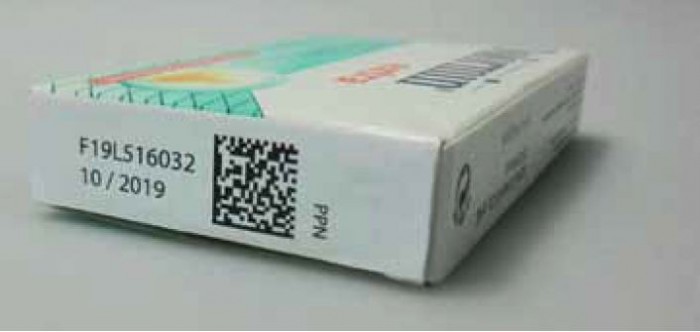

With securPharm, medicines are given a unique identifier during production. This consists of an individual product code, serial number, batch number and expiry date. This is printed on the outer packaging and registered in a manufacturer database. The pharmacist checks that the product in question has been properly registered before dispensing it to the patient (so-called end-to-end verification). In the event of irregularities, the product can be withdrawn from sale and checked before it reaches the patient.

To automate the described verification process, a standardised,machine-readable code must be printed on the packaging. This is the only way to guarantee straightforward checks anywhere along the supply chain – in the manufacturer’s goods out. department, by the wholesaler and finally by the pharmacist. In addition to clear text, the identifier also includes a two- dimensional data matrix code (DMC) which can be read by both industrial code readers and a scanner in the pharmacy.

Good readability is essential for later code checks.

Photo by SensoPart Industriesensorik GmbH

Medicines are worthless if the code cannot be read. The efficiency of the system relies on the readability of the DMC. If a code is not readable, the product in question must be withdrawn as it could be a counterfeit. A misprinted batch, therefore, represents a considerable financial loss for the manufacturer. To guarantee permanent reliable readability, codes are checked by an industrial code reader whilst still on the packaging line – immediately after application of the identifier(fig. 2).

The code reader must do more than just read the code, it must also judge its quality; this is done with the aid of so-called standardised quality parameters.

Use of a code reader which can analyse these parameters enables the continuous monitoring of code quality and the early detection of a possible deterioration over time. If the reading quality falls below a defined threshold, this is signalled, as other important information is also printed on the packaging in legible clear text, in addition to the code, e.g. expiry date. The Vision code reader VISOR ® V20 from SensoPart is able toanalyse both DMC and clear text. A high-resolution image chip (1.3 megapixels) enables extremely precise analysis of the identifier and also reliably detects small defects in the print image. It is also possible to control the identifier on moving objects. Up to 50 codes can be read per second, depending on the application. This makes the Vision code reader VISOR ® V20 ideal for fast packaging processes.

Visit http://www.sensopart.com for more information.

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Environmental Tech