3D printing post-processing: Precision for metal components

Post-processing of additively manufactured components plays a decisive role in ensuring their series production quality. While prototyping often focuses solely on form and function, dimensional accuracy, surface quality, and material properties are decisive factors in series production when it comes to the usability of components. 3D printing post processing is therefore indispensable, especially in metal 3D printing, in order to meet the high requirements of industries such as aviation, toolmaking, and medical technology.

But how exactly does the post-processing of industrial metal components work—and what role does CNC machining play in this?

Post-processing refers to all the steps that an additively manufactured component undergoes after the actual printing process. In an industrial setting, this usually includes milling, turning, grinding, and polishing, as well as quality assurance. These processes remove support structures and ensure that fits, bores, and threads meet the desired accuracy requirements. Depending on the 3D printing technology used—laser deposition welding using a powder nozzle (DED) and selective laser melting in a powder bed (SLM) are two common processes—the post-processing requirements differ significantly.

3D printing post-processing in laser deposition welding

Laser deposition welding – implemented on DMG MORI‘s LASERTEC DED hybrid models — combines additive and subtractive processes in a single setup. Milling, turning, grinding, preheating, powder deposition, and 3D scanning are integrated in a continuous 6-in-1 process.

This process integration offers the following advantages:

- There are seamless transitions between material build-up and machining

- Throughput times are reduced because there is no need for re-clamping and transport

- Constant referencing increases accuracy

- Quality is repeatable even with complex geometries

Preheating minimizes tension in this holistic process and prevents cracks between the base and weld material, while the optional use of blue lasers also makes reflective metals such as copper processable.

Post-processing in this hybrid process is unique in that it can be carried out during the metal 3D printing process. This is particularly useful for complex geometries, as some areas would be inaccessible once the build is complete. Depending on the machine, CNC finishing is performed by 5-axis simultaneous milling or 6-sided turning and milling. In both cases, grinding can also be integrated, resulting in completely finished metal components with excellent surface quality – all in a single workspace.

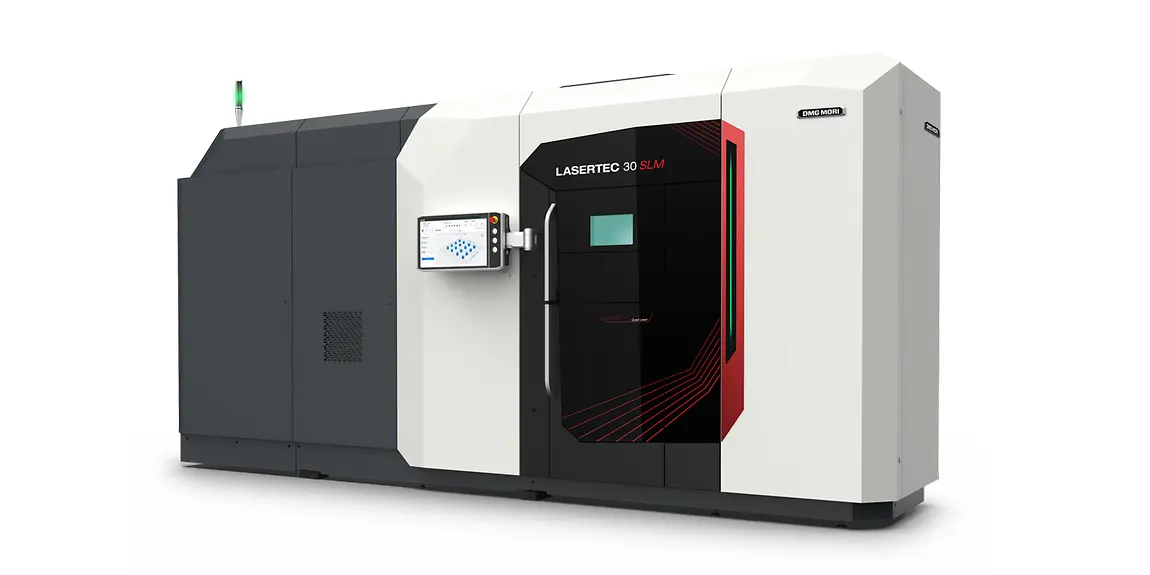

Post-processing using the powder bed process

Post-processing also plays a key role in the powder bed process, such as with the LASERTEC 30 SLM 3rd generation. Components are built up layer by layer in the machine’s powder bed – typically from stainless steel, aluminum, or titanium. Printing is followed by a multi-stage process:

- The construction container must cool down so that internal stresses are relieved.

- The parts are removed from the construction plate and freed from support structures.

- Functionally relevant surfaces and drill holes require post-processing using CNC milling or grinding.

- In addition, surfaces are often refined by polishing or blasting.

DMG MORI optimizes this process with sophisticated machine concepts: The interchangeable construction container of the LASERTEC 30 SLM eliminates downtime, while integrated camera systems and heat maps monitor layer quality. The combination of process stability and digital control ensures that post-processing is targeted and efficient. Users have access to numerous machining centers, such as the 5-axis DMU 40 universal machine, which complete the powder bed additive manufacturing process.

Material requirements in post-processing

The fact that a wide variety of metals are used in 3D printing today must also be taken into account in post-processing. This is because each material has specific properties and resulting requirements for milling, turning, or grinding. For example, titanium requires extremely specialized carbide tools and very precise process control due to its high strength, while aluminum must be machined at high spindle speeds and with optimal cooling. The type of material therefore has a direct influence on the post-processing strategy – from tool selection and cutting parameters to cooling.

From printing to the finished component

An efficient overall process that sensibly integrates post-processing is crucial for the suitability of additive manufacturing for series production. DMG MORI pursues a consistent approach here with its Machining Transformation (MX): additive manufacturing, CNC machining, and quality assurance are combined in a closed process chain. Automated workpiece and pallet handling systems enable low-manpower operation. At the same time, integrated 3D scanners perform contactless zero-point scanning and quality assurance in real time. This creates a highly productive workflow from additive construction to fully post-processed series components.

Post-processing as the key to series production

The examples show that post-processing is decisive in the transition from prototype to series production. In an industrial environment, it is much more than an additional step—it is an integral part of the manufacturing process. With the models in the LASERTEC DED hybrid and LASERTEC SLM series, DMG MORI demonstrates how additive and subtractive processes can be combined to form a holistic production system. The result: reproducible quality, shorter throughput times, and the economical production of complex metal components in series production.

For more information visit: en.dmgmori.com

News Categories

- » NEWS HOME

- » Automation & Robotics

- » Industry 4.0

- » Material Handling

- » Sensors

- » Quality & Testing

- » Machine Vision

- » Laser & Optics

- » Metalworking

- » Motion Control & Drives

- » Hydraulics & Pneumatics

- » Process Industry

- » Renewable Energy

- » Agriculture

- » Home & Office Furniture

- » Additive Manufacturing

- » Environmental Tech